Abstract

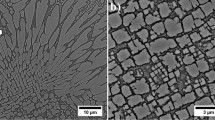

The grain structure, precipitate size, morphology, volume fraction and distribution, coarsening kinetics, hardness and cyclic oxidation behavior of (γ + γ′) Ni-13Al-2Nb (at.%) and Ni-11Al-4Nb (at.%) superalloys, aged at 800 °C from 1 to 256 h, are investigated in detail. For the earliest aging times (1 and 4 h), the morphology of the γ′ precipitates are cuboidal. With increasing aging time, the γ′ precipitates coarsen, the average precipitate radius increases, and the morphology changes from cuboidal-to-parallelepipedic-to-irregular shape. The average precipitate size also increases with increasing Nb content from 2 to 4 at.%. At 4 h aging time, Ni-13Al-2Nb and Ni-11Al-4Nb superalloys exhibit peak microhardness values of 3.7 and 3.9 GPa, respectively. The results of cyclic oxidation tests show that important scale spallation is observed for the investigated samples. In addition, the surface scale product of both superalloys at all conditions is NiO.

Similar content being viewed by others

References

M.S. Atas and M. Yildirim, Temporal Evolution, Coarsening Behavior and Oxidation Resistance of Ni-15Al Superalloy, J. Alloys Compd., 2019, 809, p 151784

C. Li, G. Guo, Z. Yuan, W. Xuan, X. Li, Y. Zhong, and Z. Ren, Chemical Segregation and Coarsening of γ′ Precipitates in Ni-Based Superalloy During Heat Treatment in Alternating Magnetic Field, J. Alloys Compd., 2017, 720, p 272–276

T.M. Pollock and S. Tin, Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties, J. Propul. Power, 2006, 22(2), p 361–374

J. Wu, C. Li, Y. Liu, Y. Wu, Q. Guo, H. Li, and H. Wang, Effect of Annealing Treatment on Microstructure Evolution and Creep Behavior of a Multiphase Ni3Al-Based Superalloy, Mater. Sci. Eng. A, 2019, 743, p 623–635

Y. Wu, Y. Liu, C. Li, X. Xia, J. Wu, and H. Li, Coarsening Behavior of γ′ Precipitates in the γ’ + γ Area of a Ni3Al-Based Alloy, J. Alloys Compd., 2019, 771, p 526–533

S. Tang, L.K. Ning, T.Z. Xin, and Z. Zheng, Coarsening Behavior of Gamma Prime Precipitates in a Nickel Based Single Crystal Superalloy, J. Mater. Sci. Technol., 2016, 32(2), p 172–176

G. Wang, H. Ding, R. Chen, J. Guo, and H. Fu, Effect of Current Intensity on Microstructure of Ni3Al Intermetallics Prepared by Directional Solidification Electromagnetic Cold Crucible Technique, Acta Metall. Sin., 2017, 53(11), p 1461–1468

C.K. Sudbrack, T.D. Ziebell, R.D. Noebe, and D.N. Seidman, Effects of a Tungsten Addition on the Morphological Evolution, Spatial Correlations and Temporal Evolution of a Model Ni-Al-Cr Superalloy, Acta Mater., 2008, 56(3), p 448–463

F.H. Latief, K. Kakehi, and Y. Tashiro, Oxidation Behavior Characteristics of an Aluminized Ni-Based Single Crystal Superalloy CM186LC Between 900 °C and 1100 °C in Air, J. Ind. Eng. Chem., 2013, 19(6), p 1926–1932

R.C. Reed, The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2008

S. Antonov, M. Detrois, R.C. Helmink, and S. Tin, Precipitate Phase Stability and Compositional Dependence on Alloying Additions in γ–γ′–δ–η Ni-Base Superalloys, J. Alloys Compd., 2015, 626, p 76–86

R. Eriş, A.O. Mekhrabov, and M.V. Akdeniz, High-Temperature Site Preference and Atomic Short-Range Ordering Characteristics of Ternary Alloying Elements in γ′-Ni3Al Intermetallics, Philos. Mag., 2017, 97(29), p 2615–2631

E.Y. Plotnikov, Z. Mao, S.-I. Baik, M. Yildirim, Y. Li, D. Cecchetti, R.D. Noebe, G. Martin, D.N. Seidman, A Correlative Four-Dimensional Study of Phase-Separation at the Subnanoscale to Nanoscale of a Ni-Al Alloy, Acta Mater. 171, 306–333 (2019)

R. Schafrik, R. Sprague, Saga of Gas Turbine Materials, Part I-Four-Part Series Traces the Evolution of High-Temperature Materials in Aircraft Gas Turbine Engines. The Story Begins in 1929, with the Filing of the Whittle, Adv. Mater. Process. 162(3), 33–36 (2004)

D.W. Yun, S.M. Seo, H.W. Jeong, and Y.S. Yoo, Effect of Refractory Elements and Al on the High Temperature Oxidation of Ni-Base Superalloys and Modelling of Their Oxidation Resistance, J. Alloys Compd., 2017, 710, p 8–19

A. Heckl, R. Rettig, R.F. Singer, Creep Rupture Strength of Re and Ru Containing Experimental Nickel-Base Superalloys, Advanced Materials Research, 2011, Trans Tech Publ., pp 339–344

F. Latief, K. Kakehi, H.A.-C. Yeh, and H. Murakami, Influences of Ruthenium and Crystallographic Orientation on Creep Behavior of Aluminized Nickel-Base Single Crystal Superalloys, Mater. Sci. Eng. A, 2014, 592, p 143–152

M. Nathal and L. Ebert, The Influence of Cobalt, Tantalum, and Tungsten on the Elevated Temperature Mechanical Properties of Single Crystal Nickel-Base Superalloys, Metall. Trans. A, 1985, 16(10), p 1863–1870

J. Zhang, J. Li, T. Jin, X. Sun, and Z. Hu, Effect of Mo Concentration on Creep Properties of a Single Crystal Nickel-Base Superalloy, Mater. Sci. Eng. A, 2010, 527(13–14), p 3051–3056

F. Weng, H. Yu, K. Wan, and C. Chen, The Influence of Nb on Hot Corrosion Behavior of Ni-Based Superalloy at 800 °C in a Mixture of Na2SO4–NaCl, J. Mater. Res., 2014, 29(21), p 2596–2603

F. Weng, H. Yu, C. Chen, and K. Wan, Fabrication of Ni-Based Superalloys Containing Nb and Their High Temperature Oxidation Behaviors, Mater. Manuf. Processes, 2015, 30(11), p 1364–1369

J. Huang, H. Fang, X. Fu, F. Huang, H. Wan, Q. Zhang, S. Deng, and J. Zu, High-Temperature Oxidation Behavior and Mechanism of a New Type of Wrought Ni-Fe-Cr-Al Superalloy up to 1300 °C, Oxidat. Met., 2000, 53(3–4), p 273–287

J.E. Battles, G. Gundersen, and R.K. Edwards, Mass Spectrometric Study of the Rhenium-Oxygen System, J. Phys. Chem., 1968, 72(12), p 3963–3969

W.E. Bell and M. Tagami, High-Temperature Chemistry of the Ruthenium—Oxygen System1, J. Phys. Chem., 1963, 67(11), p 2432–2436

N. Birks, G.H. Meier, and F.S. Pettit, Introduction to the High Temperature Oxidation of Metals, Cambridge University Press, Cambridge, 2006

Q. Yang, W. Xiong, S. Li, H. Dai, and J. Li, Characterization of Oxide Scales to Evaluate High Temperature Oxidation Behavior of Ti(C, N)-Based Cermets in Static Air, J. Alloys Compd., 2010, 506(1), p 461–467

C. Booth-Morrison, R.D. Noebe, and D.N. Seidman, Effects of Tantalum on the Temporal Evolution of a Model Ni-Al-Cr Superalloy During Phase Decomposition, Acta Mater., 2009, 57(3), p 909–920

Y. Huang, Z. Mao, R.D. Noebe, and D.N. Seidman, The Effects of Refractory Elements on Ni-Excesses and Ni-Depletions at γ (fcc)/γ′(L12) Interfaces in Model Ni-Based Superalloys: Atom-Probe Tomographic Experiments and First-Principles Calculations, Acta Mater., 2016, 121, p 288–298

C.K. Sudbrack, R.D. Noebe, and D.N. Seidman, Compositional Pathways and Capillary Effects During Isothermal Precipitation in a Nondilute Ni-Al-Cr Alloy, Acta Mater., 2007, 55(1), p 119–130

M. Fährmann, E. Fährmann, T. Pollock, and W. Johnson, Element Partitioning During Coarsening of (γ − γ′) Ni-Al-Mo Alloys, Metall. Mater. Trans. A, 1997, 28(9), p 1943–1945

M. Fährmann, P. Fratzl, O. Paris, E. Fährmann, and W.C. Johnson, Influence of Coherency Stress on Microstructural Evolution in Model Ni-Al-Mo Alloys, Acta Metall. Mater., 1995, 43(3), p 1007–1022

Y. Tu, Z. Mao, and D.N. Seidman, Phase-Partitioning and Site-Substitution Patterns of Molybdenum in a Model Ni-Al-Mo Superalloy: An Atom-Probe Tomographic and First-Principles Study, Appl. Phys. Lett., 2012, 101(12), p 121910

T. Wang, G. Sheng, Z.-K. Liu, and L.-Q. Chen, Coarsening Kinetics of γ′ Precipitates in the Ni–Al–Mo System, Acta Mater., 2008, 56(19), p 5544–5551

J. Cisse and R. Davies, Nickel-Rich Portion of the Ni-Al-Nb Phase Diagram, Metall. Trans., 1970, 1(7), p 2003–2006

J.C. Russ and R.T. Dehoff, Practical Stereology, Springer, Berlin, 2012

P.J. Bocchini, C.K. Sudbrack, R.D. Noebe, D.C. Dunand, and D.N. Seidman, Effects of Titanium Substitutions for Aluminum and Tungsten in Co-10Ni-9Al-9W (at.%) Superalloys, Mater. Sci. Eng. A, 2017, 705, p 122–132

T. Pollock and A. Argon, Directional Coarsening in Nickel-Base Single Crystals with High Volume Fractions of Coherent Precipitates, Acta Metall. Mater., 1994, 42(6), p 1859–1874

M.E. Thompson, C.S. Su, and P.W. Voorhees, The Equilibrium Shape of a Misfitting Precipitate, Acta Metall. Mater., 1994, 42(6), p 2107–2122

C.K. Sudbrack, Decomposition Behavior in Model Ni-Al-Cr-X Superalloys: Temporal Evolution and Compositional Pathways on a Nanoscale, Northwestern University Evanston, Evanston, 2004

S.V. Prikhodko, J.D. Carnes, D.G. Isaak, A.J. Ardell, Elastic Constants of a Ni-12.69 at.% Al Alloy From 295 to 1300 K, Scr. Mater. 38(1), 67–72 (1997)

K.E. Yoon, R.D. Noebe, D.N. Seidman, Effects of Rhenium Addition on the Temporal Evolution of the Nanostructure and Chemistry of a Model Ni–Cr–Al Superalloy. I: Experimental Observations, Acta Mater. 55(4), 1145–1157 (2007)

K.E. Yoon, R.D. Noebe, D.N. Seidman, Effects of Rhenium Addition on the Temporal Evolution of the Nanostructure and Chemistry of a Model Ni-Cr-Al Superalloy. II: Analysis of the Coarsening Behavior, Acta Mater. 55(4), 1159–1169 (2007)

E. Contreras-Piedras, H.J. Dorantes-Rosales, V.M. López-Hirata, F. Hernández Santiago, J.L. González-Velázquez, F.I. López-Monrroy, Analysis of Precipitation in Fe-Rich Fe-Ni-Al Alloys by Diffusion Couples, Mater. Sci. Eng. A 558, 366–370 (2012)

K. Kawasaki and Y. Enomoto, Statistical Theory of Ostwald Ripening with Elastic Field Interaction, Physica A, 1988, 150(3), p 463–498

I.M. Lifshitz and V.V. Slyozov, The Kinetics of Precipitation from Supersaturated Solid Solutions, J. Phys. Chem. Solids, 1961, 19(1), p 35–50

C. Wagner, Theorie der alterung von niederschlägen durch umlösen (Ostwald-reifung), Zeitschrift für Elektrochemie, Berichte der Bunsengesellschaft für physikalische, Chemie, 1961, 65(7–8), p 581–591

R. Wagner, R. Kampmann, and P.W. Voorhees, Homogeneous second phase precipitation, Phase transformations in materials, 1991, 5, p 213–303

A.J. Ardell and R.B. Nicholson, The Coarsening of γ’ in Ni-Al Alloys, J. Phys. Chem. Solids, 1966, 27(11), p 1793–1794

J.Z. Zhu, T. Wang, A.J. Ardell, S.H. Zhou, Z.K. Liu, and L.Q. Chen, Three-Dimensional Phase-Field Simulations of Coarsening Kinetics of γ′ Particles in Binary Ni-Al Alloys, Acta Mater., 2004, 52(9), p 2837–2845

Y. Amouyal, Z. Mao, C. Booth-Morrison, and D.N. Seidman, On the Interplay Between Tungsten and Tantalum Atoms in Ni-Based Superalloys: An Atom-Probe Tomographic and First-Principles Study, Appl. Phys. Lett., 2009, 94(4), p 041917

C. Booth-Morrison, Z. Mao, R.D. Noebe, and D.N. Seidman, Chromium and Tantalum Site Substitution Patterns in Ni 3 Al (L 1 2) γ′-Precipitates, Appl. Phys. Lett., 2008, 93(3), p 033103

M. Durand-Charre, The Microstructure of Superalloys, Gordon and Breach, Amsterdam, 1997

A. Oni, S. Broderick, K. Rajan, and J. LeBeau, Atom Site Preference and γ′/γ Mismatch Strain in NiAlCoTi Superalloys, Intermetallics, 2016, 73, p 72–78

C.T. Sims, N.S. Stoloff, and W.C. Hagel, Superalloys II, Wiley, New York, 1987

C. Jiang and B. Gleeson, Site Preference of Transition Metal Elements in Ni3Al, Scr. Mater., 2006, 55(5), p 433–436

N.J. Calos, J.S. Forrester, and G.B. Schaffer, The Mechanisms of Combustion and Continuous Reactions during Mechanical Alloying, J. Solid State Chem., 2001, 158(2), p 268–278

W.C. Wang, Y.X. Shen, J.H. Li, X.Y. Li, and B.X. Liu, Formation and Structural Transformation of the Nonequilibrium Phases in the Ru–Ta System Induced by Ion Beam Mixing, J. Phys.: Condens. Matter, 2006, 18(43), p 9911–9916

X.D. Dai, Y. Kong, J.H. Li, and B.X. Liu, Extended Finnis–Sinclair Potential for BCC and FCC Metals and Alloys, J. Phys.: Condens. Matter, 2006, 18(19), p 4527–4542

J. Zhang, M.-A. Pilette, F. Cuevas, T. Charpentier, F. Mauri, and M. Latroche, X-ray Diffraction and NMR Studies of Na3 − nLinAlH6 (n = 0, 1, 2) Alanates Synthesized by High-Pressure Reactive Ball Milling, J. Phys. Chem. C, 2009, 113(50), p 21242–21252

M. Straumanis and S. Zyszczynski, Lattice Parameters, Thermal Expansion Coefficients and Densities of Nb, and of Solid Solutions Nb-O and Nb-N-O and Their Defect Structure, J. Appl. Crystallogr., 1970, 3(1), p 1–6

A. Gorbunoff, A.A. Levin, and D.C. Meyer, Low-Temperature Thermal Expansion of Metastable Intermetallic Fe-Cr Phases, J. Alloys Compd., 2009, 480(1), p 152–156

M. Beck, M. Ellner, and E.J. Mittemeijer, The Formation of Interstitial Solid Solutions Based on Solvents Showing the FCC Structure: Elastic Versus Chemical Interaction, Acta Mater., 2001, 49(6), p 985–993

S. Ochial, Y. Oya, and T. Suzuki, Alloying Behaviour of Ni3Al, Ni3Ga, Ni3Si and Ni3Ge, Acta Metall., 1984, 32(2), p 289–298

Y. Mishima, S. Ochiai, N. Hamao, M. Yodogawa, and T. Suzuki, Solid Solution Hardening of Nickel—Role of Transition Metal and B-Subgroup Solutes, Trans. Jpn. Inst. Met., 1986, 27(9), p 656–664

T.H. Hazlett, E.R. Parker, and V.F. Zackay, Effect of Some Solid Solution Alloying Elements on the Creep Parameters of Nickel, University of California, Institute of Engineering Research, New York, 1952

A.D. Brailsford and P. Wynblatt, The Dependence of Ostwald Ripening Kinetics on Particle Volume Fraction, Acta Metall., 1979, 27(3), p 489–497

H. Aaronson and F. LeGoues, An Assessment of Studies on Homogeneous Diffusional Nucleation Kinetics in Binary Metallic Alloys, Metall. Trans. A, 1992, 23(7), p 1915–1945

J.P. Moffat, T.E. Whitfield, K.A. Christofidou, E.J. Pickering, N.G. Jones, and H.J. Stone, The Effect of Heat Treatment on the Oxidation Resistance of Cobalt-Based Superalloys, Metals, 2020, 10(2), p 248

P. Berthod, C. Vébert, and L. Aranda, Effect of Dendritic Orientation on the High Temperature Oxidation Kinetic of Tantalum-Containing Nickel-Base Alloys, J. Mater. Sci., 2007, 42(1), p 352–362

P. Berthod, S. Raude, A. Renck, C. Rapin, R. Podor, P. Steinmetz, Influence of the Microstructural Texture of Cast Superalloys on Their High-Temperature Oxidation Behaviour, Mater. Sci. Forum, 2004, Trans Tech Publ, pp. 1173–1180

X. Wang and J.A. Szpunar, Effects of Grain Sizes on the Oxidation Behavior of Ni-Based Alloy 230 and N, J. Alloys Compd., 2018, 752, p 40–52

F. Pettit, G. Meier, M. Gell, C. Kartovich, R. Bricknel, W. Kent, and J. Radovich, Oxidation and Hot Corrosion of Superalloys, Superalloys, 1984, 85, p 651–687

N. Mu, High Temperature Oxidation Behavior of [Gamma]-Ni + [Gamma]’-Ni3Al Alloys and Coatings Modified with Pt and Reactive Elements (2007)

Y. Bar-Cohen, High Temperature Materials and Mechanisms, CRC Press, Berlin, 2014

P. Berthod, Kinetics of High Temperature Oxidation and Chromia Volatilization for a Binary Ni-Cr Alloy, Oxid. Met., 2005, 64(3–4), p 235–252

M. Li, X. Sun, J. Li, Z. Zhang, T. Jin, H. Guan, Z. Hu, Oxidation Behavior of a Single-Crystal Ni-Base Superalloy in Air. I: at 800 and 900 C, Oxid. Met. 59(5–6), 591–605 (2003)

C. Tedmon, Jr., The Effect of Oxide Volatilization on the Oxidation Kinetics of Cr and Fe-Cr Alloys, J. Electrochem. Soc., 1966, 113(8), p 766

Q. Feng, B. Tryon, L. Carroll, and T. Pollock, Cyclic Oxidation of Ru-Containing Single Crystal Superalloys at 1100 °C, Mater. Sci. Eng. A, 2007, 458(1–2), p 184–194

F. Stott, Developments in Understanding the Mechanisms of Growth of Protective Scales on High-Temperature Alloys, Mater. Charact., 1992, 28(3), p 311–325

Acknowledgments

M. Ş. ATAŞ wishes to thank Konya Technical University Academic Staff Training Program (2017-ÖYP-042).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Atas, M.S., Yildirim, M. Morphological Development, Coarsening, and Oxidation Behavior of Ni-Al-Nb Superalloys. J. of Materi Eng and Perform 29, 4421–4434 (2020). https://doi.org/10.1007/s11665-020-04926-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04926-3