Abstract

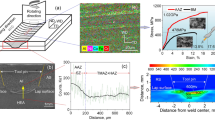

1060 Al and Al0.1CoCrFeNi are friction stir lap welded in this study in order to improve the microstructure and mechanical property of the high-entropy alloy by adding Al element into the alloy through friction stir processing. The results indicate that a crescent-shaped aluminum-addition zone featured by limited upward material flow is formed in the high-entropy alloy. The aluminum-addition friction stir processing leads to the formation of fine and homogeneously distributed microstructures and the occurrence of body-centered cubic phases in the high-entropy alloy. Owing to the synthetical strengthening effects caused by friction stir modification and Al content increase, the hardness of the Al0.1CoCrFeNi alloy is increased significantly from 100 Hv to an average value over 400 Hv and a maximum value of 600 Hv. The present study is able to provide an effective approach for the preparation and strengthening of high-entropy alloys.

Similar content being viewed by others

References

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1–93

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511

T. Yang, S. Xia, S. Liu, C. Wang, S. Liu, Y. Zhang, J. Xue, S. Yan, and Y. Wang, Effects of Al Addition on Microstructure and Mechanical Properties of AlxCoCrFeNi High-Entropy Alloy, Mater. Sci. Eng. A, 2015, 648, p 15–22

H.P. Chou, Y.S. Chang, S.K. Chen, and J.W. Yeh, Microstructure, Thermophysical and Electrical Properties in AlxCoCrFeNi (0 ≤ x ≤ 2) High-Entropy Alloys, Mater. Sci. Eng. B, 2009, 163, p 184–189

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, and J.W. Yeh, Effects of Al Addition on the Microstructure and Mechanical Property of AlxCoCrFeNi High-Entropy Alloys, Intermetallics, 2012, 26, p 44–51

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Sluggish Diffusion in Co-Cr-Fe-Mn-Ni High-Entropy Alloys, Acta Mater., 2013, 61, p 4887–4897

C.W. Tsai, Y.L. Chen, M.H. Tsai, J.W. Yeh, T.T. Shun, and S.K. Chen, Deformation and Annealing Behaviors of High-Entropy Alloy Al0.5CoCrCuFeNi, J. Alloy. Compd., 2009, 486, p 427–435

H.Y. Guan, Y.P. Zhang, Y.H. Fan, and X.N. Li, Microstructure and Properties of Sintered AlNiCrFeCuMox Alloys, Rare Met. Mater. Eng., 2012, 41, p 532–535

J.H. Pi, C.F. Yu, C. Sun, H.L. Du, Y.L. Fan, B.S. Zhang, and S.F. Yang, Effect of Cold Deformation and Heat Treatment on the Microstructure and Mechanical Behavior of High Entropy Alloy CuCrFeNi2Al0.5, J. Mater. Eng. Perform., 2019, 28, p 586–592

M. Li, Q. Zhang, B. Han, L. Song, J. Li, and J. Yang, Investigation on Microstructure and Properties of AlxCoCrFeMnNi High Entropy Alloys by Ultrasonic Impact Treatment, J. Alloy. Compd., 2020, 816, p 152626

F. Meng and I. Baker, Nitriding of a High Entropy FeNiMnAlCr Alloy, J. Alloy. Compd., 2015, 645, p 376–381

J. Li, M. Su, W. Qi, C. Wang, P. Zhao, F. Ni, and K. Liu, Mechanical Property and Characterization of 7A04-T6 Aluminum Alloys Bonded by Friction Stir Welding, J. Manuf. Process., 2020, 52, p 263–269

N. Kumar, M. Komarasamy, and R.S. Mishra, Plastic Deformation Behavior of Ultrafine-Grained Al-Mg-Sc Alloy, J. Mater. Sci., 2014, 49, p 4202–4214

B. He, L. Cui, D. Wang, Y. Liu, C. Liu, and H. Li, The Metallurgical Bonding and High Temperature Tensile Behaviors of 9Cr-1W Steel and 316L Steel Dissimilar Joint by Friction Stir Welding, J. Manuf. Process., 2019, 44, p 241–251

S.S. Nene, K. Liu, M. Frank, R.S. Mishra, R.E. Brennan, K.C. Cho, Z. Li, and D. Raabe, Enhanced Strength and Ductility in a Friction Stir Processing Engineered Dual Phase High Entropy Alloy, Sci. Rep., 2017, 7, p 16167

M.G. Jo, H.J. Kim, M. Kang, P.P. Madakashira, E.S. Park, J.Y. Suh, D.I. Kim, S.T. Hong, and H.N. Han, Microstructure and Mechanical Properties of Friction Stir Welded and Laser Welded High Entropy Alloy CrMnFeCoNi, Met. Mater. Int., 2018, 24, p 73–83

Z.G. Zhu, Y.F. Sun, M.H. Goh, F.L. Ng, Q.B. Nguyen, H. Fujii, S.M.L. Nai, J. Wei, and C.H. Shek, Friction Stir Welding of a CoCrFeNiAl0.3 High Entropy Alloy, Mater. Lett., 2017, 205, p 142–144

T. Wang, S. Shukla, M. Komarasamy, K. Liu, and R.S. Mishra, Towards Heterogeneous AlxCoCrFeNi High Entropy Alloy Via Friction Stir Processing, Mater. Lett., 2019, 236, p 472–475

L. Zhou, M. Yu, H. Zhao, Z. Jiang, F. Guo, and X. Song, Dissimilar Friction Stir Welding of AA6061 and Ti6Al4V Alloys: A Study on Microstructure and Mechanical Properties, J. Manuf. Process., 2019, 48, p 119–126

Y. Song, X. Yang, L. Cui, X.P. Hou, Z.K. Shen, and Y. Xu, Defect Features and Mechanical Properties of Friction Stir Lap Welded Dissimilar AA2024–AA7075 Aluminum Alloy Sheets, Mater. Des., 2014, 55, p 9–18

Y. Huang, L. Wan, X. Meng, Y. Xie, Z. Lv, and L. Zhou, Probe Shape Design for Eliminating the Defects of Friction Stir Lap Welded Dissimilar Materials, J. Manuf. Process., 2018, 35, p 420–427

Y. Zhang, Z.P. Lu, S.G. Ma, P.K. Liaw, Z. Tang, Y.Q. Cheng, and M.C. Gao, Guidelines in Predicting Phase Formation of High-Entropy Alloys, MRS Commun., 2014, 4, p 57–62

D. Shaysultanov, N. Stepanov, S. Malopheyev, I. Vysotskiy, V. Sanin, S. Mironov, R. Kaibyshev, G. Salishchev, and S. Zherebtsov, Friction Stir Welding of a Carbon-Doped CoCrFeNiMn High-Entropy Alloy, Mater. Charact., 2018, 145, p 353–361

N. Kumar, M. Komarasamy, P. Nelaturu, Z. Tang, P.K. Liaw, and R.S. Mishra, Friction Stir Processing of a High Entropy Alloy Al0.1CoCrFeNi, JOM, 2015, 67, p 1007–1013

H.Y. Yu, W. Fang, R.B. Chang, P.G. Ji, and Q.Z. Wang, Modifying Element Diffusion Pathway by Transition Layer Structure in High-Entropy Alloy Particle Reinforced Cu Matrix Composites, Trans. Nonferr. Met. Soc., 2019, 29, p 2331–2339

Y.S. Sato, T.W. Nelson, C.J. Sterling, R.J. Steel, and C.O. Pettersson, Microstructure and Mechanical Properties of Friction Stir Welded SAF 2507 Super Duplex Stainless Steel, Mater. Sci. Eng. A, 2005, 397, p 376–384

X. Niu, J. Julius, D. Zhou, G. Yang, and Y. Yu, Microstructure and Corrosion Properties of AlxFeCoCrNiCu (x = 0.25, 0.5, 1.0) Thin Coatings on Steel Substrates Deposited by Electron Beam Evaporation, Rare Met. Mater. Eng., 2017, 46, p 3621–3625

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-Component Alloys, Adv. Eng. Mater., 2008, 10, p 534–538

B.Y. Li, K. Peng, A.P. Hu, L.P. Zhou, J.J. Zhu, and D.Y. Li, Structure and Properties of FeCoNiCrCu0.5Alx, High-Entropy Alloy, Trans. Nonferr. Met. Soc., 2013, 23, p 735–741

I. Toda-Caraballo and P.E.J. Rivera-Diaz-del-Castillo, A Criterion for the Formation of High Entropy Alloys Based on Lattice Distortion, Intermetallics, 2016, 71, p 76–87

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303

Acknowledgments

The authors are grateful to be supported by Program for the Top Young Talents of Higher Learning Institutions of Hebei (No. BJ2019201), Fundamental Research Funds for the Central Universities (No. N2023028), State Key Laboratory of Advanced Welding and Joining Harbin Institute of Technology (No. AWJ-19M04) and Program of Innovation and Entrepreneurship of Northeastern University at Qinhuangdao (No. CX20619).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Hj., Ji, Zj., Liu, Hj. et al. Micro-characteristic of Strengthened Al0.1CoCrFeNi Alloy from Aluminum-Addition Friction Stir Processing. J. of Materi Eng and Perform 29, 4206–4211 (2020). https://doi.org/10.1007/s11665-020-04931-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04931-6