Abstract

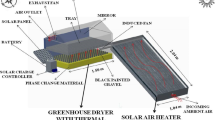

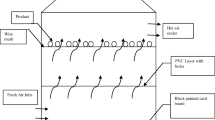

In present communication, a solar dryer having semi-transparent photovoltaic thermal (SPVT) roof has been used to dry bitter gourd. Experimentation has been done and results were validated with linear regression method through mathematical modelling as well as for non-linear Artificial Neural Network (ANN) modelling has been used. The experimental data namely, ambient air temperature, moisture evaporated, bitter gourd surface temperatures, solar intensity on different surfaces of dryer, room temperature and relative humidity have been recorded for the climatic condition of Varanasi, UP, India. The numerical value of convective heat transfer coefficients for bitter gourd found to be between 0.69–14.45 W/m2 K. The results for mass transfer (moisture evaporated) during drying of bitter gourd from theoretical model (linear regression method and ANN) and experiments showed good agreement. Further, net electrical energy, thermal energy and overall thermal energy were found to be 0.62, 3.77 and 5.41 kWh/m2/day respectively. The payback period at 10% interest rate and 4% inflation rate with ₹ 50 ($0.77) and ₹ 100 ($1.54) saving rate per kg were found to be 1.47 and 0.72 years respectively.

Similar content being viewed by others

Abbreviations

- A t :

-

Area of tray (m2)

- Cf :

-

Specific heat of air (J/kg K)

- d :

-

Effective diameter of fan exit (m)

- El :

-

Electrical energy (kWh)

- h c :

-

Convective mass transfer coefficient due to moisture evaporation in crop drying (W/m2K)

- I t :

-

Solar intensity on the wall of drying chamber (W/m2)

- I eff :

-

Total radiation in the greenhouse chamber (W)

- K v :

-

Thermal conductivity of humid air (W/mK)

- L c :

-

Characteristic length or characteristic dimension of the tray (m)

- \( {\dot{m}}_f \) :

-

Mass flow rate of air (kg/s)

- N :

-

Fan speed (RPM)

- N 1 :

-

Number of fan

- P (Tp):

-

Partial vapour pressure of moist air at crop surface temperature

- P (Te):

-

Partial vapour pressure of moist air above crop surface

- P fan :

-

Power of fan (W)

- t :

-

Time interval (s)

- T a :

-

Ambient temperature (0C)

- T o :

-

Cell temperature for optimum cell efficiency i.e. 250C

- T c :

-

Cell temperature (0C)

- T r :

-

Drying chamber temperature (0C)

- \( {\dot{Q}}_{th} \) :

-

Thermal energy (kWh)

- \( {\dot{Q}}_{th, ov} \) :

-

Overall thermal energy (kWh)

- V v :

-

Average velocity of humid air over the grape surface (m/s)

- V 1 :

-

Effective wind velocity inside the greenhouse chamber (m/s)

- α c :

-

Absorptivity of solar cell

- β 0 :

-

Temperature dependent efficiency factor

- β c :

-

Packing factor of module

- η 0 :

-

Standard efficiency at standard condition

- η c :

-

Solar cell efficiency

- η m :

-

Module efficiency

- η th :

-

Thermal efficiency

- η th,ov :

-

Overall thermal efficiency

- τg :

-

Transmittivity of module glass

- γ e :

-

Relative humidity of moist air above crop surface

- λ :

-

Latent heat of vaporization (J/kg)

References

MOFPI, Ministry of Food Processing Industries. Annual report, 2010–11. New Delhi: Government of India, http://www.mofpi.nic.in; 2011.

Arata A, Sharma VK, Spagna G (1993) Performance evaluation of solar assisted dryers for low temperature drying applications-II: experimental results. Energy Conversion & Management 34(5):417–426

Barnwal P, Tiwari GN (2008) Grape drying by using hybrid photovoltaic-thermal (PV/ T) greenhouse dryer: an experimental study. Solar Energy 82:1131–1144

Prakash O, Kumar A (2015) Annual performance of a modified greenhouse dryer under passive mode in no-load conditions. Int J Green Energy 12:1091–1099

Tiwari Sumit, Tiwari GN. Grapes (Vitis vinifera) drying by semitransparent photovoltaic module (SPVM) integrated solar dryer: an experimental study. Heat and Mass Transfer 2017; 53(352).

Tiris Cigdem, Tiris mustafa and Dincer ibrahim. Energy efficiency of a solar drying system. International Journal of Energy Research 1996; 20:767–770.

Youcef-Ali S, Moummi N, Desmons JY, Abene A, Messaoudi H, Le Ray M (2001) Numerical and experimental study of dryer in forced convection. International Journal of Energy Research 25:537–553

Abdullah A, Aydin D (2009) Thin layer solar drying and mathematical modeling of mulberry. International Journal of Energy Research 33:687–695

Nayak S, Tiwari GN (2008) Energy and exergy analysis of photovoltaic/thermal integrated with a solar greenhouse. Energy and Buildings 40:2015–2021

Janjai S, Lamlert N, Intawee P, Mahayothee B, Bala BK, Nagle M (2009) Experimental and simulated performance of a PV-ventilated solar greenhouse dryer for drying of peeled longan and banana. Solar Energy 83:1550–1565

Romero VM, Cerezo E, Garcia MI, Sanchez MH (2014) Simulation and validation of vanilla drying process in an indirect solar dryer prototype using CFD Fluent program. Energy Procedia 57:1651–1658

Guofeng Y, Liang H, Xing L, Li X, Wenxue T, Zhifeng W (2015) Experimental investigation of a solar dryer system for drying carpet. Energy Procedia 70:626–633

Akpinar E Kavak, Sarsılmaz C and Yildiz C. Mathematical modelling of a thin layer drying of apricots in a solar energized rotary dryer. International Journal of Energy Research 2004; 28:739–752.

ELkhadraoui A, Kooli S, Hamdi I, Farhat A (2015) Experimental investigation and economic evaluation of a new mixed mode solar greenhouse dryer for drying of red pepper and grape. Renewable Energy 77:1–8

Changsheng L, Haiyu W, Hong M, Bin Y (2017) The economic and social performance of integrated photovoltaic and agricultural greenhouses systems: Case study in China. Applied Energy 190:204–212

Deepak M, Priyanka P, Vasudha B, Wasim SM, Alka S (2017) Effect of drying techniques and treatment with blanching on the physicochemical analysis of bitter-gourd and capsicum. LWT - Food Science and Technology 84:479–488

Natarajan Karunaraja, Thokchom Subhaschandra Singh, verma Tikendra Nath, Nashine Prerana. Convective solar drying of Vitis vinifera & Momordica charantia using thermal storage materials. Renewable Energy 2017; 113:1193–1200.

Vijayan S, Arjunana TV, Anil K (2016) Mathematical modeling and performance analysis of thin layer drying of bitter gourd in sensible storage based indirect solar dryer. Innovative Food Science and Emerging Technologies 36:59–67

Himanshu M, Mahesh K (2017) Experimental investigation of a solar water distillation-cum-drying unit. International Journal of Green Energy 14(4):384–395

Braca Alessandra, Siciliano Tiziana, D’Arrigo, Germanòb Maria Paola. Chemical composition and antimicrobial activity of Momordica charantia seed essential oil. Fitoterapia 2008; 79(2):123–125.

Ak P, Kavak E (2010) Drying of mint leaves in a solar dryer and under open sun: Modelling, performance analysis. Energy Conversion and Management 51:2407–2418

Lingayat A, Chandramohan VP, Raju VRK (2017) Design, Development and Performance of Indirect Type Solar Dryer for Banana Drying. Energy Procedia 109:409–416

Tiwari GN (2002) Solar Energy. Design, Modelling and Applications. Narosa Publishing House, New Delhi, India, Fundamentals

Evans DL (1981) Simplified method for predicting PV array output. Sol. Energy 27:555–560

Vineet S, Sumit T, Tiwari GN (2017) Environ economic analysis of various types of photovoltaic technologies integrated with greenhouse solar drying system. Journal of Cleaner Production 156:30–40

Tiwari GN, Mishra R,K. Advance Renewable energy sources. RSC publishing 2012; ISBN: 978–1–84973-380-9.

Sumit T, Tiwari GN (2017) Energy and exergy analysis of a mixed-mode greenhouse-type solar dryer, integrated with partially covered N-PVT air collector. Energy 128:183–195

Sumit T, Tiwari GN (2016) Exergoeconomic analysis of photovoltaic-thermal (PVT) mixed mode greenhouse solar dryer. Energy 114:155–164

Tiwari S, Tiwari GN, Al-Helal IM (2016) Development and recent trends in greenhouse dryer: A review. Renewable and Sustainable Energy Reviews 65:1048–1064

Haykin S. Neural Networks a Comprehensive Foundation. Prentice Hall 1998; ISBN: 978–0–13-273350-2).

Graf HP, Jackel LD, Hubbard WE (1998) VLSI Implementation of a Neural Network Model. Computer 21(3):41–49

Erchiqui F, Ozdemir Z, Souli M, Ezzaidi H, Dituba-Ngoma G (2011) Neural networks approach for characterisation of viscoelastic polymers. Canadian Journal of chemical engineering 89

Sreekumar A (2010) Techno-economic analysis of a roof-integrated solar air heating system for drying fruit and vegetables. Energy Conversion and Management 51:2230–2238

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix I

Uncertainty Parameters | Calculation |

|---|---|

Temperature (WT,total) (Arises from thermocouples, digital thermometer, connection point and reading errors) | WT,total = [(Wthermocouple)2 + (Wthermometer)2 + (Wconnection point)2 + (Wreadings)2]1/2 = [0.12 + 0.12 + 0.12 + 0.12]1/2 = 0.20 |

Mass measurement (Wm,total) (Digital balance and reading) | Wm,total = [(Wdigital balance)2 + (Wreadings)2]1/2 = [(1)2 + (1)2]1/2 = 1.4 |

Air velocity measurement (Wv,total) (Anemometer and reading) | Wv,total = [(Wanemometer)2 + (Wreadings)2]1/2 = [(0.1)2 + (0.1)2]1/2 = 0.14 |

Relative humidity measurement (Wrh,total) (Humidity-meter and reading) | Wrh,total = [(Whumidity meter)2 + (Wreadings)2]1/2 = [(0.1)2 + (0.1)2]1/2 = 0.14 |

solar intensity measurement (Ww,total) (Digital Solarimeter and reading) | Ww,total = [(Wdigital solarimeter)2 + (Wreadings)2]1/2 = [(1)2 + (1)2]1/2 = 1.4 |

Total uncertainty in experimental measurement (W ex,total ) | Wex,total = [(WT,total)2+ (Wm,total)2+ (Wv,total)2+ (Wrh,total)2+ (Ww,total)2]1/2 = [(0.2)2+ (1.4)2+ (0.14)2+ (0.14)2+ 1.4)2]1/2 = ± 2% |

Appendix II

Various design parameters taken for numerical computation.

αc = 0.9 | τg = 0.9 | βc = 0.75 |

|---|---|---|

η0 = 0.15 | ρ = 1 kg/m3 | N = 1200 rpm |

Am = 5.75 m2 | At = 1.62 m2 | Af = 5.3 m2 |

Cf = 1005 J/kg K | d = 0.12 m | l = 0.9 m |

b = 0.9 m | t = 3600 s |

Rights and permissions

About this article

Cite this article

Tiwari, S. ANN and mathematical modelling for moisture evaporation with thermal modelling of bitter gourd flakes drying in SPVT solar dryer. Heat Mass Transfer 56, 2831–2845 (2020). https://doi.org/10.1007/s00231-020-02886-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02886-x