We study the operating conditions for the specialized tapping spout used to protect molten steel against secondary oxidation between the steel pouring ladle and the tundish in a continuous billet casting machine. The following are found to be the major factors affecting premature failure of the tapping spout: Localized damage to the tapping spout walls due to installation-related misalignment between the spout and the refractory-lined slide-gate valve, and gradual encrustation of the spout during the pour process, with oxygen lancing subsequently being required to remove the encrustation. The accuracy of spout alignment with the ladle slide gate can be improved by modifying the functional configuration of the manipulator to support self-alignment of the spout to its proper location. The wear on the spout can be reduced by using a pneumatic vibrator to induce vibration, and this has been confirmed by laboratory studies using a model experiment. The proposed modernization of the manipulator will enhance tapping spout operating efficiency by reducing premature tapping spout failures.

Similar content being viewed by others

References

A. N. Smirnov, V. L. Pilyushenko, A. A. Minaev, et al., Continuous Casting Processes [in Russian], DonNTU, Donetsk (2002).

A. V. Kuklev and A. V. Leites, Continuous Steel Casting Practice, Metallurgizdat, Moscow (2011).

A. N. Smirnov, S. V. Kuberskii, and E. V. Shtepan, Continuous Casting of Steel [in Russian], DonNTU, Donetsk (2011).

V. I. Dubodelov, A. N. Smirnov, V. G. Efimova, et al., Hydrodynamic, Physical, and Chemical Processes in Tundishes for Continuous Casting of Steel, Naukova Dumka, Kiev (2018).

S. A. Suvorov, “Elastic refractory materials,” Novye Ogneupory, No. 7, July, 40–46 (2007); English translation:Refractories and Industrial Ceramics, 48, 202–207 (2007).

S. Singh and S. C. Koria, “Dynamic variations of lance distance in impinging jet steelmaking processes,” Ironmaking and Steelmaking (UK), 21, No. 5, 394–401 (1994).

B. Harcsik, P. Tardy, and G. Karoly, “Examination of nozzle clogging in continuous casting,” Revue de Métallurgie, 109, 177–186 (2012).

H. Arcos-Gutierrez, J. de J. Barreto, S. Garcia-Hernandez, and A. Ramos-Banderas, “Mathematical analysis of inclusion removal from liquid steel by gas bubbling in a casting tundish,” J. Appl. Math., No. 2, 1–16 (2012).

A. Cwudzinski, “Numerical simulation of liquid steel flow in wedge-type one-strand slab tundish with a subflux,” Ironmaking and Steelmaking (UK), 37, No. 3, 169–180 (2010).

A. N. Bozheskov, A. V. Alenin, V. V. Kazakov, A. M. Toptygin, and V. V. Tinyakov, “Physical modeling of metal flows in an AO Volga Pipe Plant ESSW CBCM-2 tundish with the aim of improving its construction,” Metallurg, No. 12, 39–41 (2018); English translation:Metallurgist, 62, 1240–1243 (2019).

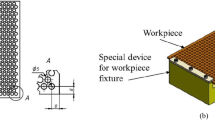

S. P. Eronko, S. V. Bykovskih, N. V. Rodionov, and E. V. Bannykh, “Improved design of manipulator for mechanized replacement of tapping spout in continuous casting of steel,” Metallurgicheskie Protsessy i Oborudovanie, No. 2, 19–25 (2010).

S. P. Eronko, M. Yu. Tkachev, and E. A. Ponamareva, “ Model studies of the effect of vibrations on accumulation in a ladle gatevalve,” Chernaya Metallurgiya. Byulleten Nauchno-Tekhnicheskoi i Ehkonomicheskoi Informatsii, 1, 51–57 (2018).

S. P. Eronko, O. V. Oshovskaya, M. Yu. Tkachev, and E. A. Ponamareva, “Model studies of operating parameters for vibration equipment used in ladle gate-valve systems,” in: Collected Scientific Papers of Donbass State Technical University, a State Educational Institution of Higher and Professional Education [in Russian], Lugansk People’s Republic, No. 11(54) (Alchevsk 2018), pp. 119–128.

S. P. Eronko, M. Yu. Tkachev, E. A. Ponamareva, et al., “Estimated rate of absorption for elastic waves in ladle gate-valve systems exposed to vibration,” in: Collected Scientific Papers of Donbass State Technical University, a State Educational Institution of Higher and Professional Education, Lugansk People’s Republic, No. 16(59) (Alchevsk 2018), pp. 69–77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 4, pp. 30–35, April, 2020.

Rights and permissions

About this article

Cite this article

Eron’ko, S.P., Danilov, V.L., Tkachev, M.Y. et al. Model Studies and Modernization of a Manipulator for Tapping Spout Replacement in Continuous Steel Casting. Metallurgist 64, 301–308 (2020). https://doi.org/10.1007/s11015-020-00996-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00996-9