Abstract

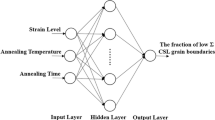

In fracture mechanics, the fatigue evaluation depends on the precise provisions of the stress intensity factor (SIF), which is a quantitative factor established to evaluate the effect of stresses along the crack front. Stress intensity factor performs a definitive role in reflecting material fracture and estimating fatigue life of tubular joints. Some researchers have proposed a series of parametric equations to predict SIF values; however, it gave arguably inaccurate results. There is still a need to improve the accuracy of the SIF prediction’s equation. Thus, to overcome this shortage, this study introduced back-propagation (BP) neural network with conjunction to genetic algorithm (GA) (GA-BP) in predicting the SIF of cracked tubular T/Y-joint. To train and verify the results of the hybrid algorithm GA-BP SIFs’ database covers a wide variety of cracked tubular T/Y joints were simulated by ABAQUS and verified against experimental results. Meanwhile, the SIFs’ result produced by the GA-BP optimization method were compared with those SIF calculated from the accessible parametric equations. The comparison indicated that the GA-BP neural network optimization method is reliable, precise and capable tool in calculating the SIFs of cracked T/Y joints and it also provides higher accuracy than common methods.

Similar content being viewed by others

References

Bowness D, Lee MMK (1995) A finite element study of stress fields and stress intensity factors in tubular joints. Journal of Strain Analysis for Engineering Design 30(2):135–142, DOI: https://doi.org/10.1243/03093247V302135

Bowness D, Lee MMK (1998) Fatigue crack curvature under the weld toe in an offshore tubular joint. International Journal of Fatigue 20(6):481–490, DOI: https://doi.org/10.1016/S0142-1123(98)00017-6

Brennan FP, Dover WD, Kar RF, Hellier AK (1999) Parametric equations for T-butt weld toe stress intensity factors. International Journal of Fatigue 21(10):1051–1062, DOI: https://doi.org/10.1016/S0142-1123(99)00090-0

Chiew SP, Gupta A, Wu NW (2001a) Neural network-based estimation of stress concentration factors for steel multiplanar tubular XT-joints. Journal of Constructional Steel Research 57:97–112, DOI: https://doi.org/10.1016/s0143-974x(00)00016-x

Chiew SP, Lie ST, Lee CK, Huang ZW (2001b) Stress intensity factors for a surface crack in a tubular T-joint. International Journal of Pressure Vessels & Piping 78(10):677–685, DOI: https://doi.org/10.1016/S0308-0161(01)00083-7

Chiew SP, Lie ST, Lee CK, Huang ZW (2003) Parametric equations for stress intensity factors of cracked tubular T&Y-joints. Proceedings of the thirteenth international offshore and polar engineering conference, Honolulu, HI, USA

Ding S, Zhang Y, Chen J, Ji W (2013) Research on using genetic algorithms to optimize Elman neural networks. Neural Computing and Applications 23(2):293–297, DOI: https://doi.org/10.1007/s00521-012-0896-3

Fathi A, Aghakouchak AA, Montazer GA (2004) Evaluating the stress intensity modification factor in offshore tubular T joints using artificial neural networks. 23rd international conference on offshore mechanics and arctic engineering, Vancouver, Canada

Holland JH (1992) Adaptation in natural and artificial systems. MIT Press Cambridge, Cambridge, MA, USA

Huang X, Hancock JW (1988) The stress intensity factors of semi-elliptical cracks in a tubular welded T-joint under axial loading. Engineering Fracture Mechanics 30(1):25–35, DOI: https://doi.org/10.1016/0013-7944(88)90252-4

Irwin GR (1957) Analysis of stresses and strains near end of a crack traversing a plate. Journal of Applied Mechanics 24(3):361–364

Kim KB, Yoon DJ, Jeong JC, Lee SS (2004) Determining the stress intensity factor of a material with an artificial neural network from acoustic emission measurements. NDT & E International 37(6):423–429

Lie ST, Li T, Shao YB (2016) Stress intensity factors of tubular T/Y-joints subjected to three basic loading. Advanced Steel Construction 12(2):109–133, DOI: https://doi.org/10.18057/IJASC.2016.12.2.3

Mohamed HS, Gao F, Guan XQ, Zhu HP (2018a) Experimental investigation on the fatigue behaviour of heat-treated tubular T-joints. KSCE Journal of Civil Engineering 22(7):2451–2463, DOI: https://doi.org/10.1007/s12205-017-1922-x

Mohamed HS, Gao F, Zhu HP (2018b) The influence of crack propagation angle on the stress intensity factors (SIFs) of cracked tubular T-joints. International Journal of Steel Structures 18(2):391–401, DOI: https://doi.org/10.1007/s13296-018-0006-1

Mohamed HS, Li X, Dong S, Hassanein MF (2020) Parametric equation to predict the SIF of cracked tubular T/Y-joints. Journal of Constructional Steel Research 164:105773, DOI: https://doi.org/10.1016/j.jcsr.2019.105773

Newman JJC, Raju IS (1981) An empirical stress-intensity factor equation for the surface crack. Engineering Fracture Mechanics 15(1):185–192, DOI: https://doi.org/10.1016/0013-7944(81)90116-8

Olowokere DO, Nwosu DI (1997) Numerical studies on crack growth in a steel tubular T-joint. International Journal of Mechanical Sciences 39(7):859–871, DOI: https://doi.org/10.1016/S0020-7403(96)00087-2

Qian XD, Petchdemaneengam Y, Swaddiwudhipong S, Marshall P, Qu ZY, Nguyen CT (2013) Fatigue performance of tubular X-joints with PJP+ welds: I — Experimental study. Journal of Constructional Steel Research 90:49–59, DOI: https://doi.org/10.1016/j.jcsr.2013.07.016

Rhee HC, Han S, Gipson GS (1991) Reliability of solution method and empirical formulas of stress intensity factors for weld toe cracks of tubular joints. 10th offshore mechanics and arctic engineering conference, Stavanger, Norway

Ritchie D, Huijskens HAM (1988) Fracture mechanics based prediction of the effect of size of tubular joint test specimens on their fatigue life. The 8th international conference on offshore mechanics and arctic engineering, Hague, Netherlands

Shao YB, Du ZF, Hu WD (2006) Finite element method for analyzing stress intensity factor of a surface crack in tubular joints. Computational Methods in Engineering & Science, Springer, Berlin, Heidelberg

Shen W, Choo YS (2012) Stress intensity factor for a tubular T-joint with grouted chord. Engineering Structures 35:37–47, DOI: https://doi.org/10.1016/j.engstruct.2011.10.014

Wu S, Abel A (1992) Fatigue crack stress intensity factors: The influence of residual stresses. The second international offshore and polar engineering conference, June 14–19, San Francisco, CA, USA, 1067–1070

Wu Z, Hu S, Zhou F (2014) Prediction of stress intensity factors in pavement cracking with neural networks based on semi-analytical FEA. Expert Systems with Applications 41:1021–1030, DOI: https://doi.org/10.1016/j.eswa.2013.07.063

Zhang W, Bao Z, Jiang S, He J (2016) An artificial neural network-based algorithm for evaluation of fatigue crack propagation considering nonlinear damage accumulation. Materials 9(6), DOI: https://doi.org/10.3390/ma9060483

Acknowledgements

This work is supported by the National Natural Science Foundation of China under Grant No. 51574198.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Li, X., Dong, S., Mohamed, H.S. et al. Prediction of Tubular T/Y-Joint SIF by GA-BP Neural Network. KSCE J Civ Eng 24, 2706–2715 (2020). https://doi.org/10.1007/s12205-020-1200-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-1200-1