Abstract

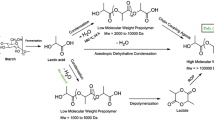

Poly(glycolic acid) (PGA) is an essential biopolymer due to its thermal and mechanical properties and biodegradability which provide utility for medical applications and renewable industry. For biomedical applications, production of PGA with high molecular weight is an essential factor to possess adequate mechanical stability. Primary pathways for PGA synthesis are ring-opening polymerization of glycolide (ROP), direct polycondensation of glycolic acid, and solid-state polycondensation of halogen acetates. For PGA synthesis, different systems have been developed with using varying parameters including catalysis, initiators, solvents, and reaction temperature. This review summarizes the different synthesis pathways and physicochemical properties of PGA. Biomedical applications of PGA are also discussed.

Similar content being viewed by others

References

Sharma A, Sharma G (2018) Biomaterials and their applications. AIP Conf Proc 1953:080041

Sionkowska A (2011) Progress in polymer science current research on the blends of natural and synthetic polymers as new biomaterials. Prog Polym Sci 36:1254–1276

Soni S, Gupta H, Kumar N, Nishad D, Mittal G, Bhatnagar A (2010) Biodegradable biomaterials. Recent Pat Biomed Eng 3:30–40

Nakafuku C, Yoshimura H (2004) Melting parameters of poly(glycolic acid). Polymer (Guildf) 45:3583–3585

Middleton JC, Tipton AJ (2000) Synthetic biodegradable polymers as orthopedic devices. Biomaterials 21(23):2335–2346

Lu Y, Schmidt C, Beuermann S (2015) Fast synthesis of high-molecular-weight Polyglycolide using Diphenyl bismuth bromide as catalyst. Macromol Chem Phys 216:395–399

Göktürk E, Pemba AG, Miller SA (2015) Polyglycolic acid from the direct polymerization of renewable C1 feedstocks. Polym Chem 6(21):3918–3925

Yamane K, Sato H, Ichikawa Y, Sunagawa K, Shigaki Y (2014) Development of an industrial production technology for high-molecular-weight polyglycolic acid. Polym J 46:769–775

(2019) Polyglycolic Acid (PGA) Market Research Report - Global Forecast till 2030. https://www.marketresearchfuture.com/reports/polyglycolic-acid-market-5749 (Accessed: August 2019)

Higgins NA (1954) Condensation polymers of hydroxyacetic acid. U.S. patent 2676945

Schmitt EE, Albert R, Chester P (1967) Surgical sutures. U.S. patent 3297033

May P, Polistina RA (1969) Process for polymerizing a Glycolide. U.S. patent 3442871

Reed AM, Road A (1980) Biodegradable polymers for use in surgery - poly(glycolic)/poly(lactic acid) homo and copolymers: 2. In vitro degradation Polymer (Guildf) 22:494–498

Ashammakhi N, Rokkanen P (1997) Absorbable polyglycolide devices in trauma and bone surgery. Biomaterials 18:3–9

Kehoe S, Zhang XF, Boyd D (2012) FDA approved guidance conduits and wraps for peripheral nerve injury: a review of materials and efficacy. Injury 43:553–572

Nair LS, Laurencin CT (2007) Biodegradable polymers as biomaterials. Prog Polym Sci 32:762–798

Suggs LJ, Moore SA, Mikos AG (2007) Synthetic biodegradable polymers for medical applications. In: Mark JE (ed) Physical properties of polymers handbook. Springer, New York, NY, pp 939–950

Jahno VD (2005) Síntese e caracterização do Poli (L-Ácido Láctico) para uso como biomaterial

Benatti ACB, Fla A, Xavier MV, et al (2019) Bioreabsorbable polymers for tissue engineering: PLA, PGA, and their copolymers. In: Holban AB, Grumezescu AM (eds) Materials for Biomedical Engineering. Elsevier, pp 83–116

Takahashi K, Taniguchi I, Miyamoto M, Kimura Y (2000) Melt/solid polycondensation of glycolic acid to obtain high-molecular-weight poly(glycolic acid). Polymer (Guildf) 41:8725–8728

Agrawal CM, Niederauer GG, Athanasiou KA (1995) Fabrication and characterization of PLA-PGA orthopedic implants. Tissue Eng 1:241–252

Sanko V, Sahin I, Aydemir Sezer U, Sezer S (2019) A versatile method for the synthesis of poly(glycolic acid): high solubility and tunable molecular weights. Polym J 51(7):637–647

Reyhanoglu Y, Sahmetlioglu E, Gokturk E (2019) Alternative approach for synthesizing Polyglycolic acid copolymers from C1 Feedstocks and fatty Ester epoxides. ACS Sustain Chem Eng 7:5103–5110

You Y, Youk JH, Lee SW, Min BM, Lee SJ, Park WH (2006) Preparation of porous ultrafine PGA fibers via selective dissolution of electrospun PGA/PLA blend fibers. Mater Lett 60:757–760

Kariduraganavar MY, Kittur AA, Kamble RR (2014) Polymer synthesis and processing. In: Laurencin CT, Deng M (eds) Sangamesh GK. Elsevier, Natural and Synthetic Biomedical Polymers, pp 1–31

Lowe CE (1954) Preparation of high molecular weight polyhydroxyacetic ester. U.S. patent 2668162

Zhaoyang W, Yaoming Z, Yurong Y et al (2004) Hecheng Xianwei Gongye. Hecheng Shuzhi Ji Suliao/China Synth Resin Plast 27:1–20

Fumiaki I, Mineo K, Masahiro O, et al (1994) Process for preparing polyhydroxycarboxylic acid. U.S. patent 5440008

Kameoka R, Higuchi C, Ajioka M, et al (1995) Aliphatic polyester and preparation process thereof. U.S. patent 5428126

Yoshida Y, Miyamoto M, Obuchi S, et al (1998) Preparation process of polyhydroxycarboxylic acid. U.S. patent 5770683

Singh V, Tiwari M (2010) Structure-processing-property relationship of poly (glycolic acid) for drug delivery systems 1: synthesis and catalysis. Int J Polym Sci 2010:1–23

Obuchi S, Elias HG (1995) Preparation process of polyhydroxycarboxylic acid. U.S. patent 5444143

Enomoto K, Ajioka M, Yamaguchi A (1994) Preparation process of polyhydroxycarboxylic acid thereof. U.S. patent 5310865

Masuda T, Kagami K, Murata K et al (1982) Copolymerizatıon of carbon-monoxide with formaldehyde using Trioxane or paraformaldehyde as a formaldehyde source in the presence of the Chlorosulfuric acid catalyst. Nippon Kagaku Kaishi 2:257–262

Ishihara K, Ohara S, Yamamoto H (2000) Direct Polycondensation of carboxylic acids and amines catalyzed by 3,4,5-Trifluorophenylboronic acid. Macromolecules 33:3511–3513

Kataoka M, Sasaki M, Hidalgo AGD, Nakano M (2001). Glycolic Acid Production Using Ethylene Glycol- Oxidizing Microorganisms 65(10):2265–2270

Buchholz B (1994) Process for preparing polyesters based on hydroxycarboxylic acids. U.S. patent 5302694

Bonsignore PV (1995) Production of high molecular weight polylactic acid. U.S. patent 5470944

Herzberg O, Epple M (2001) Formation of polyesters by thermally induced polymerization reactions of molecular solids some background information on polyesters. Eur J Inorg Chem 2001(6):1395–1406

Epple M, Herzberg O (1997) Polyglycolide with controlled porosity : an improved biomaterial. J Mater Chem 7:1037–1042

Pinkus A, Subramanyam R, Pinkus AG, Subramanyam R (1984) New high-yield, one-step synthesis of polyglycolide from haloacetic acids. J Polym Sci Polym Chem Ed 22:1131–1140

Xiguang D, Li C, Chen Q, Xuesi C (2003) Dongbei Shida Xuebao. Dongbei Shida Xuebao / Ziran Kexue Ban 35:119

Schmidt C, Behl M, Beuermann S (2014) RSC advances synthesis of high molecular weight polyglycolide in supercritical carbon dioxide. Macromol Chem Phys 4:35099–35105

Shen K, Yang S (2013) Preparation of high-molecular-weight poly (glycolic acid) by direct melt polycondensation from glycolic acid. Adv Mater Res 821:1023–1026

Leenslag JW, Pennings AJ (1987) Synthesis of high-molecular-weight poly( clactide) initiated with tin 2-ethylhexanoate. Die Makromol Chemie Macromol Chem Phys 188:1809–1814

Nieuwenhuis J (1992) Synthesis of polylactides, polyglycolides and their copolymers. Clin Mater 10(1):59–67

Dawkins J V (1989) Aqueous suspension polymerization in comprehensive polymer science. In: Pergamon press, Oxford. Pp 231

Boehringer A, Liebrecht I, Liebrecht J LW (1957) Improvements in or relating to the polymerization of cyclic esters. U.S. patent 825335

Chujo K, Kobayashi H, Suzuki J, Tokuhara S, Tanabe M (1967) Ring-opening polymerization of glycolide. Die Makromol Chemie Macromol Chem Phys 100:262–266

Bourissou D, Martin-Vaca B, Dumitrescu A, Graullier M, Lacombe F (2005) Controlled cationic polymerization of lactide. Macromolecules 38:9993–9998

Reyhanoglu Y, Gokturk E (2019) Polyglycolic acid copolymers from one-step cationic polymerization of formaldehyde, carbon monoxide, and epoxides derived from PEG. Polym Adv Technol 30:1789–1795

Albertsson AC, Varma IK (2003) Recent developments in ring opening polymerization of lactones for biomedical applications. Biomacromolecules 4:1466–1486

Jedlinski Z, Kurcok P, Kowalczuk M (1985) Polymerization of. Beta.-lactones initiated by potassium solutions. Macromolecules 18:2679–2683

Murugan KD, Radhika S, Baskaran I, Anbarasan R (2008) Clay catalyzed synthesis of bio-degradable poly (glycolic acid). Chinese J Polym Sci 26:393–398

Gharbi REL, Fradet A, Dali S (2006) Synthesis of poly (glycolic acid) in ionic liquids. J Polym Sci Part A Polym Chem 44:3025–3035

Epple M, Kirschnick H (1996) The thermally induced solid-state polymerization reaction in Halogenoacetates. Chem Ber 129:1123–1129

Amass W, Amass A, Tighe B (1998) A review of biodegradable polymers: uses, current developments in the synthesis and characterization of biodegradable polyesters, blends of biodegradable polymers and recent advances in biodegradation studies. Polym Int 47:89–144

Yu C, Bao J, Xie Q, Shan G, Bao Y, Pan P (2016) Crystallization behavior and crystalline structural changes of poly(glycolic acid) investigated: via temperature-variable WAXD and FTIR analysis. Cryst Eng Comm 18:7894–7902

Agrawal A, Saran AD, Rath SS, Khanna A (2004) Constrained nonlinear optimization for solubility parameters of poly (lactic acid) and poly (glycolic acid)—validation and comparison. Polymer (Guildf) 45:8603–8612

Van de Velde K, Kiekens P (2002) Biopolymers: overview of several properties and consequences on their applications. Polym Test 21:433–442

Kister G, Cassanas G, Vert M (1997) Morphology of poly(glycolic acid) by IR and Raman spectroscopies. Spectrochim Acta - Part A Mol Biomol Spectrosc 53:1399–1403

Chatani Y, Suehiro K, Ôkita Y, Tadokoro H, Chujo K (1968) Structural studies of polyesters. I. Crystal structure of polyglycolide. Die Makromol Chemie Macromol Chem Phys 113:215–229

Chu CC (1981) The in-vitro degradation of poly (glycolic acid) sutures—effect of pH. J Biomed Mater Res 15:795–804

Williams DF, Mort E (1977) Enzyme-accelerated hydrolysis of polyglycolic acid. J Bioeng 1:231–238

Li S (2016) Synthetic biodegradable medical polyesters. In: Zhang X (ed) science and principles of biodegradable and Bioresorbable medical polymers: materials and properties. Woodhead publishing, pp 37–70

Kumbar S, Laurencin C, Deng M (2014) Natural and synthetic biomedical polymers. Elsevier, USA

Farah S, Anderson DG, Langer R (2016) Physical and mechanical properties of PLA, and their functions in widespread applications — a comprehensive review. Adv Drug Deliv Rev 107:367–392

Lin CC (1983) The rate of crystallization of poly(ethylene terephthalate) by differential scanning Calorimetry. Polym Eng Sci 23:113–116

Engelberg I, Kohn J (1991) Physico-mechanical properties of degradable polymers used in medical applications: a comparative study. Biomaterials 12:292–304

Ueda H, Tabata Y (2003) Polyhydroxyalkanonate derivatives in current clinical applications and trials. Adv Drug Deliv Rev 55:501–518

Ulery BD, Nair LS, Laurencin CT (2011) Biomedical applications of biodegradable polymers. J Polym Sci Part B Polym Phys 49:832–864

Gunatillake P, Mayadunne R, Adhikari R (2006) Recent developments in biodegradable synthetic polymers. Biotechnol Annu Rev 12:301–347

Pätilä T, Jokinen JJ, Salminen J, Kankuri E, Harjula A (2008) Polyglycolic acid glue does not prevent Intrapericardial adhesions in a short-term follow-up. J Surg Res 148:181–184

Aysan E, Bektas H, Ersoz F et al (2010) A novel colonic anastomosis technique involving fixed polyglycolic acid mesh. Int J Clin Exp Med 3:341

Caballé-Serrano J, Munar-Frau A, Delgado L, Pérez R, Hernández –Alfaro F (2019) Physicochemical characterization of barrier membranes for bone regeneration. J Mech Behav Biomed Mater 97:13–20

Wang J, Wang L, Zhou Z, Lai H, Xu P, Liao L, Wei J (2016) Biodegradable polymer membranes applied in guided bone/tissue regeneration: a review. Polymers (Basel) 8:115

Rakhmatia YD, Ayukawa Y, Furuhashi A, Koyano K (2013) Current barrier membranes: titanium mesh and other membranes for guided bone regeneration in dental applications. J Prosthodont Res 57:3–14

Scantlebury TV (1993) 1982-1992: a decade of technology development for guided tissue regeneration. J Periodontol 64:1129–1137

Caffesse RG, Mota LF, Quiñones CR, Morrison EC (1997) Clinical comparison of resorbable and non-resorbable barriers for guided periodontal tissue regeneration. J Clin Periodontol 24:747–752

Gentile P, Chiono V, Tonda-Turo C, Ferreira AM, Ciardelli G (2011) Polymeric membranes for guided bone regeneration. Biotechnol J 6:1187–1197

Hutmacher D, Hürzeler MB, Schliephake H (1996) A review of material properties of biodegradable and bioresorbable polymers and devices for GTR and GBR applications. Int J Oral Maxillofac Implants 11:667–668

Dimitriou R, Mataliotakis GI, Calori GM, Giannoudis PV (2012) The role of barrier membranes for guided bone regeneration and restoration of large bone defects: current experimental and clinical evidence. BMC Med 10:81

Isogai N, Landis W, Kim TH et al (1999) Formation of phalanges and small joints by tissue-engineering. JBJS 81:306–316

McVicar I, Hatton PV, Brook IM (1995) Self-reinforced polyglycolic acid membrane: a bioresorbable material for orbital floor repair. Initial clinical report. Br J Oral Maxillofac Surg 33:220–223

Törmälä P (1992) Biodegradable self-reinforced composite materials; manufacturing structure and mechanical properties. Clin Mater 1:29–34

Semwal R, Semwal RB, Semwal DK (2017) Drug delivery systems: selection criteria and use. Concise Encycl Biomed Polym Polym Biomater 439–450

Mao HQ, Kdaiyala I, Leong KW et al (1999) Biodegradable polymers: polyesters. In: Mathiowitz E (ed) Encyclopedia of controlled drug delivery. John Wiley and Sons, New York, NY, pp 45–60

Langer R (2000) Biomaterials in drug delivery and tissue engineering: one laboratory’s experience. Acc Chem Res 33:94–101

Li S, Vert M (1999) Biodegradable polymers: Polyesters. Montpellier, France

Armentano I, Dottori M, Fortunati E, Mattioli S, Kenny JM (2010) Biodegradable polymer matrix nanocomposites for tissue engineering: a review. Polym Degrad Stab 95:2126–2146

Kim K, Luu YK, Chang C, Fang D, Hsiao BS, Chu B, Hadjiargyrou M (2004) Incorporation and controlled release of a hydrophilic antibiotic using poly (lactide-co-glycolide)-based electrospun nanofibrous scaffolds. J Control Release 98:47–56

Pan H, Jiang H, Chen W (2006) Interaction of dermal fibroblasts with electrospun composite polymer scaffolds prepared from dextran and poly lactide-co-glycolide. Biomaterials 27:3209–3220

Joshi J a YR, Patel RP (2012) Role of biodegradable polymers in drug delivery. Int J Curr Pharm Res 4:74–81

Braunecker J, Baba M, Milroy GE, Cameron RE (2004) The effects of molecular weight and porosity on the degradation and drug release from polyglycolide. Int J Pharm 282:19–34

Moll F, Ries R (1991) Biodegradable microtablets made of low molecular weight polyglycolic acid: Bioabbaubare Mikrotabletten aus niedermolekularer Polyglycolsäure. Arch Pharm (Weinheim) 324:939–940

Hurrell S, Cameron RE (2003) The effect of buffer concentration, pH and buffer ions on the degradation and drug release from polyglycolide. Polym Int 52:358–366

Hurrell S, Cameron RE (2002) The effect of initial polymer morphology on the degradation and drug release from polyglycolide. Biomaterials 23:2401–2409

Hurrell S, Milroy GE, Cameron RE (2003) The distribution of water in degrading polyglycolide. Part I: Sample size and drug release J Mater Sci Mater Med 14:457–464

Milroy GE, Cameron RE, Mantle MD, Gladden LF, Huatan H (2003) The distribution of water in degrading polyglycolide. Part II: magnetic resonance imaging and drug release. J Mater Sci Mater Med 14:465–473

Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M (2015) Biodegradable materials for bone repair and tissue engineering applications. Materials (Basel) 8:5744–5794

Dahlin C, Sennerby L, Lekholm U et al (1989) Generation of new bone around titanium implants using a membrane technique: an experimental study in rabbits. Int J Oral Maxillofac Implants 4:33–44

Schumann P, Lindhorst D, Wagner MEH, Schramm A, Gellrich NC, Rücker M (2013) Perspectives on resorbable osteosynthesis materials in craniomaxillofacial surgery. Pathobiology 80:211–217

Van Bakelen NB, Buijs GJ, Jansma J et al (2014) Decision-making considerations in application of biodegradable fixation systems in maxillofacial surgery - a retrospective cohort study. J Cranio-Maxillofacial Surg 42:417–422

Kanno T, Sukegawa S, Furuki Y, Nariai Y, Sekine J (2018) Overview of innovative advances in bioresorbable plate systems for oral and maxillofacial surgery. Jpn Dent Sci Rev 54:127–138

Vasenius J, Vainionpää S, Vihtonen K, Mäkelä A, Rokkanen P, Mero M, Törmälä P (1990) Comparison of in vitro hydrolysis, subcutaneous and intramedullary implantation to evaluate the strength retention of absorbable osteosynthesis implants. Biomaterials 11:501–504

Okuyama K, Yanamoto S, Naruse T, Sakamoto Y, Rokutanda S, Ohba S, Asahina I, Umeda M (2018) Clinical complications in the application of polyglycolic acid sheets with fibrin glue after resection of mucosal lesions in oral cavity. Oral Surg Oral Med Oral Pathol Oral Radiol 125:541–546

Cipurković A, Horozić E, Đonlagić N et al (2018) Biodegradable polymers: production, properties and application in medicine. Technol Acta 11:25–35

Chung C, Ki D, Park Y et al (1997) Biological effects of drug-loaded biodegradable membranes for guided bone regeneration. J Periodontal Res 32:172–175

Mooney DJ, Mazzoni CL, Breuer C, et al (1996) Stabilized polyglycolic acid fibre-based tubes for tissue engineering. In: Williams DF (ed) The biomaterials: silver Jubilee Compendium. Elsevier, pp 129–138

Li S (2017) Synthetic biodegradable medical polyesters. In: Zhang X (ed) Science and principles of biodegradable and Bioresorbable medical polymers. Elsevier, pp 37–78

Okamoto T, Rosini KS, Miyahara GI, Gabrielli MF (1994) Healing process of the gingival mucosa and dental alveolus following tooth extraction and suture with polyglycolic acid and polyglactin 910 threads. Comparative histomorphologic study in rats. Braz Dent J 5:35–43

Mizutani T, Nakayama A, Iwasaki H, Miyazawa H (2012) Suitability of polymers as screw post materials in primary teeth: an in vitro study. Eur J Paediatr Dent 13:19

Nagatomi J (2006) Mechanical adaptation of bone: bioreactors for orthopedic tissue engineering applications. In: Salz U (ed) Shalaby SW. CRC Press, Polymers for Dental and Orthopedic Applications, pp 351–367

Frölke JPM, Nulend JK, Semeins CM et al (2004) Viable osteoblastic potential of cortical reamings from intramedullary nailing. J Orthop Res 22:1271–1275

Agrawal CM (2002) Biodegradable polymers for orthopaedic applications. In: Reis RL, Cohn D (eds) Polymer based systems on tissue engineering. Replacement and Regeneration. Springer, Dordrecht, pp 25–36

Borden M, Attawia M, Laurencin CT (2002) The sintered microsphere matrix for bone tissue engineering: in vitro osteoconductivity studies. J Biomed Mater Res 61:421–429

Borden M, Attawia M, Khan Y et al (2004) Tissue-engineered bone formation in vivo using a novel sintered polymeric microsphere matrix. J Bone Jt Surgery Br Vol 86:1200–1208

Mikos AG, Sarakinos G, Leite SM et al (1993) Laminated three-dimensional biodegradable foams for use in tissue engineering. Biomater Silver Jubil Compend 14:323–330

Mikos AG, Thorsen AJ, Czerwonka LA, Bao Y, Langer R, Winslow DN, Vacanti JP (1994) Preparation and characterization of poly(l-lactic acid) foams. Polymer (Guildf) 35:1068–1077

Cooper JA, Lu HH, Ko FK, Freeman JW, Laurencin CT (2005) Fiber-based tissue-engineered scaffold for ligament replacement: design considerations and in vitro evaluation. Biomaterials 26:1523–1532

Lu HH, Cooper JA, Manuel S et al (2005) Anterior cruciate ligament regeneration using braided biodegradable scaffolds: in vitro optimization studies. Biomaterials 26:4805–4816

Cohen SB, Meirisch CM, Wilson HA, Diduch DR (2003) The use of absorbable co-polymer pads with alginate and cells for articular cartilage repair in rabbits. Biomaterials 24:2653–2660

Mikos AG, Bao Y, Cima LG, Ingber DE, Vacanti JP, Langer R (1993) Preparation of poly(glycolic acid) bonded fiber structures for cell attachment and transplantation. J Biomed Mater Res 27:183–189

Moran JM, Pazzano D, Bonassar LJ (2003) Characterization of polylactic acid-polyglycolic acid composites for cartilage tissue engineering. Tissue Eng 9:63–70

Ma PX, Langer R (1995) Degradation, structure and properties of fibrous nonwoven poly(glycolic acid) scaffolds for tissue engineering. Mater Res Soc Symp - Proc 394:99–104

Aydin HM (2011) A three-layered osteochondral plug: structural, mechanical, and in vitro biocompatibility analysis. Adv Eng Mater 13(12):511–517

Liu H, Slamovich EB, Webster TJ (2006) Less harmful acidic degradation of poly(lactic-co-glycolic acid) bone tissue engineering scaffolds through titania nanoparticle addition. Int J Nanomedicine 1:541–545

Hosseini V, Evrova O, Hoerstrup SP, Vogel V (2018) A simple modification method to obtain anisotropic and porous 3D microfibrillar scaffolds for surgical and biomedical applications. Small 14:1702650

Kodama S, Kojima K, Furuta S, Chambers M, Paz AC, Vacanti CA (2009) Engineering functional islets from cultured cells. Tissue Eng A 15:3321–3329

Pina S, Ferreira JMF (2012) Bioresorbable plates and screws for clinical applications: a review. J Healthc Eng 3:243–260

Vainionpää S, Kilpikari J, Laiho J, Helevirta P, Rokkanen P, Törmälä P (1987) Strength and strength retention vitro, of absorbable, self-reinforced polyglycolide (PGA) rods for fracture fixation. Biomaterials 8:46–48

Thompson DE, Agrawal CM, Athanasiou K (1996) The effects of dynamic compressive loading on biodegradable implants of 50–50% polylactic acid–polyglycolic acid. Tissue Eng 2:61–74

Eberhart RC, Su S-H, Nguyen KT, Zilberman M, Tang L, Nelson KD, Frenkel P (2003) Bioresorbable polymeric stents: current status and future promise. J Biomater Sci Polym Ed 14:299–312

Labinaz M, Zidar JP, Stack RS, Phillips HR (1995) Biodegradable stents: the future of interventional cardiology? J Interv Cardiol 8:395–405

Colombo A, Karvouni E (2000) Biodegradable Stents: “Fulfilling the Mission and Stepping Away.” Circulation 102:371–374

Tanguay JF, Zidar JP, Phillips HR, Stack RS (1994) Current status of biodegradable stents. Cardiol Clin 12:699–713

Van der Giessen WJ, Lincoff AM, Schwartz RS et al (1996) Marked inflammatory sequelae to implantation of biodegradable and nonbiodegradable polymers in porcine coronary arteries. Circulation 94:1690–1697

Maurus PB, Kaeding CC (2004) Bioabsorbable implant material review. Oper Tech Sports Med 12:158–160

Pillai CKS, Sharma CP (2010) Absorbable polymeric surgical sutures: chemistry, production, properties, biodegradability, and performance. J Biomater Appl 25:291–366

Tomihata K, Suzuki M, Ikada Y (2001) The pH dependence of monofilament sutures on hydrolytic degradation. J Biomed Mater Res 58:511–518

Nakamura T, Shimizu Y, Watanabe S, Hitomi S, Kitano M, Tamada J, Matsunobe S (1990) New bioabsorbable pledgets and non-woven fabrics made from polyglycolide (PGA) for pulmonary surgery: clinical experience. Thorac Cardiovasc Surg 38:81–85

Munteanu R, Eva L, Dobrovăţ B et al (2017) Longer survival of a patient with glioblastoma resected with 5-aminolevulinic acid (5-ALA)-guided surgery and foreign body reaction to polyglycolic acid (PGA) suture. Romanian J Morphol Embryol 58:671–680

Chu CC, Campbell ND (1982) Scanning electron microscopic study of the hydrolytic degradation of poly (glycolic acid) suture. J Biomed Mater Res 16:417–430

Chu CC, Williams DF (1983) The effect of gamma irradiation on the enzymatic degradation of polyglycolic acid absorbable sutures. J Biomed Mater Res 17:1029–1040

Jang J-Y, Shin YC, Han Y, Park JS, Han HS, Hwang HK, Yoon DS, Kim JK, Yoon YS, Hwang DW, Kang CM, Lee WJ, Heo JS, Kang MJ, Chang YR, Chang J, Jung W, Kim SW (2017) Effect of polyglycolic acid mesh for prevention of pancreatic fistula following distal pancreatectomy: a randomized clinical trial. JAMA Surg 152:150–155

Knecht S, Erggelet C, Endres M et al (2007) Mechanical testing of fixation techniques for scaffold-based tissue-engineered grafts. J Biomed Mater Res Part B Appl Biomater 83:50–57

Wang L, Dormer NH, Bonewald LF, Detamore MS (2010) Osteogenic differentiation of human umbilical cord mesenchymal stromal cells in polyglycolic acid scaffolds. Tissue Eng - Part A 16:1936–1948

Dunne N, Jack V, O’Hara R, Farrar D, Buchanan F (2010) Performance of calcium deficient hydroxyapatite–polyglycolic acid composites: an in vitro study. J Mater Sci Mater Med 21:2263–2270

Pihlajamäki HK, Salminen ST, Tynninen O, Böstman OM, Laitinen O (2010) Tissue restoration after implantation of polyglycolide, polydioxanone, polylevolactide, and metallic pins in cortical bone: an experimental study in rabbits. Calcif Tissue Int 87:90–98

Pihlajamäki H, Tynninen O, Karjalainen P, Rokkanen P (2007) The impact of polyglycolide membrane on a tendon after surgical rejoining. A histological and histomorphometric analysis in rabbits J Biomed Mater Res - Part A 81:987–993

Xu L, Cao D, Liu W, Zhou G, Zhang WJ, Cao Y (2010) In vivo engineering of a functional tendon sheath in a hen model. Biomaterials 31:3894–3902

Ohara T, Itaya T, Usami K et al (2010) Evaluation of scaffold materials for tooth tissue engineering. J Biomed Mater Res - Part A 94:800–805

Frisbie DD, Lu Y, Kawcak CE, DiCarlo EF, Binette F, McIlwraith CW (2009) In vivo evaluation of autologous cartilage fragment-loaded scaffolds implanted into equine articular defects and compared with autologous chondrocyte implantation. Am J Sports Med 37:71–80

Mahmoudifar N, Doran PM (2010) Chondrogenic differentiation of human adipose-derived stem cells in polyglycolic acid mesh scaffolds under dynamic culture conditions. Biomaterials 31:3858–3867

Sayasneh A, Johnson H (2010) Risk factors for mesh erosion complicating vaginal reconstructive surgery. J Obstet Gynaecol (Lahore) 30:721–724

Dai T ting, Jiang Z hua, Li S li, et al (2010) Reconstruction of lymph vessel by lymphatic endothelial cells combined with polyglycolic acid scaffolds: a pilot study. J Biotechnol 150:182–189

Abbushi A, Endres M, Cabraja M, Kroppenstedt SN, Thomale UW, Sittinger M, Hegewald AA, Morawietz L, Lemke AJ, Bansemer VG, Kaps C, Woiciechowsky C (2008) Regeneration of intervertebral disc tissue by resorbable cell-free polyglycolic acid-based implants in a rabbit model of disc degeneration. Spine (Phila Pa 1976) 33:1527–1532

Vacanti CA, Vacanti JP, Langer R (1993) Tissue engineering using synthetic biodegradable polymers. In: Ikada Y, Langer R, Williams J (eds) Shalaby. WS. ACS Publications, Polymers of Biological and Biomedical Significance, pp 16–34

Shinoka T, Shum-Tim D, Ma PX, Tanel RE, Isogai N, Langer R, Vacanti JP, Mayer Jr JE (1998) Creation of viable pulmonary artery autografts through tissue engineering. J Thorac Cardiovasc Surg 115:536–546

Shum-Tim D, Stock U, Hrkach J, Shinoka T, Lien J, Moses MA, Stamp A, Taylor G, Moran AM, Landis W, Langer R, Vacanti JP, Mayer Jr JE (1999) Tissue engineering of autologous aorta using a new biodegradable polymer. Ann Thorac Surg 68:2298–2304

Niklason LE, Gao J, Abbott WM, et al (1999) Functional arteries grown in vitro. Science (80- ) 284:489–493

Nikolovski J, Mooney DJ (2000) Smooth muscle cell adhesion to tissue engineering scaffolds. Biomaterials 21:2025–2032

Kim B-S, Nikolovski J, Bonadio J, Smiley E, Mooney DJ (1999) Engineered smooth muscle tissues: regulating cell phenotype with the scaffold. Exp Cell Res 251:318–328

Kim B-S, Nikolovski J, Bonadio J, Mooney DJ (1999) Cyclic mechanical strain regulates the development of engineered smooth muscle tissue. Nat Biotechnol 17:979–983

Agrawal CM, Athanasiou KA (1997) Technique to control pH in vicinity of biodegrading PLA-PGA implants. J Biomed Mater Res 38:105–114

Wang Y, Wang W, Wang X, Wang Y, Wang J, Fu Q, Shi G (2017) Tissue-engineered sling with adipose-derived stem cells under static mechanical strain. Exp Ther Med 14:1337–1342

Aghdam RM, Najarian S, Shakhesi S, Khanlari S, Shaabani K, Sharifi S (2012) Investigating the effect of PGA on physical and mechanical properties of electrospun PCL/PGA blend nanofibers. J Appl Polym Sci 124:123–131

Bailey MM, Wang L, Bode CJ, Mitchell KE, Detamore MS (2007) A comparison of human umbilical cord matrix stem cells and temporomandibular joint condylar chondrocytes for tissue engineering temporomandibular joint condylar cartilage. Tissue Eng 13:2003–2010

Weiser B, Prantl L, Schubert TEO, Zellner J, Fischbach-Teschl C, Spruss T, Seitz AK, Tessmar J, Goepferich A, Blunk T (2008) In vivo development and long-term survival of engineered adipose tissue depend on in vitro precultivation strategy. Tissue Eng - Part A 14:275–284

Acknowledgments

We gratefully acknowledge the financial support by Suleyman Demirel University BAP (TSG-2018-6749 Project).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Budak, K., Sogut, O. & Aydemir Sezer, U. A review on synthesis and biomedical applications of polyglycolic acid. J Polym Res 27, 208 (2020). https://doi.org/10.1007/s10965-020-02187-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02187-1