Abstract

The inadequacy of regular stone aggregate in North East India, has motivated the developers to search for an alternate construction material and prime subject of the present study is to use waste crushed bricks as a coarse aggregate in pervious concrete pavement. Pervious concrete, due to its inclusive beneficial aspects has become an embryonic solution to fight against the current hydrological and environmental threats. A number of research have been carried out to characterize the pervious concrete, however, there is a lack of study related to the fatigue performance of pervious concrete pavement. As the pavements are often subjected to fatigue loading, the present study mainly focuses on the response of pervious concrete pavement under the action of fatigue loading. Laboratory tests are performed on beam specimens under various stress levels and loading frequencies. Different types of aggregate gradations are also used to account the size effect of the coarse aggregate. The S–N curves for fatigue life is generated to obtain the relationship between the stress level and fatigue life and it is observed that the S–N curve follows a power law, irrespective of loading frequencies. The survival percentage of porous specimens are checked through non-parametric Kaplan–Meir survival analysis and the distributions of the fatigue data are checked through lognormal and 3-parameter Weibull distributions. Further, a modified fatigue model is developed for idealising the fatigue life of pervious concrete pavement made with over burnt brick aggregate and compared with the existing fatigue models.

Similar content being viewed by others

References

Sobhan MA, Zakaria M (2001) Experimental behaviour of BM mixes with brick Aggregates. J Civ Eng Inst Eng Bangladesh 29:115–123

Debieb F, Kenai S (2008) The use of coarse and fine crushed bricks as aggregate in concrete. Constr Build Mater 22:886–893. https://doi.org/10.1016/j.conbuildmat.2006.12.013

Rasel HM, Sobhan MA, Rahman MN (2011) Performance evaluation of brick chips as coarse aggregate. SAMRIDDHI-A J Phys Sci Eng Technol 2:37–46

Mazumder AR, Kabir A, Yazdani N (2006) Performance of overburnt distorted bricks as aggregates in pavement works. J Mater Civ Eng 18:777–785. https://doi.org/10.1061/(ASCE)0899-1561(2006)18:6(777)

EPA (2005) Reducing urban heat islands: compendium of strategies. EPA’s heat island reduction initiative. Environmental Protection Agency (EPA), Washington

EPA (2010) Storm Water Phase II final rule: an overview, EPA 833-F-00-001, Fact Sheet 1.0, U.S. Environmental Protection Agency, Office of Water, Washington, D.C., Jan 2000

Ibrahim A, Mahmoud E, Yamin M, Patibandla VC (2014) Experimental study on Portland cement pervious concrete mechanical and hydrological properties. Constr Build Mater 50:524–529. https://doi.org/10.1016/j.conbuildmat.2013.09.022

Wu H, Liu Z, Sun B, Yin J (2016) Experimental investigation on freeze-thaw durability of Portland cement pervious concrete (PCPC). Constr Build Mater 117:63–71. https://doi.org/10.1016/j.conbuildmat.2016.04.130

Debnath B, Sarkar PP (2018) Pervious concrete as an alternative pavement strategy: a state-of-the-art review. Int J Pavement Eng. https://doi.org/10.1080/10298436.2018.1554217

Tennis P, Leming M, Akers D (2004) Pervious concrete pavements. Portland Cement Association, New York

Debnath B, Sarkar PP (2019) Permeability prediction and pore structure feature of pervious concrete using brick as aggregate. Constr Build Mater 213:643–651. https://doi.org/10.1016/j.conbuildmat.2019.04.099

Debnath B, Sarkar PP (2020) Characterization of pervious concrete using over burnt brick as coarse aggregate. Constr Build Mater 10(242):118154. https://doi.org/10.1016/j.conbuildmat.2020.118154

Graf O, Brenner E (1934) Experiments for investigating the resistance of concrete under often repeated compression loads. Bulletin 1:17–25

Murdock JW (1965) A critical review of research on fatigue of plain concrete. University of Illinois at Urbana Champaign, College of Engineering. Engineering Experiment Station, College Station

Kesler CE (1953) Effect of speed of testing on flexural fatigue strength of plain concrete. In: Highway research board proceedings, vol 32

Medeiros A, Zhang X, Ruiz G, Rena CY, Velasco MDSL (2015) Effect of the loading frequency on the compressive fatigue behavior of plain and fiber reinforced concrete. Int J Fatigue 70:342–350. https://doi.org/10.1016/j.ijfatigue.2014.08.005

Zhang H, Tian K (2011) Properties and mechanism on flexural fatigue of polypropylene fiber reinforced concrete containing slag. J Wuhan Univ Technol Mater Sci Ed 26(3):533–540

Chandrappa AK, Biligiri KP (2017) Flexural-fatigue characteristics of pervious concrete: statistical distributions and model development. Constr Build Mater 153:1–15. https://doi.org/10.1016/j.conbuildmat.2017.07.081

Chen Y, Wang K, Wang X, Zhou W (2013) Strength, fracture and fatigue of pervious concrete. Constr Build Mater 42:97–104. https://doi.org/10.1016/j.conbuildmat.2013.01.006

Zhou J, Zheng M, Wang Q, Yang J, Lin T (2016) Flexural fatigue behavior of polymer-modified pervious concrete with single sized aggregates. Constr Build Mater 124:897–905. https://doi.org/10.1016/j.conbuildmat.2016.07.136

Liu H, Luo G, Zhou P, Wei H, Li W, Yu D (2019) Flexural-fatigue properties of sustainable pervious concrete pavement material containing ground tire rubber and silica fume. Sustainability 11(16):4467. https://doi.org/10.3390/su11164467

AlShareedah O, Nassiri S, Dolan JD (2019) Pervious concrete under flexural fatigue loading: performance evaluation and model development. Constr Build Mater 207:17–27. https://doi.org/10.1016/j.conbuildmat.2019.02.111

Chen X, Shi D, Shen N, Li S, Liu S (2019) Experimental study and analytical modeling on fatigue properties of pervious concrete made with natural and recycled aggregates. Int J Concr Struct Mater 13:10. https://doi.org/10.1186/s40069-018-0305-0

Izevbekhai BI, Eller AJ (2007) MnROAD Cell 64 pervious concrete-first year performance report (No MN/RC 2007-17)

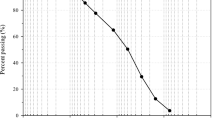

IS: 2386 (1963). Methods of test for aggregates for concrete—part I particle size and shape

IS: 2386 (1963) Methods of test for aggregates for concrete—part III specific gravity, density, voids, absorption and bulking

IS: 2386 (1963) Methods of test for aggregates for concrete—part IV mechanical properties

IS: 8112 (2013) Ordinary Portland Cement, 43 grade—specification, 2nd revision

ACI Committee 522R (2010) Report on pervious concrete, American Concrete Institute Committee 522. Technical Committee Document, Farmington Hills

IS: 10262 (2009) Concrete mix proportioning—guidelines, 1st revision

ASTM C1754 (2012) Standard test method for density and void content of hardened pervious concrete. ASTM international, West Conshohocken

ASTM D7460 (2008) Standard test method for determining fatigue failure of compacted asphalt concrete subjected to repeated flexural bending. ASTM international, West Conshohocken

Kasu SR, Deb S, Mitra N, Muppireddy AR, Kusam SR (2019) Influence of aggregate size on flexural fatigue response of concrete. Constr Build Mater 229:116922. https://doi.org/10.1016/j.conbuildmat.2019.116922

IS: 516 (2006) Methods of tests for strength of concrete—specification, 18th reprint

IS: 5816 (1996) Splitting tensile strength of concrete—method of test, First Revision

Zaetang Y, Wongsa A, Sata V, Chindaprasirt P (2013) Use of lightweight aggregates in pervious concrete. Constr Build Mater 48:585–591. https://doi.org/10.1016/j.conbuildmat.2013.07.077

Lian C, Zhuge Y, Beecham S (2011) The relationship between porosity and strength for porous concrete. Constr Build Mater 25(11):4294–4298. https://doi.org/10.1016/j.conbuildmat.2011.05.005

Chandrappa AK, Biligiri KP (2018) Methodology to develop pervious concrete mixtures for target properties emphasizing the selection of mixture variables. J Transp Eng Part B: Pavements 144(3):04018031. https://doi.org/10.1061/JPEODX.0000061

Cui X, Zhang J, Huang D, Liu Z, Hou F, Cui S, Zhang L, Wang Z (2017) Experimental study on the relationship between permeability and strength of pervious concrete. J Mater Civ Eng 29(11):04017217. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002058

Joshaghani A, Ramezanianpour AA, Ataei O, Golroo A (2015) Optimizing pervious concrete pavement mixture design by using the Taguchi method. Constr Build Mater 101:317–325. https://doi.org/10.1016/j.conbuildmat.2015.10.094

Huang B, Wu H, Shu X, Burdette EG (2010) Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr Build Mater 24(5):818–823. https://doi.org/10.1016/j.conbuildmat.2009.10.025

Shu X, Huang B, Wu H, Dong Q, Burdette EG (2011) Performance comparison of laboratory and field produced pervious concrete mixtures. Constr Build Mater 25(8):3187–3192. https://doi.org/10.1016/j.conbuildmat.2011.03.002

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Debnath, B., Sarkar, P.P. Prediction and model development for fatigue performance of pervious concrete made with over burnt brick aggregate. Mater Struct 53, 86 (2020). https://doi.org/10.1617/s11527-020-01523-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01523-7