Abstract

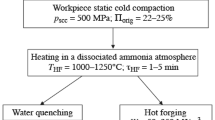

Rolling bearing rings comprise a large reserve for expanding powder metallurgy production. This reserve is being incompletely implemented. The hot forging of porous preforms makes it possible to produce high-density materials for the fabrication heavy loaded wares, in particular, rolling bearing rings. The problem of fabricating hot-forged bearing rings is associated with the presence of a large amount of impurities in the initial powders, as well as with residual one-side open pores and microcracks in the surface layer of parts caused by cooling a heated porous preform when performing operations of a hot repressing process. The possibility of improving the mechanical properties and rolling contact endurance of hot-forged steels of a eutectoid composition fabricated based on the chromium–molybdenum iron powder, as well as unalloyed iron powders with different impurity contents due to sodium microalloying, is considered. Sodium is introduced in the form of bicarbonate. To decrease the oxidation probability of a heated porous preform during hot forging (HF), the previously proposed method of fabricating the high-density iron-based chromium-containing powder material is used. This method foresees the formation of cold-pressed preforms with porosity of 10–12%, their sintering in a vacuum furnace, and subsequent HF. To determine the mechanical properties and perform the structural analysis, prismatic samples 10 × 10 × 55 mm in size are fabricated. The rolling contact endurance is investigated using cylindrical samples ∅26 × 6 mm. The tests are performed by rolling flat surfaces of cylindrical samples by balls. The introduction of Na microadditives makes it possible to substantially increase the rolling contact endurance of powder steels when compared with unalloyed samples, as well as with respect to test samples made of thermally treated steel ShKh15, which is caused by a decrease in the austenite grain size, increase in quality of interparticle intergrowth, and decrease in surface porosity. Carbon powder steels containing the optimal amount of sodium microadditive (0.2 wt %) can be used when fabricating structural products operating under contact loads.

Similar content being viewed by others

REFERENCES

Kuhn, H.A. and Ferguson, B.L., Powder Forging, Princeton, NJ: Metal Powder Industries Federation, 1990.

Selecká, M. and Šalak, A., Durability and failure of powder forged rolling bearing rings, Wear, 1999, vol. 236, no. 1, pp. 47–54.

Dorofeev, B.Yu., Dorofeev, V.Yu., and Atras, A.N., Powder parts from waste sludge of bearing production, Avtomob. Prom-st., 1988, no. 4, pp. 32–34.

Orlov, A.V., Chermenskii, O.N., and Nesterov, V.M., Ispytaniya konstruktsionnykh materialov na kontaktnuyu ustalost' (Tests of Structural Materials for Rolling Contact Fatigue), Moscow: Mashinostroenie, 1980.

Huppmann, W.J. and Hirschvogel, M., Powder forging, Int. Met. Rev., 1978, no. 5, pp. 209–239.

Dorofeev, Yu.G., Gasanov, B.G., Dorofeev, V.Yu., Mishchenko, V.N., and Miroshnikov, V.I., Promyshlennaya tekhnologiya goryachego pressovaniya poroshkovykh izdelii (Industrial Technology for Hot Pressing of Powder Products), Moscow: Metallurgiya, 1990.

Moghaddam, S.M. and Sadeghi, F., A review of microstructural alterations around nonmetallic inclusions in bearing steel during rolling contact fatigue, Tribol. Trans., 2016, vol. 59, no. 6, pp. 1142–1156.

Prucher, T., Fatigue life as a function of the mean free path between inclusions, Proc. Int. Conference “Modern Developments in P/M”, Orlando, FL, June 5–10,1988, Princeton, NJ: Metal Powder Industries Federation, 1988, vol. 18, pp. 143–154.

Strafellini, G., Marcupuscas, T., and Molinari, A., Identification of rolling-sliding damage mechanisms in porous alloys, Metall. Mater. Trans. A, 2000, vol. 31, no. 12, pp. 3091–3099.

Chernenkoff, R. and Lani, G., Rolling contact fatigue evaluation of high strength powder forgings for roller bearing applications, Proc. Int. World PM-2010: Powder Metallurgy Congress and Exhibition (Florence, October 10–14, 2010), European Powder Metallurgy Association, 2010, pp. 86–87.

Kawai, N., Notomi, K., and Furuta, S., Rolling contact fatigue property of powder forged parts, Met. Powder Rep., 1987, vol. 42, no. 11, pp. 798–800.

D’yachkova, L.N., Kerzhentseva, L.F., and Markova, L.V., Poroshkovye materialy na osnove zheleza (Iron-Based Powder Materials), Minsk: Tonpik, 2004.

Zvonarev, E.V., D’yachkova, L.N., Kerzhentseva, L.F., and Shidlovskaya, S.I., Microalloying with alkali metals of powder materials based on iron, Met. Sci. Heat Treat., 1991, vol. 33, no. 8, pp. 612–616.

D’yachkova, L.N. and Kerzhentseva, L.F., Activating the sintering process of powder carbon steels, Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokrytiya, 2012, no. 4, pp. 32–37.

D’yachkova, L.N. and Dechko, M.M., Influence of dispersed micro-additives on the structure and properties of powder carbon and high-chromium steels, Russ. J. Non-Ferrous Met., 2016, vol. 57, no. 5, pp. 477–483.

Powder Metallurgy. Applications, Advantages and Limitations, Klar, E., Ed., Metals Park, OH: American Society for Metals, 1983.

Lindqvist, B., Chromium alloyed steels—a new powder generation, Proc. European Congress and Exhibition on Powder Metallurgy EURO PM-2001, Nice, October 22–24,2001, European Powder Metallurgy Association, 2001, vol. 1, pp. 13–21.

Höganäs Handbook for Sintered Components. Iron and Steel Powders for Sintered Components, Höganäs AB, 2002.

Karlsson, H., Nyborg, L., Berg, S., and Yu, Y., Surface product formation on chromium alloyed steel powder particles, Proc. European Congress and Exhibition on Powder Metallurgy EURO PM-2001, Nice, October 22–24,2001, European Powder Metallurgy Association, 2001, vol. 1, pp. 22–27.

Heikkilä, I., Eggertson, C., Randelius, M., Caddeo-Johansson, S., and Chasoglou, D., First experiences on characterization of surface oxide films in powder particles by Glow Discharge Optical Emission Spectroscopy (GD-OES), Met. Powder Rep., 2016, vol. 71, no. 4, pp. 261–264.

Larsson, C. and Engström, U., High performance sinter-hardening materials for synchronizing hubs, Powder Metall., 2012, vol. 55, no. 2, pp. 88–91.

Hryha, E. and Nyborg, L., Effectiveness of reducing agents during sintering of Cr-prealloyed PM steels, Powder Metall., 2014, vol. 57, no. 4, pp. 245–250.

Svistun, L.I. and Sviridova, A.N., RF Patent 2588979, 2016.

Dorofeev, Yu.G., Work of densification of porous materials during compaction, Sov. Powder Metall. Met. Ceram., 1967, vol. 6, no. 3, pp. 178–182.

Bernshtein, M.L., Dobatkin, S.V., Kaputkina, L.M., and Prokoshkin, S.D., Diagrammy goryachei deformatsii, struktura i svoistva stalei. Spravochnoe izdanie (Diagrams of Hot Deformation, Structure and Properties of Steel. Handbook), Moscow: Metallurgiya, 1989.

ACKNOWLEDGMENTS

We thank Höganäs East Europe for providing iron powders produced by Höganäs АB.

Funding

This study was supported by the Russian Scientific Foundation, project no. 19-08-00107 A. Photographs using a Quanta 200 i 3D scanning microanalyzer microscope were recorded at the Nanotechnology Joint Use Center at the Platov South Russian State Polytechnic University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Dorofeyev, V.Y., Sviridova, A.N. & Svistun, L.I. Influence of Sodium Microalloying on Rolling Contact Endurance and Mechanical Properties of Hot-Deformed Powder Steels. Russ. J. Non-ferrous Metals 61, 354–361 (2020). https://doi.org/10.3103/S1067821220030062

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030062