Abstract

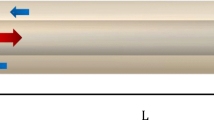

In order to enhance thermal efficiency, most process industries are fitted with heat exchangers. Without using external power, we can increase the heat transfer rate by providing different strips in tubes. This paper deals with the passive method of elliptic leaf insertion in a double pipe heat exchanger with opposite orientation and same direction and the heat transfer rate and pressure drop are found. The double elliptical leaf used in experiment has major to minor axes ratios as 2:1 and distance of 50 mm between two leaves are arranged at different angular orientations from 00 to 1800 with 100 intervals. Experimental and numerical simulations are carried and the thermal performance is evaluated at various Reynolds number. Nusselt number increases with increases of Reynolds number and among all elliptical leaf angles, 600 leaf angles gives more heat transfer rate because of high surface area and secondary flows near by the walls of the tube. Friction factor decreases with increased Reynolds number. From the obtained experimental results, a statistical tool generalized regression neural network is considered where the output values are obtained by giving known input parameters without conducting any experimentation.

Similar content being viewed by others

References

Ranjith et al. (2016) Numerical analysis on a double pipe heat exchanger with twisted tape induced swirl flow on both sides. International Conference on Emerging Trends in Engineering, Science and Technology (ICETEST-2015), pp.436–443, Procedia Technology 24

Girish S et al (2017) Enhancement Techniques Of Double Pipe Heat Exchanger. Int J Sci Dev Res (IJSDR), ISSN: 2455–2631 2(7):220–222

Sahoo M et al (2016) Experimental investigation andperformance analysis of triple concentrichelical tube heat exchanger. Int J Eng Tech (IJET),ISSN (Print): 2319–8613 ISSN (Online): 0975–4024 8:2265–2271

SwapnilS.Kamthe et al. (2017) Effect of Different types of Baffles on Heat Transfer & Pressure Drop of Shell and Tube Heat Exchanger: A review “International Journal of Current Engineering and Technology (IJCET),E-ISSN 2277–4106, P-ISSN 2347–5161.

MITCOE, & DIAT, 2017. IJCET INPRESSO Special Issue Pune, AMET-2017,

BabuKoppula S et al (2017) Study on various parameters in the Design Of Double Pipe Heat Exchanger OnHot Fluid Side In Inner Pipe. Int J Adv Res Sci Eng (IJARSE), ISSN 2319–8354 06:1017–1028

Mishra M et al (2016) Experimental Investigations Of Double Pipe Heat Exchanger With Triangular Baffles. Int Res J Eng Tech (IRJET), e-ISSN: 2395–0056,p-ISSN: 2395–0072 03(08):1137–1141

Kumar M et al (2016) Investigation of Heat Transfer and Friction Factor Characteristics of Two Phase Nano Fluids by Inserting Twisted Tape and Helical Inserts in the Tube. IOSR J Mech Civil Eng (IOSR-JMCE),e-ISSN: 2278–1684,p-ISSN: 2320-334X 13:09–16

Rao AV et al (2018) Numerical Analysis of Double Pipe HeatExchanger with and without Strip. Int J Res Appl Sci Eng Tech (IJRASET), ISSN: 2321–9653 6(VI):855–864

M. AnisMustaghfirin et al. (2018) “Effect of various number conical strip inserted inthe tube on heat transfer performance” MATEC Web of Conferences 204, 04016, IMIEC 2018.

Harsimranjot Singh et al. 2016 “An Experimental Analysis on a Double Pipe Heat Exchanger Modified with Turbulators”.

Pawan A, Sawarkar et al (2015) Experimental Analysis of Augmentation in Heat Transfer Coefficient Using Twisted Tape with Semi-Circular Cut Insert. Int J Sci Res (IJSR), ISSN (Online): 2319–7064 4(4):1174–1179

Behera VM et al (2014) Numerical Analysis Of Triple Tube Heat Exchanger Using Ansys. Int J Sci Eng Res (IJSER), ISSN 2229–5518 5(11):1226–1231

M. Anis Mustaghfirin et al. (2018) “Effect of various number conical strip inserted in the tube on heat transfer performance” MATEC Web of Conferences 204, 04016 (2018),IMIEC.

Satyabrata Kanungo et al. (2014) “Numerical Analysis To Optimize The Heat Transfer Rate Of Tube-In-Tube Helical Coil Heat Exchanger”. Nat Inst Tech Rourkela.

Nageswarrao V et al (2017) (CFD analysis of CuO/water) nanofluid flow in double pipe U-bend heat exchanger. Int J Dynamics Fluids, ISSN 0973–1784 13:137–152

Shiva Kumar et. al (2014) “Numerical study of heat transfer in a finned double pipe heat exchanger” World Journal of Modelling and Simulation,Published by World Academic Press, World Academic Union,Dept of Mechanical Engg, MIT, Manipal, India,Vol. 11

Kanojiya NC et al (2014) Heat Transfer Enhancement in Heat Exchangers With Inserts: A Review. Int J Eng Res Tech (IJERT), ISSN: 2278–0181 or IJERTV3IS100367 3:494–500

Mohan K et al (2016) Efficiency Improvement in Shell and TubeHeat Exchanger Using CFD Tool. Int J Innov Res Sci, Eng Tech (IJIRSET), ISSN(Online): 2319–8753 orISSN (Print): 2347–6710 5(3):4128–4134

Pimple DS et al (2014) Int. J. Eng. Res Appl (IJERA), ISSN: 2248–9622 4(12(Part 3)):06–11

Ranjith et al. 2016 “Numerical analysis on a double pipe heat exchanger with twisted tape induced swirl flow on both sides” Int Conf EmergTrends Eng, Sci Tech (ICETEST-2015),pp.436–443,Procedia Technology 24).

Dehanka PB et al (2014) Heat Transfer Augmentation - A Review for Helical Tape Insert. Int J Sci Eng Tech (IJSET), (ISSN: 2277–1581) 3(10):1236–1238

Vengalabothi B et al (2017) Enhancement Of Heat Transfer Rate In Double Pipe Heat Exchanger By Shot Blasting The Inner Tube. J Emerg Tech Innov Res (JETIR),ISSN-2349-5162 4:40–46

V. Vara Prasad et al. (2013) “Experimental Analysis To Enhance The Effectiveness Of Heat Exchanger Using Triangular Fins” Int J Mech Prod Eng Res Dev (IJMPERD),© TJPRC Pvt. Ltd., ISSN 2249–6890,Vol. 3,pp.1–10. Issue 2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rao, J.B.B., Yadav, J.S. Evaluation of thermal performance and implementation of prediction tool in a heat exchanger with elliptical leaf strips. Heat Mass Transfer 56, 2871–2882 (2020). https://doi.org/10.1007/s00231-020-02903-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02903-z