Abstract

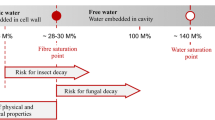

Predicting kiln-drying schedules for a given wood species is not yet possible, despite many research efforts. This is mainly due to insufficiently considering important spatio-temporal variables such as moisture and temperature gradients, and wood anatomical features during drying in the predictive modelling framework. To understand the influence of aforementioned variables, an experimental measurement set-up was developed consisting of heat-resistant load cells mounted in an oven to record the weight of the wood specimens dried at 100 °C. A camera was mounted outside the oven to acquire images of the end grain through the transparent door of the oven, as such enabling to monitor the occurrence of cracks. Furthermore, custom-made electrodes were inserted as well at different depths in the specimen to measure the electrical resistance, which relates to the moisture content. Specimens were also equipped with thermistors to record the temperature in the specimens at different depths from the surface. Heat-resistant wires from load cells, electrodes and thermistors were connected with data loggers outside the oven. Three specimens of basralocus (Dicorynia guianensis) were selected, measuring 50 mm wide, 50 mm thick and 120 mm long. The results show that it is possible to real-time monitor average moisture loss, local moisture content gradient represented by the electrical resistance gradient and wood temperature gradient as a function of time. These temporally resolved gradients can be related to the occurrence of cracks. This methodology enables to unveil interrelationships between the measured variables and changes of the wood anatomical structure, of utmost importance for the fine-tuning of kiln-drying schedules.

Similar content being viewed by others

References

Brandão A, Jankowsky I (1992) A screening to select kiln schedules. IPEF Int 2:20–24

Çengel YA, Ghajar AJ (2011) Heat and mass transfer: fundamentals & applications, 4th edn. McGraw-Hill, New York

de Andrade A, Jankowsky MA, Ducatti IP (2001) Grupamento de madeiras para secagem convencional (Grouping wood species to kiln drying). Sci For 89–99

de Souza Mendes A, Simpson WT, Verrill SP (1995) Laboratory test for grouping tropical species for kiln drying. Wood Sci Technol 29:353–362. https://doi.org/10.1007/BF00202583

Denig J, Wengert EM, Simpson WT (2000) Drying Hardwood Lumber. Gen. Tech. Rep. FPL–GTR–118. Madison, WI

Haque M (2002) Modelling of solar kilns and the development of an optimised schedule for drying hardwood timber. The University of Sydney

Ilic J, Hillis W (1986) Prediction of collapse in dried eucalypt wood. Holzforschung 40:109–112

Jankowsky IP (2012) An easy method to indicate conventional kiln schedules. In: International IUFRO wood drying conference, Belém, PA, pp 31–31

Jankowsky IP, Luiz MG (2006) Review of wood drying research in Brazil: 1984–2004. Dry Technol 24:447–455. https://doi.org/10.1080/07373930600611893

Kang H-Y, Muszyński L, Milota MR (2011) Optical measurement of deformations in drying lumber. Dry Technol 29:127–134. https://doi.org/10.1080/07373937.2010.482725

Kang CW, Muszyński L, Hong SH, Kang HY (2016) Preliminary tests for the application of an optical measurement system for the development of a kiln-drying schedule. Dry Technol 34:483–490. https://doi.org/10.1080/07373937.2015.1060604

Klaassen RKW (2018) Houtvademecum (Wood vade mecum) (In Dutch), 11th edn. Vakbladen.com & Smartwave, Zwolle

Marques MHB (2008) Agrupamento de 41 espécies de madeiras da Amazônia para secagem baseado em características anatômicas e físicas (Grouping of 41 Amazonian timbers for conventional drying based on anatomical and physical characteristics). Universidade de Brasília

Panshin AJ, De Zeeuw C (1970) Textbook of wood technology: structure, identification, uses, and properties of the commercial woods of the United States and Canada, vol 1, 3rd edn. McGraw-Hill, New York

Redman AL, Bailleres H, Turner I, Perré P (2016) Characterisation of wood—water relationships and transverse anatomy and their relationship to drying degrade. Wood Sci Technol 50:739–757. https://doi.org/10.1007/s00226-016-0818-0

Schindelin J, Arganda-Carreras I, Frise E et al (2012) Fiji: an open-source platform for biological-image analysis. Nat Methods 9:676–682. https://doi.org/10.1038/nmeth.2019

Simpson W (1991) Dry kiln operator’s manual, Agricultur. Forest Products Laboratory

Simpson W (1996) Method to estimate dry-kiln schedules and species groupings: tropical and temperate hardwoods. Res. Pap. FPL–RP–548. Madison, WI

Simpson W, Baah C (1989) Grouping tropical wood species for kiln drying. Res. Note FPL-RN-0256. Madison, WI

Simpson W, Sagoe J (1991) Relative drying times of 650 tropical woods: estimation by green moisture content, specific gravity, and green weight density. Gen. Tech. Rep. FPL-GTR-71. Madison, WI

Simpson W, Verrill S (1997) Estimating kiln schedules for tropical and temperate hardwoods using specific gravity. For Prod J 47:64–68

Skaar C (1988) Wood-water relations. Springer, Berlin Heidelberg

Acknowledgements

This research was carried out with the support of the Special Research Fund of the Ghent University (UGent), BOF Grant 01W03213, and the Anton de Kom University of Suriname (AdeKUS). Greenheart Suriname N.V., Houtexploitatie en Verwerkingsonderneming Soekhoe & Zonen N.V., National Herbarium of Suriname, and JOCA’s Lumber & Interior kindly provided the wood. The authors wish to thank Stijn Willen for preparing the specimens and his valuable help to develop the set-up. They also thank the Centre for Agricultural Research in Suriname (CELOS) for their valuable cooperation in this research project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest statement

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Botter-Kuisch, H.P., Van den Bulcke, J., Baetens, J.M. et al. Cracking the code: real-time monitoring of wood drying and the occurrence of cracks. Wood Sci Technol 54, 1029–1049 (2020). https://doi.org/10.1007/s00226-020-01200-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-020-01200-6