Abstract

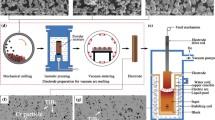

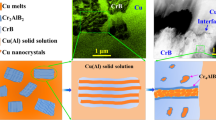

Cu matrix composites reinforced by TiB2/TiN ceramic reinforcements (Cu/TBN composites) were prepared by hot pressing method. Prior to the hot pressing, Cu/TiB2/TiN composite powders (CTBN powders), which were used as the starting materials of Cu/TBN composites, were fabricated by self-propagating high-temperature synthesis method. The CTBN particles were found to be in a special core–shell structure with a Cu–Ti alloy core and a TiB2/TiN ceramic shell. The test results presented obvious improvements in mechanical properties. The highest ultimate tensile strength reached up to 297 MPa, 77 MPa higher than that of Cu. And the highest hardness reached up to 70.7 HRF, 15.7 HRF higher than that of Cu. A comparative study indicated that the core–shell structured particles could bring about more obvious strengthening effect than the traditional irregularly shaped particles, which was due to the improved Cu/ceramics interfacial bonding, the linkage strengthening effect of both TiB2 and TiN, and higher load bearing ability of the core–shell structured reinforcements.

Similar content being viewed by others

References

M. Guo, K. Shen, M. Wang, Acta Mater. 57, 4568 (2009)

S. Sharma, T. Nanda, O.P. Pandey, Ceram. Int. 44, 104 (2018)

P. Zhang, J. Jie, H. Li, T. Wang, T. Li, J. Mater. Sci. 50, 3320 (2015)

B.-W. Ahn, J.-H. Kim, K. Hamad, S.-B. Jung, J. Alloys Compd. 693, 688 (2017)

A. Jha, S.J. Yoon, J. Mater. Sci. 34, 307 (1999)

T. Aizawa, T. Akhadejdamrong, C. Iwamoto, Y. Ikuhara, A. Mitsuo, J. Am. Ceram. Soc. 85, 21 (2002)

Y. Zhan, G. Zhang, J. Mater. Sci. 40, 223 (2005)

D.M. Jarzabek, M. Milczarek, T. Wojciechowski, C. Dziekonski, M. Chmielewski, Ceram. Int. 43, 5283 (2017)

J. Yin, D. Yao, Y. Xia, K. Zuo, Y. Zeng, J. Alloys Compd. 615, 983 (2014)

C. Zhang, J. Yin, D. Yao, K. Zuo, Y. Xia, H. Liang, Y. Zeng, Compos. Part A Appl. Sci. Manuf. 102, 145 (2017)

J. Li, F. Li, K. Hu, Y. Zhou, J. Alloys Compd. 334, 253 (2002)

J.H. Shim, J.S. Byun, Y. Whan Cho, Scr. Mater. 47, 493 (2002)

M. Kitiwan, A. Ito, T. Goto, J. Eur. Ceram. Soc. 34, 197 (2014)

C.L. Yeh, C.H. Chiang, Ceram. Int. 41, 11287 (2015)

B. Chen, Q. Bi, J. Yang, Y. Xia, J. Hao, Mater. Sci. Eng. A 491, 315 (2008)

G.J. Zhang, Z.Z. Jin, X.M. Yue, J. Am. Ceram. Soc. 78, 2831 (1995)

Y.F. Yang, H.Y. Wang, Y.H. Liang, R.Y. Zhao, Q.C. Jiang, Mater. Sci. Eng. A 445–446, 398 (2007)

Z. Xinghong, Z. Chuncheng, Q. Wei, H. Xiaodong, V.L. Kvanin, Compos. Sci. Technol. 62, 2037 (2002)

S. Cho, K. Kikuchi, T. Miyazaki, K. Takagi, A. Kawasaki, T. Tsukada, Scr. Mater. 63, 375 (2010)

Y. Zhang, H.L. Zhang, J.H. Wu, X.T. Wang, Scr. Mater. 65, 1097 (2011)

Y.A. Lu, J.F. Yang, W.Z. Lu, R.Z. Liu, G.J. Qiao, C.G. Bao, Mater. Sci. Eng. A 527, 6289 (2010)

J.N. Wei, Z.B. Li, F.S. Han, Phys. Status Solidi A 191, 125 (2002)

W.D. Fei, M. Hu, C.K. Yao, Mater. Chem. Phys. 77, 882 (2003)

N. Chawla, Y.L. Shen, Adv. Eng. Mater. 3, 357 (2001)

N. Xu, Y.P. Zong, F.Z. Hang, L. Zuo, Acta Metall. Sin. (in Chinese) 43, 863 (2007)

S.V. Kamat, A.D. Rollett, J.P. Hirth, Scr. Metall. Mater. 25, 27 (1991)

M.T. Kiser, F.W. Zok, D.S. Wilkinson, Acta Mater. 44, 3465 (1996)

P. Jin, X.B. Lv, Q.Z. Wang, Z.Y. Ma, Y. Liu, S. Li, Acta Metall. Sin. (in Chinese) 47, 298 (2011)

Q.K. Cai, C.L. He, M.J. Zhao, J. Bi, C.S. Liu, Acta Metall. Sin. (in Chinese) 39, 865 (2003)

Y. Flom, R.J. Arsenault, Acta Metall. 37, 2413 (1989)

L. Cao, C.P. Jiang, Z.K. Yao, T.Q. Lei, Acta Metall. Sin. (in Chinese) 25, 113 (1989)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2018YFF01013605), the National Natural Science Foundation of China (No. 51501215), the Youth Innovation Promotion Association CAS (No. 2019254), the Science Foundation for Youth Scholar of State Key Laboratory of High Performance Ceramics and Superfine Microstructures (No. SKL201701), the State Key Laboratory of New Ceramic and Fine Processing Tsinghua University (No. KF201806).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Yin, J., Zhou, P., Liang, H. et al. Microstructure and Mechanical Properties of Cu Matrix Composites Reinforced by TiB2/TiN Ceramic Reinforcements. Acta Metall. Sin. (Engl. Lett.) 33, 1609–1617 (2020). https://doi.org/10.1007/s40195-020-01100-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01100-5