Abstract

Cladding is an easy and economical method to design multifunctional aluminum structures with improved corrosion resistance, mechanical strength, and physical appearance. In this study, the electrochemical properties and corrosion behavior of an aluminum-clad product made of 7072/3004/7072 aluminum alloys were investigated by Tafel extrapolation and impedance spectroscopy. 3004 aluminum sheet was used as core, and it was cladded with 7072 aluminum sheets on both sides. The long-term corrosion behavior of clad samples was examined after being immersed in tap water, rainwater, and 3.5 wt.% NaCl solution for 4 weeks. The results show that because of the potential difference between 7072 and 3004 aluminum alloys, 7072 alloy behaves more anodic and corrodes preferentially (with a slower rate) compared to 3004 aluminum alloy. Cladding 3004 with embossed 7072 alloy improves the corrosion resistance of the alloy. Moreover, the electrolyte comparison demonstrates that the carbonate-forming ions (such as Ca) in tap water and HCO3−, NO3−, and SO42− in rainwater decelerate the corrosion rate.

Similar content being viewed by others

References

J.R. Davis, Corrosion of Aluminum and Aluminum Alloys, ASM International, Materials Park, 1999, p 79

Aluminium and aluminium alloys—Sheet, strip and plate—Part2: Mechanical Properties. DS/EN 485-2, Danish Standards Association, 2016.

E. Ghali, Corrosion Resistance of Aluminum and Magnesium Alloys Understanding, Performance, and Testing, Wiley, Hoboken, 2010

J. Chaudhuri, Y.M. Tan, K. Patni, and A. Eftekhari, Comparison of Corrosion-Fatigue Properties of 6013 Bare, Alclad 2024, and 2024 Bare Aluminum Alloy Sheet Materials, J. Mater. Eng. Perform., 1992, 1, p 91–96

M. Poltavtseva, A. Heyn, and E. Boese, Long Term Corrosion Behaviour of Clad Aluminum Materials Under Different Atmospheric Conditions, Mater. Corros., 2013, 64, p 723–730

Q. Shi, F. Liang, and B. Cheadle, Electrochemical Behaviors of Quad-Layer Aluminum Brazing Sheet Composite for Automotive Applications, Corros. Eng. Sect., 2004, 60, p 492–500

F. Andreatta, M.E. Druart, A. Lanzutti, M. Lekka, D. Cossement, M.G. Olivier, and L. Fedrizzi, Localized Corrosion Inhibition by Cerium Species on Clad AA2024 Aluminium Alloy Investigated by Means of Electrochemical Micro-cell, Corros. Sci., 2012, 65, p 376–386

Y. Li, P. Zhang, P. Bai, L. Wu, B. Liu, and Z. Zhao, Microstructure and Properties of Ti/TiBCN Coating on 7075 Aluminum Alloy by Laser Cladding, Surf. Coat. Technol., 2018, 334, p 142–149

N.D. Nam, V.D. Phung, P.T.P. Thuy, V.A. Dao, S.H. Kim, and J.S. Yi, Corrosion Behaviours of Hot-Extruded Al-xMg Alloys, J. Mater. Res. Technol., 2019, 8(6), p 5246–5253

H. Nie, W. Liang, L. Zheng, X. Ren, C. Chi, and H. Fan, The Microstructure, Texture and Mechanical Properties of the Rolled Al/Mg/Al Clad Sheets, J. Mater. Eng. Perform., 2016, 25, p 4695–4705

V. Sabelkin, S. Mall, and H. Misak, Investigation into Corrosion Pit-to-Fatigue Crack Transition in 7075-T6 Aluminum Alloy, J. Mater. Eng. Perform., 2017, 26, p 2535–2541

X. Han, H. Zhang, B. Shao, L. Li, X. Liu, and J. Cui, Study on Fabrication of AA4032/AA6069 Cladding Billet Using Direct Chill Casting Process, J. Mater. Eng. Perform., 2016, 25, p 1317–1326

M. Mahta, M. Emamy, X. Cao, and J. Campbell, Overview of Βeta-Al5FeSi Phase in Al-Si Alloys, Materials Science Research Trends, L.V. Olivante, Ed., Nova Science Publishers Inc, Hauppauge, 2007, p 1–16

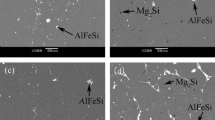

H.D. Merchant, J.G. Morris, and D.S. Hodgson, Characterization of Intermetallics in Aluminum Alloy 3004, Mater. Charact., 1990, 25, p 339–373

K. Liu and X.G. Chen, Evolution of Intermetallics, Dispersoids, and Elevated Temperature Properties at Various Fe Contents in Al-Mn-Mg 3004 Alloys, Metall. Mater. Trans. B, 2016, 47B, p 3291–3300

Z. Ahmad, Principles of Corrosion Engineering and Corrosion Control, Elsevier, Oxford, 2006

M. Shabani-Nooshabadi, S.M. Ghoreishi, and Y. Jafari, Electrosynthesis of Polyaniline-TiO2 Nanocomposite Films on Aluminum Alloy 3004 Surface and its Corrosion Protection Performance, J. Nanostruct., 2013, 3, p 65–77

H. Gerengi, M.M. Solomon, E. Kaya, F.E. Bagci, and E.J. Abai, An Evaluation of the Anticorrosion Effect of Ethylene Glycol for AA7075-T6 Alloy in 3.5% NaCl Solution, Measurement, 2018, 116, p 264–272

R.W. Revie, Uhlig’s Corrosion Handbook, Wiley, Hoboken, 2002, p 726–730

M. Zhu, D. Ding, Y. Gao, G. Chen, M. Li, and D. Mao, Effect of Zn Content on Tensile and Electrochemical Properties of 3003 Al Alloy, Trans. Nonferrous Metals Soc. China, 2010, 20, p 2118–2123

Yamada, et al., Aluminum Alloy for Cladding Excellent in Sacrificial Anode Property and Erosion–Corrosion Resistance. US Patent 4,238,233, issued 9 December 1980.

R.S. Neves, D.P.B. Silva, and A.J. Motheo, Corrosion Protection of AA7075 Aluminium Alloy by Trimethoxy-Silanes Self-Assembled Monolayers, ISRN Electrochem., 2013, 2013, p 1–9

B. Moniz and S.H. Zhang, Corrosion Tests and Standards Application and Interpretation, ASTM International, Baltimore, 2005

H. Warlimont and W. Martienssen, Springer Handbook of Materials Data, Springer, Berlin, 2018, p 191

M. Sakairi, R. Sasaki, A. Kaneko, Y. Seki, and D. Nagasawa, Evaluation of Metal Cation Effects on Galvanic Corrosion Behavior of the A5052 Aluminum Alloy in Low Chloride Ion Containing Solutions by Electrochemical Noise Impedance, Electrochim. Acta, 2014, 131, p 123–129

E.M. Sherif, A.A. Almajid, F.H. Latif, and H. Junaedi, Effects of Graphite on the Corrosion Behavior of Aluminum-Graphite Composite in Sodium Chloride Solutions, Int. J. Electrochem. Sci., 2011, 6, p 1085–1099

H. Allachi, F. Chaouket, and K. Draoui, Corrosion Inhibition of AA6060 Aluminum Alloy by Lanthanide Salts in Chloride Solution, J. Alloys Compd., 2009, 475, p 300–303

H. Ding, G. Zhou, Z. Dai, Y. Bu, and T. Jiang, Corrosion Wear Behaviours of 2024Al in Artificial Rainwater and Seawater at Fretting Contact, Wear, 2009, 267, p 292–298

F. Zheng, L. Hao, J. Li, H. Zhu, X. Chen, Z. Shi, S. Wang, and Y. Fan, Corrosion Characteristics of Aluminum in Sodium Bicarbonate Aqueous Solution at 50 °C, Int. J. Electrochem. Sci., 2019, 14, p 7303–7316

C.S. Namoco, Jr., T. Iizuka, N. Hatanaka, N. Takakura, and K. Yamaguchi, Influence of Embossing and Restoration on the Mechanical Properties of Aluminum Alloy Sheets, J. Mater. Process. Technol., 2007, 18, p 192–193

M. Lashgari, E. Kianpour, and E. Mohammadi, Aluminum Pitting Corrosion in Halide Media: A Quantum Model and Empirical Evidence, J. Mater. Eng. Perform., 2013, 22, p 3620–3625

Y. Jafari, M. Shabani-Nooshabadi, and S.M. Ghoreishi, Electropolymerized Coatings of Poly(o-anisidine) and Poly(o-anisidine)-TiO2 Nanocomposite on Aluminum Alloy 3004 by Using the Galvanostatic Method and Their Corrosion Protection Performance, Polym. Adv. Technol., 2014, 25, p 279–287

L.X. Bach, D.L. Son, M.T. Phong, L.V. Thang, M.Z. Bian, and N.D. Nam, A Study on Mg and AlN Composite in Microstructural and Electrochemical Characterizations of Extruded Aluminum Alloy, Compos. B, 2019, 156, p 332–343

B.X. Vuong, H.T. Anh, N.T. Nhan, H.H.M. Xuan, D.C. Nguyen, and N.D. Nam, Influence of the Friction Stir Welding-Traveling Speed on the Corrosion Properties of Mg-5Al Alloy, J. Mater. Eng. Perform., 2017, 26, p 3676–3685

B. Hirschorn, M.E. Orazem, B. Tribollet, V. Vivier, I. Frateur, and M. Musiani, Determination of Effective Capacitance and Film Thickness from Constant-Phase-Element Parameters, Electrochim. Acta, 2010, 55, p 6218–6227

S. Lameche-Djeghaba, A. Benchettara, F. Kellou, and V. Ji, Electrochemical Behaviour of Pure Aluminium and Al–5%Zn Alloy in 3% NaCl Solution, Arab. J. Sci. Eng., 2014, 39, p 113–122

R. Ambat, A.J. Davenport, G.M. Scamans, and A. Afseth, Effect of iron-containing intermetallic particles on the corrosion behavior of Aluminum, Corros. Sci., 2006, 48, p 3455–3471

Acknowledgments

Authors would like to thank Prof. Dr. Gultekin Goller and Mr. Huseyin Sezer for proving necessary laboratory equipments and helping with SEM analysis, to Mr. Bora Tarhan for supplying clad aluminum sheet for experiments, to Mr. Husnu Ozturk for metallographic analyses, and to Istanbul Metropolitan Municipality Environmental Protection Directorship Anatolian Side Environmental Laboratories for analyzing the chemical composition of the electrolytes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tunc, I., Karahan, B.D. & Keles, O. A Study on the Corrosion Behavior of 7072/3004/7072 Clad Aluminum Alloy in Different Media. J. of Materi Eng and Perform 29, 4506–4514 (2020). https://doi.org/10.1007/s11665-020-04948-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04948-x