Abstract

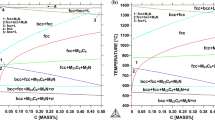

In this study, we investigated the transformation kinetics of martensite → reverted austenite in 18 wt.% grade 300 Ni maraging steel. The kinetics was evaluated based on the in situ synchrotron x-ray diffraction data collected during isothermal heat treatment at 570°C. The onset of transformation martensite → reverted austenite was detected after ~ 5 min of aging. The austenite fraction increased as a function of annealing time and reached approximately 30 vol.% after 3 h of heat treatment. The electron backscatter diffraction technique revealed that reverted austenite is formed preferentially on both the martensitic lath boundaries and sub-grain boundaries inside the laths, in particular in those with high Taylor factor values. The reverted austenite maintains an orientation relationship with the prior austenite; however, variant selection can take place.

Similar content being viewed by others

References

V.K. Vasudevan, S.J. Kim, and C.M. Wayman, Metall. Trans. A 21, 2655 (1990).

W. Sha, Scr. Mater. 42, 549 (2000).

S.S.M. Tavares, H.F.G. Abreu, J.M. Neto, M.R. Da Silva, and I. Popa, J. Alloys Compd. 358, 152 (2003).

W. Sha, A. Cerezo, and G.D.W. Smith, Metall. Mater. Trans. A 24, 1241 (1993).

W. Sha, A. Cerezo, and G.D.W. Smith, Metall. Mater. Trans. A 24, 1221 (1993).

U.K. Viswanathan, G.K. Dey, and M.K. Asundi, Metall. Trans. A 24, 2429 (1993).

D. Raabe, S. Sandlöbes, J. Millán, D. Ponge, H. Assadi, M. Herbig, and P.-P. Choi, Acta Mater. 61, 6132 (2013).

O. Dmitrieva, D. Ponge, G. Inden, J. Millán, P. Choi, J. Sietsma, and D. Raabe, Acta Mater. 59, 364 (2011).

M. Farooque, H. Ayub, A.U. Haq, and A.Q. Khan, J. Mater. Sci. 33, 2927 (1998).

D. Raabe, M. Herbig, S. Sandlöbes, Y. Li, D. Tytko, M. Kuzmina, D. Ponge, and P.-P. Choi, Curr. Opin. Solid State Mater. Sci. 18, 253 (2014).

M. Belde, H. Springer, G. Inden, and D. Raabe, Acta Mater. 86, 1 (2015).

J. Mittra, G.K. Dey, D. Sen, A.K. Patra, S. Mazumder, and P.K. De, Scr. Mater. 51, 34953 (2004).

R. Schnitzer, G.A. Zickler, E. Lach, H. Clemens, S. Zinner, T. Lippmann, and H. Leitner, Mater. Sci. Eng., A 527, 2065 (2010).

P.W. Hochanadel, G.R. Edwards, C.V. Robino, and M.J. Cieslak, Metall. Mater. Trans. A 25, 789 (1994).

J.-M. Cloué, B. Viguier, and E. Andrieu, Metall. Mater. Trans. A 36, 2633 (2005).

J. Suryawanshi, K.G. Prashanth, and U. Ramamurty, J. Alloys Compd. 725, 355 (2017).

E.V. Pereloma, A. Shekhter, M.K. Miller, and S.P. Ringer, Acta Mater. 52, 5589 (2004).

M.M. Wang, C.C. Tasan, D. Ponge, A. Kostka, and D. Raabe, Acta Mater. 79, 268 (2014).

X.C. Xiong, B. Chen, M.X. Huang, J.F. Wang, and L. Wang, Scr. Mater. 68, 321 (2013).

S. Lee, S.-J. Lee, and B.C. De Cooman, Scr. Mater. 65, 225 (2011).

C.A. Pampillo and H.W. Paxton, Metall. Trans. 3, 2895 (1972).

R. Schnitzer, R. Radis, M. Nöhrer, M. Schober, R. Hochfellner, S. Zinner, E. Povoden-Karadeniz, E. Kozeschnik, and H. Leitner, Mater. Chem. Phys. 122, 138 (2010).

J.M. Pardal, S.S.M. Tavares, V.F. Terra, M.R. da Silva, and D.R. dos Santos, J. Alloys Compd. 393, 109 (2005).

F. Habiby, T.N. Siddiqui, S.H. Khan, and A.Q. Khan, NDT E Int. 25, 145 (1992).

S.H. Khan, A.N. Khan, F. Ali, M.A. Iqbal, and H.K. Shukaib, J. Alloys Compd. 474, 254 (2009).

X. Li and Z. Yin, Mater. Lett. 24, 239 (1995).

G.M.C. Güiza and C.A.S. Oliveira, Mater. Sci. Eng., A 655, 142 (2016).

G.C.S. Nunes, P.W.C. Sarvezuk, T.J.B. Alves, V. Biondo, F.F. Ivashita, and A. Paesano Jr, J. Magn. Magn. Mater. 421, 457 (2017).

Y.Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, and Y.Y. Li, Mater. Lett. 64, 1411 (2010).

N.F. Viana, S. Nunes, and H.F.G. de Abreu, J. Mater. Res. Technol. 2, 298 (2013).

N. Nakada, T. Tsuchiyama, S. Takaki, and S. Hashizume, ISIJ Int. 47, 1527 (2007).

A. Markfeld and A. Rosen, Mater. Sci. Eng. 46, 151 (1980).

G.A. Zickler, R. Schnitzer, R. Hochfellner, T. Lippmann, S. Zinner, and H. Leitner, Int. J. Mater. Res. 100, 1566 (2009).

Y. Katz, H. Mathias, and S. Nadiv, Metall. Trans. A 14, 801 (1983).

J.M. Pardal, S.S.M. Tavares, M.P.C. Fonseca, H.F.G. Abreu, and J.J.M. Silva, J. Mater. Sci. 41, 2301 (2006).

N. Jia, Z.H. Cong, X. Sun, S. Cheng, Z.H. Nie, Y. Ren, P.K. Liaw, and Y.D. Wang, Acta Mater. 57, 3965 (2009).

R. Blondé, E. Jimenez-Melero, L. Zhao, J.P. Wright, E. Brück, S. Van der Zwaag, and N.H. Van Dijk, Acta Mater. 60, 565 (2012).

P.J. Jacques, Q. Furnémont, F. Lani, T. Pardoen, and F. Delannay, Acta Mater. 55, 3681 (2007).

J. Mu, Z. Zhu, R. Su, Y. Wang, H. Zhang, and Y. Ren, Acta Mater. 61, 5008 (2013).

J. Zhang, S. Hao, D. Jiang, Y. Huan, L. Cui, Y. Liu, H. Yang, and Y. Ren, Acta Mater. 130, 297 (2017).

M. Wiessner, E. Gamsjäger, S. van der Zwaag, and P. Angerer, Mater. Sci. Eng., A 682, 117 (2017).

E. Eidenberger, M. Schober, E. Stergar, H. Leitner, P. Staron, and H. Clemens, Metall. Mater. Trans. A 41, 1230 (2010).

P. Staron, T. Fischer, T. Lippmann, A. Stark, S. Daneshpour, D. Schnubel, E. Uhlmann, R. Gerstenberger, B. Camin, and W. Reimers, Adv. Eng. Mater. 13, 658 (2011).

J.W. Elmer, T.A. Palmer, and E.D. Specht, Metall. Mater. Trans. A 38, 464 (2007).

S. Ackermann, S. Martin, M.R. Schwarz, C. Schimpf, D. Kulawinski, C. Lathe, S. Henkel, D. Rafaja, H. Biermann, and A. Weidner, Metall. Mater. Trans. A 47, 95 (2016).

S.S. Babu, E.D. Specht, S.A. David, E. Karapetrova, P. Zschack, M. Peet, and H. Bhadeshia, Metall. Mater. Trans. A 36, 3281 (2005).

J. Epp, T. Hirsch, and C. Curfs, Metall. Mater. Trans. A 43, 2210 (2012).

F.F. Conde, J.D. Escobar, J.P. Oliveira, A.L. Jardini, W.W. Bose Filho, and J.A. Avila, Addit. Manuf. 29, 100804 (2019).

L. Yuan, D. Ponge, J. Wittig, P. Choi, J.A. Jiménez, and D. Raabe, Acta Mater. 60, 2790 (2012).

S.-H. Mun, M. Watanabe, D.B. Williams, X. Li, K.H. Oh, and H.-C. Lee, Metall. Mater. Trans. A 33, 1057 (2002).

H. Springer, M. Belde, and D. Raabe, Mater. Sci. Eng., A 582, 235 (2013).

H.M. Rietveld, Acta Crystallogr. 20, 508 (1966).

H. Rietveld, J. Appl. Crystallogr. 2, 65 (1969).

T. Roisnel and J. Rodríquez-Carvajal, Mater. Sci. Forum 378, 118 (1999).

R.J. Hill and C.J. Howard, J. Appl. Crystallogr. 20, 467 (1987).

S.S.M. Tavares, M.R. Da Silva, J.M. Neto, J.M. Pardal, M.P.C. Fonseca, and H.F.G. Abreu, J. Alloys Compd. 373, 304 (2004).

G.C.S. Nunes, P.W.C. Sarvezuk, V. Biondo, M.C. Blanco, M.V.S. Nunes, A.M.H. De Andrade, and A. Paesano, Jr. J. Alloys Compd. 646, 321 (2015).

F. Habiby, T.N. Siddiqui, H. Hussain, A.U. Haq, and A.Q. Khan, J. Mater. Sci. 31, 305 (1996).

O. Thuillier, F. Danoix, M. Gouné, and D. Blavette, Scr. Mater. 55, 1071 (2006).

D.V. Edmonds, K. He, F.C. Rizzo, B.C. De Cooman, D.K. Matlock, and J.G. Speer, Mater. Sci. Eng., A 438, 25 (2006).

E.I. Galindo-Nava, W.M. Rainforth, and P.E.J. Rivera-Díaz-del-Castillo, Acta Mater. 117, 270 (2016).

J.M. Rosenberg and H.R. Piehler, Metall. Trans. 2, 257 (1971).

G.I. Taylor, J. Inst. Met. 62, 307 (1938).

P. Van Houtte, S. Li, M. Seefeldt, and L. Delannay, Int. J. Plast 21, 589 (2005).

J.G. Speer, D.V. Edmonds, F.C. Rizzo, and D.K. Matlock, Curr. Opin. Solid State Mater. Sci. 8, 219 (2004).

F. Qian and W.M. Rainforth, J. Mater. Sci. 54, 6624 (2019).

S. Kundu, Transformation strain and crystallographic texture in steels, Ph.D. Thesis, University of Cambridge (2007).

Acknowledgements

Experimental support of Mr. F.E. Montoro, Dr. O.R. Bagnato and Dr. A.L. Gobbi (Projects SEM 21795 and LMF 20869) at Brazilian Nanotechnology National Laboratory-LNNano is acknowledged. Microstructural characterization was performed at the Analytical Centre-UFC/CT-INFRA/MCTI-SISNANO/Pró-Equipamentos CAPES and LNNano. The authors acknowledge the Brazilian Synchrotron Light Laboratory-LNLS for the use of the XTMS installation at the XRD-1 beamline. This study used the resources of the Brazilian Synchrotron Light Laboratory (Project 20170162), an open national facility operated by the Brazilian Center for Research in Energy and Materials for the Brazilian Ministry for Science, Technology, Innovations and Communications. This work was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Finance Code 001 and Conselho Nacional de Desenvolvimento Científico e Tecnológico-CNPq.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

dos Santos, L.P.M., Béreš, M., de Castro, M.O. et al. Kinetics of Reverted Austenite in 18 wt.% Ni Grade 300 Maraging Steel: An In-Situ Synchrotron X-Ray Diffraction and Texture Study. JOM 72, 3502–3512 (2020). https://doi.org/10.1007/s11837-020-04254-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04254-w