Abstract

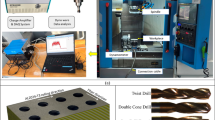

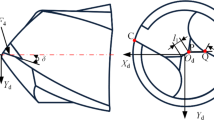

In order to reduce misalignment, enhance tight tolerance, and improve machining efficiency, a novel double cone integrated tool was developed and experimentally investigated during one-shot drilling of aluminum and aluminum alloy stacks in this paper. This special tool geometry can finish drilling, reaming, and countersinking processes at the same time. Its machining properties were comparatively evaluated with a standard twist drill (reference drill) by means of a series of experiments. Experimental results highlighted the influence of tool geometry on cutting force and vibration signals for drilling, reaming, and countersinking processes, respectively. The results indicated that the double cone integrated drill can induce a little larger thrust force than a reference drill due to its longer cutting edge. In addition, the chip morphologies generated by different processes and cutting variations also have been comparatively analyzed. The double cone drill under a larger feed rate was prone to produce smaller chips. Furthermore, the double cone drill can achieve smaller burrs, better surface integrity, and lighter tool wear compared with reference drill. The information obtained from this study can provide a better understanding of the one-shot drilling process and guidance for achieving higher efficiency and better hole quality.

Similar content being viewed by others

References

Kuo CL, Soo SL, Aspinwall DK, Thomas W, Bradley S, Pearson D, M’Saoubi R, Leahy W (2014) The effect of cutting speed and feed rate on hole surface integrity in single-shot drilling of metallic-composite stacks. Procedia CIRP 13:405–410

Tsao CC (2008) Experimental study of drilling composite materials with step-core drill. Mater Des 29(9):1740–1744

Jia Z, Chen C, Wang F, Zhang C, Wang Q (2020) Analytical model for delamination of CFRP during drilling of CFRP/metal stacks. Int J Adv Manuf Technol 106(11-12):5099–5109

Jia Z, Zhang C, Wang F, Fu R (2020) A mechanistic prediction model for thrust force and torque during drilling of CFRP/Ti stacks. Int J Adv Manuf Technol 106(7-8):3105–3115

Hussein R, Sadek A, Elbestawi M, Attia M (2019) Elimination of delamination and burr formation using high-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int J Adv Manuf Technol 105(1-4):859–873

Pardo A, Cseke A, Heinemann R, Whiffen R (2019) The effect of interlayer gap width on burr formation in drilling of aluminium-aluminium aerospace stacks. Int J Adv Manuf Technol 104(5-8):3035–3043

Shyha IS, Soo SL, Aspinwall DK, Bradley S, Dawson S, Pretorius CJ (2010) Drilling of titanium/CFRP/aluminum stacks. Key Eng Mater 2010(447–8):624–633

Kuo CL, Soo SL, Aspinwall DK, Carr C, Bradley S, Saoubi RM, Leahy W (2018) Development of single step drilling technology for multilayer metallic-composite stacks using uncoated and PVD coated carbide tools. J Manuf Process 31:286–300

Kuo CL, Soo SL, Aspinwall DK, Bradley S, Thomas W, Saoubi RM, Pearson D, Leahy W (2014) Tool wear and hole quality when single-shot drilling of metallic-composite stacks with diamond-coated tools. Proc Inst Mech Eng B J Eng Manuf 228(10):1314–1322

Fernandes M, Cook C (2006) Drilling of carbon composites using a one shot drill bit. Part I: five stage representation of drilling and factors affecting maximum force and torque. Int J Mach Tools Manuf 46(1):70–75

Fernandes M, Cook C (2006) Drilling of carbon composites using a one shot drill bit. Part II: empirical modeling of maximum thrust force. Int J Mach Tools Manuf 46(1):76–79

Wang F, Qian B, Jia Z, Fu R, Cheng D (2017) Secondary cutting edge wear of one-shot drill bit in drilling CFRP and its impact on hole quality. Compos Struct 178:341–352

Jia Z, Fu R, Niu B, Qian B, Bai Y, Wang F (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65

Segawa S, Tamura J, Suzuki S, Oka H, Meguro K, Satou Y (2013) Development of a drill bit for CFRP/aluminum-alloy stack: to improve flexibility, economical efficiency and work environment. SAE Tech Pap, 2013-01-2227

Brinksmeier E, Janssen R (2002) Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann Manuf Technol 51(1):87–90

Zhang L, Liu Z, Tian W, Liao W (2015) Experimental studies on the performance of different structure tools in drilling CFRP/Al alloy stacks. Int J Adv Manuf Technol 81(1-4):241–251

Zitoune R, Krishnaraj V, Collombet F, Le Roux S (2016) Experimental and numerical analysis on drilling of carbon fiber reinforced plastic and aluminum stacks. Compos Struct 146:148–158

Zhu Z, Guo K, Sun J, Li J, Liu Y, Zheng Y, Chen L (2018) Evaluation of novel tool geometries in dry drilling aluminum 2024-T351/titanium Ti6Al4V stack. J Mater Process Technol 259:270–281

Feito N, Díaz-Álvarez J, López-Puente J, Miguelez MH (2018) Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs. Compos Struct 184:1147–1155

Alonso U, Calamaz M, Girot F, Iriondo E (2019) Influence of flute number and stepped bit geometry when drilling CFRP/Ti6Al4V stacks. J Manuf Process 39:356–370

Zhu Z, Liu K, Sun J, Li J (2017) Investigation on performance characteristics and metallographic transformation on drilling aluminum/titanium sandwich. J Sandw Struct Mater 21:1578–1594

Liu K, Li J, Sun J, Zhu Z, Meng H (2018) Investigation on chip morphology and properties in drilling aluminum and titanium stack with double cone drill. Int J Adv Manuf Technol 94(5-8):1947–1956

Zhu Z, Sui S, Sun J, Li J, Li Y (2017) Investigation on performance characteristics in drilling of Ti6Al4V alloy. Int J Adv Manuf Technol 93(1-4):651–660

Zitoune R, Krishnaraj V, Sofiane Almabouacif B, Collombet F, Sima M, Jolin A (2012) Influence of machining parameters and new nano-coated tool on drilling performance of CFRP/Aluminum sandwich. Compos Part B 43:1480–1488

Zhu Z, Guo K, Sun J, Li J, Liu Y, Chen L, Zheng Y (2018) Evolution of 3D chip morphology and phase transformation in dry drilling Ti6Al4V alloys. J Manuf Process 34:531–539

Zhang Y, Guo K, Sun J (2019) Investigation on the milling performance of amputating clamping supports for machining with industrial robot. Int J Adv Manuf Technol 102(9-12):3573–3586

Funding

This work was supported by the National Natural Science Foundation of China under Grant 51975335 and also supported in part by the Major Scientific and Technological Project of Shandong Province under Grant 2019GGX104008 and Grant 2019GGX104006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sui, S., Song, G., Sun, C. et al. Experimental investigation on the performance of novel double cone integrated tool in one-shot drilling of metal stacks. Int J Adv Manuf Technol 109, 523–534 (2020). https://doi.org/10.1007/s00170-020-05474-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05474-9