Abstract

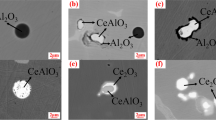

The effect of the structure of the initial charge density in liquid and solid states, as well as on the temperature–time parameters of the process of solidification of the AK6M2 alloy (Al–6% Si–2% Cu), is shown. To obtain a coarse-crystal charge (C charge), part of the melt is crystallized in ceramic forms in a sand backfill with a cooling rate of ~0.5–1.0°C/s. The fine-crystal charge (F charge) in the form of thin ingots weighing 0.2–0.3 kg is obtained by crystallization of the melt in cast-iron cold molds with ~5.0–10°C/s. Further, the charge billets are separately melted, re-refined and degassed, and the samples are poured to determine the gas content and density in the liquid (dL) and solid (dS) states. It is established that structural information from the original charge of the alloy is stable in the solid–liquid–solid system. Direct thermal analysis is used to find that the melt obtained from the F charge hardens at low temperatures: the decrease in liquidus temperature tL is 3°C; the temperature of the beginning of solidification of the eutectic is reduced by 10°C, and the temperature of the end of solidification of a eutectic is 3°C in comparison with the melt of the C charge. At the same time, the formation of α-Al and eutectic dendrites in the melt from the F charge occurs 0.4 and 0.6 min more quickly, respectively. The results obtained on the Paraboloid-4 installation show that a smaller number of pulses throughout the studied temperature range passes through the melt from the F charge, which confirms its increased density when compared to the alloy from the C charge. Thus, for the melt from the F charge, the values of the degrees of compaction were –ΔJl ~ 278.66 and –ΔJe ~ 129.83 imp/s and, for the melt from the C charge, –ΔJl ~ 302.9 and –ΔJe ~ 163.47 imp/s. The values of the phase-transition temperatures determined by anomalies on the temperature dependence Jt practically coincide with the results of direct thermal analysis. The main technological recommendations of management by structural information in aluminum alloys are formulated from the position of the phenomenon of structural heredity.

Similar content being viewed by others

REFERENCES

Nappi, C., The Global Aluminium Industry 40 Years from 1972, World Aluminium, 2013. http://www.worldaluminium.org/media/filer_public/2013/02/25/an_ outlook_of_the_global_aluminium_industry_1972_–_present_day.pdf.

Dudin, M.N., Voykova, N.A., Frolova, E.E., Artemieva, J.A., Rusakova, E.P., and Abashidze, A.H., Modern trends and challenges of development of global aluminum industry, Metalurgija, 2017, vol. 56, pp. 255–258.

Djurdjević, M.B., Odanović, Z., and Pavlović-Krstić, J., Melt quality control at aluminum casting plants, Metall. Mater. Eng., 2010, vol. 16, pp. 63–76.

McCartney, D.G., Grain refining of aluminium and its alloys using inoculants, Int. Mater. Rev., 1989, vol. 34, no. 5, pp. 247–260.

Murty, B.S., Kori, S.A., and Chakraborty, M., Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying, Int. Mater. Rev., 2002, vol. 47, no. 1, pp. 3–29.

Nikitin, V.I. and Nikitin, K.V., Nasledstvennost’ v litykh splavakh (Heredity in Cast Alloys), Moscow: Mashinostroenie-1, 2005.

Nikitin, K.V., Nikitin, V.I., and Timoshkin, I.Yu., Upravlenie kachestvom litykh izdelii iz alyuminievykh splavov na osnove yavleniya strukturnoi nasledstvennosti (Quality Control of Cast Products from Aluminum Alloys Based on the Phenomenon of Structural Heredity), Moscow: Radunitsa, 2015.

Selyanin, I.F., Deev, V.B., and Kukharenko, A.V., Resource-saving and environment-saving production technologies of secondary aluminum alloys, Russ. J. Non-Ferrous Met., 2015, vol. 56, no. 3, pp. 272–276.

Deev, V.B., Poluchenie germetichnykh alyuminievykh splavov iz vtorichnykh materialov (Fabrication of Sealed Aluminum Alloys from Recycled Materials), Moscow: Flinta-Nauka, 2006.

Sigworth, G.K., The modification of Al-Si casting alloys: Important practical and theoretical aspects, Int. J. Metalcast., 2008, vol. 2, no. 2, pp. 19–40.

Rathod, N.R. and Manghani, J.V., Effect of modifier and grain refiner on cast Al–7Si aluminum alloy: A review, Int. J. Emerging Trends Eng. Dev., 2012, vol. 5, no. 2, pp. 574–581.

Faraji, M. and Katgerman, L., Grain refinement and modification in hypoeutectic Al–Si alloys, Foundry Trade J., 2010, vol. 184, pp. 315–318.

Fang, Q. and Granger, D., Porosity formation in modified and unmodified A356 alloy castings, AFS Trans., 1989, no. 97, pp. 989–1000.

Zhang, J., Chen, H., Yu, H., and Jin, Y., Study on dual modification of Al–17% Si alloys by structural heredity, Metals, 2015, no. 5, pp. 1112–1126.

Xu, H., Jiana, X., Meek, T., and Han, Q., Degassing of molten aluminum A356 alloy using ultrasonic vibration, Mater. Lett., 2004, vol. 58, pp. 3669–3673.

Jian, X., Meek, T.T., and Han, Q., Refinement of eutectic silicon phase of aluminum A356 alloy using high-intensity ultrasonic vibration, Scr. Mater., 2006, vol. 54, no. 5, pp. 893–896.

Mizutani, Y., Miwa, K., Yasue, K., Tamura, T., Sakaguchi, Y., and Ohura, Y., Effect of the electromagnetic vibration intensity on microstructural refinement of Al–7% Si alloy, Mater. Trans., 2004, vol. 45, no. 6, pp. 1944–1948.

Mizutani, Y., Miwa, K., Yasue, K., Tamura, T., Sakaguchi, Y., and Kawai, S., Effect of the intensity and frequency of electromagnetic vibrations on refinement of primary silicon in Al–17%Si alloy, Mater. Trans., 2004, vol. 45, no. 6, pp. 1939–1943.

Donii, O., Narizhna, T., Voron, M., and Berest, D., Influence of the external magnetic field on the structure and properties of the hypereutectic aluminum-silicon alloy, Mater. Sci. Non-Equilib.Phase Transform., 2018, vol. 4, no. 3, pp. 79–82.

Brodova, I.G., Popel, P.S., and Eskin, G.I., Liquid Metal Processing: Application to Aluminium Alloy Production, New York, London: Gordon and Breach, 2004.

Quested, P., Morrell, R., Dinsdale, A., and Chapman, L., The measurement and estimation of density for selected liquid alloys, Proc. 6-th Decennial Int. Conference on Solidification Processing, Old Windsor, July 25–28,2017, Liquid Metal Engineering Hub, 2017, pp. 1–5.

Nikitin, K.V., Finkel’shtein, A.B., Chikova, O.A., and Timoshkin, I.Yu., Influence of the structure of the AlSi20 foundry alloy on the microstructure and viscosity of the Al-6% Si model silumin in solid and liquid states, Russ. J. Non-Ferrous Met., 2013, vol. 54, no. 4, pp. 314–319.

Nikitin, K.V., Nikitin, V.I., Timoshkin, I.Yu., Krivopalov, D.S., and Chernikov, D.G., Hereditary influence of the structure of charge materials on the density of aluminum alloys of the Al-Si system, Russ. J. Non-Ferrous Met., 2015, vol. 56, no. 1, pp. 20–25.

Nikitin, K.V., Nikitin, V.I., Timoshkin, I.Yu., Krivopalov, D.S., and Chernikov, D.G., Influence of the structure of charge billets, overheating, and holding time of melts on the properties of Al–5 wt % Cu alloys in liquid and solid states, Russ. J. Non-Ferr. Met., 2015, vol. 56, no. 2, pp. 165–170.

Ri, E.H., Ri, Hosen, Dorofeev, S.V., and Yakimov, V.I., Vliyanie oblucheniya zhidkoi fazy nanosekundnymi elektromagnitnymi impul’sami na ee stroenie, protsessy kristallizatsii, strukturoobrazovaniya i svoistva liteinykh splavov (Influence of Irradiation of Liquid Phase by Nanosecond Electromagnetic Pulses on its Structure, Crystallization Processes, Structure Formation and Properties of Casting Alloys), Vladivostok: Dal’nauka, 2008.

Girshovich, N.G. and Nekhendzi, Yu.A., Solidification of castings, Zatverdevanie metallov, Trudy 2-ogo sove-shchaniya po teorii liteinykh protsessov (Solidification of Metals, Proc. 2nd Conference on the Theory of Casting Processes), Moscow: Mashgiz, 1958, pp. 39–90.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

About this article

Cite this article

Nikitin, K.V., Nikitin, V.I. & Timoshkin, I.Y. Hereditary Effect of the Structure of the Charge on Density, Gas Content, and Processes of Solidification of an Al–Si–Cu Alloy System. Russ. J. Non-ferrous Metals 61, 265–270 (2020). https://doi.org/10.3103/S1067821220030104

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030104