Abstract

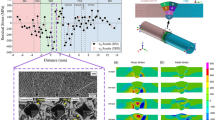

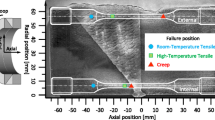

Large tensile residual stress is detrimental to the structural integrity of welded structures. As a result, it is very important to understand the residual formation during the welding process. In this paper, a new non-contact welding residual stress measurement technique based on digital image correlation (DIC) is proposed as a way to investigate residual stress formation. To investigate the stress evolution of the welded plate, we conduct a series of experiments by using this new method. High-temperature full-field strain obtained from DIC was computed by incremental theory to acquire stress increment. Stress evolution and residual stress were obtained by superimposing the stress increment. Hole-drilling residual stress measurements for verification were also implemented. The maximum difference, which was 37 MPa between the two methods demonstrated that this new technique was able to characterize the full-field welding residual stress during the welding process.

Similar content being viewed by others

References

Withers PJ, Bhadeshia HKDH (2001) Residual stress. Part 2—nature and origins. Mater Sci Technol 17(4):366–375

De A, DebRoy T (2011) A perspective on residual stresses in welding. Sci Technol Weld Join 16(3):204–208

Dong P (2005) Residual stresses and distortions in welded structures: a perspective for engineering applications. Sci Technol Weld Join 10(4):389–398

Deplus K, Simar A, Haver WV, Meester BD (2011) Residual stresses in aluminum alloy friction stir welds. Int J Adv Manuf Technol 56:493–504

Feng Z (2005) Processes and mechanisms of welding residual stress and distortion. Woodhead Publishing, Cambridge

Rossini NS, Dassisti M, Benyounis KY (2012) Methods of measuring residual stresses in components. Mater Des 35:572–588

Younis NT, Kang B (2011) Averaging effects of a strain gage. J Mech Sci Technol 25(1):163–169

Baldi A (2014) Residual stress measurement using hole drilling and integrated digital image correlation techniques. Exp Mech 54(3):379–391

Nelson DV, Makino A, Schmidt T (2006) Residual stress determination using hole drilling and 3D image correlation. Exp Mech 46(1):31–38

Gao J, Shang H (2009) Deformation-pattern-based digital image correlation method and its application to residual stress measurement. Appl Opt 48(7):1371–1381

Rangaswamy P, Griffith ML, Prime MB, Holden TM, Rogge RB, Edwards JM, Sebring RJ (2005) Residual stresses in LENS components using neutron diffraction and contour method. Mater Sci Eng A 399(1–2):72–83

Ganguly S, Stelmukh V, Edwards L, Fitzptrick ME (2008) Analysis of residual stress in metal-inert-gas-welded Al-2024 using neutron and synchrotron X-ray diffraction. Mater Sci Eng A 491(1–2):248–257

Acevedo C, Evans A, Nussbaumer A (2012) Neutron diffraction investigations on residual stresses contributing to the fatigue crack growth in ferritic steel tubular bridges. Int J Pres Ves Pip 95(7):31–38

Prime MB, Thomas G-H, Baumann JA, Lederich RJ, Bowden DM, Sebring R (2006) Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld. Acta Mater 54(15):4013–4021

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: a review. Meas Sci Technol 20(6):1–17

Jae B (2019) Completely in situ and non-contact warpage assessment using 3D DIC with virtual patterning method. Int J Adv Manuf Technol 100:2803–2811

Hild F, Roux S (2006) Digital image correlation: from displacement measurement to identification of elastic properties – a review. Strain 42(2):69–80

Li ZG, He N, Fan ZM, Liao HL (2013) The study of non-contact measure method for deformation based on the digital image correlation. Adv Mater Technol 718-720:853–857

Li GY, Xu FX, Sun GY, Li Q (2014) Identification of mechanical properties of the weld line by combining 3D digital image correlation with inverse modeling procedure. Int J Adv Manuf Technol 74:893–905

Henry TC, Phillips FR, Cole DP, Garboczi E, Haynes RA, Johnson T (2020) In situ fatigue monitoring investigation of additively manufactured maraging steel. Int J Adv Manuf Technol 107:3499–3510

Agarwal G, Gao H, Amirthalingam M, Hermans MJM (2018) In situ strain investigation during laser welding using digital image correlation and finite-element-based numerical simulation. Sci Technol Weld Join 23(2):134–139

Chen J, Feng Z (2018) Strain and distortion monitoring during arc welding by 3D digital image correlation. Sci Technol Weld Join 23(6):536–542

Chen J, Yu XH, Miller RG, Feng Z (2014) In situ strain and temperature measurement and modelling during arc welding. Sci. Technol. Weld Joining 20(3):181–188

Sutton MA, Yan JH, Tiwari V, Schreier HW, Orteu JJ (2008) The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt Lasers Eng 46(10):746–757

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation Matlab software. Exp Mech 55(6):1105–1122

Liu ZX (2010) Computational solid mechanics. China, Shanghai Jiao Tong University Publishing, Shanghai

Acknowledgments

The authors are grateful to the financial support of the National Natural Science Foundation of China (Grant No.51575348) and National Key Research and Development Program of China (No. 2018 YFC0310400).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, H., Song, Y., Chen, X. et al. In situ studies of full-field residual stress mapping of SS304 stainless steel welds using DIC. Int J Adv Manuf Technol 109, 45–55 (2020). https://doi.org/10.1007/s00170-020-05627-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05627-w