Abstract

In hot and humid climates, the evaporative cooling system not works effectively. To reduce the relative humidity of inlet air, the reciprocating desiccant mesh (RDM) is introduced before the cooling tower. The cooling tower is fabricated as per the Merkel’s theory and RDM is placed before the cooling tower. Experiments have been conducted to compare the performance of normal and RDM cooling towers at different operating conditions. The results of this study indicate that the most favorable velocity and water flow rate of the RDM cooling tower are 1.8 m/s and 17.3 L/min, respectively. At this condition, the cooling effect of the RDM cooling tower is 1.6°C greater than the normal cooling tower. Further, the maximum effectiveness of normal and RDM cooling tower are 0.72 and 0.82, respectively. At last, this study recommends that the RDM cooling tower reduces water consumption as compared to the normal cooling tower due to the lower temperature of cold water.

Similar content being viewed by others

Abbreviations

- RH:

-

Relative humidity

- RDM:

-

Reciprocating desiccant

- WBT:

-

Wet-bulb temperature

- DBT:

-

Dry bulb temperature

- ETC:

-

Evacuated tube collector

- EF:

-

Exhaust fan

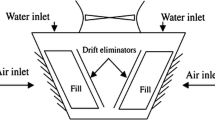

- DE:

-

Drift Eliminator

- Symbol:

-

Description Units

- w r :

-

Resultant uncertainty –

- \( \dot{G} \) :

-

Mass flow rate of air in cooling kg/s

- \( \dot{W} \) :

-

Mass flow rate of liquid water in cooling tower kg/s

- T G2 :

-

Temperature of air at the exit of cooling tower °C

- T G1 :

-

Temperature of air at the inlet of cooling tower °C

- T W2 :

-

Temperature of water at the exit of cooling tower °C

- T W1 :

-

Temperature of water at the inlet of cooling tower °C

- \( {Y}_2^{\prime } \) :

-

Humidity ratio of air at the exit of cooling tower kg/kg

- \( {Y}_1^{\prime } \) :

-

Humidity ratio of air at the inlet of cooling towerkg/kg

- Y sat :

-

Humidity ratio at saturated conditionkg/kg

- H 2 :

-

Enthalpy of air at the exit of cooling towerkJ/kg

- H 1 :

-

Enthalpy of air at the inlet of cooling towerkJ/kg

- H W1 :

-

Enthalpy of water at the inlet of cooling towerkJ/kg

- H W2 :

-

Enthalpy of water at the exit of cooling towerkJ/kg

- c wl :

-

Specific heat of liquid water kJ/kg K

- c pg :

-

Specific heat of airkJ/kg K

- ∆H vap :

-

Enthalpy of vapourizationkJ/kg

- C min :

-

Minimum heat capacityKJ/K

- k y :

-

Mass transfer coefficientkg/m2s

- a :

-

Perimeter of control volume dzm

- h c :

-

Convective heat transfer coefficientW/m2K

- \( {\dot{m}}_{cwr} \) :

-

Mass flow rate of water consumed in the condenserkg/h

- ρ avg. water :

-

Average density of waterkg/m3

- \( \dot{E} \) :

-

Evaporation losskg/h

- H tg :

-

Height of enthalpy gas transfer unitvm

- N tg :

-

Number of enthalpy gas transfer unit–

- z:

-

Height of packing sectionm

- H sat :

-

Enthalpy of air at the saturated conditionkJ/kg

- \( {\dot{m}}_s \) :

-

Mass flow rate of steam in the condenser kg/s

- p cond :

-

Saturation condenser pressurebar

- ∆T max :

-

Temperature difference between the saturation temperature of steam at condenser and inlet water temperature (outlet water temperature of cooling tower) of the shell and tube heat exchanger°C

- NCT:

-

Normal cooling tower

- RDMCT:

-

Reciprocating desiccant mesh cooling tower

References

Merkel F (1925) “Evaporative cooling”, Z. Verein Deutsch Ingen (VDI) 70:123–128

Jaber, Webb.(1989). “Design of cooling tower by effectiveness NTU method”,J Heat Transf ,doi:https://doi.org/10.1115/1.3250794

Deziani M, Rahmani K, Raoudaki SJ, Kordloo M (2017) Feasibility study for reducing water evaporative loss in a power plant cooling tower by using air to air heat exchanger with auxiliary fan. Desalination 406(16):119–124

Naik BK, Muthukumar P (2017) A novel approach for performance assessment of mechanical draft wet cooling towers. Applied Thermal Engineering 121(5):14–26

Pedraza OJG, Ibara JJP, Maya CR, Gonzalez SRG, Arista JAR (September 2018) Numerical study of the drift and evaporation of water droplets cooled down by a forced stream of air. Appl Therm Eng 142:292–302

Hassazadeh, R. And Khalili, M., “Replacing the wet cooling tower with a ground source heat exchanger as a clean technology”, Journal of Building and Engineering, Volume 18, 2018, Pages 331–342

Jani DB, Mishra M, Sahoo PK (2015) Performance studies of hybrid solid desiccant–vapour-compression air-conditioning system for hot and humid climates. Energy and Buildings 102(1):284–292

Elgendy E, Mostafa A, Fatouh M (2015) Performance enhancement of a desiccant evaporative cooling system using direct/indirect evaporative cooler. Int J Refrig 51:77–87

Gadala M, Saghafifer M (2016) Performance assessment and transient optimization of air pre-cooling in multi-stage solid desiccant air conditioning systems. Energy Conversion and Management 119(1):187–202

Hwang WB, Choi S, Lee DY (2017) In-depth analysis of the performance of hybrid desiccant cooling system incorporated with an electric heat pump. Energy 118(1):324–332

Chaudhary, G.Q., Ali, M., Seikh, N.A., Gilani, S.I. and Khushnood, S., “Integration of solar-assisted solid desiccant cooling system with an efficient evaporative cooling technique for separate load handling”, Appl Therm Eng, https://doi.org/10.1016/j.applthermaleng.2018.05.081

Heidari A, Roshendel, Vakiloroaya V et al (2019) An innovative solar-assisted desiccant-based evaporative cooling system for co-production of water and cooling in hot and humid climates. Energy Convers Manag 185:396–409

Banooni, Chitsazan (2014) Economic and Technical Assesment of Desiccant Wheel Effect on the Thermal Performance of Cross Flow Cooling Towers in Variable Wet-bulb Temperature. Heat Mass Transfer 50:1587–1596. https://doi.org/10.1007/s00231-014-1360-y

Gilani, N, Hendijani, AD, Shirmohammadi, Reza. “Developing of novel water efficient configuration for shower cooling tower integrated with the liquid desiccant cooling system, applied thermal engineering, Accepted Manuscript, https://doi.org/10.1016/j.applthermaleng.2019.03.043

Raj, G, Chandra, P, Pathak, PK, (2019). “Experimental and thermal analysis of energy efficient novel design wet cooling towers, Heat Transfer Asian Research, DOI: https://doi.org/10.1002/htj.21533

Mishra, B, Srivastava, A, Yadav, L. “Performance analysis of cooling tower using desiccant, heat and mass transfer, https://doi.org/10.1007/s00231-019-02759-y, Accepted Manuscript

Web 1: https://nptel.ac.in/courses/103103035/37

Holman, JP, (1994). Experimental methods for engineers, eighth edition

Green, DW and Perry, RH, (2008). Perry’s chemical engineers handbook, Eighth Edition

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sanjay, Verma, A.K., Prasad, A.K. et al. Performance analysis of counter flow cooling tower using reciprocating desiccant mesh. Heat Mass Transfer 56, 2779–2799 (2020). https://doi.org/10.1007/s00231-020-02912-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02912-y