Abstract

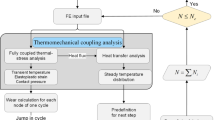

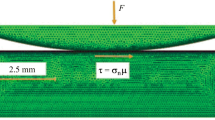

The paper proposes a finite element approach with a mathematical model and an algorithm for simulating the wear of polymer composites in friction joints with account of temperature. The polymer interaction with a counterpart is modeled by solving a stress-strain contact problem with regard for the physical nonlinearity of deformation in polymer composites. The contact temperature is estimated by solving a nonstationary heat conduction problem with regard for mechanical-to-thermal energy conversion and for heat loss via convection without any additional heat exchange assumption. Reasoning from the temperature calculated, the state of finite elements associated with the properties of a polymer composite is changed (elastic modulus, heat capacity, yield strength, tensile strength), and those elements for which one of the fracture criteria holds are deleted as “worn”. The mesh is thus rearranged into a new one with the current stress-strain and temperature values interpolated to it. The approach is applied to analyze the effect of temperature and roughness on the friction and wear of homogeneous polymer composites and polymer coating–steel substrate systems. The results of simulation are compared with experimental data for ultrahigh molecular weight polyethylene in dry sliding friction with a steel counterpart.

Similar content being viewed by others

REFERENCES

Panin, S.V., Kornienko, L.A., Nguen Suan, T., Ivanova, L.R., Shil’ko, S.V., Pleskachevskii, Yu.M., and Vat’yanatepin, N., Mechanical and Tribological Characteristics of Nano- and Microcomposites with UHMWPE–PTFE polymer–polymer matrix,J. Frict. Wear, 2015, vol. 36, no. 6, pp. 502–508. doi 10.3103/ S1068366615060124

Panin, V.E., Panin, S.V., Kornienko, L.A., Vannasri, S., Ivanova, L.R., and Shil’ko. S.V., Effect of Mechanical Activation of Ultra-High-Molecular-Weight Polyethylene on its Mechanical and Triboengineering Properties, J.Frict. Wear, 2010, vol. 31, no. 2, pp. 121–127. doi 10.3103/S106836661

Kumar, D., Rajmohan, T., and Venkatachalapathi, S., Wear Behavior of PEEK Matrix Composites, Rev.Mater. Today, 2018, vol. 5, pp. 14583–14589.

Chen, B., Li, X., Li, X., Jia, Y., Yang, J., Yang, G., and Li, C., Friction and Wear Properties of Polyimide-Based Composites with a Multiscale Carbon Fiber–Carbon Nanotube Hybrid, Tribology Lett., 2017, vol. 65, no. 3. doi 10.1007/s11249-017-0891-z

Kragelskii, I.V., Friction and Wear, London: Butterworth, 1965.

Bowden, F.P. and Tabor, D., Friction and Lubrication of Solids, Oxford: Clarendon Press, 1964.

Friction, Wear, and Lubrication, vol. 1, Kragelskii, I.V. and Alisin, V.V., Eds., Moscow: Mashinostroenie, 1978.

Fundamentals of Tribology (Friction, Wear, and Lubricants), Chichinadze, A.V., Ed., Moscow: Mashinostroenie, 2001.

Myshkin, N.K. and Kovalev, A.V., Adhesion and Surface Forces in Polymer Tribology––A Review, Friction, 2018, vol. 6, no. 2, pp. 143–155.

Panin, V.E., Pochivalov, Yu.I., Moiseenko, D.D., Maksimov, P.V., and Bikineev, G.Sh., Tribocontact in Friction Pairs as a Multiscale Hierarchically Organized System, Fiz.Mesomekh., 2010, vol. 13, no. 6, pp. 27–34.

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D.D., Bieler, T.R., and Raabe, D., Overview of Constitutive Laws, Kinematics, Homogenization and Multiscale Methods in Crystal Plasticity Finite-Element Modeling: Theory, Experiments, Applications,Acta Mater., 2010, vol. 58, pp. 1152–1211. doi 10.1016/j. actamat.2009.-10.058

Amosov, A.P., Thermophysical Models of Friction of Inert and Explosive Materials, Moscow: Mashinostroenie, 2011.

Braun, E.D., Buyanovsky, I.A., Voronin, N.A., et al.,Modern Tribology: Results and Perspectives, Frolov, K.V., Ed., Moscow: LKI, 2008.

Brostow, W., Kovacevic, V., and Vrsaljko, D., Tribology of Polymers and Polymer-Based Composites, J.Mater. Educ., 2010, vol. 32, no. 5–6, pp. 273–290.

Briscoe, B.J., Interfacial Friction of Polymer Composites. General Fundamental Principles, in Friction and Wear of Polymer Composites, Klaus F., Ed., Amsterdam: Elsevier, 1986, pp. 25–59.

Archard, J.F., Elastic Deformation and the Laws of Friction,Proc. R. Soc., 1957, vol. 243, no. 1233, pp. 190–205.

Greenwood, J.A. and Williamson, J.B.P., Contact of Nominally Flat Surfaces, Proc. R.Soc., 1966, vol. 295, no. 1442, pp. 300–319. doi 10.1098/rspa.1966.0242

Deryagin, B.V., Muller, V.M., and Toporov, Yu.P., Effect of Contact Deformation on the Adhesion of Particles, J.Colloid. Interf.Sci., 1975, vol. 53, pp. 314−326. doi 10.1016/0021-9797(75)90018-1

Johnson, K.L., Kendall, K., and Roberts, A.D., Surface Energy and the Contact of Elastic Solids, Proc.R. Soc., 1971, vol. 324, pp. 301−313.

Müser, M.H., Dapp, W.B., Bugnicourt, R. et al., Meeting the Contact-Mechanics Challenge, Tribol.Lett., 2017, vol. 65, p. 118. doi 10.1007/s11249-017-0900-2

Persson, B.N.J., Theory of Rubber Friction and Contact Mechanics, J. Chem.Phys., 2001, vol. 115, no. 8, pp. 3840–3861.

Putignano, C., Afferrante, L., Carbone, G., and Demelio, G., A New Efficient Numerical Method for Contact Mechanics of Rough Surfaces, Int. J.SolidsStruct., 2012, vol. 49, no. 2, pp. 338–343. doi 10.1016/j. ijsolstr.-2011.10.009

Akchurin, A., Bosman, R., and Lugt, P.M., A Stress-Criterion Based Model for the Prediction of the Size of Wear Particles in Boundary Lubricated Contacts, Tribol.Lett., 2016, vol. 64, p. 35. doi 10.1007/s11249-016-0772-x

Buczkowski, R. and Kleiber, M., Statistical Models of Rough Surfaces for Finite Element 3D-Contact Analysis,Arch. Comp. Meth.Eng., 2009, vol. 16, pp. 399–424. doi 10.1007/s11831-009-9037-2

Ding, J., McColl, I.R., Leen, S.B., and Shipway, P.H., A Finite Element Based Approach to Simulating the Effects of Debris on Fretting Wear, Wear, 2007, vol. 481, pp. 481–491.

Popov, V.L. and Psakhie, S.G., Numerical Simulation Methods in Tribology, Tribol. Int., 2007, vol. 40, pp. 916–923.

Yang, C. and Persson, B.N.J., Molecular Dynamics Study of Contact Mechanics: Contact Area and Interfacial Separation from Small to Full Contact, Phys. Rev.Lett., 2008, vol. 100, p. 024303.

Ezawa, Y. and Okamoto, N., Development of Contact Stress Analysis Programs Using the Hybrid Method of FEM and BEM,Comput. Struct., 1995, vol. 57, pp. 691–698.

Polonsky, I.A. and Keer, L.M., A Numerical Method for Solving Rough Contact Problems Based on the Multi-Level Multi-Summation and Conjugate Gradient Techniques, Wear, 1999, vol. 231, no. 2, pp. 206−219. doi 10.1016/S0043-1648(99)00113-1

Jackson, R.L. and Streator, J.L., A Multi-Scale Model for Contact Between Rough Surfaces, Wear, 2006, vol. 261, no. 11–12, pp. 1337–1347. doi 10.1016/j. wear.-2006.03.015

Dmitriev, A.I., Smolin, A.Yu., Popov, V.L., and Psakhie, S.G., A Multilevel Computer Simulation of Friction and Wear by Numerical Methods of Discrete Mechanics and a Phenomenological Theory,Phys. Mesomech., 2009, vol. 12, no. 1–2, pp. 11–19.

Kato, K., Classification of Wear Mechanisms/Models,J. Eng. Tribol., 2002, vol. 216, pp. 349−355.

Myshkin, N.K., Petrokovets, M.I., and Kovalev, A.V., Tribology of Polymers: Adhesion, Friction, Wear, and Mass-Transfer,Tribol. Int., 2005, vol. 38, pp. 910–921. doi 10.1016/j.triboint.2005.07.016

Persson, B.N.J. and Scaraggi, M., Theory of Adhesion: Role of Surface Roughness, J. Chem.Phys., 2014, vol. 141, no. 12, p. 124701.

Kondratyuk, A.A., Klopotov, A.A., Mulenkov, A.N, Ziganshin, A.I., and Vasendina, E.A., Specific Heat Capacity of Filled Composites, Izv. Vyssh.Uchebn. Zaved.,Fiz., 2012, vol. 55, no. 5/2, pp. 151–155.

Ultrahigh Molecular Weight Polyethylene of High Density, Andreyeva, I.N., Veselovskaya, E.V., Nalivaiko, E.I., et al., Eds., Leningrad: Khimia, 1982.

Zienkiewicz, O.C., Taylor R.L., and Zhu, J.Z., The Finite Element Method: Its Basis and Fundamentals, Woburn, MA: Butterworth-Heinemann, 2013.

Lyukshin, P.A., Lyukshin, B.A., Matolygina, N.Yu., and Panin, S.V., Determination of Effective Thermophysical Characteristics of a Composite Material, Fiz. Mezomekh., 2008, vol. 11, no. 5, pp. 103–110.

Lyukshin, B.A., Panin, S.V., Bochkareva, S.A., Grishaeva, N.Yu., Kornienko, L.A., Lyukshin, P.A., Matolygina, N.Yu., and Reutov, A.I., Computer Simulation and Design of Filled Compositions, Novosibirsk: SB RAS, 2015.

Iosilevich, G.B., Stress and Strain Concentration in Machine Parts, Moscow: Mashinostroenie, 1981.

Lyukshin, B.A., Shilko, S.V., Panin, S.V., Mashkov, Yu.K., Kornienko, L.A., Lyukshin, P.A., Pleskachevsky, Yu.M., Kropotin, O.V., Bochkareva, S.A., Matolygina, N.Yu., Chernous, D.A., Grishaeva, N.Yu., and Reutov, Yu.A., Dispersion-Filled Polymer Composites for Technical and Medical Purposes, Gerasimov, A.V., Ed., Novosibirsk: SB RAS, 2017.

Funding

The work was performed according to the Government research assignment for ISPMS SB RAS, project No. III.23.1.3 and under grant of the President of the Russian Federation for State Support of Leading Scientific Schools (NSh-2718.2020.8).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © The Author(s), 2019, published in Fizicheskaya Mezomekhanika, 2019, Vol. 22, No. 1, pp. 54–68.

Rights and permissions

About this article

Cite this article

Bochkareva, S.A., Panin, S.V., Lyukshin, B.A. et al. Simulation of Frictional Wear with Account of Temperature for Polymer Composites. Phys Mesomech 23, 147–159 (2020). https://doi.org/10.1134/S102995992002006X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102995992002006X