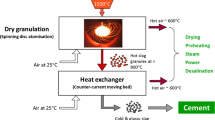

The world’s leading countries develop dry slag granulation units that are capable of producing solid slag granules and recovering the sensible heat of slag. The main element of such units is a granulation chamber where molten slag is atomized and solidified. In this chamber, up to 30% of the sensible heat of the molten slag is extracted. To recover more heat, the solid granules from the granulation chamber should be fed to fluidized beds. The more there are such beds, the better the granulated slag can be cooled and, therefore, the more heat can be recovered. Foreign publications on dry slag granulation do not provide methods for designing fluidized beds for dry slag granulation units. A method for analyzing the heat transfer in fluidized beds during cooling of slag granules by counter airflow is presented. The method allows determining the heat flow from the slag to the air in fluidized beds and the temperatures of the slag and air exiting the fluidized beds. Recommendations on choosing the airflow velocity, the rational mass of slag in one fluidized bed, the number and dimensions of beds and evaluating air pressure losses in fluidized beds are formulated. It is shown that three fluidized beds in a dry slag granulation unit are sufficient to recover up to 92% of the sensible heat of slag.

Similar content being viewed by others

References

S. J. Pickering, N. Hay, T. F. Roylance, and G. H. Thomas, “New process for dry granulation and heat recovery from molten slag,” Ironmaking and Steelmaking, 12, No. 1, 14–21 (1985).

D. Xie, S. Jahanshali, and T. Norgate, “Dry granulation to provide a sustainable option for slag treatment,” in: Proc. Sustainable Mining Conf., Kalgoorlie, WA, Australia, August 17–19 (2010), pp. 22–28.

H. Kappes and D. Michels, “Dry slag granulation with energy recovery — from inception to pilot plant,” Stahl und Eisen, 134, No. 11, 124–131 (2014).

H. Zhang, H. Wang, X. Zhu, Y. Qiu, K. Li, R. Chen, and Q. Liao, “A review of waste heat recovery technologies towards molten slag in steel industry,” Appl. Energy, 112, 956–966 (2013).

P. Yu, S. Wang, Y. Li, and G. Xu, “A review of granulation process for blast furnace slag,” in: Proc. 3rd Int. Conf. on Industrial Engineering and Applications (ICIEA 2016), Vol. 68, Hong Kong, April 28–30 (2016), pp. 6–0.

A. S. Kadyrov, V. A. Kunaev, and I. V. Georgiadi, “Prospects for processing of ferrous metallurgical waste based on Arcelormittal Temirtau experience,” Metallurgist, 62, No. 1–2, 22–28 (2018).

S. V. Filatov, A. V. Lozovich, V. N. Titov, S. A. Zagainov, and I. F. Kurunov, “Analysis of the blast-furnace process at high smelting rate,” Metallurgist, 61, No. 9-10, 844–848 (2018).

S. V. Filatov, I. F. Kurunov, V. N. Titov, and S. A. Zagainov, “Introduction of energy efficient solutions during cast iron smelting at PJSC ‘NLMK’,” Metallurgist, 63, No. 3-4, 335–340 (2019).

O. P. Onorin, A. A. Polinov, A. V. Pavlov, N. A. Spirin, and I. A. Gurin, “About a possibility of using blast furnace heat balance to control heat losses,” Metallurgist, 62, No. 3-4, 218–224 (2018).

E. G. Urbanovich, V. A. Panov, V. F. Voropaev, and V. I. Basov, “Molten blast-furnace slag heat losses and technical solutions reducing them,” Izv. VUZov: Chern. Metallurg., No. 7 (1303), 51–56 (2008).

S. V. Lukin, N. I. Shestakov, and E. M. Il’icheva, “Heat exchange in the granulation chamber of an installation for slag dry granulation,” Metallurgist, 63, No. 7-8, 804–812 (2019).

A. P. Baskakov, Heat and Mass Transfer in Fluidized Bed [in Russian], Metallurgiya, Moscow (1978).

E. I. Kazantsev, Industrial Furnaces: A Handbook [in Russian], Metallurgiya, Moscow (1975).

B. P. Yur’ev, “Studying the thermophysical properties of blast-furnace slag during heat treatment,” Izv. VUZov: Chern. Metallurg., No. 11, 5–10 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 4, pp. 16–29, April, 2020.

Rights and permissions

About this article

Cite this article

Lukin, S.V., Fokin, A.V. & Il’icheva, E.M. Heat Transfer in Fluidized Beds in a Dry Slag Granulation Unit. Metallurgist 64, 281–287 (2020). https://doi.org/10.1007/s11015-020-00994-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00994-x