Abstract

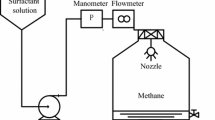

Methane hydrate preparation is an effective method to store and transport methane. In promoters to facilitate methane hydrate formation, homogeneous surfactant solutions, sodium dodecyl sulfate (SDS) in particular, are more favorable than heterogeneous particles, thanks to their faster reaction rate, more storage capacity, and higher stability. Foaming, however, could not be avoided during hydrate dissociation with the presence of SDS. This paper investigated the ability of five fluorinated surfactants: potassium perfluorobutane sulfonate (PBS), potassium perfluorohexyl sulfonate (PHS), potassium perfluorooctane sulfonate (POS), ammonium perfluorooctane sulfonate (AOS), and tetraethylammonium perfluorooctyl sulfonate (TOS) to promote methane hydrate formation. It was found that both PBS and PHS achieve a storage capacity of 150 (V/V, the volume of methane that can be stored by one volume of water) within 30 min, more than that of SDS. Cationic ions and the carbon chain length were then discussed on their effects during the formation. It was concluded that PBS, PHS, and POS produced no foam during hydrate dissociation, making them promising promoters in large-scale application.

Similar content being viewed by others

References

Yang M J, Zheng J N, Gao Y, Ma Z, Lv X, Song Y. Dissociation characteristics of methane hydrates in South China Sea sediments by depressurization. Applied Energy, 2019, 243: 266–273

Zhang J, Yip C, Xia C, Liang Y. Evaluation of methane release from coals from the San Juan basin and Powder River basin. Fuel, 2019, 244: 388–394

Rathi R, Lavania M, Singh N, Sarma P M, Kishore P, Hajra P, Lal B. Evaluating indigenous diversity and its potential for microbial methane generation from thermogenic coal bed methane reservoir. Fuel, 2019, 250: 362–372

Wang A, Austin D, Song H. Investigations of thermochemical upgrading of biomass and its model compounds: opportunities for methane utilization. Fuel, 2019, 246: 443–453

Guo H, Cheng Y, Huang Z, Urynowicz M A, Liang W, Han Z, Liu J. Factors affecting co-degradation of coal and straw to enhance biogenic coalbed methane. Fuel, 2019, 244: 240–246

Lay C, Vo T, Lin P Y, Abdul P M, Liu C M, Lin C Y. Anaerobic hydrogen and methane production from low-strength beverage wastewater. International Journal of Hydrogen Energy, 2019, 44(28): 14351–14361

Andres-Garcia E, Dikhtiarenko A, Fauth F, Silvestre-Albero J, Ramos-Fernández E V, Gascon J, Corma A, Kapteijn F. Methane hydrates: nucleation in microporous materials. Chemical Engineering Journal, 2019, 360: 569–576

Gbaruko B C, Igwe J C, Gbaruko P N, Nwokeoma R C. Gas hydrates and clathrates: flow assurance, environmental and economic perspectives and the Nigerian liquified natural gas project. Journal of Petroleum Science Engineering, 2007, 56(1–3): 192–198

Ohmura R, Takeya S, Uchida T, Ebinuma T. Clathrate hydrate formed with methane and 2-propanol: confirmation of structure II hydrate formation. Industrial & Engineering Chemistry Research, 2004, 43(16): 4964–4966

Jin Y, Kida M, Konno Y, Nagao J. Clathrate hydrate equilibrium in methane-water systems with the addition of monosaccharide and sugar alcohol. Journal of Chemical & Engineering Data, 2017, 62(1): 440–444

Imasato K, Tokutomi H, Ohmura R. Crystal growth behavior of methane hydrate in the presence of liquid hydrocarbon. Crystal Growth & Design, 2015, 15(1): 428–433

Susilo R, Alavi S, Ripmeester J, Englezos P. Tuning methane content in gas hydrates via thermodynamic modeling and molecular dynamics simulation. Fluid Phase Equilibria, 2008, 263(1): 6–17

Mimachi H, Takahashi M, Takeya S, Gotoh Y, Yoneyama A, Hyodo K, Takeda T, Murayama T. Effect of long-term storage and thermal history on the gas content of natural gas hydrate pellets under ambient pressure. Energy & Fuels, 2015, 29(8): 4827–4834

Takeya S, Yoneyama A, Ueda K, Hyodo K, Takeda T, Mimachi H, Takahashi M, Iwasaki T, Sano K, Yamawaki H, Gotoh Y. Nondestructive imaging of anomalously preserved methane clathrate hydrate by phase contrast X-ray imaging. Journal of Physical Chemistry C, 2011, 115(32): 16193–16199

Gupta P, Sakthivel S, Sangwai J S. Effect of aromatic/aliphatic based ionic liquids on the phase behavior of methane hydrates: experiments and modeling. Journal of Chemical Thermodynamics, 2018, 117: 9–20

Jadav S, Sakthipriya N, Doble M, Sangwai J S. Effect of biosurfactants produced by Bacillus subtilis and Pseudomonas aeruginosa on the formation kinetics of methane hydrates. Journal of Natural Gas Science and Engineering, 2017, 43: 156–166

Ganji H, Manteghian M, Sadaghiani Zadeh K, Omidkhah M R, Rahimi Mofrad H. Effect of different surfactants on methane hydrate formation rate, stability and storage capacity. Fuel, 2007, 86(3): 434–441

Erfani A, Fallahjokandan E, Varaminian F. Effects of non-ionic surfactants on formation kinetics of structure H hydrate regarding transportation and storage of natural gas. Journal of Natural Gas Science and Engineering, 2017, 37: 397–408

Verrett J, Servio P. Evaluating surfactants and their effect on methane mole fraction during hydrate growth. Industrial & Engineering Chemistry Research, 2012, 51(40): 13144–13149

Aliabadi M, Rasoolzadeh A, Esmaeilzadeh F, Alamdari A M. Experimental study of using CuO nanoparticles as a methane hydrate promoter. Journal of Natural Gas Science and Engineering, 2015, 27: 1518–1522

Choudhary N, Hande V R, Roy S, Chakrabarty S, Kumar R. Effect of sodium dodecyl sulfate surfactant on methane hydrate formation: a molecular dynamics study. Journal of Physical Chemistry B, 2018, 122(25): 6536–6542

Siangsai A, Inkong K, Kulprathipanja S, Kitiyanan B, Rangsunvigit P. Roles of sodium dodecyl sulfate on tetrahydrofuran-assisted methane hydrate formation. Journal of Oleo Science, 2018, 67(6): 707–717

Watanabe K, Niwa S, Mori Y H. Surface tensions of aqueous solutions of sodium alkyl sulfates in contact with methane under hydrate-forming conditions. Journal of Chemical & Engineering Data, 2005, 50(5): 1672–1676

Bhattacharjee G, Barmecha V, Kushwaha O S, Kumar R. Kinetic promotion of methane hydrate formation by combining anionic and silicone surfactants: scalability promise of methane storage due to prevention of foam formation. Journal of Chemical Thermodynamics, 2018, 117: 248–255

Pandey G, Bhattacharjee G, Veluswamy H P, Kumar R, Sangwai J S, Linga P. Alleviation of foam formation in a surfactant driven gas hydrate system: insights via a detailed morphological study. ACS Applied Energy Materials, 2018, 1: 6899–6911

Song Y, Wang F, Guo G, Luo S J, Guo R B. Amphiphilic-polymercoated carbon nanotubes as promoters for methane hydrate formation. ACS Sustainable Chemistry & Engineering, 2017, 5(10): 9271–9278

Wang F, Guo G, Luo S J, Guo R B. Grafting of nano-Ag particles on −SO3− -coated nanopolymers for promoting methane hydrate formation. Journal of Materials Chemistry, 2017, 5(35): 18486–18493

Wang F, Liu G, Meng H L, Guo G, Luo S J, Guo R B. Improved methane hydrate formation and dissociation with nanosphere-based fixed surfactants as promoters. ACS Sustainable Chemistry & Engineering, 2016, 4(4): 2107–2113

Wang F, Meng H, Guo G, Luo S J, Guo R B. Methane hydrate formation promoted by −SO3− -coated graphene oxide nanosheets. ACS Sustainable Chemistry & Engineering, 2017, 5(8): 6597–6604

Wang F, Guo G, Luo S J, Guo R B. Preparation of −SO3−-coated nanopromoters for methane hydrate formation: effects of the existence pattern of −SO3− groups on the promotion efficiency. Journal of Materials Chemistry, 2017, 5(6): 2640–2648

Song Y, Wang F, Liu G, Luo S, Guo R. Promotion effect of carbon nanotubes-doped SDS on methane hydrate formation. Energy & Fuels, 2017, 31(2): 1850–1857

Wang F, Song Y, Liu G Q, Guo G, Luo S J, Guo R B. Rapid methane hydrate formation promoted by Ag & SDS-coated nanospheres for energy storage. Applied Energy, 2018, 213: 227–234

Wang F, Jia Z, Luo S J, Fu S F, Wang L, Shi X S, Wang C S, Guo R B. Effects of different anionic surfactants on methane hydrate formation. Chemical Engineering Science, 2015, 137: 896–903

Prajapati R R, Bhagwat S S. Effect of foam boosters on the micellization and adsorption of sodium dodecyl sulfate. Journal of Chemical & Engineering Data, 2012, 57(12): 3644–3650

Hu Z, Verheijen W, Hofkens J, Jonas A M, Gohy J F. Formation of vesicles in block copolymer-fluorinated surfactant complexes. Langmuir, 2007, 23(1): 116–122

Jackson A, Li P, Dong C C, Thomas R K, Penfold J. Structure of partially fluorinated surfactant monolayers at the air-water interface. Langmuir, 2009, 25(7): 3957–3965

Wang F, Guo G, Liu G Q, Luo S J, Guo R B. Effects of surfactant micelles and surfactant-coated nanospheres on methane hydrate growth pattern. Chemical Engineering Science, 2016, 144(144): 108–115

Shiloach A, Blankschtein D. Prediction of critical micelle concentrations of nonideal ternary surfactant mixtures. Langmuir, 1998, 14(15): 4105–4114

Evans J B, Evans D F. A comparison of surfactant counterion effects in water and formamide. Journal of Physical Chemistry, 1987, 91(14): 3828–3829

Tabuteau H, Ramos L, Nakaya-Yaegashi K, Imai M, Ligoure C. Nonlinear rheology of surfactant wormlike micelles bridged by telechelic polymers. Langmuir, 2009, 25(4): 2467–2472

Petkova R, Tcholakova S, Denkov N D. Foaming and foam stability for mixed polymer-surfactant solutions: effects of surfactant type and polymer charge. Langmuir, 2012, 28(11): 4996–5009

Acknowledgements

This work was financially supported by the Key R&D Project of Shandong Province (No. 2017GSF16106), DICP & QIBEBT Unite Fund (No.: DICP & QIBEBT UN201807) and Strategic Priority Research Program of the Chinese Academy of Science (No. XDA 21060400).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Cao, Q., Xu, D., Xu, H. et al. Efficient promotion of methane hydrate formation and elimination of foam generation using fluorinated surfactants. Front. Energy 14, 443–451 (2020). https://doi.org/10.1007/s11708-020-0683-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-020-0683-2