Abstract

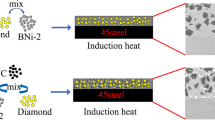

The diamond enhanced (NiCoCrTi0.5Nb0.5)Cx (x = 3, 6, 12 wt.%) high-entropy alloy coatings were well-prepared by laser cladding, which are denoted as C3, C6 and C12, respectively. The macroscopic morphology, phase, microstructure, hardness and wear resistance were investigated. The coatings without pores and cracks, are well-metallurgically bonded with the substrate. The width, melting depth and dilution rate of (NiCoCrTi0.5Nb0.5)Cx coating decrease with the increase of diamond content. The coatings are mainly composed of BCC solid solution, (Ti,Nb)C and Cr3C2. The increase of diamond content results in the precipitation of (Ti,Nb)C and Cr3C2, and the coating with x = 12 wt.% retains more diamonds. The hardness of coatings is much higher than that of the substrate. As the diamond content increases, the average hardness of (NiCoCrTi0.5Nb0.5)Cx coating increases first and then decreases. The abrasive wear occurs in each coating. The wear depth, roughness and wear rate decrease first and then increase as the diamond content increases. The C6 coating with the better wear resistance produces a smooth worn surface, which indicates that C6 coating can be fully applied to various tools, molds and mechanical parts.

Similar content being viewed by others

References

C.K. Hou, C.T. Hu, and S. Lee, The Effect of Aluminium on the Magnetic Properties of Lamination Steels, IEEE Trans. Magn., 1991, 27(5), p 4305-4309

R.F. Shyu and C.T. Ho, In Situ Reacted Titanium Carbide-Reinforced Aluminum Alloys Composite, J. Mater. Process. Technol., 2006, 171(3), p 411-416

C.M. Sonsino and K. Dieterich, Fatigue Design with Cast Magnesium Alloys Under Constant and Variable Amplitude Loading, Int. J. Fatigue, 2006, 28(3), p 183-193

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299-303

L. Jiang, W. Wu, Z. Cao, D. Deng, and T. Li, Microstructure Evolution and Wear Behavior of the Laser Cladded CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb High-Entropy Alloy Coatings, J. Therm. Spray Technol., 2016, 25(4), p 806-814

F.Y. Shu, L. Wu, H.Y. Zhao, S.H. Sui, L. Zhou, and J. Zhang, Microstructure and High-Temperature Wear Mechanism of Laser Cladded CoCrBFeNiSi High-Entropy Alloy Amorphous Coating, Mater. Lett., 2017, 211, p 235-238

T.S. Reddy, I.S. Wani, T. Bhattacharjee, S.R. Reddy, R. Saha, and P.P. Bhattacharjee, Severe Plastic Deformation Driven Nanostructure and Phase Evolution in a Al0.5CoCrFeMnNi Dual Phase High Entropy Alloy, Intermetallics, 2017, 91, p 150-157

W. Wu, L. Jiang, H. Jiang, X. Pan, and T. Li, Phase Evolution and Properties of Al2CrFeNiMo x High-Entropy Alloys Coatings by Laser Cladding, J. Therm. Spray Technol., 2015, 24(7), p 1333-1340

H. Zhang, Y. Pan, and Y. He, Effects of Annealing on the Microstructure and Properties of 6FeNiCoCrAlTiSi High-Entropy Alloy Coating Prepared by Laser Cladding, J. Therm. Spray Technol., 2011, 20(5), p 1049-1055

S. Zhang, C.L. Wu, C.H. Zhang, M. Guan, and J.Z. Tan, Laser Surface Alloying of FeCoCrAlNi High-Entropy Alloy on 304 Stainless Steel to Enhance Corrosion and Cavitation Erosion Resistance, Opt. Laser Technol., 2016, 84, p 23-31

R.F. Zhao, B. Ren, G.P. Zhang, Z.X. Liu, B. Cai, and J.J. Zhang, CoCrxCuFeMnNi High-Entropy Alloy Powders with Superior Soft Magnetic Properties, J. Magn. Magn. Mater., 2019, 491, p 165574

H. Liang, H. Yao, D. Qiao, S. Nie, Y. Lu, D. Deng, Z.Q. Cao, and T. Wang, Microstructures and Wear Resistance of AlCrFeNi2W0.2Nbx High-Entropy Alloy Coatings Prepared by Laser Cladding, J. Therm. Spray Technol., 2019, 6(28), p 1318-1329

D. Lin, N. Zhang, B. He, X. Gong, Y. Zhang, D. Li, and F.Y. Dong, Structural Evolution and Performance Changes in FeCoCrNiAlNbx High-Entropy Alloy Coatings Cladded by Laser, J. Therm. Spray Technol., 2017, 26(8), p 2005-2012

R.B. Nair, H.S. Arora, S. Mukherjee, S. Singh, H. Singh, and H.S. Grewal, Exceptionally High Cavitation Erosion and Corrosion Resistance of a High Entropy Alloy, Ultrason. Sonochem., 2017, S135-04177(17), p 30450

Y.Y. Chen, T. Duval, U.D. Hung, J.W. Yeh, and H.C. Shih, Microstructure and Electrochemical Properties of High Entropy Alloys—A Comparison with type-304 Stainless Steel, Corros. Sci., 2005, 47(9), p 2257-2279

T.K. Chen, T.T. Shun, J.W. Yeh, and M.S. Wong, Nanostructured Nitride Films of Multi-Element High-Entropy Alloys by Reactive DC Sputtering, Surf. Coat. Technol., 2004, 188-189, p 193-200

X.W. Qiu, Y.P. Zhang, and C.G. Liu, Effect of Ti Content on Structure and Properties of Al2CrFeNiCoCuTix High-Entropy Alloy Coatings, J. Alloy. Compd., 2014, 585, p 282-286

L.L. Hou, J.T. Hui, Y.H. Yao, J. Chen, and J.N. Liu, Effects of Boron Content on Microstructure and Mechanical Properties of AlFeCoNiBx High Entropy Alloy Prepared by Vacuum Arc Melting, Vacuum, 2019, 164, p 212-218

N.N. Guo, L.S. Luo, Y.Q. Su, and J.J. Guo, Microstructure and Mechanical Properties of ZrNbMoHfV High Entropy Alloy, Mater. Res. Innov., 2014, 18(sup4), p 766-769

Q.F. Wu, Z.J. Wang, T. Zheng, D. Chen, Z.S. Yang, J.J. Li, J.J. Kai, and J.C. Wang, A Casting Eutectic High Entropy Alloy with Superior Strength-Ductility Combination, Mater. Lett., 2019, 253, p 268-271

L. Jiang, Y.P. Lu, Y. Dong, T.M. Wang, Z.Q. Cao, and T.J. Li, Annealing Effects on the Microstructure and Properties of Bulk High-Entropy CoCrFeNiTi0.5 Alloy Casting Ingot, Intermetallics, 2014, 44, p 37-43

P.K. Farayibi, T.E. Abioye, A. Kennedy, and A.T. Clare, Development of Metal Matrix Composites by Direct Energy Deposition of ‘Satellited’ Powders, J. Manuf. Process., 2019, 45, p 429-437

H.F. El-Labban, E.R.I. Mahmoud, and A. Algahtani, Microstructure, Wear, and Corrosion Characteristics of TiC-Laser Surface Cladding on Low-Carbon Steel, Metall. Mater. Trans. B, 2016, 47(2), p 974-982

A.T. Clare, O. Oyelola, T.E. Abioye, and P.K. Farayibi, Laser Cladding of Rail Steel with Co–Cr, Surf. Eng., 2013, 29(10), p 731-736

O.S. Adesina, A.P.I. Popoola, S.L. Pityana, and D.T. Oloruntoba, Microstructural and Tribological Behavior of In Situ Synthesized Ti/Co Coatings on Ti-6Al-4 V Alloy Using Laser Surface Cladding Technique, Int. J. Adv. Manuf. Technol., 2018, 95, p 1265-1280

T.F. Han, M. Xiao, Y. Zhang, and Y.F. Shen, Laser Cladding Composite Coatings by Ni–Cr–Ti–B4C with Different Process Parameters, Mater. Manuf. Process., 2019, 34(8), p 898-906

D.M. Goodarzi, J. Pekkarinen, and A. Salminen, Analysis of Laser Cladding Process Parameter Influence on the Clad Bead Geometry, Weld World, 2017, 61(5), p 883-891

M.Z. Ibrahim, A.A.D. Sarhan, T.Y. Kuo, F. Yusof, and M. Hamdi, Characterization and Hardness Enhancement Of Amorphous Fe-Based Metallic Glass Laser Cladded on Nickel-Free Stainless Steel for Biomedical Implant Application, Mater. Chem. Phys., 2019, 235, p 121745

Y. Zhang, T.F. Han, M. Xiao, and Y.F. Shen, Effect of Nb Content on Microstructure and Properties of Laser Cladding FeNiCoCrTi0.5Nbx High-Entropy Alloy Coating, Optik, 2019, 198, p 163316

M.M. Khruschov, Principles of Abrasive Wear, Wear, 1974, 28(1), p 69-88

Funding

This study was supported by the National key R&D program of China (2018YFB1105801), the National natural science foundation of China, youth fund project (51605473).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Han, T., Xiao, M. et al. Preparation of Diamond Reinforced NiCoCrTi0.5Nb0.5 High-Entropy Alloy Coating by Laser Cladding: Microstructure and Wear Behavior. J Therm Spray Tech 29, 1827–1837 (2020). https://doi.org/10.1007/s11666-020-01067-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01067-w