Abstract

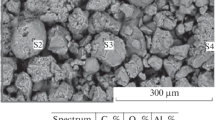

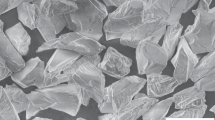

—A two-stage method was developed for the synthesis of 1,3-butadiene by dehydration of 1-butanol to a mixture of butenes on γ-Al2O3 granules prepared by self-propagating high-temperature synthesis (SHS) followed by dehydrogenation of the butene fraction to 1,3-butadiene using a porous ceramic catalytic SHS converter [Fe,Cr]/γ-Al2O3(K,Ce)/α-Al2O3. The dehydration of 1-butanol to the butene mixture proceeded almost completely at ~100% selectivity on γ-Al2O3 granules obtained by SHS at 300°C, which is 50 degrees lower than on industrial gamma-alumina granules. The use of an original hybrid catalytic membrane reactor (HCMR) with selective removal of hydrogen from the reaction zone led to a ~1.3-fold increase in the yield of 1,3-butadiene at ultrapure hydrogen extraction of up to 16 mol % of the total amount of the hydrogen product. The catalytic activity of the system did not decrease after 20 h of experiment, in contrast to its activity in the industrial process, where catalyst regeneration is performed every 8–15 min.

Similar content being viewed by others

REFERENCES

Lebedev, S.V., Zh. Ross. Khim. Obshch., 1909, vol. 41, p. 42.

White, W.C., Chem.–Biol. Interact., 2007, vol. 166, nos. 1–3, p. 10

Doelle, H.W., Rokem, J.S., and Berovic, M., Biotechnology,V. IV:Fundamentals in Biotechnology, Oxford: Eolss, 2009.

Ochoa, J.V., Bandinelli, C., Vozniuk, O., Chieregato, A., Malmusi, A., Recchi, C., and Cavani, F., Green Chem., 2016, vol. 18, no. 6, p. 1653.

Farzad, S., Mandegari, M.A., and Görgens, J.F., Bioresour. Technol., 2017, vol. 239, p. 37.

IHS Markit, Chemical Economics Handbook, Global butadiene production overview. https://ihsmarkit. com/products/butadiene-chemical-economics-handbook.html. Accessed July 25, 2019.

Makshina, E.V., Dusselier, M., Janssens, W., Degrève, J., Jacobs, P.A., and Sels, B.F., Chem. Soc. Rev., 2014, vol. 43, no. 22, p. 7917.

Arpe, H-J. and Hawkins, S. Industrial Organic Chemistry, New York: Wiley, 2010, 5th ed., p. 525.

Kondakov, I.L., Sinteticheskii kauchuk ego gomologi i analogi: Tip. Mattisena (Synthetic Rubber its Homologies and Analogies. Matissen Type), 1912, p. 151.

Zhang, J., Wang, S., and Wang, Y. Advances in Bioenergy, Ch. 1: Biobutanol Production from Renewable Resources Recent Advances, Elsevier: Netherlands, 2016, vol. 1, p. 1.

Doelle, H.W., Rokem, J.S., and Berovic, M., Biotechnology,V. VI:Fundamentals in Biotechnology, Oxford: Eolss, 2009.

Silvester, L., Lamonier, J.F, Lamonier, C., Capron, M., Vannier, R.N., Mamede, A.S., and Dumeignil, F., ChemCatChem, 2017, vol. 9, no. 12, p. 2250.

Tsodikov, M.V., Yandieva, F.A., Kugel, V.Y., Chistyakov, A.V., Gekhman, A.E., and Moiseev, I.I., Catal. Lett., 2008, vol. 121, nos. 3–4, p. 199.

Tsodikov, M.V., Chistyakov, A.V., Nikolaev, S.A., Kriventsov, V.V., Gekhman, A.E., and Moiseev, I.I., Chemistry of Biomass. Biofuels and Bioplastics: Scientific Word, 2017, p. 223.

Research and Markets, Global Bio-Butanol Market. Segmented by Application and Geography 2017–2022. https://www.researchandmarkets.com/reports/4390693/ global-bio-butanol-market-segmented-by. Cited July 25, 2019.

Biomass Magazine, Minnesota n-butanol plant comes online. http://biomassmagazine.com/articles/14006/ minnesota-butanol-plant-comes-online. Accessed July 25, 2019.

Stabnikov, V.N., Peregonka i rektifikatsiya etilovogo spirta (Distillation and Rectification of Ethyl Alcohol), Moscow: Pishchevaya Promyshlennost’, 1969, 2nd ed., p. 456.

Chistyakov, A.V., Zharova, P.A, Tsodikov, M.V., Nikolaev, S.A., Krotova, I.N., and Ezzhelenko, D.I., Kinet. Catal., 2016, vol. 57, no. 6, p. 803.

Fedotov, A.S., Antonov, D.O., Uvarov, V.I., and Tsodikov, M.V., Int. J. Hydrogen Energy, 2018, vol. 43, no. 14, p. 7046.

Tsodikov, M.V., Fedotov, A.S., Antonov, D.O., Uvarov, V.I., Bychkov, V.Y., and Luck, F.C., Int. J. Hydrogen Energy, 2016, vol. 41, no. 4, p. 2424.

Fedotov, A.S., Antonov, D.O., Bukhtenko, O.V., Uvarov, V.I., Kriventsov, V.V., and Tsodikov, M.V., Int. J. Hydrogen Energy, 2017, vol. 42, no. 38, p. 24131.

Kantaev, A.S. and Brus, I.D., Opredelenie razmera por fil’truyushchego elementa (Determination of Pore Size of Filtering Element), Tomsk: Tomsk Polytechnic University, 2014, p. 16.

Guczi, L. and Erdöhelyi, A., Catalysis for Alternative Energy Generation, Berlin: Springer, 2012, p. 538.

Khan, Y., Marin, M., Karinen, R., Lehtonen, J., and Kanervo, J., Chem. Eng. Sci., 2015, vol. 137, p. 740.

Grub, J. and Löser, E., Butadiene, in Ullmann’s Encyclopedia of Industrial Chemistry, Weinheim: Wiley, 2012.

Berteau, P., Ruwet, M., and Delmon, B., Bull. Des Sociétés Chim.Belges, 1985, vol. 94, nos. 11–12, p. 859.

Phung, T.K., Lagazzo, A., Rivero Crespo, M.Á., Sánchez Escribano, V., and Busca, G., J. Catal., 2014, vol. 311, p. 102.

Tyuryaev, I.Ya., Usp. Khim., 1966, vol. 35, no. 1, p. 121.

Fedotov, A.S., Antonov, D.O., Uvarov, V.I., Tsodikov, M.V., and Khadzhiev, S.N., Pet. Chem., 2018, vol. 58, no. 1, p. 62.

Biesinger, M.C., Payne, B.P., Grosvenor, A.P., Lau, L.W., Gerson, A. R., and Smart, R.S.C., Appl. Surf. Sci., 2011, vol. 257, no. 7, p. 2717.

Teplyakov, V.V. and Tsodikov, M.V., Porous Inorganic Membrane Reactors. In Simulation of Membrane Reactors, Ed. A. Basile and F. Gallucci, New York: Nova Science, 2009, p. 123.

ACKNOWLEDGMENTS

We are grateful to D.O. Antonov for his help in performing catalytic experiments, and to Benjamin Katryniok, Joelle Thuriot, and Olivier Gardoll for help with SEM-EDX, XRD, and TG analyses.

A.S. Fedotov thanks the Embassy of France in Moscow for awarding him the “Mechnikov scholarship-2018: Scientific visits,” which made it possible to perform a wide range of structural analyses at the Catalysis and Solid State Chemistry Laboratory of the Lille University.

We also thank Chevreul Institute (FR 2638); Ministry of Higher Education, Research, and Innovation; Hauts-de-France region; National Center for Scientific Research; European Regional Development Fund; École centrale de Lille; and Central Initiative Fund for financial support.

Funding

This study was supported by the Russian Science Foundation (grant no. 17-13-01270).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by L. Smolina

Abbreviations: GLC, gas-liquid chromatography; GC-MS, gas chromatography-mass spectrometry; FID, flame ionization detector; HCMR, hybrid catalytic membrane reactor; SHS, self-propagating high-temperature synthesis; SEM-EDX, scanning electron microscopy with energy dispersive X-ray spectroscopy; TGA, thermogravimetric analysis; TPReduction-H2, thermally programmed reduction with hydrogen; TEM, transmission electron microscopy; XPS, X-ray photoelectron spectroscopy.

Rights and permissions

About this article

Cite this article

Fedotov, A.S., Uvarov, V.I., Tsodikov, M.V. et al. Synthesis of 1,3-Butadiene from 1-Butanol on a Porous Ceramic [Fe,Cr]/γ-Al2O3(K,Ce)/α-Al2O3 Catalytic Converter. Kinet Catal 61, 390–404 (2020). https://doi.org/10.1134/S002315842003009X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002315842003009X