Abstract

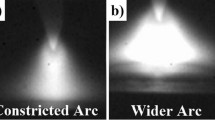

The magnetic arc constriction technique was used to control the heat input-related metallurgical problems such as segregation of Nb and laves phase formation in the weld metal region of gas tungsten arc welding (GTAW) of Inconel 718 alloy. The delta current (arc constriction current) and delta current frequency are the two important parameters in controlling the arc characteristics. The main effect of the delta current and delta current frequency on the microstructural modification and corresponding influence on the tensile properties of a gas tungsten constricted arc (GTCA) welded 2-mm-thick Inconel 718 alloy sheet was investigated systematically and presented in this article. Superior tensile properties were exhibited by the joints made using a delta current of 50 A and delta current frequency of 4 kHz because of the grain refinement in the fusion zone and finer, distinct laves phase formation.

Similar content being viewed by others

References

T. Pollock and S. Tin: J. Prop. P., 2006, 2 (2), 361-374.

J. X. Dong, X. S. Xie, and R. G. Thompson: Metall. Mater. Trans. A, 2000, vol.31(9), pp. 2135–2144.

H. J. Wagner and A. Hall: Report No. 217, Defence Metals Information Centre (DMIC), Battle Memorial Institute Columbus Ohio, 1965.

D. S. Duvall and W. A. Owczarski: Weld. J., 1969, 48(1), 10–22

S. Gobbi, L. Zhang, J. Norris, K. H. Richter, and J. H. Loreau: J. Mater. Proc. Technol., 1996, Vol. 56 (1-4), pp. 333–345.

M. Qian and J. C. Lippold: Weld. J., 2003, Vol.82 (6), pp. 145s – 150s.

T. Alam, P. J. Felfer, M. Chaturvedi, L. T. Stephenson, M. R. Kilburn and J. M. Cairney: Metall. Mater. Trans. A, 2012, Vol. 43(7), pp. 2183–2191.

CH. Radhakrishna and K. PrasadRao: J. Mater. Sci., 1997, vol. 32, pp. 1977-1984.

S.G.K. Manikandan, D. Sivaprasad, K PrasadRao and M. Kamaraj: Mater. Charact., 2015, vol. 100, pp. 192-206.

G.D.J. Ram, A. Reddy, K. PrasadRao, G. M. Reddy and J. SarinSundar: J. Mater. Proc. Technol., 2005, vol. 167, pp.73-82.

G. M. Reddy, C. V. SrinivasaMurthy, N. Viswanathan and K. PrasadRao: Sci. Technol. Weld. Join., 2007, vol. 12(2), pp.106–114.

R. Cortés, E. R. Barragán, V. H. López, R. R. Ambriz and D. Jaramillo: Inter. J. Adv. Manuf. Technol., 2017, Vol. 94(9-12), pp. 3949–3961.

N. K. Rodríguez, E. R. Barragán, I. V. Lijanova, R. Cortés, R. R. Ambriz, C. Méndez and D. Jaramillo: Proc. 17th Int. Conf. New Trends in Fatigue and Fracture 2017, pp. 255–62.

W. Chen, M. C. Chaturvedi and N. L. Richards: Metall. Mater. Trans. A, 2001, vol. 32(4), pp. 931–939.

C.V.S. Murthy, A.G. Krishna, G.M. Reddy, Trans. Indian Inst. Met. 2019, vol. 72, pp. 2433–2441.

C. V. S. Murthy, A. G. Krishna and G. M. Reddy: Def. Technol., 2019, vol. 15 (1), pp. 111-121.

V. Vaithiyanathan, V. Balasubramanian, S. Malarvizhi, V. Pateley and S. Verma: Metall. Micro. Anal., 2020, vol. 9 (2), pp. 194-211.

V. Vaithiyanathan, V. Balasubramanian, S. Malarvizhi, V. Pateley and S. Verma: SN. Appl. Sci., 2020, vol. 2 (88), pp. 1-12.

V. Vaithiyanathan, V. Balasubramanian, S. Malarvizhi, V. Pateley and A. G. Rao: Mater. Res. Express, 2019, vol. 6(9), pp. 1-13.

G. D. J. Ram, A VenugopalReddy, K. PrasadRao and G. M. Reddy: Sci. Technol. Weld. Join., 2004, Vol. 9, pp.390-398.

G. D. J. Ram, A. V. Reddy, K. P. Rao, and G. M. Reddy: J. Mater. Sci., 2005, vol. 40(6), 1497–1500.

K. Sivaprasad, S. G. SundaraRaman, P. Mastanaiah and G. M. Reddy: Mater. Sci. Eng. A, 2006, vol. 428, pp.327–331.

K. Sivaprasad and S. G. S. Raman: Mater. Sci. Eng. A, 2007, vol. 448(1-2), pp. 120–127.

S.G.K. Manikandan, D. Sivakumar, D. Karthikesan, K. PrasadRao and M. Kamaraj: Proc. Mater. Sci. Technol. 2013, Vol. 1, pp. 1361–1375.

K. D. Ramkumar, B. M. Kumar, M. G. Krishnan, S. Dev, A. J. Bhalodi, N. Arivazhagan, and S. Narayanan: Mater. Sci. Eng. A, 2015, vol. 639, pp. 234–244.

G. M. Reddy, C. V. S. Murthy, K. SrinivasaRao and K. PrasadRao: Int. J. Adv. Manuf. Technol., 2008, vol. 43(7-8), pp. 671–680.

A. K. JawwadAbdul, M. Strangwood and C. L. Davis: Metall. Mater. Trans. A, 2005, vol. 36(5), pp. 1237–1247.

S. I. Kwon, S. H. Bae, J. H. Do, C. Y. Jo and H. U. Hong: Metall. Mater. Trans. A, 2015, Vol. 47(2), pp. 777–787.

X. Cao, B. Rivaux, M. Jahazi, J. Cuddy and A. Birur: J. Mater. Sci., 2009, vol. 44(17), pp. 4557–4571.

K. R. Vishwakarma, N. L. Richards and M. C. Chaturvedi: Mater. Sci. Eng. A, 2008, vol. 480(1-2), 517–528.

R. Mehrabian, B.H. Kear, M. Cohen, Rapid Solidification Processing: Principles and Technologies. Part I, Claitor’s Publication Division, Baton Rouge, LA, 1978.

S. H. Bae, S. I. Kwon, J. G. Yoon, J. H. Lee, J. H. Do, I. S. Kim and H. U. Hong, Metall. Mater. Trans. A, 2013, vol.45(2), pp. 537–542.

G. SudarshanRao, K. Saravanan, G. Harikrishnan, V. M. J. Sharma, P. RameshNarayan, K. Sreekumar and P. Sinha: Mater. Sci. Forum, 2012, vol. 710, pp. 439-444.

Odabasi, N. Unlu, G. Goller and MN Eruslu: Metall. Mater. Trans. A, 2010. vol. 41, pp.2357-2365.

S. G. K. Manikandan, D. Sivakumar, K. P. Rao and M. Kamaraj: J. Mater. Proc. Technol., 2014, vol. 214(2), pp.358–364.

A. Bansal, A. K. Sharma, S. Das, P. Kumar: Kovo. Mater., 2016, vol. 54, pp. 27-35.

Acknowledgments

The authors express their sincere gratitude to the Director, Vikram Sarabhai Space Centre (VSSC), ISRO, Thiruvananthapuram, Kerala, for providing the financial support and base material to carry out this investigation through the ISRO RESPOND scheme (Project No. ISRO/RES/3/728/16-17).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 20, 2019.

Rights and permissions

About this article

Cite this article

Sonar, T., Balasubramanian, V., Malarvizhi, S. et al. Effect of Delta Current and Delta Current Frequency on Microstructure and Tensile Properties of Gas Tungsten Constricted Arc (GTCA)-Welded Inconel 718 Alloy Joints. Metall Mater Trans A 51, 3920–3937 (2020). https://doi.org/10.1007/s11661-020-05853-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05853-7