Abstract

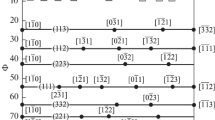

The structure and properties of cold-rolled strips with a thickness of 3 mm from an experimental aluminum alloy 1580 with a lower scandium content of 0.03% (wt.) relative to the grade of the aluminum alloy and a 5083 similar alloy without scandium were studied. Ingots obtained at the laboratory installation of semicontinuous casting of the foundry department of the Siberian Federal University (Siberian Federal University, Russia, Krasnoyarsk) were used. The preparation of ingots for rolling included milling up to sizes of 40 × 100 × 145 mm and annealing according to a two-stage mode: at a temperature of 350 °C for 3 h (first stage) and at a temperature of 425 °C for 4 h (second stage). Hot rolling was carried out in the laboratory of the Department of Metal Forming at the Siberian Federal University at a temperature of 450 °C on a two-roll hot rolling mill with a roll diameter of 330 mm and a barrel length of 520 mm to a thickness of 5 mm, which corresponded to a total reduction of 88% with a single reduction of 2–5%. For cold rolling, a two-roll sheet rolling mill with a roll diameter of 200 mm and a barrel length of 400 mm grade LS 400 AUTO was used. Rolling was carried out to a thickness of 3 mm with a single reduction of 2–5%, and then the strip was annealed. The results of determining the mechanical properties by tension by the universal LFM400 machine showed that with an increase in the annealing temperature in the range from 250 to 350 °C for 3 h, ultimate tensile strength of the cold-rolled strips of aluminum alloy 1580 decreases from 385 to 365 MPa. For aluminum alloy 5083, a decrease in this strength characteristic is also observed from 345 to 320 MPa. A decreasing tendency with increasing annealing temperature was also observed for the conditional yield strength Rp, and over the entire range of annealing temperatures, the values of Rp for strips of alloy 1580 were higher than for alloy 5083 by 35–40 MPa, which amounted to 14–17% The values of the plastic properties, for which the value of the elongation to failure was analyzed, were close throughout the range of annealing temperatures for both alloys. The results of the analysis of micro- and fine structure allowed to conclude that an increase in the strength properties of cold-rolled and annealed sheets from the experimental alloy 1580, compared with alloy 5083, is a consequence of the addition of scandium in the experimental alloy 1580, which leads to an increase in the temperature of recrystallization of the alloy, preserving it contains a subgrain structure and dispersion hardening caused by precipitation of Al3(Sc, Zr) phase particles during the decomposition of a solid solution.

Similar content being viewed by others

References

Bronz AV, Efremov VI, Plotnikov AD, Chernyavskiy AG (2014) Kosmicheskaya tekhnika i tekhnologii [Space Engineering and Technology]. 4(7):62–67

Filatov YA, Plotnikov AD (2011) Tekhnologiya legkikh splavov [Light alloy technology] 2:15–26

Baranov VN, Sidelnikov SB, Zenkin YA, Frolov VF, Voroshilov DS, Yakivyuk OV, Konstantinov IL, Sokolov RE, Belokonova IN (2017) Investigation of the strength properties of semi-finished products from economically alloyed high-strength aluminum-scandium alloys for use in automobile transport and shipping. In the collection: Non-ferrous metals and minerals - 2017. Collection of reports of the Ninth International Congress:717–718

Drits ME, Toropova LS, Bykov YG (1980) Metallovedenie i termicheskaya obrabotka metallov [Metallurgy and heat treatment of metals] 10:35–37

Drits ME, Pavlenko SG, Toropova LS et al (1981) DAN SSSR. Metally [DAS USSR. Metals] 257(2):353–356

M.E. Drits, L.S. Toropova, Yu.G. Bykov et al. Metallurgiya i metallovedenie tsvetnykh splavov [Metallurgy and material science of non-ferrous alloys]. – M.: Nauka, 1982, 213–223

Elagin VI, Zakharov VV, Rostova TD (1982) Prospects for alloying aluminum alloys with scandium. Tsvetnye metally 12:96–99

Drits ME, Bykov YG, Toropova LS (1985) Metallovedenie i termicheskaya obrabotka metallov [Metallurgy and heat treatment of metals] 4:48–50

Zakharov VV (2014) Metallovedenie i termicheskaya obrabotka metallov [Metallurgy and heat treatment of metals] 6:3–8

Filatov YA (2009) VILS: Tekhnologiya legkikh splavov [RILA: Light alloy technology]. 3:42–45

Elagin VI, Zakharov VV, Rostova TD (1992) Metallovedenie i termicheskaya obrabotka metallov [Metallurgy and heat treatment of metals] 1:24–28

Davydov VG, Elagin VI, Zakharov VV, Rostova TD (1996) Tsvetnye metally i splavy [Non-ferrous metals and alloys], vol 8, pp 25–30

Belov NA, Alabin AN (2007) Promising aluminum alloys with zirconium and scandium additives. Tsvetnye metally 2:99–106

Filatov YA (1996) Metallovedenie i termicheskaya obrabotka metallov [Metallurgy and heat treatment of metals] 6:33–36

Fujikawa S-I, Sakauchi S (1998) Kinetics of Precipitation in Al–0,20 mass % Sc Alloy. Aluminium Alloys. Their Physical and Mechanical Properties. Proc. of the 6th Int. Conf. on Aluminium Alloys, ICAA-6. Toyohashi, Japan. – The Japan Institute of Light Metals, 1998, 2, 805–810

Koryagin YD, Il'in SI (2017) Recrystallization features of deformable aluminium-magnesium alloys with scandium. Bulletin of the South Ural State University. Series “Metallurgy” 17(1):65–72

Shi C, Liang Z, Wu G, Zhang X, Chen A, Tao J (2017) Effects of Sc addition on the microstructure and mechanical properties of cast Al-3Li-1.5Cu-0.15Zr alloy. Mater Sci Eng А680:232–238

Li M, Pan Q, Shi Y, Xue S, Xiang H (2017) High strain rate superplasticity in an Al–Mg–Sc–Zr alloy processed via simple rolling. Mater Sci Eng А687:298–305

Buranova Y, Kulitskiy V, Peterlechner M, Mogucheva A, Kaibyshev R, Divinski SV, Wilde G (2017) Al3(Sc, Zr) - based precipitates in AlMg alloy: effect of severe deformation. Acta Mater 124:210–224

Keith E (2011) Knipling, David N. Seidman, David C. Dunand. Ambient- and high-temperature mechanical properties of isochronally aged Al–0.06Sc, Al–0.06Zr and Al–0.06Sc–0.06Zr (at.%) alloys. Acta Mater 59:943–954

V. Rajinikanth, Vikas Jindal, V.G. Akkimardi, Mainak Ghosha, K. Venkateswarlu. Transmission electron microscopy studies on the effect of strain on Al and Al–1% Sc alloy. Scr Mater, 2007, 57, 425–428

Lee S-L, Chang J-K, Cheng Y-C, Lee K-Y, Chen W-C (2011) Effects of scandium addition on electrical resistivity and formation of thermal hillocks in aluminum thin films. Mater Charact 519:3578–3581

Zakharov VV (2003) MiTOM [MS&MPT] 7:7–15

Jones MJ, Humphreys FJ (2003) Interaction of recrystallization and precipitation: the effect of Al3Sc on the recrystallization behavior of deformed aluminium. Acta Mater 51(8):2149–2159

Lohara AK, Mondala B, Rafajab D, Klemmb V, Panigrahic SC (2009) Microstructural investigations on as-cast and annealed Al–Sc and Al–Sc–Zr alloys. Mater Charact 60:1387–1394

Stock R, Köhler B, Bomas H, Zoch H-W (2010) Characteristics of aluminium–scandium alloy thin sheets obtained by physical vapour deposition. Mater Des 31:76–81

Marquis EA, Seidman EA (1909–1919) Nanoscale structural evolution of Al3Sc precipitates in Al (Sc) alloys. Acta Mater 2001:49

Norman AF, Prangnell PB, McEwen RS (1998) The solidification behavior of dilute aluminium–scandium alloys. Acta Mater 46:5715–5732

Pereiraa PHR, Wang YC, Huang Y, Terence G (2017) Langdon. Influence of grain size on the flow properties of an Al-Mg-Sc alloy over seven orders of magnitude of strain rate. Mater Sci Eng А685:367–376

Mondol S, Alamb T, Banerjee R, Kumar S, Chattopadhyay K (2017) Development of a high temperature high strength Al alloy by addition of small amounts of Sc and Mg to 2219 alloy. Mater Sci Eng А687:221–231

Baranov VN, Sidelnikov SB, Zenkin EY, Konstantinov IL, Lopatina ES, Yakivyuk OV, Voroshilov DS, Belokonova IN, Frolov VA (2019) Study on the influence of heat treatment modes on mechanical and corrosion properties of rolled sheet products from a new aluminum alloy, economically alloyed with scandium. Vestnik of Nosov Magnitogorsk State Technical University 17(1):76–81

Baranov VN, Zenkin EY, Konstantinov IL, Sidelnikov SB (2019) The research of the cold rolling modes for plates of aluminum alloy sparingly doped with scandium. Non-Ferrous Metals 47(2):48–53

Baranov VN, Sidelnikov SB, Frolov VF, Zenkin EY, Orelkina TA, Konstantinov IL, Voroshilov DS, Yakivyuk OV, Belokonova IN (2018) Vestnik gorno-metallurgicheskoy sektsii Rossiyskoy akademii estestvennykh nauk. Otdelenie metallurgii [Bulletin of the mining and metallurgical section of the Russian Academy of Natural Sciences. Metallurgy department]. 41:184–190

Baranov V, Sidelnikov S, Voroshilov D, Yakivyuk O, Konstantinov I, Sokolov R, Belokonova I, Zenkin E, Frolov V (2018) Study of strength properties of semi-finished products from economically alloyed high-strength aluminium-scandium alloys for application in automobile transport and shipbuilding. Open Engineering 8(1):69–76

Baranov VN, Sidelnikov SB, Frolov VF, Zenkin EY, Orelkina TA, Konstantinov IL, Voroshilov DS, Yakivyuk OV, Belokonova IN (2017) Study of the mechanical properties of cold-rolled, annealed and welded semi-finished products from experimental alloys of the Al-Mg system, economically alloyed with scandium. In: The collection: Metallurgy: technology, innovation, quality, proceedings of the XX International Scientific and Practical Conference: in 2 parts, pp 149–153

Baranov VN, Sidelnikov SB, Zenkin EY, Bezrukikh AI, Konstantinov IL, Sokolov RE, Voroshilov DS, Belokonova IN, Yakivyuk OV (2017) Study of the mechanical properties of semi-finished products from aluminum-scandium alloy. Bulletin of the Tula State University 11(1):147–153

Dovzhenko IN, Dovzhenko NN, Sidelnikov SB, Konstantinov IL (2017) 3D modelling of the large-capacity ingots of an Al - mg system aluminium alloy doped with scandium rolling process. Non-Ferrous Metals 43(2):60–64

Sidelnikov SB, Yakivyuk OV, Baranov VN, Zenkin EY, Dovzhenko IN (2020) Developing, simulating, and researching a production process of long deformed semi-fabricated aluminum–magnesium products with a varying scandium content. Russian Journal of Non-Ferrous Metals 61:81–88

Baranov VN, Sidelnikov SB, Zenkin EY, Belokonova IN, Lopatina ES, Yakivyuk OV, Voroshilov DS (2020) Study on the structure and properties of strips and plates from the alloy of the Al-mg system, economically alloyed with scandium. Journal of Chemical Technology and Metallurgy 55(3):538–543

Acknowledgments

The manuscript was prepared using the results of the work carried out during the project 03.G25.31.0265 “Development of economically alloyed high-strength Al-Sc alloys for use in road transport and navigation” in the framework of the program for the implementation of complex projects for the creation of high-tech production, approved by the Government of the Russian Federation on April 9, 2010 №218.

The work is performed as a part of the state assignment for the science of Siberian Federal University, project number FSRZ-2020-0013.

The use of equipment of Krasnoyarsk Regional Center of Research Equipment of Federal Research Center “Krasnoyarsk Science Center SB RAS” is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Konstantinov, I.L., Baranov, V.N., Sidelnikov, S.B. et al. Investigation of the structure and properties of cold-rolled strips from experimental alloy 1580 with a reduced scandium content. Int J Adv Manuf Technol 109, 443–450 (2020). https://doi.org/10.1007/s00170-020-05681-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05681-4