Abstract

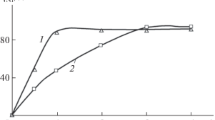

The hydrometallurgical processing of industrial converter mattes with the copper-to-nickel concentration ratios (Ni : Cu) of 2 : 1 and 3 : 4 is studied in order to demonstrate the advantages of hydrometallurgical processing methods, which can improve the environment and increase the number of important components extracted from raw materials. The results obtained indicate the possibility of direct leaching of the converter mattes with different copper and nickel contents under atmospheric conditions. During leaching, the extraction of to 94–95% nickel into a solution takes place; the solution is subjected to electroextraction; and the solid residue (copper cake) contains to 95% copper of its initial content in the converter matte. A high copper content in the converter matte is found to decrease the extraction of nickel into the solution.

Similar content being viewed by others

REFERENCES

I. F. Khudyakov, A. I. Tikhonov, V. I. Deev, and S. S. Naboichenko, Metallurgy of Copper, Nickel, and Cobalt (Metallurgiya, Moscow, 1976), pp. 59–76.

I. D. Reznik, G. P. Ermakov, and Ya. M. Shneerson, in Nickel (Nauka Tekhnol., Moscow, 2003), Vol. 3, pp. 276–398.

A. G. Ryabko, G. I. Grodinskii, and B. F. Serebryakov, “Study of the Cu–Cu2S–NiS–Ni system,” Izv. Vyssh. Uchebn. Zaved. Tsvetn. Metall., No. 4, 23–26 (1980).

G. Kallerud, “Cu–Ni–S system,” in Experimental Petrology and Mineralogy, Papers of Geophysical Carnegie Institute (Nedra, Moscow, 1962–1963), Vol. 62, p. 155.

M. N. Naftal, S. S. Naboichenko, R. Yu. Sharkii, A. F. Petrov, and N. A. Lapshina, “Increase in the extraction of nickel and platinum-group metals in the technology of autoclave-oxidation leaching of nickel pyrrhotite concentrates,” Tsvetn. Met., No. 9, 100–113 (2013).

V. A. Distler, “Petrological and geochemical regularities of the formation of platinum-containing copper–nickel ores,” Extended Abstract of Doctoral (Geol.-Mineral.) Dissertation, IGEM AN SSSR, Moscow, 1985.

V. F. Borbat, Metallurgy of Platinum Metals (Metallurgiya, Moscow, 1977).

A. G. Ryabko, N. I. Solovov, Yu. A. Karasev, and A. F. Ivanova, Optimization of Cooling Process of Copper–Nickel Converter mattes. New Directions in Pyroprocessing of Nickel (Gipronikel, Leningrad, 1980), Vol. 16, pp. 56–61.

S. S. Naboichenko, L. P. Ni, Ya. M. Shneerson, and L. V. Chugaev, AutoclaveHydrometallurgy of Nonferrous Metals (GOU UGTU-UPI, Yekaterinburg, 2001).

A. V. Vydysh, M. N. Naftal, and A. F. Petrov, “Chemism and regularities of oxidation of sulfur in sulfides in leaching technology of high-copper converter matte,” Tsvetn. Met., No. 12, 37–41 (2005).

L. V. Volkov, “Electrolysis of nickel as the final operation of technological processing schemes of nickel raw,” Tsvent. Met., No. 7, 84 (2003).

G. P. Miroevskii, I. O. Popov, and A. N. Golov, “Main ways to optimize the processing technology of copper–nickel converter mattes in the Severonikel Complex,” Byull. Tsvetn. Metall., Nos. 2–3, 1–4 (2001).

“New nickel process increasing production at Outokumpu Harjavalta Metals Oy (Finland),” in Proceedings of ALTA 1997 Nickel/Cobalt Pressure Leaching and Hydrometallurgy Forum (Perth, 1997).

M. N. Naftal, R. D. Shestokova, T. V. Galantseva, A. F. Petrov, and A. L. Kozhanov, “Peculiarities of leaching technology of high-copper converter matte,” Tsvetn. Met., No. 6, 44–49 (2000).

Funding

This work was performed in terms of state assignment no. 007-00129-18-00.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Bol’shikh, A.O., Tsybin, O.I., Bol’shikh, M.A. et al. Substantiation of the Possibility of Hydrometallurgical Processing of a Copper–Nickel Converter Matte. Russ. Metall. 2020, 718–722 (2020). https://doi.org/10.1134/S0036029520070034

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520070034