Abstract

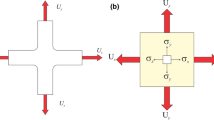

Cruciform flat specimen is mostly used to investigate experimentally the in-plane biaxial mechanical behavior of sheet metals. In this study, a modified cruciform specimen design is proposed and validated against the performance of current standard design. The existing standard cruciform specimen prepared through laser cutting for sheet metal can accurately provide biaxial stress–strain curve through biaxial tensile test by ensuring superior homogeneous stress and strain field in gauge section. However, preparation of such specimen using laser cut is cumbersome, expensive and prone to errors. The current standard cruciform specimen design features slotted arm of fixed length and width with specific gauge. Few other designs also feature reduced gauge section to localize failure. Both need high precision of laser cutting and machining to prepare specimens which can achieve biaxial stress–strain curve for more than 4% equivalent plastic strain level. The proposed specimen design features running slits in all four arms of specimen with uniform gauge section machined using electrical discharge machining (EDM) owing to higher accuracy and minimum heat-affected zone (HAZ). This technique also avoids machining effects with an understanding that proposed specimen design is to determine the yield behavior of material only. Also, specimen fabricated from as received sheets and without any thickness reduction in gauge area allows the user to keep full thickness in biaxial condition. The modified design qualifies the commonly accepted performance criteria for cruciform specimen, i.e., stress and strain distribution in the gauge section is found to be homogeneous and the biaxial stress–strain curve can be generated until 4% of equivalent plastic strain. The proposed specimen design is evaluated experimentally by conducting biaxial test at various stress ratios, and it is compared with alike experiments using standard specimen design. One automotive grade material, interstitial-Free high-strength (IFHS) steel sheet of thickness 0.70 mm is tested in this study to validate the specimen design.

Similar content being viewed by others

References

F. Barlat, H. Aretz, J.W. Yoon, M.E. Karabin, J.C. Brem, and R.E. Dick, Linear Transfomation-Based Anisotropic Yield Functions, Int. J. Plast., 2005, 21(5), p 1009–1039

T. Kuwabara, Advances in Experiments on Metal Sheets and Tubes in Support of Constitutive Modeling and Forming Simulations, Int. J. Plast., 2007, 23(3), p 385–419

C.C. Tasan, J.P. Hoefnagels, G. Quaak, and M.G. Geers, In-Plane Biaxial Loading of Sheet Metal Until Fracture, in Proceedings of the 2008 SEM XI International Congress and Exposition on Experimental and Applied Mechanics, Orlando, Florida, 2008 June 2, p 2–5

T. Kuwabara, S. Ikeda, and K. Kuroda, Measurement and Analysis of Differential Work Hardening in Cold-Rolled Steel Sheet Under Biaxial Tension, J. Mater. Process. Technol., 1998, 1(80), p 517–523

ISO 16842, Metallic Materials—Sheet and Strip—Biaxial Tensile Testing Method Using a Cruciform Test Piece, 2014

T. Kuwabara, Biaxial Stress Testing Methods for Sheet Metals, ed. by S. Hashmi, G. Ferreira Batalha, C.J. Van Tyne, B. Yilbas. Comprehensive Materials Processing (Elsevier, 2014), p 95–111. https://doi.org/10.1016/B978-0-08-096532-1.00106-0

L.F. Medellín and J.Á. De la Peña, Design of a Biaxial Test Module for Uniaxial Testing Machine, Mater. Today: Proc., 2017, 4(8), p 7911–7920

M. Brieu, J. Diani, and N. Bhatnagar, A New Biaxial Tension Test Fixture for Uniaxial Testing Machine, J. Test. Eval., 2007, 35(4), p 364–372

A. Barroso, E. Correa, J. Freire, and F. París, A Device for Biaxial Testing in Uniaxial Machines. Design, Manufacturing and Experimental Results Using Cruciform Specimens of Composite Materials, Exp. Mech., 2018, 58(1), p 49–53

L. Leotoing, D. Guines, S.Y. Zhang, and E. Ragneau, A Cruciform Shape to Study the Influence of Strain Paths on Forming Limit Curves, in Key Engineering Materials, vol. 554, p 41–46. Trans Tech Publications, 2013

F. Abu-Farha, L.G. Hector, and M. Khraisheh, Cruciform-Shaped Specimens for Elevated Temperature Biaxial Testing of Lightweight Materials, JOM, 2009, 61(8), p 48–56

A. Hannon and P. Tiernan, A Review of Planar Biaxial Tensile Test Systems for Sheet Metal, J. Mater. Process. Technol., 2008, 198(1–3), p 1–3

M. Härtel, S. Pfeiffer, S. Schmaltz, B. Söhngen, D. Kulawinski, K. Willner, S. Henkel, H. Biermann, and M.X. Wagner, On the Identification of an Effective Cross Section for a Cruciform Specimen, Strain, 2018, 54(1), p e12257

D. Kulawinski, K. Nagel, S. Henkel, P. Hübner, H. Fischer, M. Kuna, and H. Biermann, Characterization of Stress–Strain Behavior of a Cast TRIP Steel Under Different Biaxial Planar Load Ratios, Eng. Fract. Mech., 2011, 78(8), p 1684–1695

J. Granlund, Structural Steel Plasticity: Experimental Study and Theoretical Modelling (Doctoral dissertation, Luleå tekniska universitet), 1997

J. Gozzi, Plastic Behaviour of Steel: Experimental Investigation and Modelling (Doctoral dissertation, Luleå tekniska universitet), 2004

B. Zillmann, M.F.X. Wagner, S. Schmaltz, E. Schmidl, T. Lampke, K. Willner, and T. Halle, In-Plane Biaxial Compression and Tension Testing of Thin Sheet Materials, Int. J. Solids Struct., 2015, 66, p 111–120

Y. Hanabusa, H. Takizawa, and T. Kuwabara, Numerical Verification of a Biaxial Tensile Test Method Using a Cruciform Specimen, J. Mater. Process. Technol., 2013, 213(6), p 961–970

M. Geiger, W. Hußnätter, and M. Merklein, Specimen for a Novel Concept of the Biaxial Tension Test, J. Mater. Process. Technol., 2005, 167(2–3), p 177–183

Y. Yu, M. Wan, X.D. Wu, and X.B. Zhou, Design of a Cruciform Biaxial Tensile Specimen for Limit Strain Analysis by FEM, J. Mater. Process. Technol., 2002, 123(1), p 67–70

D. Lecompte, A. Smits, H. Sol, J. Vantomme, and D. Van Hemelrijck, Mixed Numerical–Experimental Technique for Orthotropic Parameter Identification Using Biaxial Tensile Tests on Cruciform Specimens, Int. J. Solids Struct., 2007, 44(5), p 1643–1656

S. Schmaltz and K. Willner, Material Parameter Identification Utilizing Optical Full-Field Strain Measurement and Digital Image Correlation, J. Jpn. Soc. Exp. Mech., 2013, 13(Special_Issue), p s120–s125

S. Schmaltz and K. Willner, Comparison of Different Biaxial Tests for the Inverse Identification of Sheet Steel Material Parameters, Strain, 2014, 50(5), p 389–403

M. Springmann and M. Kuna, Determination of Ductile Damage Parameters by Local Deformation Fields: Measurement and Simulation, Arch. Appl. Mech., 2006, 75(10–12), p 775

N. Deng, T. Kuwabara, and Y.P. Korkolis, Cruciform Specimen Design and Verification for Constitutive Identification of Anisotropic Sheets, Exp. Mech., 2015, 55(6), p 1005–1022

L. Leotoing, D. Guines, I. Zidane, and E. Ragneau, Cruciform Shape Benefits for Experimental and Numerical Evaluation of Sheet Metal Formability, J. Mater. Process. Technol., 2013, 213(6), p 856–863

D.E. Green, K.W. Neale, S.R. MacEwen, A. Makinde, and R. Perrin, Experimental Investigation of the Biaxial Behaviour of an Aluminum Sheet, Int. J. Plast, 2004, 20(8–9), p 1677–1706

S. Demmerle and J.P. Boehler, Optimal Design of Biaxial Tensile Cruciform Specimens, J. Mech. Phys. Solids, 1993, 41(1), p 143–181

C.L. Walters, The Effect of Machining the Gage Section on Biaxial Tension/Shear Plasticity Experiments of DP780 Sheet Steel, Exp. Mech., 2013, 53(9), p 1647–1659

R.E. Graham, Why a Laser Cutting System: A Comparison with More Conventional Cutting Systems. General Fabrication Department, US, Amada.

R.K. Garg et al., Review of Research Work in Sinking EDM and WEDM on Metal Matrix Composite Materials, Int. J. Adv. Manuf. Technol., 2010, 50, p 611–624

50 kN Servo Electric Bi-axial Test System Service Manual, BISS, ITW

T. Kuwabara, M. Kuroda, V. Tvergaard, and K. Nomura, Use of Abrupt Strain Path Change for Determining Subsequent Yield Surface. Experimental Study with Metal Sheets, Acta Mater., 2000, 48, p 2071–2079

T. Kuwabara, A. Van Bael, and E. Iizuka, Measurement and Analysis of Yield Locus and Work Hardening Characteristics of Steel Sheets with Different r Values, Acta Mater., 2002, 50, p 3717–3729

GOM Testing Technical Documentation as of V8 SR1, Digital Image Correlation and Strain Computation Basics

Acknowledgment

The authors acknowledge the material support extended by Tata Steel, Jamshedpur. The technical discussions with Dr. Pinaki Biswas and Mr. Shaik Shamshoddin are gratefully acknowledged. They would also like to thank Mr Nitish Ranjan Goutam and Mr. Guna Bari for sample preparation and helping with experimental work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raj, A., Singh, P.K., Verma, R.K. et al. Cruciform Specimen Machining Using EDM and a New Design Verification for Biaxial Testing. J. of Materi Eng and Perform 29, 4716–4724 (2020). https://doi.org/10.1007/s11665-020-04921-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04921-8