Abstract

Stringent fire safety regulations have limited the use of green biocomposites in practical applications due to vulnerability of their constituents to heat and fire. To counter this weakness, several flame-retardant treatments and techniques have been introduced, such as halogenated and non-halogenated flame-retardants, nano fillers, layered silicates, copolymerization, grafting, and synergistic use of natural fibre and fire retardant. While the physical and chemical treatment of green biocomposites has improved their heat resistance to some extent, these materials still fail to comply with strict fire safety regulations such as the Federal Motor Vehicle Safety Standard No. 302 (FMVSS 302) and the code of Federal Aviation Regulation 25.853 applicable in the automotive and aerospace industry, respectively. Therefore, an in-depth study of thermal decomposition and fire behaviour of green biocomposites is inevitable to improve flame retardancy techniques, to discover flame-retardants that are more suitable and environment friendly, and to select appropriate natural fibres and biopolymers to develop fire safe biocomposite products. This article analyses the research done in the last decades for improving the thermal behaviour and fire resistance of green materials as well as the efficient synergistic techniques and fire retardant treatments to counter this vulnerability.

Similar content being viewed by others

Abbreviations

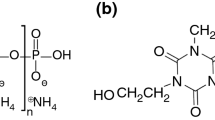

- APP:

-

Ammonium polyphosphate

- ATH:

-

Aluminium trihydrate

- AlHP:

-

Aluminium hypophosphite

- BS:

-

Barely straw

- BnF:

-

Banana fibre

- BF:

-

Bamboo fibre

- CNTs:

-

Carbon nanotubes

- CF:

-

Coconut fibre

- CS:

-

Chitosan

- C30B:

-

Closite 30B

- CaHP:

-

Calcium hypophosphite

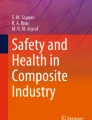

- CopoP:

-

Copolymer of methyl phosphonic acid and methacrylate

- DMRP:

-

Double layered microencapsulated red phosphorous

- DAP:

-

Di-ammonium phosphate

- DOPO:

-

9,10-Dihydro-9-oxa-10-phosphaphanthrene-10-oxide

- DDGS:

-

Distiller’s dried grain solubles

- DHAP:

-

Dihydrogen ammonium phosphate

- DSC:

-

Differential scanning calorimetry

- EG:

-

Expandable graphite

- FR:

-

Flame retardant

- FTIR:

-

Fourier transform infrared spectroscopy

- FAR:

-

Federal Aviation Regulation

- FMVSS:

-

Federal Motor Vehicle Safety Standard

- FF:

-

Flax fabric

- FRF:

-

Fire retardant ramie fibre

- FPLA:

-

Fire-retardant polylactic acid

- GBC:

-

Green biocomposite

- GMA:

-

Glycidyl methacrylate

- GP:

-

Glycerol phosphate

- HRR:

-

Heat release rate

- HB:

-

Horizontal burning

- HF:

-

Hemp fabric

- HFS:

-

Horizontal flame test

- H:

-

Hemp

- HDPE:

-

High-density polyethylene

- HomoP:

-

Homopolymer of methacrylate

- HP:

-

Hypophosphite

- HRC:

-

Heat release capacity

- HQDOPO:

-

10-Hydro-9-oxa-10-phosphahenanthrene10-oxide

- IFR:

-

Intumescent flame-retardants

- ICN:

-

Iso-cyanate

- JF:

-

Jute fibre

- JFb:

-

Jute fabric

- KF:

-

Keratin fibre

- KF:

-

Kenaf fibre

- LOI:

-

Limiting oxygen index

- LDPE:

-

Low density polyethylene

- LS:

-

Layered silicates

- Mw :

-

Molecular mass

- MA:

-

Maleic acid

- MAPP:

-

Micro ammonium polyphosphate

- MCC:

-

Microscale combustion calorimetry

- MH:

-

Magnesium hydroxide

- MDH:

-

Magnesium dihydroxide

- MA-g-PP:

-

Maleic anhydride grafted polypropylene

- MMP:

-

Melamine phosphate

- MMB:

-

Melamine borate

- MMT:

-

Montmorillonite

- MLR:

-

Mass loss rate

- MWCNTs:

-

Multi walled carbon nanotubes O-MMT organic montmorillonite

- OWF:

-

Oxidised wood flour PFR phosphorous flame retardant

- PHR:

-

Parts per hundred rubbers

- PHRR:

-

Peak heat release rate

- PEG:

-

Polyethylene glycol

- PMMA:

-

Polymethylmethacrylate

- PP:

-

Polypropylene

- POSS:

-

Polyhedral oligomeric silsesquioxanes

- PLA:

-

Polylactic acid

- PHA:

-

Polyhydroxyalkanoates

- PBS:

-

Polybutylene succinate

- PE:

-

Polyethylene

- PP:

-

Polypropylene

- PS:

-

Poly styrene

- PNFC:

-

POSS-modified cellulose

- PSi:

-

Phosphorous treated silane

- REACH:

-

Registration, evaluation, authorisation, restriction of chemical substance

- RP:

-

Red phosphorous

- RDP:

-

Resorcinol diphenyl phosphate

- SPR:

-

Smoke production rate

- SEP:

-

Sepiolite

- SEM:

-

Scanning electron microscope

- Si:

-

Silicon

- SiBnF:

-

Silicon treated banana fibre

- SFb:

-

Sisal fabric

- TGA:

-

Thermogravimetric analysis

- TTI:

-

Time to ignition

- THR:

-

Total heat release

- TPS:

-

Thermoplastic starch

- TPS-G:

-

Thermoplastic starch-glycerol

- Tg :

-

Glass transition temperature

- Tm :

-

Melt temperature

- Tcc :

-

Crystallisation temperature

- Tc :

-

Post crystallisation temperature

- UL-94:

-

Underwriter Laboratories

- WPC:

-

Wood plastic composite

- WF:

-

Wood flour

- ZnO:

-

Zinc oxide

References

Chen Y, Chiparus O, Sun L, Negulescu I, Parikh DV, Calamari TA (2005) Natural fibers for automotive nonwoven composites. J Ind Text 35(1):47–62. https://doi.org/10.1177/1528083705053392

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58:80–86. https://doi.org/10.1007/s11837-006-0234-2

Monteiro SN, Lopes FPD, Ferreira AS, Nascimento DCO (2009) Natural-fiber polymer-matrix composites: cheaper, tougher, and environmentally friendly, JOM 61:17–22. https://doi.org/10.1007/s11837-009-0004-z

Rao S, Das R, Bhattacharyya D (2013) Investigation of bond strength and energy absorption capabilities in recyclable sandwich panels. Compos Part A 45:6–13. https://doi.org/10.1016/j.compositesa.2012.09.004

Ramli N, Mazlan N, Ando Y, Leman Z, Abdan K, Aziz AA, Sairy NA (2018) Natural fiber for green technology in automotive industry: a brief review. Mater Sci Eng. https://doi.org/10.1088/1757-899x/368/1/012012

Zini E, Scandola M (2011) Green composites: an overview. Polym Compos. https://doi.org/10.1002/pc.21224

Kandpal BC, Chaurasia R, Khurana V (2015) Recent advances in green composites—a review recent advances in green composites—a review. Int J Technol Res Eng 2:742–747

Al-Oqla FM, Omari MA (2016) Sustainable biocomposites: challenges, potential and barriers for development. Green Energy Technol. https://doi.org/10.1007/978-3-319-46610-1_2

Nam TH, Ogihara S, Kobayashi S (2012) Interfacial, mechanical and thermal properties of coir fiber-reinforced poly (lactic acid) biodegradable composites. Adv Compos Mater 21:103–122. https://doi.org/10.1163/156855112x629540

Wongsriraksa P, Togashi K, Nakai A, Hamada H (2013) Continuous natural fiber reinforced thermoplastic composites by fiber surface modification. Adv Mech Eng. https://doi.org/10.1155/2013/685104

Kalia S, Kaith BS, Kaur I (2009) Pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci 49:1253–1272. https://doi.org/10.1002/pen.21328

Keener TJ, Stuart RK, Brown TK (2004) Maleated coupling agents for natural fibre composites. Compos Part A Appl Sci Manuf 35:357–362. https://doi.org/10.1016/j.compositesa.2003.09.014

Lee CH, Salit MS, Hassan MR (2014) A review of the flammability factors of kenaf and allied fibre reinforced polymer composites. Adv Mater Sci Eng. https://doi.org/10.1155/2014/514036

Shah AR, Prabhakar M, Song J-I (2017) Current advances in the fire retardancy of natural fiber and bio-based composites—a review. Int J Precis Eng Manuf Technol 4:247–262. https://doi.org/10.1007/s40684-017-0030-1

Kim NK, Dutta S, Bhattacharyya D (2018) A review of flammability of natural fibre reinforced polymeric composites. Compos Sci Technol 162:64–78. https://doi.org/10.1016/j.compscitech.2018.04.016

Al-oqla FM, Salit MS, Ishak R (2014) Combined multi-criteria evaluation stage technique as an agro waste evaluation indicator for polymeric composites: date palm fibers as a case study. Bioresources 9:4608–4621. https://doi.org/10.15376/biores.9.3.4608-4621

Mohanty AK, Misra M, Drzal LT (2002) Sustainable bio-composites from renewable resources: opportunities and challenges in the green materials world. J Polym Environ 10:19–26. https://doi.org/10.1023/a:1021013921916

John M, Anandjiwala R (2008) Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym Compos 29:187–207. https://doi.org/10.1002/pc.20461

Luo S, Netravali AN (1999) Interfacial and mechanical properties of environment-friendly “green” composites made from pineapple fibers and poly(hydroxybutyrate-co-valerate) resin. J Mater Sci 34:3709–3719. https://doi.org/10.1023/a:1004659507231

Price D, Anthony G, Carty P (2001) Introduction: polymer combustion, condensed phase pyrolysis and smoke formation. In: Horrocks AR, Price D (eds) Fire retardant materials. Woodhead Publishing, Cambridge, pp 1–30. https://doi.org/10.1533/9781855737464.1

Bhattacharyya D, Subasinghe A, Kim NK (2015) Chapter 4. Natural fibers: their composites and flammability characterizations. In: Breuer U (ed) Multifunctionality of polymer composites: challenges and new solutions. Elsevier, Amsterdam. https://doi.org/10.1016/b978-0-323-26434-1.00004-0

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24:221–274. https://doi.org/10.1016/s0079-6700(98)00018-5

Chapple S, Anandjiwala R (2010) Flammability of natural fiber-reinforced composites and strategies for fire retardancy: a review. J Thermoplast Compos Mater 23:877–893. https://doi.org/10.1177/0892705709356338

Hapuarachchi TD, Ren G, Fan M (2007) Fire retardancy of natural fibre reinforced sheet moulding compound. Appl Compos Mater. https://doi.org/10.1007/s10443-007-9044-0

Kozłowski R, Władyka-Przybylak M (2008) Flammability and fire resistance of composites reinforced by natural fibers. Polym Adv Technol 19:446–453. https://doi.org/10.1002/pat.1135

Toldy A, Keszei S, Anna P, Bertalan G, Marosi G, Matko S (2005) Flame retardancy of biodegradable polymers and biocomposites, Polym Degrad Stab 88:138–145. https://doi.org/10.1016/j.polymdegradstab.2004.02.023

Puchalski M, Szparaga G, Biela T, Gutowska A (2018) Molecular and supramolecular changes in polybutylene succinate (PBS) and polybutylene succinate adipate (PBSA) Copolymer during degradation in various environmental conditions. Polymers. https://doi.org/10.3390/polym10030251

Khedari J, Charoenvai S, Hirunlabh J (2003) New insulating particleboards from durian peel and coconut coir. Build Environ 38:435–441. https://doi.org/10.1016/s0360-1323(02)00030-6

Bocz K, Szolnoki B, Adyka-przybylak MW, Bujnowicz K, Harakály G, Bodzay B, Zimonyi E, Toldy A, Marosi G (2013) Flame retardancy of biocomposites based on thermoplastic starch. Polimery 58:385–394

Gallo E, Schartel B, Acierno D, Cimino F, Russo P (2013) Tailoring the flame retardant and mechanical performances of natural fiber-reinforced biopolymer by multi-component laminate. Compos Part B 44:112–119. https://doi.org/10.1016/j.compositesb.2012.07.005

Prabhakar MN, Atta Ur Rehaman S, Jung-II S (2017) Improved flame-retardant and tensile properties of thermoplastic starch/flax fabric green composites. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2017.03.036

Kandola BK (2012) Flame Retardant characteristics of natural fibre composites. In: John M, Sabu T (eds) Natural polymers, composites, vol 1. The Royal Society of Chemistry, pp 86–117. https://doi.org/10.1039/9781849735193-00086

Lyon R, Walters R (2005) Flammability of automotive plastics. SAE Technical Paper. https://doi.org/10.4271/2006-01-1010

Mngomezulu ME, John MJ, Jacobs V, Luyt AS (2014) Review on flammability of biofibres and biocomposites. Carbohydr Polym 111:149–182. https://doi.org/10.1016/j.carbpol.2014.03.071

Zhou L, Ju Y, Liao F, Yang Y, Wang X (2016) Improve the mechanical property and flame retardant efficiency of the composites of poly(lactic acid) and resorcinol di(phenyl phosphate) (RDP) with ZnO-coated kenaf. Fire Mater 40:129–140. https://doi.org/10.1002/fam.2274

Avella M, Martuscelli E, Raimo M (2000) Properties of blends and composites based on poly(3-hydroxy) butyrate (PHB) and poly(3-hydroxybutyrate-hydroxyvalerate) (PHBV) copolymers. J Mater Sci 5:523–545. https://doi.org/10.1023/a:1004740522751

Dittenber DB, Gangarao HVS (2012) Critical review of recent publications on use of natural composites in infrastructure. Compos Part A 43:1419–1429. https://doi.org/10.1016/j.compositesa.2011.11.019

Das O, Sarmah AK (2015) Mechanism of waste biomass pyrolysis: effect of physical and chemical pre-treatments. Sci Total Environ 537:323–334. https://doi.org/10.1016/j.scitotenv.2015.07.076

Horrocks AR (2008) An introduction to the burning behaviour of cellulosic fibres. J Soc Dye Colour 99:191–197. https://doi.org/10.1111/j.1478-4408.1983.tb03686.x

Ferdous D, Dalai AK, Bej SK, Thring RW (2002) Pyrolysis of lignins: experimental and kinetics studies. Energy Fuels 16:1405–1412. https://doi.org/10.1021/ef0200323

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442. https://doi.org/10.1016/j.matdes.2012.11.025

Galaska ML, Horrocks AR, Morgan AB (2017) Flammability of natural plant and animal fibers: a heat release survey. Fire Mater 41:275–288. https://doi.org/10.1002/fam.2386

Borysiak S, Paukszta D, Helwig M (2006) Flammability of wood-polypropylene composites Polym Degrad Stab 91:3339–3343. https://doi.org/10.1016/j.polymdegradstab.2006.06.002

Bertini F, Canetti M, Patrucco A, Zoccola M (2013) Wool keratin-polypropylene composites: properties and thermal degradation. Polym Degrad Stab 98:980–987. https://doi.org/10.1016/j.polymdegradstab.2013.02.011

Subasinghe A, Bhattacharyya D (2014) Performance of different intumescent ammonium polyphosphate flame retardants in PP/kenaf fibre composites. Compos Part A 65:91–99. https://doi.org/10.1016/j.compositesa.2014.06.001

Sperling LH (2005) Introduction to polymer science. In: Introduction to physical polymer science. Wiley, Hoboken, pp 1–28. https://doi.org/10.1002/0471757128.ch1

Li H, Huneault MA (2007) Effect of nucleation and plasticization on the crystallization of poly(lactic acid). Polymer (Guildf) 48:6855–6866. https://doi.org/10.1016/j.polymer.2007.09.020

Peelman N, Ragaert P, Ragaert K, De Meulenaer B, Devlieghere F, Cardon L (2015) Heat resistance of new biobased polymeric materials, focusing on starch, cellulose, PLA, and PHA. J Appl Polym Sci. https://doi.org/10.1002/app.42305

Wang CZ, Wu WH, Ye X, Liu L (2013) Zinc hydroxystannate-coated mineral grade Mg(OH)2 as flame-retardant and smoke suppression for flexible PVC. Adv Mater Mater Process. https://doi.org/10.4028/www.scientific.net/amr.652-654.481

Martins MSS, Schartel B, Magalhães FD, Pereira CMC (2017) The effect of traditional flame retardants, nanoclays and carbon nanotubes in the fire performance of epoxy resin composites. Fire Mater 41:111–130. https://doi.org/10.1002/fam.2370

Camino G, Maffezzoli A, Braglia M, De Lazzaro M, Zammarano M (2001) Effect of hydroxides and hydroxycarbonate structure on fire retardant effectiveness and mechanical properties in ethylene-vinyl acetate copolymer. Polym Degrad Stab 74:457–464. https://doi.org/10.1016/s0141-3910(01)00167-7

Belousova RG, Schwartz EM, Zari IE, Valdniece DJ (2010) Low-toxicity boron-containing fire-retardant additives for polymeric coatings. Macromol Compd Polym Mater 83:328–331. https://doi.org/10.1134/s1070427210020278

Alaee M, Arias P, Sjödin A, Bergman Å (2003) An overview of commercially used brominated flame retardants, their applications, their use patterns in different countries/regions and possible modes of release. Environ Int 29:683–689. https://doi.org/10.1016/s0160-4120(03)00121-1

Hites RA (2006) Dechlorane Plus, a chlorinated flame retardant, in the Great Lakes. Environ Sci Technol 40:1184–1189. https://doi.org/10.1021/es051911h

Chang Y, Wang Y, Ban D, Yang B, Zhao G (2004) A novel phosphorus-containing polymer as a highly effective flame retardant. Macromol Mater Eng 289:703–707. https://doi.org/10.1002/mame.200400064

Van Der Veen I, De Boer J (2012) Phosphorus flame retardants: properties, production, environmental occurrence, toxicity and analysis. Chemosphere 88: 1119–1153. https://doi.org/10.1016/j.chemosphere.2012.03.067

Gallo E, Schartel B, Braun U, Russo P, Acierno D (2011) Fire retardant synergisms between nanometric Fe2O3 and aluminum phosphinate in poly(butylene terephthalate). Polym Adv Technol 22:2382–2391. https://doi.org/10.1002/pat.1774

Gallo E, Schartel B, Acierno D, Russo P (2011) Flame retardant biocomposites: Synergism between phosphinate and nanometric metal oxides. Eur Polym J 47: 1390–1401. https://doi.org/10.1016/j.eurpolymj.2011.04.001

Kashiwagi T, Du F, Winey KI, Groth KM, Shields JR, Bellayer SP, Kim H, Douglas JF (2005)Flammability properties of polymer nanocomposites with single-walled carbon nanotubes: effects of nanotube dispersion and concentration. Polymer (Guildf) 46:471–481. https://doi.org/10.1016/j.polymer.2004.10.087

Schartel B, Pötschke P, Knoll U, Abdel-Goad M (2005) Fire behaviour of polyamide 6/multiwall carbon nanotube nanocomposites. Eur Polym J 41:1061–1070. https://doi.org/10.1016/j.eurpolymj.2004.11.023

Bocchini S, Frache A, Camino G, Claes M (2007) Polyethylene thermal oxidative stabilisation in carbon nanotubes based nanocomposites. Eur Polym J 43:3222–3235.https://doi.org/10.1016/j.eurpolymj.2007.05.012

Dittrich B, Wartig K-A, Hofmann D, Mülhaupt R, Schartel B (2013) Flame retardancy through carbon nanomaterials: carbon black, multiwall nanotubes, expanded graphite, multi-layer graphene and graphene in polypropylene. Polym Degrad Stab 98:1495–1505. https://doi.org/10.1016/j.polymdegradstab.2013.04.009

Kashiwagi T, Du F, Douglas JF, Winey KI, Harish Jr RH, Shields JR (2005) Nanoparticle networks reduce the flammability of polymer nanocomposites. Nat Mater 4:928–933 https://doi.org/10.1038/nmat1502

Franchini E, Galy J, Gérard J-F, Tabuani D, Medici A (2009) Influence of POSS structure on the fire retardant properties of epoxy hybrid networks. Polym Degrad Stab 94:1728–1736. https://doi.org/10.1016/j.polymdegradstab.2009.06.025

Dasari A, Yu Z-Z, Mai Y-W, Cai G, Song H (2009) Roles of graphite oxide, clay and POSS during the combustion of polyamide 6. Polymer (Guildf) 50:1577–1587. https://doi.org/10.1016/j.polymer.2009.01.050

Ma H, Tong L, Xu Z, Fang Z (2007) Synergistic effect of carbon nanotube and clay for improving the flame retardancy of ABS resin. Nanotechnology 18:8. https://doi.org/10.1088/0957-4484/18/37/375602

Beyer G (2002) Short communication: carbon nanotubes as flame retardants for polymers. Fire Mater 26:291–293. https://doi.org/10.1002/fam.805

Yen Y-Y, Wang H-T, Guo W-J (2012) Synergistic flame retardant effect of metal hydroxide and nanoclay in EVA composites. Polym Degrad Stab 97:863–869. https://doi.org/10.1016/j.polymdegradstab.2012.03.043

Lin M, Li B, Li Q, Li S, Zhang S (2011) Synergistic effect of metal oxides on the flame retardancy and thermal degradation of novel intumescent flame-retardant thermoplastic polyurethanes. J Appl Polym Sci 121:1951–1960. https://doi.org/10.1002/app

Mode of action (n.d.) https://www.flameretardants-online.com/flame-retardants/mode-of-action. Accessed 30 Dec 2019

Xu G, Cheng J, Wu H, Lin Z, Zhang Y, Wang H (2013) Functionalized carbon nanotubes with oligomeric intumescent flame retardant for reducing the agglomeration and flammability of poly(ethylene vinyl acetate) nanocomposites. Polym Compos 34:109–121. https://doi.org/10.1002/pc.22382

Sypaseuth FD, Gallo E, Schartel B (2017) Polylactic acid biocomposites: approaches to a completely green flame retarded polymer. Polymers (Basel) 17: 449–462. https://doi.org/10.1515/epoly-2017-0024

Zhang Z, Yuan L, Liang G, Gu A, Qiang Z, Yang C, Chen X (2014) Unique hybridized carbon nanotubes and their high performance flame retarding composites with high smoke suppression, good toughness and low curing temperature. J Mater Chem A 2:4975–4988. https://doi.org/10.1039/c3ta14687a

Huang M-F, Yu J-G, Ma X-F (2004) Studies on the properties of Montmorillonite-reinforced thermoplastic starch composites. Polymer (Guildf) 45: 7017–7023. https://doi.org/10.1016/j.polymer.2004.07.068

Yu T, Jiang N, Li Y (2014) Functionalized multi-walled carbon nanotube for improving the flame retardancy of ramie/poly(lactic acid) composite. Compos Sci Technol 104:26–33. https://doi.org/10.1016/j.compscitech.2014.08.021

Horrocks AR, Kandola BK (2005) Flammability and fire resistance of composites. In: Long AC (ed) Design and manufacture of textile composites. Woodhead Publishing, Cambridge, pp 330–363. https://doi.org/10.1533/9781845690823.330

Nafchi A, Moradpour M, Saeidi M, Karim A (2013) Thermoplastic starches: properties, challenges, and prospects. Starch-Stärke 65:61–72. https://doi.org/10.1002/star.201200201

Ma X, Yu J (2004) Studies on the properties of formamide plasticized-thermoplastic starch. Acta Polym Sin 2:240–245

Peelman N, Ragaert P, De Meulenaer B, Adons D, Peeters R, Cardon L, Van Impe F (2013) Application of bioplastics for food packaging. Trends Food Sci Technol 32:128–141. https://doi.org/10.1016/j.tifs.2013.06.003

Anglès MN, Dufresne A (2000) Plasticized starch/tunicin whiskers nanocomposites. 1. Structural analysis. Macromolecules 33:8344–8353. https://doi.org/10.1021/ma0008701

Avella M, De Vlieger JJ, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93:467–474. https://doi.org/10.1016/j.foodchem.2004.10.024

Bastioli C (1998) Properties and applications of mater-bi starch-based materials. Polym Degrad Stab 59:263–272. https://doi.org/10.1016/s0141-3910(97)00156-0

Gotro J (2013) Thermoplastic starch: a renewable, biodegradable bioplastic. https://polymerinnovationblog.com/thermoplastic-starch-a-renewable-biodegradable-bioplastic/

Weber CJ, Haugaard V, Festersen R, Bertelsen G (2002) Production and applications of biobased packaging materials for the food industry. Food Addit Contam 19:172–177. https://doi.org/10.1080/02652030110087483

Gallo E, Sanchez-Olivares G, Schartel B (2013) Flame retarded starch-based biocomposites—aluminum hydroxide-coconut fiber synergy. Polimery 58:395–402. https://doi.org/10.14314/polimery.2013.395

Prabhakar MN, Song J (2018) Fabrication and characterisation of starch/chitosan/flax fabric green flame-retardant composites. Int J Biol Macromol 119:1335–1343. https://doi.org/10.1016/j.ijbiomac.2018.07.006

Rabe S, Sanchez-olivares G, Pérez-chávez R, Schartel B (2019) Natural keratin and coconut fibres from industrial wastes in flame retarded thermoplastic starch biocomposites. Materials (Basel) 12:1–24. https://doi.org/10.3390/ma12030344

Duquesne S, Samyn F, Ouagne P, Bourbigot S (2015) Flame retardancy and mechanical properties of flax reinforced woven for composite applications. J Ind Text 44:665–681. https://doi.org/10.1177/1528083713505633

Silva-Guzmán JA, Anda RR, Fuentes-Talavera FJ, Manríquez-González R, Lomelí-Ramírez MG (2018) Properties of thermoplastic corn starch based green composites reinforced with barley (Hordeum vulgare L.) straw particles obtained by thermal compression. Fibers Polym 19:1970–1979. https://doi.org/10.1007/s12221-018-8023-4

Cardon L, Deckers J, Verberckmoes A, Ragaert K, Delva L, Shahzad K, Vleugels J, Kruth J-P (2012) Polystyrene-coated alumina powder via dispersion polymerization for indirect selective laser sintering applications. J Appl Polym Sci 128:2121–2128. https://doi.org/10.1002/app.38388

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602. https://doi.org/10.1016/j.progpolymsci.2006.03.002

Bogaert J, Coszach P (2000) Poly(lactic acids): a potential solution to plastic waste dilemma. Macromol Symp 153:287–303. https://doi.org/10.1002/1521-3900(200003)153:1%3c287::aid-masy287%3e3.0.co;2-e

Jamshidian M, Tehrany EA, Imran M, Jacquot M, Desobry S (2010) Poly-lactic acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf 9:552–571. https://doi.org/10.1111/j.1541-4337.2010.00126.x

John RP, Nampoothiri KM (2007) Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Appl Microbiol Biotechnol 74:524–534. https://doi.org/10.1007/s00253-006-0779-6

Rasal RM, Janorkar AV, Hirt DE (2010) Poly(lactic acid) modifications. Prog Polym Sci 35:338–356. https://doi.org/10.1016/j.progpolymsci.2009.12.003

Siracusa V, Dalla M (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643. https://doi.org/10.1016/j.tifs.2008.07.003

Södergård A, Stolt M (2002) Properties of lactic acid based polymers and their correlation with composition. Prog Polym Sci 27:1123–1163. https://doi.org/10.1016/s0079-6700(02)00012-6

Réti C, Casetta M, Duquesne S, Bourbigot S, Delobel R (2008) Flammability properties of intumescent PLA including starch and lignin. Polym Adv Technol 19:628–635. https://doi.org/10.1002/pat.1130

Shumao L, Jie R, Hua Y, Weizhong Y (2010) Influence of ammonium polyphosphate on the flame retardancy and mechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites. Polym Int 59:242–248. https://doi.org/10.1002/pi.2715

Fox DM, Lee J, Citro CJ, Novy M (2013) Flame retarded poly(lactic acid) using POSS-modified cellulose. 1. Thermal and combustion properties of intumescing composites. Polym Degrad Stab 98:590–596. https://doi.org/10.1016/j.polymdegradstab.2012.11.016

Bocz K, Szolnoki B, Marosi A, Tábi T, Wladyka-przybylak M, Marosi G (2013) Flax fibre reinforced PLA/TPS biocomposites flame retarded with multifunctional additive system. Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2013.10.025

Zhang R, Xiao X, Tai Q, Huang H, Hu Y (2012) Modification of lignin and its application as char agent in intumescent flame-retardant poly(lactic acid). Polym Eng Sci 52:2620–2626. https://doi.org/10.1002/pen.23214

Young W, Tsao Y (2014) The mechanical and fire safety properties of bamboo fiber reinforced polylactide biocomposites fabricated by injection molding. J Compos Mater. https://doi.org/10.1177/0021998314554437

Shukor F, Hassan A, Islam MS, Mokhtar M, Hasan M (2014) Effect of ammonium polyphosphate on flame retardancy, thermal stability and mechanical properties of alkali treated kenaf fiber filled PLA biocomposites. Mater Des 54:425–429. https://doi.org/10.1016/j.matdes.2013.07.095

Vp S, Mohanty S, Nayak SK (2015) A study on thermal degradation kinetics and flammability properties of poly(lactic acid)/banana fiber/nanoclay hybrid bionanocomposites. Polym Compos. https://doi.org/10.1002/pc.23779

Vp S, Mohanty S, Nayak SK (2016) Influence of nanoclay and graft copolymer on the thermal and flammability properties of poly (lactic acid)/banana fiber biocomposites. J Vinyl Addit Technol. https://doi.org/10.1002/vnl

Yu T, Tuerhongjiang T, Sheng C, Li Y (2017) Phosphorus-containing diacid and its application in jute/poly(lactic acid) composites: mechanical, thermal and flammability properties. Compos Part A 97:60–66. https://doi.org/10.1016/j.compositesa.2017.03.004

Tao Y, Ding D, Cong S, Tuerdi T, Yan L (2017) Enhanced mechanical properties and flame retardancy of short jute fiber/poly(lactic acid) composites with phosphorus-based compound. Sci China Technol Sci 60:1716–1723. https://doi.org/10.1007/s11431-016-9009-1

Shi X, Ju Y, Zhang M, Wang X (2018) The intumescent flame—retardant biocomposites of poly(lactic acid) containing surface—coated ammonium polyphosphate and distiller’s dried grains with solubles (DDGS). Fire Mater 42:190–197. https://doi.org/10.1002/fam.2479

Kandola BK, Mistik SI, Pornwannachai W, Anand SC (2018) Natural fibre-reinforced thermoplastic composites from woven–nonwoven textile preforms: mechanical and fibre performance study. Compos Part B 153:456–464. https://doi.org/10.1016/j.compositesb.2018.09.013

Yang Y, Haurie L, Wen J, Zhang S, Ollivier A, Wang D (2019) Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites. Ind Crop Prod 130:301–309. https://doi.org/10.1016/j.indcrop.2018.12.090

Taylor P, Zaikov GE, Artsis MI (1996) International Journal of Polymeric Fire Retardant Polymers (Fifth European Conference). Int J Polym Mater Polym Biomater 33:261–263. https://doi.org/10.1080/00914039608029410

Hapuarachchi TD, Peijs T (2010) Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos Part A 41:954–963. https://doi.org/10.1016/j.compositesa.2010.03.004

Fox DM, Lee J, Zammarano M, Katsoulis D, Eldred DV, Haverhals LM, Trulove PC, De Long HC, Gilman JW (2012) Charforming behavior of nanofibrillated cellulose treated with glycidyl phenyl POSS. Carbohydr Polym 88:847–858. https://doi.org/10.1016/j.carbpol.2012.01.015

Fox DM, Lee J, Ford E, Balsley E, Zammarano M, Matko S, Gilman JW (2000) POSS-modified cellulose for improving flammability characteristics of polystyrene. In: 10th international conference wood biofiber plastic composites, pp 337–342

Huneault MA, Li H (2007) Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer (Guildf) 48:270–280. https://doi.org/10.1016/j.polymer.2006.11.023

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Composites: part A silane coupling agents used for natural fiber/polymer composites: a review. Compos Part A 41:806–819. https://doi.org/10.1016/j.compositesa.2010.03.005

Arbelaiz A, Fern B, Ramos JA, Mondragon I (2006) Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: effect of treatments. Thermochim Acta 440:111–121. https://doi.org/10.1016/j.tca.2005.10.016

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Exceptionally high young modulus observed for individual carbon nanotubes. Nature 381:678–680. https://doi.org/10.1038/381678a0

Robertson DH, Brenner DW, Mintmire JW (1992) Energetics of nanoscale graphitic tubules. Phys Rev B 45:592–595. https://doi.org/10.1103/physrevb.45.12592

Zhang W, Chen B, Zhao H, Yu P, Fu D, Wen J, Peng X (2013) Processing and characterization of supercritical CO2 batch foamed poly(lactic acid)/poly(ethylene glycol) scaffold for tissue engineering application. J Appl Polym Sci 130:3066–3073. https://doi.org/10.1002/app.39523

Orue A, Eceiza A, Arbelaiz A (2018) The effect of sisal fiber surface treatments, plasticizer addition and annealing process on the crystallization and the thermo-mechanical properties of poly(lactic acid) composites. Ind Crop Prod 118:321–333. https://doi.org/10.1016/j.indcrop.2018.03.068

Fujimaki T (1998) Processability and properties of aliphatic polyesters, ‘BIONOLLE’, synthesized by polycondensation reaction. Polym Degrad Stab 59:209–214. https://doi.org/10.1016/s0141-3910(97)00220-6

Nova Institution (n.d.) Biobased polybutylene succinate (PBS)—an attractive polymer for biopolymer compounds polybutylene succinate—an interesting building block for biopolymer compounds based on biobased succinic acid

Jacquel N, Freyermouth F, Fenouillot F, Rousseau A, Pascault JP, Fuertes P, Saint-Loup R (2011) Synthesis and properties of poly(butylene succinate): efficiency of different transesterification catalysts. J Polym Sci Part A Polym Chem 49:5301–5312. https://doi.org/10.1002/pola.25009

Zeikus JG, Jain MK, Elankovan P (1999) Biotechnology of succinic acid production and markets for derived industrial products. Appl Microbiol Biotechnol 51:545–552. https://doi.org/10.1007/s002530051431

Dorez G, Taguet A, Ferry L (2013) Thermal and fibre behavior of natural fibers/PBS biocomposites. Polym Degrad Stab 98:87–95. https://doi.org/10.1016/j.polymdegradstab.2012.10.026

Ferry L, Dorez G, Taguet A, Otazaghine B, Lopez-Cuesta JM (2015) Chemical modification of lignin by phosphorus molecules to improve the fire behavior of polybutylene succinate. Polym Degrad Stab 113:135–143. https://doi.org/10.1016/j.polymdegradstab.2014.12.015

Jiang S, Yang Y, Ge S, Zhang Z, Peng W (2018) Preparation and properties of novel flame-retardant PBS wood–plastic composites. Arab J Chem 11:844–857. https://doi.org/10.1016/j.arabjc.2017.12.023

Nie S, Liu X, Dai G, Yuan S, Cai F, Li B, Hu Y (2012) Investigation on flame retardancy and thermal degradation of flame retardant poly(butylene succinate)/bamboo fiber biocomposites. J Appl Polym Sci 125:E485–E489. https://doi.org/10.1002/app.36915

Dash BN, Nakamura M, Sahoo S, Kotaki M, Nakai A, Hamada H (2008) Mechanical properties of hemp reinforced poly(butylene succinate) biocomposites. J Biobased Mater Bioenergy 2:273–281. https://doi.org/10.1166/jbmb.2008.403

Hobbs C (2019) Recent advances in bio-based flame retardant additives for synthetic polymeric materials. Polymers (Basel) 11:224. https://doi.org/10.3390/polym11020224

Laachachi A, Burger N, Apaydin K, Sonnier R, Ferriol M (2015) Is expanded graphite acting as flame retardant in epoxy resin? Polym Degrad Stab 117:22–29. https://doi.org/10.1016/j.polymdegradstab.2015.03.016

Wang Y, Zhao J (2019) Effect of graphene on flame retardancy of graphite doped intumescent flame retardant (IFR) coatings: synergy or antagonism. Coatings 9:94. https://doi.org/10.3390/coatings9020094

Fontaine G, Gallos A, Bourbigot S (2014) Role of montmorillonite for enhancing fire retardancy of intumescent PLA. Fire Saf Sci. https://doi.org/10.3801/iafss.fss.11

I. Bureau (2010) WO 2010/069835 Al (81), 21

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rashid, M., Chetehouna, K., Cablé, A. et al. Analysing Flammability Characteristics of Green Biocomposites: An Overview. Fire Technol 57, 31–67 (2021). https://doi.org/10.1007/s10694-020-01001-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-020-01001-0