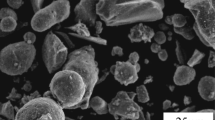

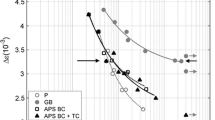

Two condensed electron-beam copper coatings, one consisting of copper and the other of Hf/Ag/Ni/Cr microlayers, were deposited onto a titanium alloy (Ti−6Al−4V) substrate to study the energy dissipation and fatigue resistance in the uncoated and coated samples under nonbreaking and breaking cyclic stresses. The microlayer coating is peculiar in that a material with a higher elastic modulus is used in each subsequent layer (from the substrate to the outer layer) and the coating layers and submicron twins in the binder sublayer have a columnar microstructure peculiar to electron-beam evaporation and vacuum condensation. Having layered macro- and microstructure, the coating absorbs the energy of vibrations through both internal friction (between the coating layers and between the coating and substrate) and dissipation of vibration energy on numerous defects in the columnar structure (intercolumnar porosity). Resonant first- and secondmode vibrations were excited in cantilevered samples to determine how the vibration decrement depended on their maximum stresses and the breaking fatigue stresses on the number of load cycles. In addition, vibration transmission coefficients for cyclic stresses and vibration energy were experimentally defined and justified for use. One coefficient is equal to the ratio of difference in stresses between the uncoated and coated samples to stresses in the uncoated sample, relative machine power being the same in various tests. The other coefficient is equal to the ratio of difference in energy between the uncoated and coated samples to the energy of vibrations induced in the uncoated sample, relative machine power being the same in various tests. The Hf/Ag/Ni/Cr coating is shown to provide greater energy dissipation but lower fatigue properties than the Cu coating and substrate. The vibration transmission coefficients are more sensitive to energy dissipation than the vibration decrement is.

Similar content being viewed by others

References

G.S. Pisarenko, V.V. Matveev, and A.P. Yakovlev, Methods for Determining Damping Characteristics of Elastic Systems [in Russian], Naukova Dumka, Kyiv (1976), p. 86.

G.S. Pisarenko, A.P. Yakovlev, and V.V. Matveev, Vibration Absorbing Properties of Structural Materials [in Russian], Naukova Dumka, Kyiv (1971), p. 375.

A.P. Yakovlev, Dissipative Properties of Inhomogeneous Materials and Systems [in Russian], Naukova Dumka, Kyiv (1985), p. 245.

V.T. Troshchenko, Fatigue and Inelasticity of Metals [in Russian], Naukova Dumka, Kyiv (1971), p. 268.

V.A. Kuzmenko (ed.), Fatigue at High Stress Rates [in Russian], Naukova Dumka, Kyiv (1979), p. 336.

V.A. Gryaznov, S.S. Gorodetski, Yu.S. Nalimov, L.A. Zaslotska, I.A. Makovetska, L.F. Shestopal, and A.A. Rabinovich, Fatigue of Creep-Resistant Alloys and Gas Turbine Engine Blades [in Russian], Naukova Dumka, Kyiv (1992), p. 264.

Yu.F. Lugovskoi, “Methodology for fatigue bending tests of composites produced by electron-beam evaporation,” Probl. Spets. Elektrometall., No. 4, 61–65 (1987).

V.V. Matveev, “Improvement of vibration reliability of structural elements by vibration damping,” Probl. Prochn., No. 10, 6–16 (1980).

Yu.V. Lugovskoi and S.A. Firstov, “Vibrodeformation properties of construction, composite, and highporosity sintered materials,” Powder Metall. Met. Ceram., 45, No. 7–8, 371–380 (2006).

K.Yu. Yakovchuk, Yu.E. Rudoi, A.V. Mikitchik, E.V. Onoprienko, A.O. Akhtyrski, and S.M. Romanenko, “Influence of condensation conditions on the structure and properties of B4C hard coatings produced by electron-beam vacuum evaporation,” Sovr. Elektrometall., No. 3, 15–19 (2012), http://nbuv.gov.ua/UJRN/sovele_2012_3_4.

A.V. Mikitchik, Yu.E. Rudoi, I.V. Grushetski, A.O. Akhtyrski, and S.M. Romanenko, “Effect of multilayer condensed coatings on damping characteristics of VT-6 titanium alloy,” Sovr. Elektrometall., No. 1, 26–31 (2016).

William R. Lull, Damped Blade: US Patent 3,301,530, filed August 3 (1965), No. 476, 816. (CI. 253–77).

I.N. Frantsevich (ed.), F.F. Voronov, and S.A. Bakuta, Elastic Constants and Elastic Moduli of Metals and Nonmetals [in Russian], Naukova Dumka, Kyiv (1982), p. 288.

“Transmission coefficient,” in: A.M. Prokhorov (ed.), Physical Encyclopedia [in Russian], Great Russian Encyclopedia, Moscow (1994), Vol. 4, p. 149; http://ru.solverbook.com/spravochnik/koefficienty/koefficient-propuskaniya.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 1–2 (531), pp. 95–105, 2020.

Rights and permissions

About this article

Cite this article

Lugovskoi, Y.F., Yakovchuk, K.Y. & Mikitchik, A. Effective Reduction of Cyclic Stresses in Coated Samples. Powder Metall Met Ceram 59, 68–75 (2020). https://doi.org/10.1007/s11106-020-00139-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00139-4