Abstract

Financial gain is a main driver for committing food fraud and replacement of ingredients with cheaper alternatives is an easy way to do it. Coconut sugar is becoming popular as an alternative to beetroot or cane sugar due to its high mineral content and lower glycaemic index. As its market price is about twice as high as that of conventional sugar, coconut sugar may become target to fraudulent manipulation. The present work explores the feasibility of using energy-dispersive X-ray fluorescence as a screening tool to verify its authenticity. Mass fractions of P, Cl, S, K, Ca, Fe, Cu, Br, Rb, and Sr determined in eleven coconut, ten cane, and one beetroot sugar samples, purchased in Belgian, Spanish, Polish, and Italian supermarkets were used for discriminating the different sugars. On average, the mass fractions of all the mentioned elements were higher in coconut than in cane and beetroot sugars. Multivariate analysis of the elemental fingerprint by Soft Independent Modelling of Class Analogies was used for authentication purposes. Models constructed were characterised by zero false positives; three coconut sugars (27%) could not be classified as such, neither as cane sugars.

Similar content being viewed by others

Introduction

The expression “food fraud” covers a set of malpractices aiming at deceiving consumers to increase financial profit as reflected in the definitions given by several organisations [1].

Substitution of expensive products by cheaper ones is an easy way to achieve economic benefit and it is one of the main types of food fraud.

Palm sugars are natural sugars obtained from the sap or nectar of the flowers of several species of palms: sugar palm (Arenga pinnata), palmyra palm (Borassus flabellifer), nipa palm (Nypa fruticans), and coconut palm (Cocos nucifera) [2]. The demand of coconut in the world has increased 500% in the last 10 years, making producers to have problems to keep pace [3]. Coconut sugar is strongly advertised as being richer in minerals and with a lower glycaemic index than cane sugar [4, 5]. Due to claims about its health beneficial effects, consumers are willing to pay a high price for coconut sugar; the price of a kilo coconut sugar can vary from 15 to 45 €, while the price of the common refined sugar in 2017 was 0.75 € [6]. Hence, substitution practices would result in a financial gain, as it is the case for other types of palm sugar such as Palmyra palm (Borassus flavellifer) [7].

The fraudulent addition of exogenous sugars to several food commodities has been frequently detected by 13C/12C isotopic analysis with Elemental Analysis Isotope Ratio Mass Spectrometry (EA-IRMS) [8] and after separation of the sugars by liquid chromatography (LC-IRMS) [9, 10]. Coconut is the fruit of a C3 plant, which assimilates CO2 with participation of the enzyme ribulose-1,5-bisphosphate carboxylase/oxygenase (Rubisco), while cane is a C4 plant that fixes CO2 with phosphoenolpyruvate (PEP) carboxylase. C3 plants have a 13C/12C ratio lower than the C4, and this difference is the basis of the IRMS-based methods. The method has been used to detect addition of cane sugar to coconut water [11] and to coconut sugar [6]. Beet is also a C3 plant, and for that reason, IRMS could not be applied to detect the addition of beetroot sugar to coconut sugar. The approach is sensitive and efficient, but it requires developed analytical skills and expensive instruments, and is not suitable for screening purposes [12].

Other approaches have been applied to detect adulteration of sugars. Nine different parameters, such as pH, reducing sugars, titratable acidity, and others, were used to detect adulteration of palm sugar [17] and trace-element fingerprints obtained by inductively coupled plasma-mass spectrometry (ICP-MS) has been used to control the authenticity of organic cane sugar [13]. The elemental fingerprints have also been used to classify honey (a matrix that consists mostly of sugars) on the basis of their botanical composition and geographical origin [14, 15]. Rodushkin et al. [16] characterised raw and refined cane and beetroot sugars using different analytical approaches, Atomic Emission Spectrometry-Inductively Coupled Plasma (AES-ICP), mass spectrometry-ICP (MS-ICP), and thermal ionization MS (TIMS); the concentrations of most elements were higher in raw than in refined sugars. In the same work, IRMS is used to classify sugars according to their geographical origin. Processing has a big influence in the elemental content of sugars. Non-centrifugal cane sugar (NCS) (also called rapadura, panela, gur, kokuto, chancaca, piloncillo, muscovado, jaggery, etc.) is an unrefined sugar obtained by evaporation of cane juice without any further processing, and it is different than the so-called “brown sugar” or “turbinado sugar” that are obtained mixing refined saccharose with sugar cane molasses [17]. The concentrations of Ca, Cl, Cr, Cu, I, Fe, Mg, Mn, P, K, Se, Na, and Zn are significantly higher in NCS than in refined sugars as indicated in a review published on the nutritional and functional components of NCS [17].

Since coconut sugar is claimed to have a different elemental content than cane sugar, elemental characterisation of the coconut sugars was considered a suitable option for authentication purposes. In contrast to ICP-MS, energy dispersive X-ray fluorescence (ED-XRF) allows the simultaneous determination of several elements without requiring any sample treatment other than milling and preparation of pellets.

In this work, the multivariate evaluation by Soft Independent Modelling of Class Analogies (SIMCA), of the elemental fingerprint of coconut, cane, and beetroot sugars obtained by ED-XRF, was used to classify coconut sugars.

Materials and methods

Coconut, cane, and beetroot samples

Twenty-two commercially available sugars (11 coconut, 10 cane, and 1 beetroot) were purchased in Belgian, Spanish, Polish, and Italian supermarkets along a year. According to the labels, none of the sugars had undergone a refining process; nevertheless, differences in their colour were observed: five of the cane sugars were light brown in colour, while all the remaining sugars (coconut, cane, and beetroot) were dark brown. According to their respective labels, Sugar 013 is “rapadura” and Sugar 020 is “panela”; as mentioned in the introduction, both terms are used to define the sugar obtained by evaporating the water from the juice produced pressing the cane without any further processing.

The beetroot sugar was produced in the EU, no information about geographical origin was given for three cane sugars, four coconut sugars were produced in Indonesia, two cane sugars in the Antilles, and one cane sugar in Latin America, according to their labels. For the remaining samples, the only reference to their geographical origin was” Product of non-EU agriculture”.

The previously mentioned information together with the dates that the sugars were purchased is summarised in Table 1.

Sample preparation and instrumentation

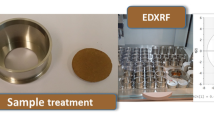

ED-XRF measurements were carried out on 40 mm-diameter pellets made with 5 g of sugar thoroughly mixed with 1 g of wax, CEREOX® (Fluxana GmbH, Bedburg-Hau) using a metal-free spatula. Attempts to prepare the pellets only with sugar without the addition of wax resulted in a non-homogenous appearance of the sample, with a gradient of colour going from dark in the centre of the pellet to lighter close to the border. Measurements carried out on a pellet made only with wax showed that the mass fractions of all the elements used in this study for authentication purposes were below the quantification limits (LoQ) of the method.

An ED-XRF method previously validated for the analyses of different organic and inorganic samples was used for the determination of P, Cl, K, Ca, Cr, Fe, Cu, Br, Rb, and Sr, with an Epsilon 5 ED-XRF spectrometer (PANalytical, Almelo, The Netherlands). Detailed information about the ED-XRF instrument and the analytical method used, including its performance characteristics, has been published elsewhere [18]. To summarise, the calibration curves used for quantification purposes are built-up with 47 Certified Reference Materials (CRMs), 23 out of which are organic matrices. The accuracy of the method was evaluated using 21 CRM (10 organic and 11 inorganic matrices) and 4 reference materials of organic matrix. The organic matrices used to evaluate the accuracy of the method are: corn bran (BRAN-1), durum wheat flour (DUWF-1), soft winter wheat flour (SOWW-1), rice flour (NIST 1568b), brown bread (BCR-191), tobacco (PVTL-6), mussels tissue (ERM-CE278IK), tuna fish (ERM-CE464), skimmed milk (ERM-BD150), and feed (IMEP-119). Unfortunately, to the best of our knowledge, there is no CRM with certified values for elemental mass fractions in sugar. However, wheat flour, rice flour, corn bran, and brown bread are good representatives of matrices that consist mainly of carbohydrates.

The standard uncertainty was calculated analysing in triplicate three pellets in one measurement session. One pellet was analysed on three different measurement sessions, using a newly constructed calibration curve in each session. Also the influence of different analysts and amounts of sample used to prepare the pellets was studied. The main contribution to the uncertainty of the results was the within-pellet variation which was larger than the uncertainty due to the between-pellet and between-session variations. In the Epsilon 5 spectrometer, the pellets spin during the measurements, so that the results obtained are calculated taking into consideration the mass fractions in different points of the pellet reflecting the dispersion of results due to the heterogeneity within a pellet. For that reason, one pellet per sugar sample was measured. The expanded uncertainty (k = 2), given in Table 2, includes within- and between-pellet variation calculated by Analysis of Variance (ANOVA) for a confidence interval of 95%.

The LoQs were empirically calculated as those mass fractions for which certain trueness and intermediate precision were achieved.

The ED-XRF performance was checked once a week with the reference sample FLX-S13 (Fluxana, Bedburg-Hau). The ED-XRF was recalibrated every week with the mentioned reference sample to correct the normal drift. Tobacco is, among all the matrices measured to evaluate the accuracy of the method, the one in which more elements were certified, and for this reason, the CRM PVTL-6 was measured every week after measuring the FLX-S13 standard. No systematic bias was observed for any of the measured elements in the period of time in which the sugar analyses were carried out.

Multivariate analysis

The multivariate analysis of the data was carried out using the software SIMCA Version 15.0.2, Umetrics (Malmö, Sweden) [19].

Principal Component Analysis (PCA) was used as non-supervised multivariate tool to evaluate whether coconut sugars form a cluster separated from cane and beetroot sugars, based on their elemental composition.

Soft Independent Modelling of Class Analogies (termed PCA-Class in the SIMCA software from Umetrics) was used to construct models for coconut and cane sugar. A model for beetroot sugar could not be built up, because it was not possible to find more than one non-refined beetroot sugar commercially available. To avoid overfitting, keeping in mind that the amount of samples available was not large, the number of principal components was kept to 3.

The presence of outliers was assessed using the Mahalanobis distance (DModX PS+), which is the distance from a point to the centroid of the distribution. Samples for which the Mahalanobis distance was larger than Dcrit (95% confidence interval) were considered outliers.

PCA-Class was the supervised technique used for classification purposes. The Mahalanobis distance was used to detect false positives (FP) (related to the specificity of the approach), which are cane sugars not flagged as outliers by the coconut sugar model. To detect false negatives (FN) (related to the sensitivity of the approach), which are coconut sugars flagged as outliers by the coconut sugar model, different PCA-Class models were constructed leaving each time one of the coconut sugars out and using the resulting models to classify the sample that had been left out.

For the construction of PCA and PCA-Class models, two different approaches were used: (1) to use only the mass fractions above the LoQ of the method, and (2) to use all the results as provided by the Epsilon 5 software, also those below the respective LoQs of the different elements.

Results and discussion

Elemental fingerprint of coconut and cane sugar

One of the reasons why the price of coconut sugar is higher than that of cane and beetroot sugars is the claim that it contains higher levels of essential elements. The results of the analysis carried out in this study, Table 2, confirmed that the mass fractions of the quantifiable major and trace elements are higher in coconut sugar than in cane sugar (Student’s t test, 95% confidence interval). The mass fractions obtained for the beetroot sugar sample are also given in Table 2 for informative purposes, showing that its elemental composition is more similar to cane than to coconut sugar.

Some elemental mass fractions were below the LoQ (< LoQ) of the method. The mass fractions of P, Cu, and Br were < LoQ in all cane sugars and the same applies to Rb and Sr with the exception of one and two samples, Sugar 013 and Sugar 020, respectively. It was also observed that the K mass fraction was lower in the light brown cane sugars than in those with a dark colour; a similar trend although not so marked is followed by Cl, only the Cl content in sample Sugar 012 was above the LoQ. Although, according to the labels, all samples were not refined, differences in the processing steps, such as extraction, concentration, and crystallisation, may have led to the differences in the colour of the sugars and also in their elemental fingerprints. This could also explain the relatively higher contents for most of the elements in samples Sugar 013 and 020 (rapadura and panela according to their labels), the only ones among the cane sugars where Rb (in Sugar 013) and Sr (in Sugar 013 and 020) could be quantified. K, Ca, and Sr mass fractions in Sugar 013 and 020 and Fe and Rb in Sugar 013 are higher than those reported by Rodushkin et al. [25]. The mass fractions found in Sugar 013 and 020 are in good agreement with the values reported in a review on NCS [17].

The mass fractions of the elements in the different sugar types are reported in Table 2; median and mean values are only reported if more than five samples contained quantifiable mass fractions. Following this approach, median and mean were reported only for Ca and Fe in cane sugars. For samples with a content < LoQ, half of the value of the LoQ was used to calculate median and mean. The median can be considered as a robust estimate of the mean, which, contrary to the arithmetic mean, is not strongly affected by extreme outliers. The element content of the coconut sugars seems to be normally distributed, because there is always a good agreement between median and mean. The same does not apply to cane sugar for which there is a large difference between median and mean, reflecting a more random distribution of the mass fractions among different samples.

Other elements such as Mg, S, Mn, Ni, Zn, As, Cd, Ba, and Pb were also measured, but are not included in Table 2, because either the mass fractions were < LoQ for all samples, or were quantifiable in only one or two samples of all those analysed.

An easy way to classify coconut and cane sugars would be the use of cut-off values, at least for those elements that could not be quantified in any of the cane sugars, such as P, Cu, and Br; the respective LoQs would be suitable cut-off values (171, 1.2, and 1.7 mg kg−1, respectively). The mass fraction range of Rb in cane sugars and in coconut sugars did not overlap, but could be quantified in some cane sugars; the cut-off value for Rb could be fixed dividing by two the difference between the lowest Rb content in coconut sugars and the highest in cane sugars (cut-off value of 20 mg kg−1). Nevertheless, the use of cut-off values would not allow detecting coconut sugars to which a certain amount of cane sugar had been added, given that the amount added is small.

To include in the classification process the mass fractions of all the elements that could be detected in coconut sugars, multivariate analyses were used.

Classification studies using a chemometric approach

The larger differences in the elemental fingerprints of coconut and cane sugars supported the idea that they can be used for classification purposes. PCA is a way to reduce the number of variables, i.e., the mass fractions of the ten elements scrutinised, to a smaller number of principal components that preserve the available information.

One of the problems of the present study could be the rather small amount of samples included in the study. The impact of small sample size in chemometrics has been studied [20] and there are methods available to calculate the minimum amount of samples to be used in PCA in some specific fields [21]. The amount of samples recommended to validate a method is 30–50 [22]. According to the developers of the software used, PCA can accept situations in which observations > variable, observations < variables, and observations = variables (square matrices) [31]. In this study both, the amount of observations (22) and of variables (10) is small, with a ratio observation/variable of 2.2. It seems to be generally accepted that a ratio of 10 is optimal, but since the study was conducted on commercially available samples, it was difficult to find such a large amount of sugar samples from different brands. Samples of the same brand when purchased at different locations, even if in different countries, could just be representatives of one single batch of sugar distributed to different retailers. The number of observations would be artificially high and the standard deviation of the model artificially low. Although the performance characteristics of the method would be good, the model could fail to classify any sample not belonging to that batch. A similar problem would occur with models constructed with genuine samples obtained from one single producer in the country of origin.

Initially, only mass fractions above the LoQ of the concerned elements were used in the construction of the PCA models. Paradoxically, the intrinsic large differences between the fingerprints of the two populations jeopardised the proper classification of coconut sugars samples using multivariate analysis. The large number of cane sugar samples where most of the mass fractions of most elements was less than the LoQ hampered the creation of PCA models due to the lack of numerical information (missing values). For that reason, the results as provided by the Epsilon 5 software, even if < LoQ, were used to build up the models, since they would be representative of the variability within the samples, although not fit for strict quantitative purposes.

Figure 1 shows the PCA score plot obtained for all the sugar samples included in this study, where two perfectly separated clusters can be observed for the coconut and cane sugar populations. The beetroot sample clusters together with the cane sugars. Further studies were, hence, run using all the results, including those < LoQ.

No outliers in any of the two models (coconut and cane) were found by making use of the Mahalanobis distance as described in Sect. 2.3, and all of them were used for further class modelling. However, Sugar 013 and Sugar 020 were projected away from the rest of the cane sugars; this was expected considering their elemental profile, as described in Sect. 3.1. The mass fractions of most elements in those two samples were much higher than in the other cane sugars although lower than in the coconut sugars. As discussed above, this could be due to some differences in the processing of the sugar during manufacturing. Other factors that could explain this behaviour, such as the geographical origin, could not be evaluated, because the geographical origin of Sugar 013 was not indicated on the label. Sugar 020 was produced in “Latin America”, but the information about the specific country was not available.

The appropriateness of the PCA-Class models to separate the coconut and cane sugars was confirmed by the lack of false positives. All cane sugars and the beetroot sugar had a DModX PS + higher than the Dcrit of the coconut sugar model and were, therefore, flagged as outliers of that population, Fig. 2, indicating that the specificity of the model is 100%.

The sensitivity of the PCA-Class models was evaluated as mentioned in Sect. 2.3. Eight samples out of the eleven were properly classified as coconut sugar, corresponding to a specificity of 72.7%. Sugars 010, 011, and 018 could not be classified, neither as coconut nor as cane sugar. Figure 3 shows the PCA-class score plot of the coconut sugars and it can be seen that, although not flagged as outliers by the Mahalanobis distance, the three samples are projected separated from the rest.

The low concentrations of Ca and Sr in Sugar 010 and of Br and Rb in Sugar 011 are very likely the cause of the problem. The mass fractions of the other elements were in good agreement with those of the other coconut sugars, although the content of K in Sugar 010 was the lowest in the population. Neither the label information nor the visual observation of the sample helped to explain the mentioned differences in elemental content in those two samples.

Sugar 018 was an interesting case, as the mass fractions of all elements were above the respective LoQs, but when examined in detail, the P, Cl, K, Ca, and Cu contents were lower than in the other coconut sugars, even when considering the expanded measurement uncertainties associated with the results [18]. The mass fractions for the other elements followed the same trend but not when taking the expanded uncertainties into considerations. Figure 4 shows a comparison of the mass fractions in Sugar 018 and the mean of the coconut sugar population. Such a systematic trend could be due to a mixture of coconut sugar with a different type of sugar.

Comparison of the mass fractions of the different elements in Sugar 018 with the mean of the coconut population: a P, Cl, K, Ca and b Fe, Cu, Br, Rb and Sr. The error bars correspond to the expanded uncertainty. The mass fractions in Sugar 018 as % of the mean of the population are indicated on top of the Sugar 018 series

Just on the basis of the elemental fingerprints, it is not possible to elucidate if the three samples that could not be classified are false negatives resulting from a poor fit of the model or cases of fraudulent substitution of coconut sugar by a cheaper one.

Unfortunately, little information about the geographical origin of the coconut and cane sugars analysed was provided on the labels. Coconut palm grows in the cost of Indian and Pacific oceans and, according to the Dutch Ministry of Foreign Affairs, the main suppliers of coconut sugar are Indonesia, the Philippines, and Thailand [23]. The production of sugar cane is more distributed around the world, Brazil being the main producer followed by India, China, and Thailand [24]. As indicated in the Materials and methods section, four coconut sugars came from Indonesia and two cane sugars were produced in Antilles and one in “Latin America”, but no information about the exact production region was provided for the remaining ones. Strictly speaking, the two clusters observed in Fig. 1 could be due to the geographical origin (Asia vs America) more than to the type of sugar (coconut vs cane). Nevertheless, the differences in elemental composition are too large to be exclusively due to a different geographical origin. Rodushkin et al. [25] reported the normal ranges for 63 elements, in a set of cane and beetroot sugars of different geographical origin, and used carbon isotopic ratios to classify the sugar samples on the basis of their origin. The concentrations in coconut sugar found by ED-XRF are clearly outside those ranges. The geographical origin could have an impact of some elements not related to the composition of the soil but to other factors. Waheed et al. [25] report Br values in NCS and brown cane sugars from Pakistan of 4.54 and 5.88 mg kg−1, respectively, attributing this relatively high Br content to the use of Br-containing fumigants. In this work, similar Br contents were found in all coconut sugars, while the Br mass fractions in cane and beetroot sugars were always below the LoQ of the method (1.7 mg kg−1). This could be due to the use of the mentioned fumigants in some regions but not in others. Some of the issues previously discussed could be solved including “certified” genuine coconut, cane, and beetroot sugars together with the commercially available ones. Ideally, genuine samples should come from the main producing countries (Indonesia, Philippines, and Thailand) and from other countries in the coastal Pacific region, for instance Central and South American countries. In addition, genuine samples from the different producing regions within each country should also be included to cover the maximum variability among genuine samples. Commercially available samples must also be included in the models to incorporate changes during transport and storage under different conditions. Unfortunately, most control laboratories do not have access to such a broad amount of genuine samples. The use of commercially available sugars purchased in different countries, from different brands, and purchased along a year, could be a way to incorporate into the models the large variability expected in this type of food commodity. For all the mentioned reasons, it was considered that the selected set of samples would fulfil the requirements of our feasibility study.

Conclusions

This work, although purely observational due to sampling from retail outlets instead of using samples with documented traceability for building the statistical models, has demonstrated the potential of elemental fingerprinting to authenticate coconut sugar. To make the approach fit for official control purposes, a higher number of samples would contribute to a better coverage of the natural variation in elemental composition of coconut sugars, including geographical origin, production techniques, and year of production. This would very likely increase the sensitivity of the approach reducing the amount of false negatives and/or of samples that cannot be classified.

ED-XRF is a suitable technique for the authentication of coconut sugar, because it has the sensitivity required to analyse many of the essential elements P, Cl, K, Ca, Fe, Cu, Br, Rb, and Sr in coconut sugar. The lack of sensitivity to detect most of the mentioned elements in cane sugar, and seemly in beetroot sugar although more samples in this category should be analysed to confirm this hypothesis, makes this method particularly suitable for the purpose of detecting substitution of coconut sugar by cane sugar. A coconut sugar in which the mass fractions of several of the elements mentioned are either below the LoQ of the method or outside the normal range should be considered suspect and if deemed necessary undergo further, more elaborated/specific tests. As hardly any sample treatment is needed, ED-XRF analysis in combination with statistical data treatment would be a good screening method for authentication/classification of coconut sugar, being an attractive alternative to IRMS. Many control laboratories have experience in the analysis of major and trace elements and could easily implement the method described. ED-XRF analysis can be carried out with hand-held devices, making it very competitive from an economic point of view.

References

Spink J, Hegarty PV, Forten ND, Elliot CT, Moyer DC (2019) The application of public policy theory to the emerging food fraud risk: next steps. Trends Food Sci Technol 85:116–128

Saputro AD, Van de Walle D, Dewettinck K (2019) Palm sap sugar: a review. Sugar Tech 21(6):862–867

Rethinam P (2018) International scenario of coconut sector. In: Nampoothiri KUK, Krishnakumar V, Thampan PK, Achuthan Nair M (eds) The coconut palm (Cocos nucifera L.)-research and development perspectives. Springer, Singapore

Asghar MT, Yusof YA, Mokhtar MN, Ya'acob ME, Ghazal HM, Chang LS, Manaf YN (2019) Coconut (Cocos nucifera L.) sap as a potential source of sugar: antioxidant and nutritional properties. Food Sci Nutr. https://doi.org/10.1002/fsn3.1191

Rajamohan T, Archana U (2018) Nutrition and health aspects of coconut. In: Nampoothiri K, Krishnakumar V, Thampan P, Nair M (eds) The coconut palm (Cocos nucifera L.)—research and development perspectives. Springer, Singapore

Wrage J, Burmester S, Kuballa J, Rohn S (2019) Coconut sugar (Cocos nucifera L.): production process, chemical characterization, and sensory properties. LWT. https://doi.org/10.1016/j.lwt.2019.05.125

Wiboonsirikul J (2016) Differentiation between adulterated and non-adulterated palm sap using physical and chemical properties combined with discriminant analysis. Int Food Res J 23(1):61–67

Winkler FJ, Schmidt HL (1980) Scope of the application of 13C isotope mass spectrometry in food analysis. Z Lebensm Unters Forsch 171:85–94

Xu JZ, Liu X, Wu B, Cao YZ (2018) A comprehensive analysis of 13C isotope ratios data of authentichoney types produced in China using the EA-IRMS and LC-IRMS. J Food Sci Technol 57(4):1216–1232

Berriel V, Perdomo CH (2019) Differentiating pasture honey from eucalyptus honey based on carbon isotopic data in Uruguay. Heliyon. https://doi.org/10.1016/j.heliyon.2019.e01228

Psomiadis D, Zisi N, Koger C, Horvath B, Bodiselitsch B (2018) Sugar-specific carbon isotope ratio analysis of coconut waters for authentication purposes. J Food Sci Technol 55(8):2994–3000

Zábrodská B, Vorlová L (2015) Adulteration of honey and available methods for detection: a review. Acta Veterinaria Brno 83(10):85–102

Barbosa RM, Batista BL, Bariāo CV, Varrique RM, Coelho VA, Campiglia AD, Barbosa F Jr (2015) A simple and practical control of the authenticity of organic sugarcane samples based on the use of machine-learning algorithms and trace elements determination by inductively coupled plasma mass spectrometry. Food Chem 184:154–159

Nozal Nalda MJ, Bernal Yagüe JL, Diego calva JC, Martín Gómez MT (2005) Classifying honeys from the Soria province of Spain via multivariate analysis. Anal Bioanal Chem 382:311–319

Fiamegos Y, Dumitrascu C, Ghidotti M, de la Calle Guntiñas MB (2020) Use of energy-dispersive X-ray fluorescence combined with chemometric modelling to classify honey according to botanical variety and geographical origin. Anal Bioanal Chem 412:463–472

Rodushkin I, Baxter DC, Engström E, Hoogewerff J, Horn P, Papesch W, Watling J, Latkoczy C, van der Peijl G, Berends-Montero S, Ehleringer J, Zdanowicz V (2011) Elemental and isotopic characterization of cane and beet sugars. J Food Compos Anal 24:70–78

Jaffe WR (2015) Nutritional and functional components of non centrifugal cane sugar: a compilation of the data from the analytical literature. J Food Compos Anal 43:194–202

Fiamegos Y, de la Calle MB (2018) Validation strategy for an ed-xrf method to determine trace elements in a wide range of organic and inorganic matrices based on fulfilment of performance criteria. Spectrochim Acta Part B 150:59–66

Eriksson L, Byrne T, Johansson E, Trygg J, Vikström C (2013) Multi-and megavariate data analysis. Basic principles and applications. Umetrics Academy, Malmö

Beleites C, Salzer R (2008) Assessing and improving the stability of chemometric modelsin small sample size situations. Anal Bioanal Chem 390:1261–1271

Saccenti E, Timmerman ME (2016) Approaches to sample size determination for multivariate data: applications to PCA and PLS-DA of omics data. J Proteome Res 15(8):2379–2393

Gemperline P (2006) Practical Guide to Chemometrics. CRC Press, Francis & Taylor, Baco Raton

https://www.cbi.eu/market-information/honey-sweeteners/palm-sugar/palm-sugar-europe/. Accessed 23 Apr 2020

https://www.statista.com/statistics/267865/principal-sugar-cane-producers-worldwide/. Accessed 23 Apr 2020

Waheed S, Rahman S, Gill KP (2009) INAA and AAS of different products from sugar cane industry in Pakistan: toxic trace elements for nutritional safety. J Radioanal Nucl Chem 279(3):725–731

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zdiniakova, T., de la Calle, M.B. Feasibility study about the use of element profiles determined by ED-XRF as screening method to authenticate coconut sugar commercially available. Eur Food Res Technol 246, 2101–2109 (2020). https://doi.org/10.1007/s00217-020-03559-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-020-03559-z