Abstract

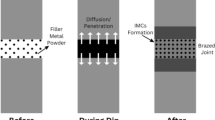

Active metal brazing of SiC-base ceramics and composites to Ti, Cu-clad-Mo, and nickel was carried out to screen promising commercial braze compositions with liquidus temperatures of 810-1040 °C. Microstructure, elemental composition, and microhardness were characterized using FESEM, EDS, and Knoop test in joints brazed using Ag-Cu-Ti alloys (Cusil-ABA and Ticusil) and a Ni-base alloy (MBF-20). Ti- and Si-rich interfacial layers developed in joints brazed using Ti-containing brazes, whereas Ni- and Si-rich layers formed in joints brazed using Ni-base brazes. Monolithic SiC/Mo and SiC/Kovar joints with Cusil-ABA had sound interfaces and compressive shear strengths of 25-30 MPa. In the case of composites, surface preparation influenced bond quality: ground SiC-SiC samples led to sound joints and unground samples led to interfacial decohesion at low thermal strains whereas joints cracked regardless of the surface preparation at large thermal strains. Among SiC-SiC/metal joints, SiC-SiC/Cu-clad-Mo had the best microstructure and bond quality. Microstructures of joints made using MBF-20 mixed with low-expansion Si-X (X: Y, Ta, Hf, Ti, B) eutectic powders to control the thermal expansion are also presented.

Similar content being viewed by others

References

J. Lamon, Chemical vapor infiltrated SiC/SiC composites (CVI SiC/SiC), Handbook of Ceramic Composites, N.P. Bansal (ed.), Kluwer, pp 55-76.

J.A. DiCarlo, H-M. Yun, G.N. Morscher and R.T. Bhatt, SiC/SiC composites for 1200C and above, Handbook of Ceramic Composites, N.P. Bansal (ed.), Kluwer, pp 77–98.

G.S. Corman and K.L. Luthra, Silicon melt infiltrated ceramic composites (HiPerComp), Handbook of Ceramic Composites, N.P. Bansal (ed.), Kluwer, pp. 99–115.

M. Salvo, M. Ferraris, P. Lemoine, M.A. Montorsi, and M. Merola, Joining of CMCs for Thermonuclear Fusion Applications, J. Nuclear Mater., 1996, 233–235, p 949–953

B. Riccardi, C.A. Nannetti, J. Woltersdorf, E. Pippel, and T. Petrisor, Joining of SiC-Base Ceramics and Composites with Si-16Ti and Si-18Cr Eutectic Alloys, Int. J. Mater. Product Technol., 2004, 20(5–6), p 440–451

J.R. McDermid and R.A.L. Drew, Brazing of Reaction-Bonded Silicon Carbide and Inconel 600 with an Iron-Based Alloy, J. Mater. Sci., 1990, 25(11), p 4804–4809

L. Giancarli, J.P. Bonal, A. Caso, G. Le Marois, N.B. Morley, and J.F. Salavy, Design Requirements for SiC/SiC Composites Structural Material in Fusion Power Reactor Blankets, Fusion Eng. Des., 1998, 41, p 165–171

I. Ahmad, R. Silberglitt, Y. Tian, J. D. Katz, Microwave joining of SiC ceramics and composites, Report LA-UR-97-458, Los Alamos National Lab, 1998.

X. Chen, J. Yan, S. Ren, Q. Wang, J. Wei, and G. Fan, Microstructure, Mechanical Properties, and Bonding Mechanism of Ultrasonic-Assisted Brazed Joints of SiC Ceramics with ZnAlMg Filler Metals in Air, Ceram. Int., 2014, 40(1), p 683–689

M. Singh and E. Lara-Curzio, Design, Fabrication and Testing of Ceramic Joints for High Temperature SiC-SiC Composites, Trans ASME, 2001, 123, p 288–292

M. Singh, T. Matsunaga, H.-T. Lin, R. Asthana, and T. Ishikawa, Microstructure and Mechanical Properties of Joints in Sintered SiC Fiber-Bonded Ceramics Brazed with Ag-Cu-Ti Alloys, Mater. Sci. Eng. A, 2012, 557, p 69–76

C. H. Henager, Jr., D. J. Edwards, and A. L. Schemer-Kohrn, Low activation joining of SiC/SiC Composites for fusion applications, Fusion Materials Semi-Annual Progress Report, DOE-ER-0313/47, Feb 2010, ORNL, Oak Ridge, TN, pp 42-46.

M. Singh, T.P. Shpargel, R. Asthana, and G.N. Morscher, Effect of composite substrate properties on the mechanical behavior of brazed joints in metal-composite system, in Brazing and Soldering, J.J. Stephens and K. Scott Weil (eds.), ASM International and AWS, 2006, 246–251.

M. Singh, R. Asthana, and T.P. Shpargel, Brazing of Ceramic-Matrix Composites to Ti and Hastealloy Using Ni-Base Metallic Glass Interlayers, Mater. Sci. Eng. A, 2008, 498(1–2), p 19–30

R. Asthana, M. Singh, and N. Sobczak, Wetting Behavior and Interfacial Microstructure of Pd and Ag-Based Braze Alloys with Ceramic-Matrix Composites, J. Mater. Sci., 2010, 45(16), p 4276–4290

W.S. Steffier, Brazing SiC/SiC composites to metals, NASA Tech Briefs, September 2004, p. 5

M. Singh, NASA/CR-1999-209316, Sept 1999, NASA Glenn Research Center, Cleveland, OH.

C.A. Harper, Electronic Materials and Processes Handbook, McGraw-Hill, 10.67–10.68, 2003.

http://www.hightempmetals.com/techdata/hitempInconel625data.php

R.F. Brooks, A.T. Dinsdale, and P.N. Quested, The Measurement of Viscosity of Alloys: A Review of Methods, Data and Models, Measurement Sci. Technol., 2005, 16, p 354–362

G.W. Liu, F. Valenza, M.L. Muolo, and A. Passerone, SiC/SiC and SiC/Kovar Joining by Ni-Si and Mo Interlayers, J. Mater. Sci., 2010, 45(16), p 4299–4307

J.-W. Park, P.F. Mendez, and T.W. Eager, Strain Energy Distribution in Ceramic-to-Metal Joints, Acta Mater., 2002, 50(5), p 883–899

J.-W. Park, P.F. Mendez, and T.W. Eager, Strain Energy Release in Ceramic-to-Metal Joints by Ductile Metal Interlayers, Scr. Mater., 2005, 53(7), p 857–861

M.C. Halbig, B.P. Coddington, R. Asthana, and M. Singh, Characterization of Silicon Carbide Joints Fabricated Using SiC Particulate-Reinforced Ag-Cu-Ti Alloys, Ceram. Int., 2013, 39, p 4151–4162

R. Asthana, M. Singh, H.T. Lin, T. Matsunaga, and T. Ishikawa, Joining of SiC Fiber-Bonded Ceramics Using Ag, Cu, Ni, Pd and Si-Base Alloy Interlayers, Int. J. Appl. Ceram. Technol., 2013, 10(5), p 801–813

H. Mizuhara and K. Mally, Ceramic-to-Metal Joining with Active Brazing Filler Metal, Weld. J., 1985, 64(10), p 27–32

A.J. Moorhead, W.H. Elliott, Jr., and H.-E. Kim, Brazing of ceramic and ceramic-to-metal joints, in Brazing and Soldering, ASM Metals Handbook, 1993, pp 948–960

http://www.osti.gov/bridge/servlets/purl/7048768-oKEamK/7048768.pdf

Acknowledgements

R. Asthana acknowledges the research support from Ohio Aerospace Institute, Cleveland, OH. The authors wish to thank Mr. Bryan P. Coddington for his help in experimental work and Mr. Michael C. Halbig, NASA Glenn Research Center, Cleveland, for his constructive comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to JMEP selected from presentations at the Symposium “Joining and Related Technologies,” belonging to the topic “Processing” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2019), held September 1–5, 2019, in Stockholm, Sweden, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Singh, M., Asthana, R. & Sobczak, N. Active Brazing of SiC-Base Ceramics to High-Temperature Alloys. J. of Materi Eng and Perform 29, 4898–4912 (2020). https://doi.org/10.1007/s11665-020-04934-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04934-3