Abstract

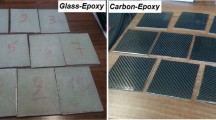

The effect of sea water immersion on the durability and performance of the PET fibre reinforced epoxy composites were experimentally investigated. The reinforcing fibres and their respective composite samples were immersed in artificial seawater over a period of 120 days. The extent of degradation post immersion was studied using thermal gravimetric analysis. Water uptake behaviour of the composites and the losses in their mechanical properties were studied by testing them under tensile, flexural and impact loads before and after immersion. Effect of degradation in interfacial region and the fracture morphology in the failed samples were analysed through SEM micrographs. The outcome of these results was compared with the glass fibre reinforced epoxy counterparts, which are often used in today’s marine structures. It was found that the glass–epoxy composites experienced about 8% decrease in their overall mechanical properties while polyester-epoxy composites remain unaffected to seawater ageing. Therefore, PET-epoxy material combinations can be approached to cater the long term structural requirements of maritime applications and further open up new gateways for utilization of recycled hazardous plastics.

Similar content being viewed by others

References

Feng P, Wang J, Wang Y, Loughery D, Niu D (2014) Effects of corrosive environments on properties of pultruded GFRP plates. Compos B 67:427–433

Selvaraju S, Ilaiyavel S (2011) Applications of composites in marine industry. J Eng Res Stud II:89–91

Tsai S (2018) Introduction to composite materials. Routledge, Boca Raton

Kootsookos A, Mouritz AP (2004) Seawater durability of glass-and carbon-polymer composites. Compos Sci Technol 64(10–11):1503–1511

Garcia-Espinel JD, Castro-Fresno D, Gayo PP, Ballester-Muñoz F (2015) Effects of sea water environment on glass fibre reinforced plastic materials used for marine civil engineering constructions. Mater Des (1980–2015) 66:46–50

Manjunath RN, Behera BK (2017) Modelling the geometry of the unit cell of woven fabrics with integrated stiffener sections. J Tex Inst 108(11):2006–2012

Manjunath RN, Behera BK, Mawkhlieng U (2019) Flexural stability analysis of composite panels reinforced with stiffener integral woven preforms. J Tex Inst 110(3):368–377

Bian L, Xiao J, Zeng J, Xing S (2012) Effects of seawater immersion on water absorption and mechanical properties of GFRP composites. J Compos Mater 46(25):3151–3162

Hammami A, Al-Ghuilani N (2004) Durability and environmental degradation of glass-vinylester composites. Polym Compos 25(6):609–616

Aldajah S, Alawsi G, Rahmaan SA (2009) Impact of sea and tap water exposure on the durability of GFRP laminates. Mater Des 30(5):1835–1840

Mourad AH, Abdel-Magid BM, El-Maaddawy T, Grami ME (2010) Effect of seawater and warm environment on glass/epoxy and glass/polyurethane composites. Appl Compos Mater 17(5):557–573

Xu LR, Krishnan A, Ning H, Vaidya U (2012) A seawater tank approach to evaluate the dynamic failure and durability of E-glass/vinyl ester marine composites. Compos B 43(5):2480–2486

Fang Y, Wang K, Hui D, Xu F, Liu W, Yang S, Wang L (2017) Monitoring of seawater immersion degradation in glass fibre reinforced polymer composites using quantum dots. Compos B 112:93–102

Bazli M, Ashrafi H, Oskouei AV (2016) Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos B 99:203–215

Assarar M, Scida D, El Mahi A, Poilâne C, Ayad R (2011) Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: flax–fibres and glass–fibres. Mater Des 32(2):788–795

Jiang X, Kolstein H, Bijlaard FS (2013) Moisture diffusion in glass–fibre-reinforced polymer composite bridge under hot/wet environment. Compos B 45(1):407–416

Cabral-Fonseca S, Correia JR, Rodrigues MP, Branco FA (2012) Artificial accelerated ageing of GFRP pultruded profiles made of polyester and vinylester resins: characterisation of physical–chemical and mechanical damage. Strain 48(2):162–173

Guermazi N, Tarjem AB, Ksouri I, Ayedi HF (2016) On the durability of FRP composites for aircraft structures in hygrothermal conditioning. Compos B 85:294–304

Carra G, Carvelli V (2014) Ageing of pultruded glass fibre reinforced polymer composites exposed to combined environmental agents. Compos Struct 108:1019–1026

Carra G, Carvelli V (2015) Long-term bending performance and service life prediction of pultruded glass fibre reinforced polymer composites. Compos Struct 127:308–315

Carvelli V, Carra G. Service life prediction of pultruded glass fibre reinforced polymer composites for building construction. In 8th International Conference on Advanced Composites in Construction (ACIC 2017) GBR. 2017. pp. 1–6.

Firdosh S, Murthy HN, Pal R, Angadi G, Raghavendra N, Krishna M (2015) Durability of GFRP nanocomposites subjected to hygrothermal ageing. Compos B 69:443–451

Volf MB. Technical approach to glass (No. 10). Elsevier Science Limited. (1990)

Qiu Q, Kumosa M (1997) Corrosion of E-glass fibres in acidic environments. Compos Sci Technol 57(5):497–507

Sawpan MA (2019) Shear properties and durability of GFRP reinforcement bar aged in seawater. Polym Test 75:312–320

Nguyen T, Aouadi K, Alsheh D, Chin J. Effects of civil engineering environments of interfacial properties of polymer/glass fibre composites. In 4th International Conference on Composites Engineering 1997. pp. 725–726.

Kafodya I, Xian G, Li H (2015) Durability study of pultruded CFRP plates immersed in water and seawater under sustained bending: Water uptake and effects on the mechanical properties. Compos B Eng 70:138–148

Yang S, Liu W, Fang Y, Huo R (2019) Influence of hygrothermal aging on the durability and interfacial performance of pultruded glass fibre-reinforced polymer composites. J Mater Sci 54(3):2102–2121

Jesthi DK, Nayak RK (2019) Evaluation of mechanical properties and morphology of seawater aged carbon and glass fibre reinforced polymer hybrid composites. Compos B 174:106980

Nayak RK, Ray BC (2018) Influence of seawater absorption on retention of mechanical properties of nano-TiO2 embedded glass fibre reinforced epoxy polymer matrix composites. Arch Civil Mech Eng 18(4):1597–1607

Nayak RK, Mahato KK, Ray BC (2016) Water absorption behavior, mechanical and thermal properties of nano TiO2 enhanced glass fibre reinforced polymer composites. Compos A 90:736–747

Shafique U, Zaman WU, Anwar J, Munawar MA, Salman M, Dar A, Rehman R, Ashraf U, Ahmad S (2011) A rapid, economical, and eco-friendly method to recycle terephthalic acid from waste poly (ethylene terphthalate) bottles. Int J Polym Mater 60(14):1147–1151

Sarioğlu E, Kaynak HK. PET bottle recycling for sustainable textiles. In Polyester-production, characterization and innovative applications 2017 Dec 20. IntechOpen.

Akgun M (2014) Surface roughness properties of polyester woven fabrics after abrasion. J Text Inst 105(4):383–391

Manjunath RN, Khatkar V, Behera BK (2019) Influence of augmented tuning of core architecture in 3D woven sandwich structures on flexural and compression properties of their composites. Adv Compos Mater. https://doi.org/10.1080/09243046.2019.1680925

Manjunath RN, Khatkar V, Behera BK (2019) Comparative assessment of static and dynamic mechanical properties of glass and PET fiber reinforced epoxy composites. Mater Today 18:4048–4057

Kester DR, Duedall IW, Connors DN, Pytkowicz RM (1967) Preparation of artificial seawater 1. Limnol Oceanogr 12(1):176–179

Khatkar V, Behera BK, Manjunath RN (2020) Textile structural composites for automotive leaf spring application. Compos B 182:107662

Dong C, Davies IJ (2013) Flexural properties of glass and carbon fibre reinforced epoxy hybrid composites. Proc Inst Mech Eng Part L J Mater 227(4):308–317

Gellert EP, Turley DM (1999) Seawater immersion ageing of glass-fibre reinforced polymer laminates for marine applications. Compos A Appl Sci Manuf 30(11):1259–1265

Ellyin F, Rohrbacher C (2000) Effect of aqueous environment and temperature on glass-fibre epoxy resin composites. J Reinf Plast Compos 19(17):1405–1427

Wood CA, Bradley WL (1997) Determination of the effect of seawater on the interfacial strength of an interlayer E-glass/graphite/epoxy composite by in situ observation of transverse cracking in an environmental SEM. Compos Sci Technol 57(8):1033–1043

Bai Y, Post NL, Lesko JJ, Keller T (2008) Experimental investigations on temperature-dependent thermo-physical and mechanical properties of pultruded GFRP composites. Thermochim Acta 469(1–2):28–35

Faraj MG, Ibrahim K, Ali MK (2011) PET as a plastic substrate for the flexible optoelectronic applications. Optoelectron Adv Mater 5(8):879–882

Blaga A (1972) Weathering study of glass-fibre reinforced polyester sheets by scanning electron microscopy. Polym Eng Sci 12(1):53–58

Krauklis AE, Echtermeyer AT (2018) Mechanism of yellowing: carbonyl formation during hygrothermal aging in a common amine epoxy. Polymers 10(9):1017

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Manjunath, R.N., Khatkar, V. & Behera, B.K. Investigation on Seawater Ageing of PET-Epoxy Composites: An Ecological and Sustainable Approach for Marine Applications. J Polym Environ 28, 2289–2300 (2020). https://doi.org/10.1007/s10924-020-01771-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01771-2