Abstract

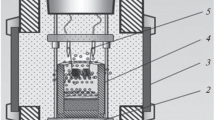

It is known that materials based on MAX phases possess a large potential for use in aerospace, automobile, and industrial spheres because they have a unique combination of features of both metals and ceramics with high mechanical, chemical, thermal, and electrical properties. In this work, the experimental results of fabricating cast materials in the Cr–Al–C system with different ratios between the Cr2AlC MAX phase and chromium aluminides and carbides by SHS metallurgy are presented. The experiments were performed in an SHS reactor 3 L in volume at an initial inert gas (argon) pressure of 5 MPa. The synthesis was performed based on chemically coupled reactions: weakly exothermic (heat acceptor)—Cr2O3/3Al/C and strongly exothermic (heat donor)—3CaO2/2Al. The experimental results have good correlation with the preliminary thermodynamic calculations. It is shown that, when varying the composition of initial mixtures, it is possible to substantially affect the calculated and experimental synthesis parameters, as well as the phase composition and microstructure of final products. Optimal synthesis conditions of the material providing the maximal yield of the Cr2AlC phase in the ingot composition are established. The determining factor affecting the Cr2AlC content in the product is the occurrence time of the liquid phase under the synthesis conditions. It is shown that the maximal content of the Cr2AlC MAX phase and target product yield are attained at the 30% content of the strongly exothermic additive (3CaO2/2Al) in the initial charge.

Similar content being viewed by others

REFERENCES

Barsoum, M.W., MAX Phases: Properties of Machinable Ternary Carbides and Nitrides, Weinheim: Wiley-VCH, 2013.

Radovic, M. and Barsoum, M.W., MAX phases: Bridging the gap between metals and ceramics, Am. Ceram. Soc. Bull., 2013, vol. 92, no. 3, pp. 20–27.

Barsoum, M.W. and Radovic, M., Elastic and mechanical propertiesof the MAX phases, Annu. Rev. Mater. Res., 2011, vol. 41, no. 1, pp. 195–227.

Barsoum, M. and El-Raghy, T., The MAX phases: Unique new carbide and nitride materials, Am. Sci., 2001, vol. 89, no. 4, pp. 336–345.

Poon, B., Ponson, L., Zhao, J., and Ravichandran, G., Damage accumulation and hysteretic behavior of MAX phase materials, J. Mech. Phys. Solids, 2011, vol. 59, no. 10, pp. 2238–2257.

Atikur Rahman, M. Study on structural, electronic, optical and mechanical properties of MAX phase compounds and applications: Review, Am.J. Mod. Phys., 2015, vol. 4, no 2, pp. 75–91.

Li, H., Li, S., and Zhou, Y., Cyclic thermal shock behavior of a Cr2AlC ceramic, Mater. Sci. Eng., A, 2014, vol. 607, pp. 525–529.

Tian, W.B., Wang, P.L., Kan, Y.M., Zhang, G.J., Li, Y.X., and Yan, D.S., Phase formation sequence of Cr2AlC ceramics starting from Cr–Al–C powders, Mater. Sci. Eng., A, 2007, vol. 443, nos. 1–2, pp. 229–234.

Xiao, L.O., Li, S.B., Song, G., and Sloof, W.G., Synthesis and thermal stability of Cr2AlC, J. Eur. Ceram. Soc., 2011, vol. 31, no. 8, pp. 1497–1502.

Duan, X., Shen, L., Jia, D., Zhou, Y., van der Zwaag, S., and Sloof, W.G., Synthesis of high-purity, isotropic or textured Cr2AlC bulk ceramics by spark plasma sintering of pressure-less sintered powders, J. Eur. Ceram. Soc., 2015, vol. 35, no. 5, pp. 1393–1400.

Panigrahi, B.B., Chu, M.-C., Kim, Y.-Il., Cho, S.-J., and Gracio, J.J., Reaction synthesis and pressureless sintering of Cr2AlC powder, J. Am. Ceram. Soc., 2010, vol. 93, no. 6, pp. 1530–1533.

Tian, W., Vanmeensel, K., Wang, P., Zhang, G., Li, Y., Vleugels, J., and Van der Biest, O., Synthesis and characterization of Cr2AlC ceramics prepared by spark plasma sintering, Mater. Lett., 2007, vol. 61, no. 22, pp. 4442–4445.

Merzhanov, A.G., The chemistry of self-propagating high-temperature synthesis, J. Mater. Chem., 2004, vol. 14, no. 12, pp. 1779–1786.

Levashov, E.A., Mukasyan, A.S., Rogachev, A.S., and Shtansky, D.V., Self-propagating high-temperature synthesis of advanced materials and coatings, Int. Mater. Rev., 2017, vol. 62, no. 4, pp. 203–239.

Łopaciński, M., Puszynski, J., and Lis, J., Synthesis of ternary titanium aluminum carbides using self-propagating high-temperature synthesis technique, J. Am. Ceram. Soc., 2001, vol. 84, no. 12, pp. 3051–3053.

Zhu, C.-C., Zhu, J., Wu, H., and Lin, H., Synthesis of Ti3AlC2 by SHS and thermodynamic calculation based on first principles, Rare Met., 2015, vol. 34, no. 2, pp. 107–110.

Konovalikhin, S.V., Kovalev, D.Y., Sytschev, A.E., Vadchenko, S.G., and Shchukin, A.S., Formation of nanolaminate structures in the Ti–Si–C system: A crystallochemical study, Int. J. Self-Propag. High-Temp. Synth., 2014, vol. 23, no. 4, pp. 217–221.

Yukhvid, V.I., High-temperature liquid-phase SHS processes: New trends and missions, Izv. Vyssh. Uchebn. Zaved.,Tsvetn. Metall., 2006, vol. 5, pp. 62–78.

Levashov, E.A., Rogachev, A.S., Kurbatkina, V.V., Maksimov, Yu.M., and Yukhvid, V.I., Perspektivnye materialy i tekhnologii samorasprostranyayushchegosya vysokotemperaturnogo sinteza (Promising Materials and Technologies for Self-Propagating High-Temperature Synthesis), Moscow: National Univ. of Science and Technology MISiS, 2011.

Gorshkov, V.A., Miloserdov, P.A., Luginina, M.A., Sachkova, N.V., and Belikova, A.F., High-temperature synthesis of a cast material with a maximum content of the MAX phase Cr2AlC, Inorg. Mater., 2017, vol. 53, no. 3, pp. 271–277.

Gorshkov, V.A., Miloserdov, P.A., Sachkova, N.V., Luginina, M.A., and Yukhvid, V.I., SHS metallurgy of Cr2AlC MAX phase-based cast materials, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 5, pp. 570—575.

Gorshkov, V.A., Miloserdov, P.A., Karpov, A.V., Shchukin, A.S., and Sytschev, A.E., Investigation of the composition and properties of a Cr2AlC MAX phase-based material prepared by metallothermic SHS, Phys. Met. Metallogr., 2019, vol. 120, no. 5, pp. 471–475.

Merzhanov, A.G. and Khaikin, B.I., Theory of combustion waves in homogeneous media, Prog. Energy Combust. Sci., 1988, vol. 14, no. 1, pp. 1–98.

Merzhanov, A.G., Thermally coupled processes of self-propagating high-temperature synthesis, Dokl. Phys. Chem., 2010, vol. 434, no. 2, pp. 159–162.

Shiryaev, A., Thermodynamics of SHS processes: An advanced approach, Int. J. Self-Propag. High-Temp. Synth., 1995, vol. 4, no. 4, pp. 351–362.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare to have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Gorshkov, V.A., Miloserdov, P.A., Khomenko, N.Y. et al. Production of Cast Materials Based on the Cr2AlC MAX Phase by SHS Metallurgy Using Coupled Chemical Reactions. Russ. J. Non-ferrous Metals 61, 362–367 (2020). https://doi.org/10.3103/S1067821220030086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220030086