Abstract

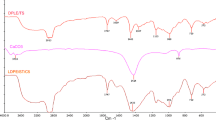

In order to improve high hydrophilicity and low mechanical properties of biodegradable high-methoxy pectin (HMP) film, dialdehyde starch (DS) were introduced. In this study, different HMP/DS blended films were prepared by varying DS contents. It was observed from Infrared spectra that lower peak intensity of C=O stretching was detected after the incorporation of DS into HPM film. Moreover, moisture uptake of various HMP/DS blended films was found to be significantly lower than those of HMP film with the addition of low DS content. The improvement of mechanical properties was observed in various HPM/DS blended films. In addition, color parameters, swelling power, morphological and biodegradable properties of various HMP/DS blended films were also investigated.

Similar content being viewed by others

References

Stephen AM, Phillips GO, Williams PA (2006) Food polysaccharides and their applications. CRC/Talor & Francis, Boca Raton

Coffin DR, Fishman ML (1993) Viscoelastic properties of pectin/starch blends. J Agri Food Chem 41(8):1192–1197. https://doi.org/10.1021/jf00032a005

Gouveia TIA, Biernacki K, Castro MCR, Goncalves MP (2019) A new approach to develop biodegradable films based on thermoplastic pectin. Food Hydrocolloids 97:105175. https://doi.org/10.1016/j.foodhyd.2019.105175

Freitas DGS, Berbari D, Prati SAG, Fakhouri P, Queiroz C, Vicente FP (2009) Reducing fat uptake in cassava product during deep-fat frying. J Food Eng 94(3):390–394. https://doi.org/10.1016/j.jfoodeng.2009.04.005

Nesic A, Ruzic J, Ostojic S, Micic D, Onjia A (2017) Pectin polyvinylpyrrolidone films: a sustainable approach to the development of biobased packaging materials. Compos B Eng 110:56–61. https://doi.org/10.1016/j.compositesb.2016.11.01

BeMiller JN, Whistler RL (2009) Starch: chemistry and technology. Academic Press, New York

Coffin DR, Fishman ML (1994) Physical and mechanical properties of highly plasticized pectin/starch films. J Appl Polym Sci 54(9):1311–1320. https://doi.org/10.1002/app.1994.070540913

Fishman ML, Coffin DR, Konstance RP, Onwulata CI (2000) Extrusion of pectin/starch blends plasticized with glycerol. Carbohydr Polym 41(4):317–325. https://doi.org/10.1016/S0144-8617(99)00117-4

Tomasik P, Schilling CH (2004) Chemical modification of starch. Adv Carbohydr Chem Biochem 59:175–403. https://doi.org/10.1016/S0065-2318(04)59005-4

Fiedorowicz M, Para A (2006) Structural and molecular properties of dialdehyde starch. Carbohydr Polym 63(3):360–366. https://doi.org/10.1016/j.carbpol.2005.08.054

Veelaert S, Wit D, Gotlieb KF, Verhe R (1997) Chemical and physical transitions of periodate oxidized potato starch in water. Carbohydr Polym 33(2):153–162. https://doi.org/10.1016/S0144-8617(97)00046-5

Wongsagon R, Shobsngob S, Varavinit S (2005) Preparation and physicochemical properties of dialdehyde tapioca starch. Starch/Starke 57(3–4):166–172. https://doi.org/10.1002/star.200400299

Yu J, Chang PR, Ma X (2010) The preparation and properties of dialdehyde starch and thermoplastic dialdehyde starch. Carbohydr Polym 79(2):296–300. https://doi.org/10.1016/j.carbpol.2009.08.005

Zuo Y, Liu W, Xiao J, Zhao X, Zhu Y, Wu Y (2017) Preparation and characterization of dialdehyde starch by one-step acid hydrolysis and oxidation. Int J Biol Macromol 103:1257–1264. https://doi.org/10.1016/j.ijbiomac.2017.05.188

Du YL, Cao Y, Lu F, Li F, Cao Y, Wang XL, Wang YZ (2008) Biodegradation behaviors of thermoplastic starch (TPS) and thermoplastic dialdehyde starch (TPDAS) under controlled composting conditions. Polym Test 27(8):924–930. https://doi.org/10.1016/j.polymertesting.2008.08.002

McDonald R (1997) Color physics for industry. Society of Dyers and Colourists, West Yorkshire

Bower DI, Maddams WF (1996) The vibrational spectroscopy of polymers. Cambridge University Press, Cambridge

Pawlak A, Mucha M (2003) Thermogravimetric and FTIR studies of chitosan blends. Thermo Chem Acta 396(1):153–166. https://doi.org/10.1016/S0040-6031(02)00523-3

Tena-Salcido CS, Rodríguez-González FJ, Méndez-Hernández ML, Contreras-Esquivel JC (2008) Effect of morphology on the biodegradation of thermoplastic starch in LDPE/TPS blends. Polym Bull 60(5):677–688. https://doi.org/10.1007/s00289-008-0903-0

Onuoha F (2013) Effect of soil burial on properties of polypropylene (PP)/plasticized potato starch (PPS) blends. Int J Eng Sci 2:1813–2319. https://doi.org/10.1155/2013/326538

Acknowledgements

We thank KMITL Research Fund (KREF046108) for financial support and Faculty of Science for facility support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prachayawarakorn, J., Poomkaew, S. Property Improvement of Biodegradable High-Methoxy Pectin Film by Different Contents of Dialdehyde Starch. J Polym Environ 28, 2227–2235 (2020). https://doi.org/10.1007/s10924-020-01767-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01767-y