Abstract

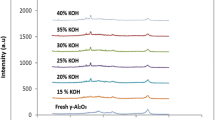

In this study, catalytic transesterification of Parkia seed oil with methanol to biodiesel was studied. Attapulgite clay, treated with HCl and then functionalized with C4H6O4KNa and Na2C2O4 was used as a solid base catalyst. Having screened the catalytic action of attapulgite treated with HCl and functionalized with C4H6O4KNa at different concentrations, 4 M solution C4H6O4KNa was chosen for the functionalization and the results were compared with data obtained with 4 M Na2C2O4. Impregnation method was applied to prepare catalysts. Functionalized catalysts dried and calcined at 450°C for 4 h were characterized by Hammett indicators, nitrogen adsorption isotherms, Fourier transform infrared spectroscopy, X-ray diffraction, scanning electron microscopy and thermogravimetric analyses. The performance of HCl treated attapulgite and functionalized with 4 M C4H6O4KNa (4NK/HCl-Atta-4) was superior both to HCl treated attapulgite functionalized with Na2C2O4 (4NC/HCl-Atta-4) and to HCl treated attapulgite (HCl-Atta-4, reference). Maximum yields of biodiesels of 94.7 and 92.2% were obtained by using 4NK/HCl-Atta-4 and 4NC/HCl-Atta-4, respectively. The optimum reaction conditions were: ratio methanol : oil = 9 : 1; catalyst amount, 6 wt %; and reaction temperature, 60°C; reaction time, 6 h. The catalysts preserved catalytic activity after 5 runs of reuse. The properties of the biodiesels were comparable with those required by American and European Union standards and they could be considered as a realistic alternative fuel to diesel.

Similar content being viewed by others

REFERENCES

Wan, L., Liu, H., and Skala, D., Appl. Catal., B, 2014, vols. 152–153, p. 352.

Asakuma, Y., Maeda, K., Kuramochi, H., and Fukui, K., Fuel, 2009, vol. 88, p. 786.

Babu, N.S., Sree, R., Prasad, P.S., and Lingaiah, N., Energy Fuels, 2008, vol. 22, p. 1965.

Kawashima, A., Matsubara, K., and Honda, K., Bioresour. Technol., 2008, vol. 99, p. 3439.

Dang, T.H., Chen, B.-H., and Lee, D.-J., Bioresour. Technol., 2013, vol. 145, p. 175.

You, Q., Yin, X., Zhao, Y., and Zhang, Y., Bioresour. Technol., 2013, vol. 148, p. 202.

Lim, J.-S., Kim, S.-M., Lee, S.-Y., Stach, E.A., Culver, J.N., Harris, M.T., J. Colloid Interface Sci., 2011, vol 356, p. 31.

Galan, E., Clay Miner., 1996, vol. 31, p. 443.

Ahmad, M., Zafar, M., Sultana, S., Azam, A., and Khan, M.A., Int. J. Green Energy, 2014, vol. 11, p. 589.

Li, F., Yang, L., Zhao, T., Zhao, J., Zou, J., Zou, Y., and Wu, X., Food Bioprod. Process., 2012, vol. 90, p. 87.

Takase, M., Zhang, M., Feng, W., Chen, Y., Zhao, T., Cobbina, S.J., Yang, L., and Wu, X., Energy Convers. Manage., 2014, vol. 80, p. 117.

Xie, W., Peng, H., and Chen, L., Appl. Catal., A, 2006, vol. 300, p. 67.

Takase, M., Feng, W., Wang, W., Gu, X., Zhu, Y., Li, T., Yang, L., and Wu, X., Fuel Process. Technol., 2014, vol. 123, p. 19.

Benita, S., Microencapsulation: Methods and Industrial Applications, Boca Paton: CRC Press, 2005, p. 228.

Demirbas, A., Energy Convers. Manage., 2003, vol. 44, p. 2093.

Xu, J.-M., Li, W., Yin, Q.-f., and Zhu, Y.-L., Electrochim. Acta, 2007, vol. 52, p. 3601.

Wu, W., Fan, Q., Xu, J., Niu, Z., and Lu, S., Appl. Radiat. Isot., 2007, vol. 65, p. 1108.

Li, Y., Ye, B., Shen, J., Tian, Z.L., Wang, L., Zhu, T., Ma, D., and Yang, F., Bioresour. Technol., 2013, vol. 137, p. 220.

Kulkarni, M.G., Gopinath, R., Meher, L.C., and Dalai, A.K., Green Chem., 2006, vol. 8, p. 1056.

ACKNOWLEDGMENTS

The research was supported by MICMOD FOUNDATION, Ghana.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Abbreviations: EDS, energy dispersive X-ray spectroscopy; FT-IR, Fourier transform infrared spectroscopy; XRD, X-ray diffraction; SEM, scanning electron microscopy; TGA, thermogravimetric analysis.

Rights and permissions

About this article

Cite this article

Adipah, S., Takase, M. Acid Treated Attapulgite Functionalized with Sodium Compounds as Novel Bifunctional Heterogeneous Solid Catalysts for Biodiesel Production. Kinet Catal 61, 405–413 (2020). https://doi.org/10.1134/S0023158420030015

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158420030015