Abstract

Rice is one of the most important crops throughout the world, as it contributes toward satisfying the food demand of much of the global population. It is well known that rice production generates a considerable number of by-products, among which rice bran deserves particular attention. This by-product is exceptionally rich in nutrients, since it contains a wide spectrum of macronutrients (proteins, fats, carbohydrates) as well as dietary fibers and bioactive compounds. However, rice bran is usually wasted or just used for the production of low-cost products. The lipidic fraction of rice bran contains an unsaponifiable fraction that is rich in such functional components as tocopherols, γ-oryzanol, tocotrienols, and phytosterols. This lipidic fraction can be extracted to obtain rice bran oil (RBO), a high value-added product with unique health properties as a result of its high concentration in γ-oryzanol, a powerful antioxidant mixture of bioactive molecules. Conventional extraction methods employ hexane as the solvent, but these methods suffer from some drawbacks linked to the toxicity of hexane for humans and the environment. The aim of the review presented herein is to point out the new green technologies currently applied for the extraction of RBO, by highlighting reliable alternatives to conventional solvent extraction methods that are in line with the twelve principles of green chemistry and a circular economy.

Similar content being viewed by others

1 Introduction

Rice represents one of the most important food crops in the world, accounting for around 20% of the dietary energy intake of the global population [1]. According to estimations, the world’s rice production will reach 499.31 million metric tons over the 2019–2020 period [2]. After rice harvesting, the whole grain is subjected to a milling process to obtain the well-known white rice kernels that are abundantly consumed all around the world. Depending on the rice variety, cultivation procedure, and the employed technique, around 40% of the total grain is lost during the milling process in the form of by-products [3]. The by-products generated through various milling steps are husk, bran, germs, and broken rice, and they are usually discarded or used for animal feeds. Bran is the most attractive of these by-products, because even though it represents only 9% of the rice weight, it contains around 65% of the nutrients of the whole rice grain [4, 5]. One of the most common uses of rice bran is the extraction of rice bran oil (RBO), which is mainly produced and consumed in Asian countries [6], where it is considered as a “healthy oil,” thanks to its extraordinary proprieties. Several studies have demonstrated a significant antioxidant and anti-inflammatory activity of RBO, thereby confirming its antihypertensive, antidiabetic, anti-obesity, and anticarcinogenic properties [7, 8]. One of the principal ingredients responsible for this set of beneficial health effects seems to be γ-oryzanol, an antioxidant mixture of ferulic acid esters of phytosterols [9]. RBO is commonly extracted using non-polar solvents, such as hexane, an organic, petroleum-derived solvent that is toxic for humans and the environment [6, 10]. As a result of the growing concerns about environmental and human safety, and after the development of green chemistry, most researchers are now focusing on alternative green extraction procedures to counter the disadvantages of conventional techniques. These emerging technologies of extraction are designed to use non-conventional solvents, to reduce the process time and the energy consumption, and to produce high-quality products stable over time [11, 12]. Innovative and green extraction techniques often include some technologies employed to intensify the process such as ultrasound, microwave, supercritical fluid, subcritical water, pulsed electric field, enzymatic extraction, ultrafiltration, and pressurized hot water. Most of these emerging technologies have already got promising result in the extraction of high-added value compounds, in particular natural antioxidant, from different sources such as plants or by-products of food processing [13,14,15,16,17,18].

The purpose of this paper is to describe the main green extraction technologies applied for the extraction of RBO. The first part provides a general overview of the rice chain, from the global production to a description of the rice milling by-products. Rice bran, rice bran oil, and their respective proprieties are presented in the second part and, then, the green RBO extraction techniques are illustrated. Non-conventional solvent extraction, microwave-assisted extraction, ultrasound-assisted extraction, supercritical fluid extraction, enzyme-assisted aqueous extraction, and subcritical water extraction are analyzed, a comprehensive overview of the main results obtained using these green techniques is provided, and it is demonstrated that high yields of RBO and γ-oryzanol can be obtained without resorting to the use of petroleum-based solvents.

2 An overview of rice production

Cereals, including rice, wheat, and maize, represent the principal staple food of the world. The global cereal production for 2019, as estimated by FAO, is 2719 million tons, and of the three major crops, rice is the most important staple food for the world’s population and the third most important in terms of production [19, 20]. The US Department of Agriculture (USDA) has estimated that the world’s 2019–2020 production of rice will reach 499.31 million tons [2]. Rice contains proteins, carbohydrates, fats, vitamins, minerals, and starch and contributes to about 21% of the global human pro capita energy intake and to 15% of the pro capita protein intake [21].

Rice is cultivated all around the world, except in Antarctica [22]. Nearly 22 species of rice currently exist, but the ones consumed most are Oryza sativa and Oryza glaberrima, which are mainly cultivated in Asia and Africa, respectively.

The primary producer and consumer of rice is China, followed by India and Indonesia (Fig. 1). China and India produced 148.5 and 116.4 million metric tons of milled rice in the 2018/2019 crop year, respectively. China is also the main rice consumer (around 143.79 million metric tons per year), while India is the main exporter of milled rice throughout the world (12.5 million metric tons in the 2018/2019 crop year) [23, 24].

The first seven rice producers are highlighted on the map: China, India, Indonesia, Bangladesh, Vietnam, Thailand, Myanmar, The Philippines, Japan, and Brazil. Bars represent the amount of milled rice produced by China, India, and Indonesia in a million metric tons [23]

This large spread of rice cultivation throughout the world is due to the capability of this semi-aquatic annual plant to grow in a wide range of soil types and water regimes. The main rice varieties are currently cultivated in flooded fields and rainfed lowlands [25]; however, 75% of the global rice production is obtained from irrigated lowland systems, which integrate water from rainfalls with a further water supply [26].

After the growing step, the rice enters a post-production line. The mature crop is first collected (harvesting step) and separated from straw, which represents the first by-product of rice production. The crop is then naturally, artificially, or mechanically dried (drying step). The rice is stored, in order to prevent grain losses (storage step). Finally, the rice is milled to obtain edible white rice (milling step). The latter step is the most critical and produces the highest number of by-products [26,27,28].

2.1 Rice milling and by-products

As already mentioned, one of the most critical steps in rice post-production is the milling phase. Rice is milled to obtain an edible white rice kernel, after the removal of the outermost layers of the grain and any possible impurities [29].

Before removing these layers, the whole rice kernel (or grain) is called “paddy.” Paddy is generally composed by hull or husk (~ 20%), bran (~ 9%), rice kernel or starchy endosperm (~ 70%), and rice germ or embryo (~ 1%) (Fig. 2) [5].

The portions removed from rice are the husk, bran, and germ. The husk is the outer layer, which protects the kernel during growth; it is not edible and can easily be removed from the rice (dehusking or dehulling process). The kernel deprived of this layer is called brown rice, and it is covered by a second layer: bran. This second layer reduces the commercial quality of rice, and it is therefore removed by means of a complex milling step (whitening or polishing process), together with the germ. Rice grains may be damaged or broken during the entire milling process, due to the mechanical stress induced by the used milling system [27, 30].

Three primary milling systems are currently employed: (1) one-step milling, (2) two-step milling, and (3) multi-stage milling.

In the one-step milling system, white rice is obtained by removing both the husk and the bran from the rice in a single step, but its application is discouraged due to the massive generation of broken rice. In the two-step milling system, the husk is initially separated, brown rice is produced as the intermediate outcome, and the bran is then also removed, in the same machine or in a different one. The multi-stage milling process involves several steps, levels, and machines. This process is more complex and is the commercial system that is usually adopted for the production of white rice, because it was set up to minimize the quantity of broken rice generated and maximize the yield [3, 31, 32].

The whole milling process generates more than 30% of by-products, composed of rice husks, bran, germs, and broken rice, which are still rich in nutritive substances and high-value molecules.

Rice husk is the protective layer of the grain, and it is the most abundant inedible by-product generated by the milling process. It is mostly composed of cellulose, lignin, and silica in amorphous and hydrate forms [26]. Rice husk is primary used for the production of energy, by means of thermal processes, such as gasification and combustion [33].

The whitening or polishing process generates a number of by-products that overall represents around 5–20% of the whole kernel, including the bran and germ, or embryo. Commercial rice bran is usually a mixture of these two rice by-products [34]. This fraction possesses an extraordinary quantity of nutritive compounds, such as fibers, fats, proteins, vitamins (vitamin E and B complexes), and antioxidant molecules. It contains 10–23% of oil, which is usually extracted using a solvent [35]. Rice bran is generally employed in food industries, but new applications have recently been introduced in the nutraceutical and pharmaceutical industries as a result of its demonstrated human health benefits.

The kernel is often subjected to fragmentation, during the complete milling process, and when the length of the fragment is less than three-fourths of the whole grain, it is considered broken and usually transformed into flour and employed in the food industry [3].

3 Rice bran

The whitening or pearling process applied to brown rice produces bran, a finely pulverized material composed of the pericarp, aleurone, crushed germ, and some fragments of the endosperm [36].

The final composition and the chemical and physical proprieties of rice bran change on the basis of the rice variety, the growing conditions, but also on the type and type of milling system. Rice bran is considered a healthy food, due to its high concentration of nutraceutical compounds [37]. Rice bran in fact contains about 60% of all the nutrients of the entire rice grain [4]. It incorporates around 11–17% of proteins, 12–22% of oil, 6–14% of fiber, 10–15% of moisture, and 8–17% of ash, and it is rich in micronutrients, such as vitamins, and in minerals, such as aluminum, calcium, chlorine, iron, magnesium, and manganese. It contains high nutritional value proteins that are abundant in essential amino acids. Rice bran is a source of dietary fiber, and the lipidic fraction is rich in polyunsaturated fatty acids and contains significant quantities of bioactive and antioxidant compounds, such as γ-oryzanol, tocotrienol, and tocopherol [38].

Despite all of these attractive properties of rice bran, millions of tons of this by-product are wasted every year or employed as low-quality animal feeds [39]. This incredible waste of high-grade food is due to the instability of rice bran, and its tendency to become rancid because of its natural lipase enzyme that catalyzes the hydrolysis of oil into glycerol and free fatty acids [36]. The use of rice bran is only possible after a stabilization process to deactivate the lipase; such a step limits the rancidity and helps to maintain the quality of rice bran during storage. Several techniques exist and have been studied for bran stabilization: these include parboiling, chemical methods, stove toasting methods, ohmic heating techniques, retained moisture heating, added moisture heating, dry heating under atmospheric pressure, extrusion cooking, microwave heating, and infrared heating. Many researchers agree that the most effective of the aforementioned methods is microwave heating, an inexpensive and fast method that generates a product with a low range of free fatty acid that remains stable over time [4, 38,39,40]. After stabilization, rice bran can be employed directly or can be subjected to other processes in order to obtain high-value products for food, nutraceutical or pharmaceutical industry applications. One of the most popular and commercialized products derived from the processing of rice bran is rice bran oil.

3.1 Rice bran oil

Rice bran contains up to 25% of rice bran oil (RBO), depending on the rice variety, milling process, and stabilization system. RBO is produced and consumed in great quantities in Asian countries, such as India, Japan, China, Korea, Taiwan, Thailand, and Indonesia. India, China, and Japan produce around 472, 90, and 65 thousands of tons of RBO annually, respectively.

The Japanese were the first to extract RBO from rice bran using the hydraulic press technique, which is still used nowadays, but recently, the preferred industrial technique for commercial uses is extraction using non-polar solvents, such as hexane [6]. After the extraction, the crude rice bran oil is often refined in order to improve its quality and commercial value. The fundamental steps of the refining process include dewaxing, degumming, neutralization of the free fatty acids, bleaching, and steam deodorization.

The World Health Organization (WHO), the American Heart Association (AHA), and other international food and health organizations have recognized RBO as a “healthy oil,” because of its well-balanced fatty acid content, which consists of 47% of monounsaturated fatty acids (MUFAs), 33% of polyunsaturated fatty acids (PUFAs), and 20% of saturated fatty acids (SFA).The main unsaturated fatty acids are oleic acid, linoleic acid, and linolenic acid, and the primary saturated fatty acids are palmitic, myristic, and stearic acid, as reported in Table 1. [7, 41,42,43],

Furthermore, crude rice bran oil also contains 2.5–3.2% of an unsaponifiable fraction that is rich in functional components, such as tocopherols (vitamin E), γ-oryzanol, tocotrienols, and phytosterols, and in other micronutrients, such as squalene and phospholipids. However, the refining process can reduce the quantity of some of these micronutrients [6, 44].

It has been demonstrated that RBO has antioxidative and anti-inflammatory proprieties as well as antihypertensive, antidiabetic, anti-obesity, and anticarcinogenic properties. Furthermore, it has a positive effect on cholesterol levels, insomnia and other diseases [7, 8].

Υ-oryzanol, tocotrienols, tocopherols, and the other phytosterols contained in rice bran oil are the main micronutrients that are responsible for the antioxidant activity of RBO. The ferulic acid ester content in γ-oryzanol is known to be a powerful antioxidant, anti-free radical, and strong radical scavenger. It can decrease plasma and serum cholesterol, thanks to the structure of some phytosterols that can inhibit its absorption. Υ-oryzanol and tocotrienol moderate the hyperinsulinemic response, and these high levels of antioxidants may increase metabolic activity, thereby favoring weight losses. Moreover, RBO is also extremely stable at elevated temperatures and is characterized by a smoke point of 254 °C. All these features make RBO an excellent candidate for food, nutraceutical, pharmaceutical, cosmetic, and food applications. RBO is also excellent for use in the cosmetics industry. It can in fact enhance the moisturizing activity of the skin and encourage hair growth; moreover, the ferulic acid and esters of γ-oryzanol prevent skin from aging. Υ-oryzanol may protect the skin from lipidic peroxidation induced by UV-light, making RBO an ideal component of sunscreen creams [6, 43].

3.2 Υ-oryzanol

As mentioned in the previous section, one of the main micronutrients that is responsible for a variety the beneficial human effects is γ-oryzanol. This functional compound was first isolated from rice bran oil in 1945 by Kaneko and Tsuchiya [8]. γ-Oryzanol was first identified as a single component, but further investigations confirmed that γ-oryzanol is actually a mixture of ferulic acid and phytosterol esters [9, 45]. Confusion has arisen about the total number of components of this bioactive mixture, but a recent research has discovered, separated and identified twenty-three components of γ-oryzanol [46]. However, four main esters constitute around 80% of the γ-oryzanol in RBO: cycloartenyl ferulate, 24-methylenecycloartenyl ferulate, campesteryl ferulate, and β-sitosteryl ferulate (Fig. 3) [47, 53]. All these components are characterized by a ferulic acid fraction composed of several alcoholic groups (OH), which cause an increase in polarity, making γ-oryzanol soluble in polar and non-polar solvents.

The amount of γ-oryzanol in crude RBO can fluctuate between 1.5 and 2.9%, and an oil refining process may lower this percentage [44]. Moreover, the total content of γ-oryzanol and its composition in RBO depend on different factors, such as the rice variety, environmental conditions, cultivation techniques, the oil extraction system, and the final refining process employed [7].

The separation and detection of γ-oryzanol components are usually performed by means of high-performance liquid chromatography (HPLC), using an ultraviolet (diode-array detector DAD or photodiode array detector PDA) or a mass spectrometry revelation system (HPLC/MS) [7, 44].

The complete spectra of all the biofunctional activities of this mixture are still under investigation and continuously growing. Several studies have confirmed its antioxidant activity, an essential role in cholesterol moderation, a role in the inhibition of the progression of tumors, and on the treatment of the menopausal syndrome [54].

4 Green extraction techniques

The recovery methodology of high added-value compounds from food wastes must be properly chosen in order to maximize the yield and the purity of the extract, to avoid loss in functionality and to obtain a food grade final product. To reach these goals it is possible to identify the so called “5-Stages Universal Recovery Process,” consisting in macroscopic and microscopic level procedures: (1) macroscopic pre-treatment, (2) separation of macro-molecules and micro-molecules, (3) extraction, (4) isolation and purification, and (5) product formation [55]. Extraction is a mass transport phenomenon involving the migration of a solute from the matrix to the solvent and is the most important and critical among the above mentioned five steps [12].

RBO extraction is usually achieved by means of hydraulic pressing or solvent extraction. Hexane is the main solvent that is used, because of its exceptional solubilizing capability, its low boiling point and its low cost, despite its human and environmental toxicity [56].

In the last few years, global interest in environmental and human safety concerns has increased. The scientific community has addressed this issue by working on new alternatives in food, cosmetic, and pharmaceutical industrial processes. The publication of the twelve principles of green chemistry and the twelve principles of green engineering represents a first attempt to formally deal with these aspects. These twenty-four principles define the best “green” measures that can be introduced to improve chemical and industrial apparatus and to obtain more sustainable processes [57].

Moreover, six other principles, which recommend optimizing the existing processes, shifting to innovative non-conventional technologies and processes, and exploiting alternative solvents, have been introduced in the field of green extraction [16].

Recently, several experiments have been performed in order to extract oil from this rice by-product, optimizing the existing processes or developing innovative technologies, in line with the six green extraction principles. Notably, RBO has been successfully extracted using non-conventional solvents, or applying emerging technologies such as microwaves, ultrasounds, supercritical fluids, sub-critical water, or enzymatic extraction. All the procedures analyzed in this paper show remarkable advantages, especially from an environmental point of view. Indeed, authors performed the extraction replacing traditional solvents that are volatile, inflammable, and are often released in the atmosphere contributing to the air pollution and to the greenhouse effect, with less impactful compounds such as bio-solvents or water. Moreover, all the techniques reported in this review allow for a reduction in energy consumption, optimizing or assisting existing processes with intensification techniques or creating innovative procedures aimed to reduce the number of extraction steps and consequently the reaction time. As reported by Chemat et al. [11] and by Galanakis [12], with some green extraction techniques is possible to save ~ 80% of the process thermal energy, reducing by ~ 90% the extraction time without altering the extract properties. The oil extraction from rice bran, that is usually wasted, is an example of biorefinery valorization of food by-product in the perspective of an integrated approach and of a circular economy. The RBO and γ-oryzanol green extraction techniques, resumed in Table 2, are discussed below.

4.1 Non-conventional solvent extraction

The solvents applied in the extraction processes are generally organic compounds derived from non-renewable sources [16]. Hexane is the most common solvent used in rice bran oil extraction [85]. This solvent is cheap and efficient, but it is a petroleum-based solvent, volatile, flammable, and dangerous for humans and for the environment [11]. Several efforts have recently been made to find alternatives to this organic compound, focusing on green, non-petroleum-derived, and bio-based solvents.

The primary non-conventional solvents applied in RBO extraction are ethanol, isopropanol, ethyl acetate, and D-limonene.

All of these compounds are bio-based solvents and can be derived from agricultural biomasses (Fig. 4) [16].

Overview of the main bio-based solvents [16]

These solvents are labeled as “recommended” or “preferred” in several guidelines, such as the GlaxoSmithKline (GSK) [86], Pfizer [87] Sanofi [88], AstraZeneca, and Green Chemistry Institute-Pharmaceutical Roundtable (GCI-PR) solvent guidelines. These guides deal with solvents from the safety, occupational health, environment, technical constraint, and cost perspectives [89].

Hu et al. [58] compared RBO and γ-oryzanol yields, after extraction with hexane and isopropanol at a 2:1 or 3:1 w/w solvent-to-bran ratio at a temperature of 40 °C or 60 °C and for extraction times of 5, 10, 15, 20, and 30 min. They reported that extraction conducted with 60 °C preheated isopropanol (3:1 w/w) for 10 min produces only a slightly lower amount of RBO (201.2 g/kg dry rice bran) than oil extracted with hexane (211 g/kg dry rice bran). Furthermore, the γ-oryzanol yield (3003 mg/kg dry rice bran) is comparable with the hexane extraction yield.

These results are similar to those reported by Zigoneanu et al. [59], who compared hexane and isopropanol extraction at a 3:1 w/w solvent-to-bran ratio, but at 40 °C and for 15 min.

Capellini et al. [60] attempted to replace hexane with ethanol and isopropanol to produce rice bran oil. They investigated the effect of different solvent hydration degrees (0, 6, or 12 mass % water) and temperatures (50 to 80 °C) on oil and minor compound extraction, using a 3:1 w/w solvent-to-bran ratio and a reaction time of 1 h. The study highlighted a negative effect on oil extraction, with an increase in the water content of the solvent, but a positive effect on the yield of lipid components as a result of an increase in temperature. The maximum RBO extraction yield (16 g/100 g rice bran) was obtained using pure ethanol and isopropanol at 80 °C, while the highest γ-oryzanol yield was obtained using ethanol with 6% of water, regardless of the temperature.

These results reflect those of Oliveira et al. [61], who also found that the RBO extraction yield is influenced to a great extent by the water content in the solvent and by the temperature. They used a response surface approach to investigate the effect of solvent hydration, temperature, the solvent-to-rice bran mass ratio, and stirrer speed on rice bran oil extraction. Their results show that it is possible to obtain a maximum oil yield of 20.05 g/100 g rice bran in a three-hour extraction in ethanol with 6% of water at 82.5 °C, with a 4:1 w/w solvent-to-bran ratio and a stirring speed of 137.5 rpm. The γ-oryzanol content varies between 1527 and 4164 mg/kg of fresh rice bran.

Shukla at al. [62] reported that isopropanol gave the same yield as hexane (17.09 g/100 g rice bran), but a higher yield than ethanol after 4 h of extraction using a soxhlet apparatus. Furthermore, the RBO extracted with ethanol contained a higher γ-oryzanol concentration (2.609 ppm) than that of the RBO extracted with hexane (2.229 ppm) or isopropanol (2.094 ppm).

Ruen-Ngam et al. [63] investigated the use of isopropanol, ethyl acetate, and ethanol as green solvents for RBO extraction under different rice bran-to-solvent ratios (1:2, 1:4 and 1.6 w/w) at 30 °C for 1 h. The highest percentage of oil was extracted using a 1:3 rice bran-to-solvent ratio for all the solvents, except for ethanol, in which the maximum yield was obtained using a 1:6 rice bran-to-solvent ratio. The authors identified γ-oryzanol in each experiment, even though they did not quantify the amount.

Liu and Mamidipally [64] extracted RBO using d-limonene and reported that they extracted more oil when using this green solvent than when using hexane under their experimental conditions. Despite this advantage, this kind of extraction requires a higher energy expenditure than hexane in order to separate the solvent from the oil, because of the higher boiling point of d-limonene (176°C). This issue makes this process too expensive from an economic and energetic perspective, and further studies are needed to optimize the use of limonene as a potential solvent for RBO extraction.

In short, the above reported studies demonstrate the feasibility of using green solvents, instead of hexane or other toxic solvents, to extract RBO. Isopropanol and ethanol gave the best results, in terms of RBO yield and amount of γ-oryzanol extracted. However, further studies are necessary before green solvents can be used in RBO extraction.

4.2 Microwave-assisted extraction

Microwave-assisted extraction (MAE) seems to be one of the most promising new emerging green technologies for the extraction of different compounds in different matrices, thanks to its capability to reach high temperatures in short reaction times, with a lower expenditure of solvents and energy, thereby allowing high yields and purity in oil and bioactive compounds [90].

Microwaves are electromagnetic waves made up of two oscillating perpendicular fields, i.e., electrical and magnetic. As shown in Fig. 5, molecule dipoles are in a chaotic state in nature; when a continuous electric field is applied, a dipole alignment occurs; and when a high-frequency electromagnetic field (like a microwave) is applied, these dipoles start to rotate continuously. Electromagnetic energy produces heat through ionic conduction and dipole rotation in both the solvent and the matrix [91, 92].

The actions of molecular dipoles under a no electric field, b a continuous electric field, and c a microwave. Figure adapted from Destandau et al. [91]

In the case of plant matrix extraction, fast heating causes an increase in the pressure inside the plant cells, which may lead to the rupture of the cell walls, thus accelerating mass transfer between the solvent and bioactive compounds [91, 92].

Zigoneanu et al. [59] extracted RBO using such a system with isopropanol (a polar solvent) and hexane (a non-polar solvent), a 3:1 w/w solvent-to-rice bran ratio and five extraction temperatures (40, 60, 80, 100, and 120 °C). As already mentioned, the extraction yield increases with temperature when isopropanol is used. At 120 °C, the oil extracted using isopropanol in a 15 min extraction is 50% higher than the amount of oil extracted with hexane. These outcomes are comparable with the results obtained by Duvernay et al. [65], who tested MAE with isopropanol at 80, 110, and 140 °C. They noted a 54% increase in RBO yield when operating at a temperature of 140 °C for 15 min. Moreover, Shukla at al. [62], using isopropanol coupled with MAE, also reported a higher oil yield than when using hexane, at a temperature of 82 °C, a pressure of 2.1 bar, and a power of 95 W for an extraction time of 30 min. The authors also reported that the RBO extracted with isopropanol, under the same experimental conditions, contained 2.256 ppm of γ-oryzanol.

Isopropanol was confirmed to have a better solvent ability, at higher temperatures, than hexane in RBO extraction [63]. Moreover, polar solvents, such as isopropanol and ethanol, were found to be better solvents for microwave oil extraction, due to their ability to absorb microwaves [92].

Kumar et al. [66] conducted a comparative experiment using methanol with hexane and petroleum ether as solvents in MAE. The authors highlighted that the polar nature of the solvent is an essential condition for RBO and γ-oryzanol extraction. They found that methanol (a polar solvent) extracted around 96.03% of the oil present in rice bran and 85.0 ± 0.20 ppm of γ-oryzanol.

Kanitkar et al. [67] performed a MAE of RBO using ethanol. This solvent is less toxic than hexane, it can be derived from bio sources, and it is relatively cheap. In their study, the authors investigated the influence of the temperature (from 60 to 120 °C) and time (3, 9, 15, 20 min) on RBO microwave extraction using a 3:1solvent-to-rice bran ratio. They observed that the MAE oil yields increased with the temperature and extraction times, reaching a maximum of 17.2% ± 0.4% at 120 °C and for 20 min of reaction time.

Terigar et al. [68] studied the optimization of RBO microwave extraction in a continuous MAE, from the laboratory to a pilot-scale system. The authors optimized the lab-scale system and obtained the maximum oil yield at 73 °C after 21 min of extraction using a 3:1 ethanol-to-rice bran ratio and a flow rate of 100 ml/min. They then applied the same temperature and a flow rate of 1.0 and 0.6 l/min to the pilot-scale system and obtained 90% of recoverable oil in only 8 min.

All these relevant results show the advantages of using MAE to extract RBO and γ-oryzanol by minimizing the time and solvent consumption, in comparison to conventional solvent extraction techniques. Furthermore, MAE allows hexane to be substituted with a less toxic and green solvent, such as ethanol or isopropanol.

4.3 Ultrasound-assisted extraction

Over the last few decades, the application of ultrasound in extraction processes has increased considerably for both classical and green innovative extraction techniques, especially in the food and natural product fields. Ultrasound-assisted extraction (UAE) is a cheap and environmental friendly process that satisfies all the green-chemistry principles. Compared with standard extraction techniques, UAE allows a reduction of the extraction time, and of the energy and solvent consumption to be achieved, and at the same time maintains the high-purity of the final product [93, 94].

Ultrasounds (US) present frequencies in the 20 kHz to 10 MHz range and are classified as high-power or low frequency (20 kHz–100 kHz), intermediate-power or medium frequency (100 kHz – 1 MHz), and low-power or high frequency US (up to 10 MHz) [95]. These frequencies are generated by two main US devices employed in research and industry: the ultrasonic bath and the probe-type ultrasonic system (Fig. 6). The high-power ultrasonic probe is considered the best extraction system, and its large-scale commercial and industrial applications have been improved over the last decade [94, 95].

The extraction effect of ultrasounds is the sum of several physical and chemical phenomena, which occur both in the solvent and in the matrix, such as shear forces, pressure changes, agitation, cavitation, microjets, radical formation, and also fragmentation, erosion, capillarity, and sonoporation, as highlighted by Chemat et al. [93]. Acoustic cavitation seems to be the main factor responsible for the sonication effect. This phenomenon occurs when ultrasound waves induce a succession of rarefaction and compression cycles that create microbubbles in a medium, such as a solvent. These bubbles ultimately collapse, because of fast and continuous pressure changes. When this implosive collapse occurs in the cell membrane, breaking points start to develop on the cell surface, the mass transfer of molecules between the matrix and the solvent increases, and their diffusion accelerates. All these features make this technique suitable for the extraction of different bioactive compounds, such as antioxidants, polyphenols, anthocyanins, or other organic substances, from several kinds of matrices using different solvents [95, 96]. Unfortunately, despite all of these advantages, only a few studies have been conducted on the UAE of RBO and γ-oryzanol.

Cravotto et al. [69] were the first to extract RBO under high-intensity ultrasounds, using a basic aqueous solution instead of an organic solvent. The authors extracted 21% of oil, with respect to the weight of the starting material, using a 12:1 water-to-bran ratio at pH 12. Sonication was conducted through an immersion horn (12 kHz, 300 W) at 45 °C for 30 min.

Khoei and Chekin [70] also extracted RBO using water instead of organic solvents and investigated the influence of pH, temperature, and extraction time on oil extractability. They mixed rice bran and water in a 1:10 ratio at a specific pH and the mixture were then immersed in an ultrasound bath, with the power set at 60 kHz, for a variable time and temperature. The authors showed that it is possible to obtain an RBO yield close to that obtained by means of Soxhlet extraction using hexane as the solvent. The best extraction conditions were obtained using a basic medium (pH 12), at 25 °C, and an extraction time of 70 min. These two research works confirmed the feasibility of the UAE of RBO at low temperatures, without the application of any dangerous organic solvent.

Other authors have highlighted the possibility of extracting oil and antioxidants from rice bran using UAE and alcoholic solutions. Tabaraki and Nateghi [71] optimized the extraction of oil, polyphenols, and antioxidants from rice bran using a response surface methodology. They investigated three variables: (1) the ethanol concentration, (2) the extraction temperature, and (3) the reaction time. The authors obtained the maximum yield after 28 min of sonication in an ultrasonic bath (35 kHz and 140 W) at 60 °C, using an ethanol concentration of 87% and a 21:1 solvent-to-bran ratio.

Ghasemzadeh et al. [97] also used an ethanolic solution to extract polyphenols, flavonoid compounds, tocopherols, and tocotrienols with UAE. The antioxidant molecules were extracted using an ethanol concentration of 50% at 45 °C, and a power of 150 W for 1 h; the authors did not report the RBO yield.

Kumar et al. [66] compared UAE with MAE and conventional extraction methods using a variety of solvents (petroleum ether, hexane and methanol). Rice bran was mixed with the three different solvents in a 3:1 solvent-to-bran ratio, and the mixtures were then sonicated using a high-intensity ultrasonic probe at 24 kHz and 38 °C for 60 min. The UAE with methanol generated an RBO yield of 154.5 ± 0.04 mg/g of rice bran with 85,032 ± 0.04 ppm of γ-oryzanol. These values are slightly lower than those obtained from microwave extraction, although they were significantly higher than those obtained by means of the conventional solvent extraction method.

UAE represents a promising green technology that allows a reduction in the amount of conventional solvent to be achieved or, alternatively, water or greener solvents, such as ethanol to be used. It decreases the extraction time and generates comparable RBO and antioxidant yields with those of conventional extraction methods.

4.4 Supercritical fluid extraction

Interest in supercritical fluid extraction (SFE) and in particular in supercritical carbon dioxide (scCO2) extraction has grown over the last four decades. After the first industrial applications in the decaffeination and beer production fields, it has evolved into a green, environmental friendly process, especially for food industries [98, 99].

SFE utilizes fluids at temperatures and pressures that are above their critical points, with high densities, low viscosities, and diffusivities that fall between gases and liquids. Compared with organic solvents, supercritical fluids exhibit more advantageous transport properties and a higher penetration power of the matrix, therefore allowing a faster and more efficient extraction [100, 101].

Through the manipulation of the temperature and pressure, it is possible to modulate the solubility power and the selectivity of supercritical fluids. It is also possible to recover the dissolved compounds and obtain a pure and solvent-free extract by merely reducing the fluid density and by decreasing the temperature and pressure.

Most SFE systems extract chemical compounds using supercritical carbon dioxide instead of an organic solvent [102], which has a relatively low critical pressure and temperature (31.06 °C and 73.7 bar) (Fig. 7) and is used routinely in food processing industries to extract lipids from several kinds of matrices.

This gas can be used to extract thermolabile components; it is non-flammable, non-toxic, non-corrosive, cheap, and available at a high purity grade; and it can be recovered and recycled. It is a non-polar solvent, but its polarity and selectivity toward some molecules can be modulated by adding more polar co-solvents, such as water or ethanol, during the extraction process [101, 103].

Researchers started working on RBO extraction almost 40 years ago [102]; however, it is only more recently that they have begun to focus on the concentration of antioxidants, such as γ-oryzanol, in the extracts.

Most of the works focused on the optimization of the scCO2 of RBO analyzing temperature, pressure, CO2 flow, extraction time, and raw material size as the principal variables. These operative conditions were investigated considering different instrumental configurations, in order to find the best compromise between the extraction yield, product quality, and operational cost of the process [104].

Garcia et al. [64] investigated the influence of temperature (40° to 70°), pressure (10, 16.2, 22, and 28 MPa), the size of the rice bran fractions (0.038–0.1, 0.3–0.4, 0.5–0.7, and 0.038–1 mm), and time (from 30 min to 4 h) on the extraction yield. The maximum RBO yield (71.1 mg/g dry rice bran) was obtained at 28 MPa, at a temperature of 70 °C, and over a 0.038–1 mm range. The authors showed that no significant yield increase occurred after 2 h of extraction.

Kuk and Dowd [73] also investigated the effect of temperature and pressure on RBO and γ-oryzanol yield. The authors applied pressures ranging from 7000 and 9000 psi and temperatures in the 70–100 °C range and obtained an oil yield of 20.4% for the maximum pressure and temperature applied. Moreover, they obtained 1.5% of sterols from γ-oryzanol at 7000 psi and 80 °C.

Xu et al. and Al-Okbi et al. [74, 75] extracted RBO under a constant pressure regime. Xu et al. [85] applied a pressure of 680 atm and varied the temperature from 30 °C to 75 °C, with a flow rate of 250 ml/min for 25 min. The percentage yield of RBO varied from 9 to 13%.

All these works compared the RBO yield obtained with scCO2 with conventional hexane extraction, and in all the illustrated cases, the percentage of oil extracted with a supercritical fluid was slightly lower or just comparable with those obtained by means of conventional solvent extraction.

These results were confirmed by Balachandran et al. [76], who investigated the influence of pressure (350, 425, and 500 bar), temperature (50, 60 and 70 °C), time (0.5, 1 and 1.5 h), and packing (pebbles, glass beads, and structured stainless steel rings) on RBO and γ-oryzanol yields at a CO2 flow rate of 40 g/min. The maximum oil yield (22.5%) was reached at 500 bar, at a temperature of 60 °C, and for 1.5 h, with structured stainless steel rings used as the packing material; the γ-oryzanol concentration varied from 5800 to 11,110 ppm.

The RBO extracted in scCO2 has a smaller number of phosphatides than the oil extracted by means of conventional methods, likely because of the insolubility of these compounds in CO2 and their high molecular weight. Moreover, a supercritical extract contains less wax and fewer pro-oxidant metals, such a Fe or Cu, and shows an excellent color quality. Such excellent features allow some refining steps (e.g., degumming, bleaching) to be avoided, which would otherwise be mandatory to obtain a good quality and marketable oil, at a reduced cost.

Overall, the works that have dealt with RBO extracted in scCO2 have demonstrated that the role of temperature changes is more important than that of pressure variations on oil yield [768]. The scCO2 density in fact decreases when the temperature increases, and elevated temperatures may alter some physical proprieties of rice bran, making it easier for the solvent to penetrate the matrix. Moreover, if the pressure is far above the CO2 critical point, high temperatures can increase the oil vapor pressure, thereby causing an increase in solubility [74].

Wang et al. [77], using scCO2 extraction from rice bran, also obtained an 18.1% RBO yield and a γ-oryzanol extraction efficiency of 88.5%. These authors employed a response surface methodology to establish the optimal pressure (30 MPa) and temperature (40 °C) in order to improve the γ-oryzanol concentration in the extracted oil.

Tomita et al. [78] showed that the interaction between temperature and pressure influences RBO recovery. The authors varied the extraction pressure from 20 to 40 MPa and the temperature from 40 to 80 °C at a fixed flow rate of 3 ml/min. They observed that at higher pressures, temperature increases produced only small changes in RBO recovery. A significant decrease in oil recovery was instead observed when the temperature was increased from 40 to 80 °C. As already explained, the solubility of oil in scCO2 is linked to the solvent density and the solute vapor pressure, which change for different temperatures and pressures. A temperature increase can lower the CO2 density to a great extent at low pressures, thereby causing a decrease in oil solubility. On the other hand, an increase in oil vapor pressure is the dominant controlling factor at high pressures, and density variations do not play a relevant role in modulating the solubility of oil. Consequently, oil solubility shows small variations as does the oil yield.

Tomita et al. [78] investigated the behavior of extraction varying the CO2 flow rate. These authors observed a slight increase in recovery as the flow rate rose, which in turn influenced the mass transfer. This effect is due to a rise in solvent molecules per unit of volume in the extractor, which induces an increase in solvent-oil intermolecular interactions and oil solubility.

Xu et al. [74] and Imsanguan et al. [79] evaluated the yield of γ-oryzanol extracted using scCO2. Xu et al. [74] applied the conditions described above and obtained a maximum yield (5.39 mg/g of rice bran) at a temperature of 50 °C.

Imsanguan et al. [79] instead varied both the temperature and the pressure (45–65 °C and 38 and 48 MPa), but kept the CO2 flow rate constant at 0.45 ml/min. The highest γ-oryzanol yield (11,371.79 mg/kg of rice bran) was obtained at 48 MPa and a temperature of 65 °C in continuous mode. Both of these works compared SFE and conventional solvent extraction with hexane and showed that the yield of γ-oryzanol in SFE was higher than the highest yield reached using conventional solvent extraction and, moreover, for a lower reaction time.

Bitencourt et al. [80] conducted a study on γ-oryzanol solubility in supercritical CO2. The authors demonstrated that it is possible to obtain a γ-oryzanol rich extract using fractional extraction and separating the bioactive compound from the oil.

In short, RBO extracted by means of scCO2 may lead to an excellent color quality, a higher number of antioxidants, and fewer undesired compounds. Therefore, this method can be considered extremely valuable for the recovery of high value-added products from by-product materials.

4.5 Enzyme-assisted aqueous extraction

Aqueous enzymatic oil extraction is an emerging green technology [105]. This technique facilitates the release of oil in aqueous extraction processes, while avoiding the use of organic solvents. It is worth noting that the main components of plant cell walls are cellulose, hemicellulose, pectin, lignin, and protein. The oil in rice bran is accumulated in organelles, which are called “lipid bodies.” These organelles are surrounded by a phospholipid monolayer, which contains a group of structural proteins named “oleosins.” Enzymes can help to disrupt this envelope by allowing oil to migrate outside the cell. Enzyme-assisted aqueous extraction (EAAE) requires a lower energy and solvent consumption than conventional solvent extraction, and results in an excellent product, which does not require any further refining steps. The main enzyme classes exploited for RBO extraction are cellulase, pectinase, and protease [81, 105, 106].

Sengupta and Bhattacharyya [81] were the first to apply EAAE and to investigate the yield and quality of RBO produced using pectinase (Pectinex Ultra SPL) and cellulase (Celluclast R), as a function of the temperature, reaction time, and of the enzyme and rice bran concentrations. These authors showed that this technique allows a high-quality rice bran oil to be obtained, with similar features as those of conventional solvent extracted oil. They also noted that EAAE allows different parts of bran, such as protein and oil, to be fractionized, thereby avoiding the formation of by-products during the extraction process, since these fractions can easily be separated and used for different purposes. Nevertheless, EAAE alone did not produce a high yield of RBO, and a further hexane extraction step was needed. These results were confirmed by Hernandez et al. [107], who used amylase, followed by hexane extraction, to obtain an increase of only a 5%, compared with conventional solvent extraction.

Sharma et al. [82] tried to increase oil yield extraction using a combination of different commercial enzymes: ProtizymeTM (protease), PalkodexTM (α- amylase), and cellulase. Amylase and cellulase are hydrolases that are able to break down cell walls, and protease permeabilizes the liposome membrane, thus allowing oil to flow from lipid bodies to the solvent. The authors showed that for an optimum ratio between the enzymes, a temperature of 65 °C, and pH 7 with continuous shaking at 80 rpm for 18 h, it is possible to obtain an RBO recovery of 76–78% of those normally obtained with conventional extraction methods, but without having to resort to an organic solvent.

Hanmoungjai et al. [83] optimized EAAE with a commercial protease (Alcalase 0.6 L) using a response surface methodology. These authors investigated the influence of the enzyme concentration, reaction time, and temperature on the RBO extraction yield. The results were then compared with the hexane extraction of RBO. The maximum oil extraction yield that was obtained was 79%, and it was obtained with a γ-oryzanol content of 1.76%. From a compositional point of view, oil extracted with Alcalase in water is similar to solvent extracted oil, but it presents a lower free fatty acid value and a higher peroxide value. The good quality of RBO produced in this way reduces the number of further refining steps that are necessary.

Hanmoungjai et al. [108] also compared the effect of Alcalase in the EAAE of RBO with another five enzymes: Celluclast 1.5 L, hemicellulase, Pectinex Ultra SP-L, Viscozyme L, and papain. The obtained results demonstrated that Alacalse produced a 75% oil yield in only 1 h of reaction, thus confirming its crucial role in aqueous extraction.

EAAE represents an innovative eco-friendly extraction method that allows a high-quality RBO to be obtained and, simultaneously, the protein fraction to be extracted with almost no waste production.

One of the major drawbacks of this technique is the cost. EAAE requires a considerably higher capital investment than conventional solvent extraction methods. Sharma et al. [82] suggested the use of immobilized enzymes, which may allow the operational cost to be reduced as the enzymes may be reused but, to the best of our knowledge, this approach has never been applied for RBO extraction. However, research is moving toward the study of a more affordable enzymatic process [106].

4.6 Subcritical water extraction

Subcritical water extraction (SWE) represents a new option in green extraction methods, especially for those that employ food and plants as the starting matrices. SWE employs water, which is the green-solvent par excellence, as it is non-flammable, non-toxic, easily available, and cheap. Water is a highly polar molecule, and under certain environmental conditions, it is unable to dissolve the majority of organic compounds. In SWE, water is brought to higher temperatures than its boiling point, usually from 100 to 374 °C (Fig. 8), under a high pressure, with the aim of preserving its liquid state. The dielectric constant and the polarity of the water are modified under subcritical conditions, thereby making it able to act more like a solvent of non-polar compounds. At temperatures above 200 °C, the water dielectric constant is similar to that of organic solvents, such as ethanol or methanol. Temperature is one of the main factors that can affect the efficiency and selectivity of an extraction process. When the temperature is raised, the viscosity, the permittivity, and the surface tension of water decrease, and diffusivity increases. These factors result in it having an improved matrix penetration capacity and an increased efficiency and velocity of extraction. The maximum working extraction temperature should be chosen carefully, according to the materials employed in the process, in order to avoid the degradation of the analytes of interest. Other parameters that need to be considered are the pressure, pH, flow rate, extraction time, and the chemical structure of the analytes [109,110,111].

Phase diagram of water. The yellow oval represents the subcritical phase that occurs at higher temperatures than the boiling point (from 100 to 374 °C) and under high pressure with the aim of preserving its liquid state (above 1 atm) [13]

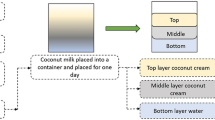

Pourali et al. [84] demonstrated that it is possible to obtain a simultaneous stabilization and extraction of RBO using subcritical water extraction. As already described in previous chapters, it is necessary to stabilize rice bran deactivating lipase enzymes in order to avoid the hydrolytic rancidity process. These authors investigated the stabilization and the behavior of extraction over a 120 and 240 °C temperature range for 10 and 20 min. An increase in oil yield was observed as the temperature and time rose. They obtained a complete decomposition of the lipase enzyme and a maximum RBO yield of 249 mg/g of dry rice bran (94% of the total oil from rice bran), which is comparable with the quantity obtained by means of hexane extraction. These results indicate that SWE can be considered a competitive extraction process that does not require the use of any toxic organic solvents and which has a very short reaction time.

Unfortunately, even though this technique has already provided excellent results for the extraction of other oils, such as sunflower, soybean, cottonseed, or jojoba oil [112, 113] and certain functional compounds, such as polyphenols, essential oils, carotenoids, flavonoids, and flavor and fragrance compounds [101], but it is still not applied extensively for RBO extraction. Furthermore, SWE presents several remarkable benefits compared with conventional techniques; i.e., it uses water instead of organic solvents, and it has faster extraction times, relatively lower process costs and higher quality extracts [111].

5 Conclusion and future perspectives

Rice is the staple food of over half the world’s population. After the harvest process, the rice is subjected to several milling steps in order to obtain edible rice. The milling process produces a considerable number of by-products, including rice bran. This by-product represents around 9% of all milled rice, and it is full of nutritional and bioactive compounds, but despite these positive proprieties, it is usually wasted or used for animal feeds. Rice bran is particularly rich in oil, which is generally extracted by means of mechanical pressing or organic solvent extraction. RBO is highly rich in phytochemicals, which offer several health benefits, and in particular in γ-oryzanol, a powerful antioxidant. These properties have increased the demand for RBO. Security risks and environmental issues, linked to the extensive use of hexane in conventional RBO extraction methods, have encouraged the development and application of the green extraction technologies that are summarized herein. Non-conventional solvent extraction and supercritical fluid extraction are the green technologies that have been investigated and applied the most, and these are followed by ultrasound and microwave extraction techniques. To date, enzyme-assisted aqueous extraction and subcritical water extraction are still somewhat underexploited, but they seem very promising and deserve further attention. All the here reported green extraction techniques allow a high-quality rice bran oil and high concentrations of γ-oryzanol to be obtained and show comparable yields with the extraction methods that employ hexane.

The green extraction processes reported in this review represent a starting but promising point toward the reduction or the elimination of toxic solvents in RBO extraction. Such techniques may significantly lower the environmental impact, the energy costs, and the process times. New process based on green solvents, particularly innovative technologies able to exploit water as solvent, is urgently needed [114, 115]. Among them, pressurized hot water, high-voltage electrical discharge, or pulsed electric field extraction should be seriously considered, since they already gave excellent results in the extraction of bioactive compounds [12, 116]. In addition, a scale up of these new RBO extraction methods is necessary in order to evaluate the commercial feasibility of the extracted product. Process scale up could be challenging for researchers, since they will have to adapt the existing methodologies, trying to reduce the number of steps, aiming to obtain a cheaper production without altering the features of the final products. Finally, a case-by-case evaluation of the environmental impact of the extraction methods through a life cycle assessment must be considered in order to address their real sustainability.

Currently, the high cost of the majority of these techniques precludes the complete replacement of conventional RBO extraction methods. However, the advantages of the promising approaches herein presented will certainly stimulate the researches aimed at identifying more affordable and cheaper processes.

Data availability

Not applicable.

Code availability

Not applicable.

References

Rice and human nutrition. Food and Agriculture Organization of the United Nations (FAO) http://www.fao.org/rice2004/en/f-sheet/factsheet3.pdf Accessed 11 Apr 2020

World Rice Production 2019/2020 World Agricultural Production. http://www.worldagriculturalproduction.com/crops/rice.aspx. Accessed 11 Apr 2020

Bodie AR, Micciche AC, Atungulu GG, Rothrock MJ, Ricke SC (2019) Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Front Sustain Food Syst 3:47. https://doi.org/10.3389/fsufs.2019.00047

Begum A, Sarma J, Borah P, Moni Bhuyan P, Saikia R, Hussain Ahmed T, Rai L (2015) Microwave (MW) energy in enzyme deactivation: stabilization of rice bran from few widely consumed indigenous rice cultivars (Oryza sativa L.) from Eastern Himalayan range. Curr Nutr Food Sci 11:240–245. https://doi.org/10.2174/1573401311666150521233113

Limtrakul P, Semmarath W, Mapoung S (2019) Anthocyanins and proanthocyanidins. IntechOpen https://wwwintechopencom/books/phytochemicals-in-human-health/anthocyanins-and-proanthocyanidins-in-natural-pigmented-rice-and-their-bioactivities Accessed 11 Apr 2020

Rohman A (2014) Rice bran oil’s role in health and cooking. In: Wheat and Rice in Disease Prevention and Health. Academic Press, pp 481–490

Lai OM, Jacoby JJ, Leong WF, Lai WT (2019) Nutritional studies of Rice bran oil. In: Rice Bran and Rice Bran Oil. AOCS Press, pp 19–54

Wang Y (2019) Applications of rice bran oil. In: Rice Bran and Rice Bran Oil. AOCS Press, Urbana, pp 159–168

Ghatak S, Panchal SJ (2011) Gamma-oryzanol—a multi-purpose steryl ferulate. Curr Nutr Food Sci 7:10–20. https://doi.org/10.2174/157340111794941120

Hexane.Environmental Protection Agency (EPA) https://www.epa.gov/sites/production/files/2016-09/documents/hexane.pdf Accessed 11 Apr 2020

Chemat F, Vian MA, Ravi HK et al (2019) Review of alternative solvents for green extraction of food and natural products: panorama, principles, applications and prospects. Molecules 24. https://doi.org/10.3390/molecules24163007

Galanakis CM (2013) Emerging technologies for the production of nutraceuticals from agricultural by-products: a viewpoint of opportunities and challenges. Food Bioprod Process 91:575–579. https://doi.org/10.1016/j.fbp.2013.01.004

Rahmanian N, Jafari SM, Galanakis CM (2014) Recovery and removal of phenolic compounds from olive mill wastewater. JAOCS J Am Oil Chem Soc 91:1–18. https://doi.org/10.1007/s11746-013-2350-9

Zinoviadou KG, Galanakis CM, Brnčić M, Grimi N, Boussetta N, Mota MJ, Saraiva JA, Patras A, Tiwari B, Barba FJ (2015) Fruit juice sonication: implications on food safety and physicochemical and nutritional properties. Food Res Int 77:743–752. https://doi.org/10.1016/j.foodres.2015.05.032

Galanakis CM (2015) Separation of functional macromolecules and micromolecules: from ultrafiltration to the border of nanofiltration. Trends Food Sci Technol 42:44–63. https://doi.org/10.1016/j.tifs.2014.11.005

Chemat F, Vian MA, Cravotto G (2012) Green extraction of natural products: concept and principles. Int J Mol Sci 13:8615–8627. https://doi.org/10.3390/ijms13078615

Barba FJ, Galanakis CM, Esteve MJ, Frigola A, Vorobiev E (2015) Potential use of pulsed electric technologies and ultrasounds to improve the recovery of high-added value compounds from blackberries. J Food Eng 167:38–44. https://doi.org/10.1016/j.jfoodeng.2015.02.001

Deng Q, Zinoviadou KG, Galanakis CM, Orlien V, Grimi N, Vorobiev E, Lebovka N, Barba FJ (2015) The effects of conventional and non-conventional processing on Glucosinolates and its derived forms, isothiocyanates: extraction, degradation, and applications. Food Eng Rev 7:357–381. https://doi.org/10.1007/s12393-014-9104-9

Cereal Supply and Demand Brief. Food and Agriculture Organization of the United Nations (FAO) http://www.fao.org/worldfoodsituation/csdb/en/ Accessed 11 Apr 2020

Shahbandeh M (2019) Worldwide production of grain in 2018/19, by type. Statista https://wwwstatistacom/statistics/263977/world-grain-production-by-type/ Accessed 11 Apr 2020

Kumar A, Roy A, Priyadarshinee R, Sengupta B, Malaviya A, Dasguptamandal D, Mandal T (2017) Economic and sustainable management of wastes from rice industry: combating the potential threats. Environ Sci Pollut Res 24:26279–26296. https://doi.org/10.1007/s11356-017-0293-7

Muthayya S, Sugimoto JD, Montgomery S, Maberly GF (2014) An overview of global rice production, supply, trade, and consumption. Ann N Y Acad Sci 1324:7–14. https://doi.org/10.1111/nyas.12540

Shahbandeh M (2020) Top countries based on production of milled rice 2018/2019. Statista https://www.statista.com/statistics/255945/top-countries-of-destination-for-us-rice-exports-2011/ accessed 11 Apr 2020

Shahbandeh M (2019) Principal rice exporting countries worldwide in 2018/2019. Statista https://wwwstatistacom/statistics/255947/top-rice-exporting-countries-worldwide-2011/ Accessed 11 Apr 2020

Beighley DH (2010) Growth and production of rice. UNESCO-EOLSS https://wwweolssnet/ebooklib/ebookcontents/E1-05A-ThemeContentspdf Accessed 11 Apr 2020

Moraes CA, Fernandes IJ, Calheiro D, Kieling AG, Brehm FA, Rigon MR, Osorio E (2014) Review of the rice production cycle: by-products and the main applications focusing on rice husk combustion and ash recycling. Waste Manag Res 32:1034–1048. https://doi.org/10.1177/0734242X14557379

Postproduction. International Rice Research Institute (IRRI) http://www.knowledgebank.irri.org/step-by-step-production/postharvest Accessed 11 Apr 2020

Lantin R (1999) RICE: post-harvest operations, Food and Agriculture Organization of the United Nations (FAO) http://www.fao.org/fileadmin/user_upload/inpho/docs/Post_Harvest_Compendium_-_RICE.pdf accessed 11 Apr 2020

Prabhakaran P, Ranganathan R, Kumar VM, Rajasekar R, Devakumar L, Pal SK (2017) Review on parameters influencing the rice breakage and rubber roll wear in sheller. Arch Metall Mater 62:1875–1880. https://doi.org/10.1515/amm-2017-0284

Afzalinia S, Shaker M, Zare E (2004) Comparison of different rice milling methods. Canadian biosystems engineering http://wwwcsbe-scgabca/docs/journal/46/c0244pdf Accessed 11 Apr 2020

Dhankhar P, Hissar T (2014) Rice milling. IOSR J Eng 4:34–42. https://doi.org/10.9790/3021-04543442

Milling. International Rice Research Institute (IRRI) http://www.knowledgebank.irri.org/step-by-step-production/postharvest/milling Accessed 11 Apr 2020

Milling by-products. International Rice Research Institute (IRRI) http://www.knowledgebank.irri.org/step-by-step-production/postharvest/milling/milling-byproducts-and-their-utilization Accessed 11 Apr 2020

Moongngarm A, Daomukda N, Khumpika S (2012) Chemical compositions, phytochemicals, and antioxidant capacity of rice bran, rice bran layer, and rice germ. Apcbee Procedia 2:73–79. https://doi.org/10.1016/j.apcbee.2012.06.014

Rice bran. International Rice Research Institute (IRRI) http://www.knowledgebank.irri.org/step-by-step-production/postharvest/milling/milling-byproducts-and-their-utilization/rice-bran Accessed 11 Apr 2020

Saunders RM (1985) Rice bran: composition and potential food uses. Food Rev Int 1:465–495. https://doi.org/10.1080/87559128509540780

Alauddina M, Islama J, Shirakawaa H, Kosekib T, Komaia AM (2017) Rice bran as a functional food: an overview of the conversion of Rice bran into a superfood/functional food. InTech Open https://wwwintechopencom/books/superfood-and-functional-food-an-overview-of-their-processing-and-utilization/rice-bran-as-a-functional-food-an-overview-of-the-conversion-of-rice-bran-into-a-superfood-functiona Accessed 11 Apr 2020

Sharif MK, Butt MS, Anjum FM, Khan SH (2014) Rice bran: a novel functional ingredient. Crit Rev Food Sci Nutr 54(6):807–816. https://doi.org/10.1080/10408398.2011.608586

Dubey B, Fitton D, Nahar S, Howarth M (2019) Comparative study on the rice bran stabilization processes: a review. Research & development in material science https://crimsonpublisherscom/rdms/pdf/RDMS000759pdf Accessed 11 Apr 2020, 11

Jiang Y (2019) Bioprocessing technology of rice bran oil. In: Rice bran and rice bran oil. AOCS Press, Urbana, pp 97–123

Godber JS (2009) Rice bran oil. In: Gourmet and health-promoting specialty oils. AOCS Press, Urbana, pp 377–408

He D, Liu L (2019) Analytical aspects of Rice bran oil. In: Rice bran and rice bran oil. AOCS Press, Urbana, pp 169–181

Maurya NK, Kushwaha R (2019) Pharmacognosy of rice bran oil—a review. Int J Green Pharm 12:784–789. https://doi.org/10.22377/ijgp.v12i04.2255

Singanusong R, Garba U (2019) Micronutrients in rice bran oil. In: Rice bran and rice bran oil. AOCS Press, Urbana, pp 125–158

Sohail M, Rakha A, Butt MS, Iqbal MJ, Rashid S (2017) Rice bran nutraceutics: a comprehensive review. Crit Rev Food Sci Nutr 57:3771–3780. https://doi.org/10.1080/10408398.2016.1164120

Aladedunye F, Przybylski R, Rudzinska M, Klensporf-Pawlik D (2013) γ-Oryzanols of North American wild rice (Zizania palustris). J Am Oil Chem Soc 90:1101–1109. https://doi.org/10.1007/s11746-013-2252-x

Castanho A, Lageiro M, Calhelha RC, Ferreira IC, Sokovic M, Cunha LM, Brites C (2019) Exploiting the bioactive properties of γ-oryzanol from bran of different exotic rice varieties. Food Funct 10:2382–2389. https://doi.org/10.1039/c8fo02596g

Cycloartenol ferulate. National Center for Biotechnology Information PubChem Database.https://pubchem.ncbi.nlm.nih.gov/compound/Cycloartenol-ferulate Accessed 12 Apr 2020

24-Methylene-cycloartanol. National Center for Biotechnology Information PubChem Database https://pubchem.ncbi.nlm.nih.gov/compound/9547213 Accessed 12 Apr 2020

Ferulic acid. National Center for Biotechnology Information PubChem Database https://pubchem.ncbi.nlm.nih.gov/compound/Ferulic-acid Accessed 12 Apr 2020

Campesteryl ferulate. National Center for Biotechnology Information PubChem Database.https://pubchem.ncbi.nlm.nih.gov/compound/Campesteryl-ferulate Accessed 12 Apr 2020

beta-Sitosteryl ferulate. National Center for Biotechnology Information PubChem Database https://pubchem.ncbi.nlm.nih.gov/compound/beta-Sitosteryl-ferulate Accessed 12 Apr 2020

Lesma G, Luraghi A, Bavaro T, Bortolozzi R, Rainoldi G, Roda G, Silvani A (2018) Phytosterol and γ-oryzanol conjugates: synthesis and evaluation of their antioxidant, antiproliferative, and anticholesterol activities. J Nat Prod 81:2212–2221. https://doi.org/10.1021/acs.jnatprod.8b00465

Srikaeo K (2014) Organic rice bran oils in health. In wheat and Rice. In: Disease prevention and health. Academic Press, Cambridge, pp 453–465

Galanakis CM (2012) Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci Technol 26:68–87. https://doi.org/10.1016/j.tifs.2012.03.003

Kumar SJ, Prasad SR, Banerjee R, Agarwal DK, Kulkarni KS, Ramesh KV (2017) Green solvents and technologies for oil extraction from oilseed. Chem Cent J 11:9. https://doi.org/10.1186/s13065-017-0238-8

Tang SY, Bourne RA, Smith RL, Poliakoff M (2008) The 24 principles of green engineering and green chemistry: “Improvements productively”. Green Chem 10:268–269. https://doi.org/10.1039/B719469M

Hu W, Wells JH, Shin TS, Godber JS (1996) Comparison of isopropanol and hexane for extraction of vitamin E and oryzanols from stabilized rice bran. J Am Oil Chem Soc 73:1653–1656. https://doi.org/10.1007/BF02517967

Zigoneanu IG, Williams L, Xu Z, Sabliov CM (2008) Determination of antioxidant components in rice bran oil extracted by microwave-assisted method. Bioresour Technol 99:4910–4918. https://doi.org/10.1016/j.biortech.2007.09.067

Capellini MC, Giacomini V, Cuevas MS, Rodrigues CE (2017) Rice bran oil extraction using alcoholic solvents: physicochemical characterization of oil and protein fraction functionality. Ind Crop Prod 104:133–143. https://doi.org/10.1016/j.indcrop.2017.04.017

Oliveira R, Oliveira V, Aracava KK, Costa Rodrigues CE (2012) Effects of the extraction conditions on the yield and composition of rice bran oil extracted with ethanol—a response surface approach. Food Bioprod Process 90(1):22–31. https://doi.org/10.1016/j.fbp.2011.01.004

Shukla HS, Pratap A (2017) Comparative studies between conventional and microwave assisted extraction for rice bran oil. J Oleo Sci 66(9):973–979. https://doi.org/10.5650/jos.ess17067

Ruen-Ngam D, Thawai C, Nokkoul R, Sukonthamut S (2014) Gamma-oryzanol extraction from upland rice bran. Int J Biosci Biochem Bioinform 4:252–255. https://doi.org/10.7763/ijbbb.2014.v4.350

Liu SX, Mamidipally PK (2005) Quality comparison of rice bran oil extracted with d-limonene and hexane. Cereal Chem 82(2):209–215. https://doi.org/10.1094/cc-82-0209

Duvernay WH, Assad JM, Sabliov CM, Lima M, Xu Z (2005) Microwave extraction of antioxidant components from rice bran. Pharmaceutical Engineering https://ispeorg/pharmaceutical-engineering/july-august-2005 Accessed 12 Apr 2020

Kumar P, Yadav D, Kumar P, Panesar PS, Bunkar DS, Mishra D, Chopra HK (2016) Comparative study on conventional, ultrasonication and microwave assisted extraction of γ-oryzanol from rice bran. J Food Sci Technol 53:2047–2053. https://doi.org/10.1007/s13197-016-2175-2

Kanitkar A, Sabliov CM, Balasubramanian S, Lima M, Boldor D (2011) Microwave-assisted extraction of soybean and rice bran oil: yield and extraction kinetics. T ASABE 54:1387–1394. https://doi.org/10.13031/2013.39007

Terigar BG, Balasubramanian S, Sabliov CM, Lima M, Boldor D (2011) Soybean and rice bran oil extraction in a continuous microwave system: from laboratory-to pilot-scale. J Food Eng 104:208–217. https://doi.org/10.1016/j.jfoodeng.2010.12.012

Cravotto G, Binello A, Merizzi G, Avogadro M (2004) Improving solvent-free extraction of policosanol from rice bran by high-intensity ultrasound treatment. Eur J Lipid Sci Technol 106:147–151. https://doi.org/10.1002/ejlt.200300914

Khoei M, Chekin F (2016) The ultrasound-assisted aqueous extraction of rice bran oil. Food Chem 194:503–507. https://doi.org/10.1016/j.foodchem.2015.08.068

Tabaraki R, Nateghi A (2011) Optimization of ultrasonic-assisted extraction of natural antioxidants from rice bran using response surface methodology. Ultrason Sonochem 18:1279–1286. https://doi.org/10.1016/j.ultsonch.2011.05.004

Garcia A, De Lucas A, Rincón J, Alvarez A, Gracia I, García MA (1996) Supercritical carbon dioxide extraction of fatty and waxy material from rice bran. J Am Oil Chem Soc 73(9):1127–1131. https://doi.org/10.1007/BF02523373

Kuk MS, Dowd MK (1998) Supercritical CO2 extraction of rice bran. J Am Oil Chem Soc 75:623–628. https://doi.org/10.1007/s11746-998-0075-y

Xu Z, Godber JS (2000) Comparison of supercritical fluid and solvent extraction methods in extracting γ-oryzanol from rice bran. J Am Oil Chem Soc 77:547–551. https://doi.org/10.1007/s11746-000-0087-4

Al-Okbi SY, Mohamed DA, Hamed IM, Agoor FS, Ramadan AMA, El-Saed S, Helal AM (2013) Comparative study on Egyptian rice bran extracted by solvents and supercritical CO2. Adv Food Sci file:///C:/Users/user/Downloads/A_2012_028_Original_Paper_pp23_29.pdf Accessed 12 Apr 2020

Balachandran C, Mayamol PN, Thomas S, Sukumar D, Sundaresan A, Arumughan C (2008) An ecofriendly approach to process rice bran for high quality rice bran oil using supercritical carbon dioxide for nutraceutical applications. Bioresour Technol 99:2905–2912. https://doi.org/10.1016/j.biortech.2007.06.004

Wang CH, Chen CR, Wu JJ, Wang LY, Chang CMJ, Ho WJ (2008) Designing supercritical carbon dioxide extraction of rice bran oil that contain oryzanols using response surface methodology. J Sep Sci 31:1399–1407. https://doi.org/10.1002/jssc.200700583

Tomita K, Machmudah S, Fukuzato R, Kanda H, Quitain AT, Sasaki M, Goto M (2014) Extraction of rice bran oil by supercritical carbon dioxide and solubility consideration. Sep Purif Technol 125:319–325. https://doi.org/10.1016/j.seppur.2014.02.008

Imsanguan P, Roaysubtawee A, Borirak R, Pongamphai S, Douglas S, Douglas PL (2008) Extraction of α-tocopherol and γ-oryzanol from rice bran. LWT-Food Sci Technol 41:1417–1424. https://doi.org/10.1016/j.lwt.2007.08.028

Bitencourt RG, Rammazzina Filho WA, Paula JT, Garmus TT, Cabral FA (2016) Solubility of γ-oryzanol in supercritical carbon dioxide and extraction from rice bran. J Supercrit Fluids 107:196–200. https://doi.org/10.1016/j.supflu.2015.09.009

Sengupta R, Bhattacharyya DK (1996) Enzymatic extraction of mustard seed and rice bran. J Am Oil Chem Soc 73(6):687–692. https://doi.org/10.1007/BF02517941

Sharma A, Khare SK, Gupta MN (2001) Enzyme-assisted aqueous extraction of rice bran oil. J Am Oil Chem Soc 78(9):949–951. https://doi.org/10.1007/s11746-001-0369-x

Hanmoungjai P, Pyle DL, Niranjan K (2001) Enzymatic process for extracting oil and protein from rice bran. J Am Oil Chem Soc 78:817–821. https://doi.org/10.1007/s11746-001-0348-2

Pourali O, Asghari FS, Yoshida H (2009) Simultaneous rice bran oil stabilization and extraction using sub-critical water medium. J Food Eng 95:510–516. https://doi.org/10.1016/j.jfoodeng.2009.06

Garba U, Singanusong R, Jiamyangyuen S, Thongsook T (2017) Extraction and utilization of rice bran oil: a review. La Rivista Italiana Delle Sostanze Grasse. https://www.innovhub-ssi.it/c/document_library/get_file?uuid=209e3cc1-5ef3-4065-bd01-6f4e1b6acb11&groupId=10157 Accessed 12 Apr 2020

Henderson RK, Jiménez-González C, Constable DJ, Alston SR, Inglis GG, Fisher, Curzons AD (2011) Expanding GSK's solvent selection guide—embedding sustainability into solvent selection starting at medicinal chemistry. Green Chem 134:854–862. https://doi.org/10.1039/C0GC00918K

Joshi DR, Adhikari N (2019) An overview on common organic solvents and their toxicity. J Pharm Res Int 28:1–18. https://doi.org/10.9734/jpri/2019/v28i330203

Prat D, Pardigon O, Flemming HW, Letestu S, Ducandas V, Isnard P, Hosek P (2013) Sanofi’s solvent selection guide: a step toward more sustainable processes. Org Process Res Dev 17:1517–1525. https://doi.org/10.1021/op4002565

Prat D, Hayler J, Wells A (2014) A survey of solvent selection guides. Green Chem 16:4546–4551. https://doi.org/10.1039/C4GC01149J

Soquetta MB, Terra LDM, Bastos CP (2018) Green technologies for the extraction of bioactive compounds in fruits and vegetables. Cyta-J Food 16:400–412. https://doi.org/10.1080/19476337.2017.1411978

Destandau E, Michel T, Elfakir C (2013) Microwave-assisted extraction. In: Natural product extraction: principles and applications. RSC Green Chem:113–156

Pandey R, Shrivastava SL (2018) Comparative evaluation of rice bran oil obtained with two-step microwave assisted extraction and conventional solvent extraction. J Food Eng 218:106–114. https://doi.org/10.1016/j.jfoodeng.2017.09.009

Chemat F, Rombaut N, Sicaire AG, Meullemiestre A, Fabiano-Tixier AS, Abert-Vian M (2017) Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem 34:540–560. https://doi.org/10.1016/j.ultsonch.2016.06.035

Tiwari BK (2015) Ultrasound: a clean, green extraction technology. TrAC Trends Anal Chem 71:100–109. https://doi.org/10.1016/j.trac.2015.04.013

Gallo M, Ferrara L, Naviglio D (2018) Application of ultrasound in food science and technology: a perspective. Foods 7:164. https://doi.org/10.3390/foods7100164

Esclapez MD, García-Pérez JV, Mulet A, Cárcel JA (2011) Ultrasound-assisted extraction of natural products. Food Eng Rev 3:108–120. https://doi.org/10.1007/s12393-011-9036-6

Ghasemzadeh A, Jaafar HZ, Juraimi AS, Tayebi-Meigooni A (2015) Comparative evaluation of different extraction techniques and solvents for the assay of phytochemicals and antioxidant activity of hashemi rice bran. Molecules 20:10822–10838. https://doi.org/10.3390/molecules200610822

Majid A, Phull AR, Khaskheli AH et al (2019) Applications and opportunities of supercritical fluid extraction in food processing technologies: a review. Int J Adv Appl Sci 6:99–103. https://doi.org/10.21833/ijaas.2019.07.013

Srinivas K, King JW (2018) Developments in the processing of foods and natural products using pressurized fluids. In Alternatives to conventional food processing, RCS, pp 196–250

Mohamed RS, Mansoori GA (2002) The use of supercritical fluid extraction technology in food processing. Food Technol Mag https://wwwacademiaedu/34656950/The_Use_of_Supercritical_Fluid_Extraction_Technology_in_Food_Processing Accessed 12 Apr 2020

Rozzi NL, Singh RK (2002) Supercritical fluids and the food industry. Compr Rev Food Sci F 1:33–44. https://doi.org/10.1111/j.1541-4337.2002.tb00005.x

Zhao W, Shishkura A, Fujimoto K, Arai K, Saito S (1987) Fractional extraction of rice bran oil with supercritical carbon dioxide. Agric Biol Chem 51:1773–1777. https://doi.org/10.1080/00021369.1987.10868305

Palmer MV, Ting SST (1995) Applications for supercritical fluid technology in food processing. Food Chem 52:345–352. https://doi.org/10.1016/0308-8146(95)93280-5

Sookwong P, Mahatheeranont S (2017) Supercritical CO2 extraction of rice bran oil–the technology, manufacture, and applications. J Olo Sci 66:557–564. https://doi.org/10.5650/jos.ess17019

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Tech 19:402–420. https://doi.org/10.1016/S0141-0229(96)80004-F