Abstract

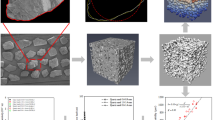

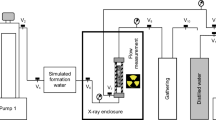

Ore particles, especially fine interlayers, commonly segregate in heap stacking, leading to undesirable flow paths and changeable flow velocity fields of packed beds. Computed tomography (CT), COMSOL Multiphysics, and MATLAB were utilized to quantify pore structures and visualize flow behavior inside packed beds with segregated fine interlayers. The formation of fine interlayers was accompanied with the segregation of particles in packed beds. Fine particles reached the upper position of the packed beds during stacking. CT revealed that the average porosity of fine interlayers (24.21%) was significantly lower than that of the heap packed by coarse ores (37.42%), which directly affected the formation of flow paths. Specifically, the potential flow paths in the internal regions of fine interlayers were undeveloped. Fluid flowed and bypassed the fine interlayers and along the sides of the packed beds. Flow velocity also indicated that the flow paths easily gathered in the pore throat where flow velocity (1.8 × 10−5 m/s) suddenly increased. Fluid stagnant regions with a flow velocity lower than 0.2 × 10−5 m/s appeared in flow paths with a large diameter.

Similar content being viewed by others

References

S.H. Yin, L.M. Wang, E. Kabwe, X. Chen, R.F. Yan, K. An, L. Zhang, and A.X. Wu, Copper bioleaching in China: Review and prospect, Minerals, 8(2018), No. 2, p. 32.

C.L. Brierley and J.A. Brierley, Progress in bioleaching, Part B: Applications of microbial processes by the minerals industries, Appl. Microbiol. Biotechnol., 97(2013), No. 17, p. 7543.

L.M. Wang, S.H. Yin, A.X. Wu, and W. Chen, Synergetic bio-leaching of copper sulfdies using mixed microorganisms and its community structure succession, J. Cleaner Prod., 245(2020), art. No. 118689.

H.R. Watling, The bioleaching of sulphide minerals with emphasis on copper sulphides—A review, Hydrometallurgy, 84(2006), No. 1–2, p. 81.

C.L. Brierley, Biohydrometallurgical prospects, Hydrometallurgy, 104(2010), No. 3–4, p. 324.

X.D. Hao, Y.L. Liang, H.Q. Yin, H.W. Liu, W.M. Zeng, and X.D. Liu, Thin-layer heap bioleaching of copper flotation tailings containing high levels of fine grains and microbial community succession analysis, Int. J. Miner. Metall. Mater., 24(2017), No. 4, p. 360.

Y. Jia, H.Y. Sun, Q.Y. Tan, H.S. Gao, X.L. Feng, and R.M. Ruan, Linking leach chemistry and microbiology of low-grade copper ore bioleaching at different temperatures, Int. J. Miner. Metall. Mater., 25(2018), No. 3, p. 271.

P.J. van Staden and J. Petersen, The effects of simulated stacking phenomena on the percolation leaching of crushed ore, Part 1: Segregation, Miner. Eng., 128(2018), p. 202.

P.J. van Staden and J. Petersen, The effects of simulated stacking phenomena on the percolation leaching of crushed ore, Part 2: Stratification, Miner. Eng., 131(2019), p. 216.

Y.B. Dong, Y. Liu, and H. Lin, Leaching behavior of V, Pb, Cd, Cr, and As from stone coal waste rock with different particle sizes, Int. J. Miner. Metall. Mater., 25(2018), No. 8, p. 861.

S.H. Yin, L.M. Wang, A.X. Wu, M.L. Free, and E. Kabwe, Enhancement of copper recovery by acid leaching of high-mud copper oxides: A case study at Yangla Copper Mine, China, J. Cleaner Prod., 202(2018), p. 321.

D. McBride, I.M.S.K. Ilankoon, S.J. Neethling, J.E. Gebhardt, and M. Gross, Preferential flow behaviour in unsaturated packed beds and heaps: Incorporating into a CFD model, Hydromeatllurgy, 171(2017), p. 402.

S. Zhang, W.Y. Liu, and G. Giuseppe, Effects of grain size gradation on the porosity of packed heap leach beds, Hydrometallurgy, 179(2018), p. 238.

N. Eriksson and G. Destouni, Combined effects of dissolution kinetics, secondary mineral precipitation, and preferential flow on copper leaching from mining waste rock, Water Resour. Res., 33(1997), No. 3, p. 471.

S. Orr, Enhanced heap leaching—Part 1: Insights, Min. Eng., 54(2002), No. 9, p. 31.

S.H. Yin, L.M. Wang, A.X. Wu, X. Chen, and R.F. Yan, Research progress in enhanced bioleaching of copper sulfides under the intervention of microbial community, Int. J. Miner. Metall. Mater., 26(2019), No. 11, p. 1337.

T. Masuoka and Y. Takatsu, Turbulence model for flow through porous media, Int. J. Heat Mass Transfer, 39(1996), No. 13, p. 2803.

G. Parameswaran, Smoothed Particle Hydrodynamics Studies of Heap Leaching Hydrodynamics and Thermal Transport [Dissertations], Imperial College London, London, 2015.

C.L. Lin, A.R. Videla, and J.D. Miller, Advanced three-dimensional multiphase flow simulation in porous media reconstructed from X-ray Microtomography using the He-Chen-Zhang Lattice Boltzmann Model, Flow Meas. Instrum., 21(2010), No. 3, p. 255.

A. Jafari, P. Zamankhan, S.M. Mousavi, and K. Pietarinen, Modeling and CFD simulation of flow behavior and dispersivity through randomly packed bed reactors, Chem. Eng. J., 144(2008), No. 3, p. 476.

M.A. Fagan, A.J. Sederman, S.T.L. Harrison, and M.L. Johns, Phase distribution identification in the column leaching of low grade ores using MRI, Miner. Eng., 48(2013), p. 94.

M.A. Fagan, I.E. Ngoma, R.A. Chiume, S.H. Minnaar, A.J. Sederman, M.L. Johns, and S.T.L. Harrison, MRI and gravimetric studies of hydrology in drip irrigated heaps and its effect on the propagation of bioleaching micro-organisms, Hydrometallurgy, 150(2014), p. 210.

C.L. Lin and J.D. Miller, Pore structure analysis of particle beds for fluid transport simulation during filtration, Int. J. Miner. Process., 73(2004), No. 2–4, p. 281.

A.H. Thaker, G.M. Karthik, and V.V. Buwa, PIV measurements and CFD simulations of the particle-scale flow distribution in a packed bed, Chem. Eng. J., 374(2019), p. 189.

S. Satake, Y. Aoyagi, N. Unno, K. Yuki, Y. Seki, and M. Enoeda, Three-dimensional flow measurement of a water flow in a sphere-packed pipe by digital holographic PTV, Fusion Eng. Des., 98–99(2015), p. 1864.

I.M.S.K. Ilankoon and S.J. Neethling, Inter-particle liquid spread pertaining to heap leaching using UV fluorescence based image analysis, Hydrometallurgy, 183(2019), p. 175.

C.L. Lin, J.D. Miller, and C. Garcia, Saturated flow characteristics in column leaching as described by LB simulation, Miner. Eng., 18(2005), No. 10, p. 1045.

B.H. Yang, A.X. Wu, H.C. Jiang, and X.S. Chen, Evolvement of permeability of ore granular media during heap leaching based on image analysis, Trans. Nonferrous Met. Soc. China, 18(2008), No. 2, p. 426.

E. Govender, C.G. Bryan, and S.T.L. Harrison, A novel experimental system for the study of microbial ecology and mineral leaching within a simulated agglomerate-scale heap bioleaching system, Biochem. Eng. J., 95(2015), p. 86.

A.X. Wu, S.H. Yin, B.H. Yang, J. Wang, and G.Z. Qiu, Study on preferential flow in dump leaching of low-grade ores, Hydrometallurgy, 87(2007), No. 3–4, p. 124.

A.X. Wu, S.H. Yin, H.J. Wang, W.Q. Qin, and G.Z. Qiu, Technological assessment of a mining-waste dump at the Dexing copper mine, China, for possible conversion to an in situ bio-leaching operation, Bioresour. Technol., 100(2009), No. 6, p. 1931.

L.M. Wang, S.H. Yin, A.X. Wu, and W. Chen, Effect of stratified stacks on extraction and surface morphology of copper sulfides, Hydrometallurgy, 191(2020), art. No. 105226.

R.M. Ruan, G. Zou, S.P. Zhong, Z.L. Wu, B. Chan, and D.Z. Wang, Why Zijinshan copper bioheapleaching plant works efficiently at low microbial activity—Study on leaching kinetics of copper sulfides and its implications, Miner. Eng., 48(2013), p. 36.

B.H. Li, X.Q. Tan, F.Y. Wang, P.Q. Lian, W.B. Gao, and Y.Q. Li, Fracture and vug characterization and carbonate rock type automatic classification using X-ray CT images, J. Pet. Sci. Eng., 153(2017), p. 88.

B.L. Avanthi Isaka, P.G. Ranjith, T.D. Rathnaweera, M.S.A. Perera, and V.R.S. De Silva, Quantification of thermally-induced microcracks in granite using X-ray CT imaging and analysis, Geothermics, 81(2019), p. 152.

S. Zhang and W.Y. Liu, Application of aerial image analysis for assessing particle size segregation in dump leaching, Hydrometallurgy, 171(2017), p. 99.

H.J. Heinen, Percolation leaching of clayey gold-silver ores, [in] Nevada Bureau of Mines and Geology, Report 36, Papers Given at the Precious-Metals Symposium, Sparks, Nevada, 1980, p. 87.

J.F. Rauld, R.J. Montealegre, P.N. Schmidt, and E.M. Domic, T.L. Leaching process: A phenomenological model for oxide copper ores treatment, [in] TMS-AIME Annual Meeting, New Orleans, 1986, p. 75.

B.H. Yang, A.X. Wu, G.A. Narsilio, X.X. Miao, and S.Y. Wu, Use of high-resolution X-ray computed tomography and 3D image analysis to quantify mineral dissemination and pore space in oxide copper ore particles, Int. J. Miner. Metall. Mater., 24(2017), No. 9, p. 965.

S.H. Yin, L.M. Wang, X. Chen, and A.X. Wu, Effect of ore size and heap porosity on capillary process inside leaching heap, Trans. Nonferrous Met. Soc. China, 26(2016), No. 3, p. 835.

I.M.S.K. Ilankoon and S.J. Neethling, Liquid spread mechanisms in packed beds and heaps. The separation of length and time scales due to particle porosity, Miner. Eng., 86(2016), p. 130.

I.M.S.K. Ilankoon and S.J. Neethling, Hysteresis in unsaturated flow in packed beds and heaps, Miner. Eng., 35(2012), p. 1.

W.A.M. Fernando, I.M.S.K. Ilankoon, A. Rabbani, and M, Yellishetty, Inter-particle fluid flow visualisation of larger packed beds pertaining to heap leaching using X-ray computed tomography imaging, Miner. Eng., 151(2020), art. No. 106334.

R. Yusuf, Liquid Flow Characteristics in Heap and Dump Leaching [Dissertation], University of New South Wales, Australia, 1984.

I.M.S.K. Ilankoon and S.J. Neethling, The effect of particle porosity on liquid holdup in heap leaching, Miner. Eng., 45(2013), p. 73.

T.K. Perkins and O.C. Johnston, A review of diffusion and dispersion in porous media, Soc. Pet. Eng. J., 3(1963), No. 1, p. 70.

S.C. Bouffard and D.G. Dixon, Investigative study into the hydrodynamics of heap leaching processes, Metall. Mater. Trans. B, 32(2001), No. 5, p. 763.

W.A.M. Fernando, I.M.S.K. Ilankoon, M.N. Chong, and T.H. Syed, Effects of intermittent liquid addition on heap hydrodynamics, Miner. Eng., 124(2018), p. 108.

T. Vethosodsakda, M.L. Free, A. Janwong, and M.S. Moats, Evaluation of liquid retention capacity measurements as a tool for estimating optimal ore agglomeration moisture content, Int. J. Miner. Process., 119(2013), p. 58.

S.H. Yin, A.X. Wu, K.J. Hu, Y.M. Wang, and Z.L. Xue, Visualization of flow behavior during bioleaching of waste rock dumps under saturated and unsaturated conditions, Hydrometallurgy, 133(2013), p. 1.

B.H. Yang, A.X. Wu, and S.H. Yin, Simulation of pore scale fluid flow of granular ore media in heap leaching based on realistic model, J. Cent. South Univ. Technol., 18(2011), No. 3, p. 848.

T. Li, A.X. Wu, Y.T. Feng, H.J. Wang, L.M. Wang, X. Chen, and S.H. Yin, Coupled DEM-LBM simulation of saturated flow velocity characteristics in column leaching, Miner. Eng., 128(2018), p. 36.

H.G. Kristensen and T. Schaefer, Granulation: A review on pharmaceutical wet-granulation, Drug Dev. Ind. Pharm., 13(1987), No. 4–5, p. 803.

S. Zhang, Y. Zhang, M.C. Liu, D.A.H. Hanaor, and Y.X. Gan, Dynamic contact angle hysteresis in liquid bridges, Colloids Surf. A, 555(2018), p. 365.

C.M. Ai, P.P. Sun, A.X. Wu, X. Chen, and C. Liu, Accelerating leaching of copper ore with surfactant and the analysis of reaction kinetics, Int. J. Miner. Metall. Mater., 26(2019), No. 3, p. 274.

Acknowledgements

This work was financially supported by the National Science Fund for Excellent Young Scholars (No. 51722401), the Fundamental Research Funds for the Central Universities (No. FRF-TP-18-003C1), and the Key Program of the National Natural Science Foundation of China (No. 51734001). Leiming Wang would like to thank Prof. David Dreisinger and the Chinese Scholar Council (CSC) for giving him an opportunity to learn in the University of British Columbia, Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Lm., Yin, Sh. & Wu, Ax. Visualization of flow behavior in ore-segregated packed beds with fine interlayers. Int J Miner Metall Mater 27, 900–909 (2020). https://doi.org/10.1007/s12613-020-2059-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2059-3