Abstract

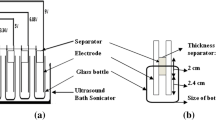

In this study, a new method of rapid preparation of carbon nanotube (CNT) solution with highly dispersed morphology by free arc excitation is proposed, which shortens the time of the preparation of CNT solution with low concentration. The principle is that the high-energy flow density heat generated by the free arc makes the vaporizable substance coated on the surface of CNTs vaporize rapidly, and then generates the bulk increasing motion, which makes the CNTs aggregates dispersed, and finally forms the CNTs gas-phase dispersion monomer with high dispersion or the cross-linking morphology of few CNTs. In this paper, the influence of gum Arabic (GA) and deionized water (DI water) contents in CNTs mixed electrode on the dispersion of CNTs in different environments (gas phase and liquid phase) is explored. In the limited case of this work, the dispersion effect is better when the mass ratio of CNTs, GA and DI water is 1:0.04:3.96 in the liquid-phase environment. The preparation method reported in this work is expected to be a rapid way to obtain low-concentration nanodispersion.

Similar content being viewed by others

References

Zhang W, Chen X, Yong T, Xu N, Guan R, Yue L (2016) Multiwalled carbon nanotube webs welded with Si nanoparticles as high-performance anode for lithium-ion batteries. J Alloys Compd 688:216

Jung JH, Hwang GB, Lee JE, Bae GN (2011) Preparation of airborne Ag/CNT hybrid nanoparticles using an aerosol process and their application to antimicrobial air filtration. Langmuir 27:10256–10264

Ma PC, Zhang Y (2014) Perspectives of carbon nanotubes/polymer nanocomposites for wind blade materials. Renew Sust Energ Rev 30:651

Jian X, Chen G, Liu H, Mahmood N, Zhu S, Yin L, Tang H, Lv W, He W, Zhang KHL et al (2016) Vapor–dissociation–solid growth of three-dimensional graphite-like capsules with delicate morphology and atomic-level thickness control. Cryst Growth Des 16:5040

Grossiord N, Regev O, Loos J, Meuldijk J, Koning CE (2005) Time-dependent study of the exfoliation process of carbon nanotubes in aqueous dispersions by using UV–visible spectroscopy. Anal Chem 77:5135

Ürk D, Demir E, Bulut O, Çakıroğlu D, Cebeci FC, Öveçoğlu ML, Cebeci H (2016) Understanding the polymer type and CNT orientation effect on the dynamic mechanical properties of high volume fraction CNT polymer nanocomposites. Compos Struct 155:255

Rasheed A, Fawad I (2016) Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J Nanotechnotechnol 7:1174

Sergio M, Jean-Christophe P (2019) Methods for dispersing carbon nanotubes for nanotechnology applications: liquid nanocrystals, suspensions, polyelectrolytes, colloids and organization control. Int Nano Lett 9:31

Xia T, Guo X, Lin YX et al (2019) Aggregation of oxidized multi-walled carbon nanotubes: interplay of nanomaterial surface O-functional groups and solution chemistry factors. Environ Pollut 251:921

Yu J, Grossiord N, Koning CE, Loos J (2007) Controlling the dispersion of multi-wall carbon nanotubes in aqueous surfactant solution. Carbon 45:618

Li Q, Church JS, Kafi A, Naebe M, Fox BL (2014) An improved understanding of the dispersion of multi-walled carbon nanotubes in non-aqueous solvents. J Nanopart Res 16:2513

Pierard N, Fonseca A, Konya Z, Willems I, Tendeloo GV, Nagy JB (2001) Production of short carbon nanotubes with open tipes by ball milling. Chem Phys Lett 335:1

Ma PC, Tang BZ, Kim JK (2008) Converting semiconducting behavior of carbon nanotubes using ball milling. Chem Phys Lett 458:166

Akizuki N, Aota S, Mouri S, Matsuda K, Miyauchi Y (2015) Efficient near-infrared up-conversion photoluminescence in carbon nanotubes. Nat Commun 6:8920

Gao Y, Jing HW, Chen SJ, Dua MR, Chen WQ, Duan WH (2019) Influence of ultrasonication on the dispersion and enhancing effect of graphene oxide–carbon nanotube hybrid nanoreinforcement in cementitious composite. Compos B 164:45

Zapata-Massot C, Bolay NL (2008) Effect of ball milling in a tumbling ball mill on the properties of multi-wall carbon nanotubes. Chem Eng Process Process Intensif 47:1356

Liu XY, Xu Y, Chen L et al (2013) Study on the influence facors of the dispersion of carbon nanotubes in aqueous solution. Key Eng Mater 539:239

Li SL, He Y, Jing CW, Gong XB, Cui LL, Cheng ZY, Zhang CQ, Nan F (2018) A novel preparation and formation mechanism of carbon nanotubes aerogel. Carbon Lett 28:16

Li SL, Zhang CQ, He Y, Feng M, Ma C, Cui Y (2019) Multi-interpolation mixing effects under the action of micro-scale free arc. J Mater Process Technol 271:645

Yong JK, Sang HL, Do YB et al (2006) Electrostatic ejection of single-walled carbon nanotubes suspended in solution. Key Eng Mater 326:321–324

Bandyopadhyaya R, Nativ-Roth E, Regev O et al (2002) Stabilization of individual carbon nanotubes in aqueous solution. Nano Lett 2:25

Yuan CS, Zhou X, Lei SU et al (2014) Combined effect of ultra high pressure and temperature on ageing modification of arabic gum. Food Eng 4:24

Alafogianni P, Dassios K, Farmaki S, Antiohos SK, Matikas TE, Barkoula NM (2016) On the efficiency of UV–vis spectroscopy in assessing the dispersion quality in sonicated aqueous suspensions of carbon nanotubes. Colloids Surf A Physicochem Eng Asp 495:118

Liu H, Cui SP, Wang JC, Wang JF (2017) Influence of chemical admixtures on the dispersion of carbon nanotubes in water and cement pastes. IOP Conf Ser Mater Sci Eng 182:012029

Acknowledgements

This work was supported by the National Science Foundation of China (NSFC. Grant no. 51676103) and Major research plan for public welfare in Shandong (2018GGX102007). The authors acknowledge the support from Qingdao University of Science and Technology and special expert of Shandong Taishan Scholars for their special support. This research made use of the Ministry of Science and Technology of polymer processing technology and related thermal physics international cooperation base.

Author information

Authors and Affiliations

Contributions

SL and HY had the idea for and designed the experiments and supervised the Work. YD and CQ carried out the device fabrication and performed the experiments and characterization. ZD and YD wrote the draft of the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, S., Ci, Y., Zhang, D. et al. Free arc liquid-phase dispersion method for the preparation of carbon nanotube dispersion. Carbon Lett. 31, 287–295 (2021). https://doi.org/10.1007/s42823-020-00164-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-020-00164-8