Abstract

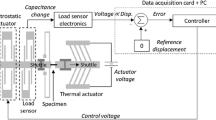

Background: MEMS-based nanomechanical testing has received much interests. However, it remains challenging to perform displacement- and force-controlled nanomechanical tests (e.g., stress relaxation and creep). Objective: We report a MEMS-based device for displacement- and force-controlled tensile testing of 1D nanomaterials using feedback control. Methods: The device consists of an electrostatic actuator, a load cell, and two differential capacitive sensors. A specimen is mounted between a fixed anchor on one side and a displacement sensor on the other side. Using a multi-channel capacitive readout, both specimen displacement and force (thus strain and stress) can be measured from the readout simultaneously, without the need of imaging that is often used for displacement measurement. Results: With the feedback control, both displacement- and force-controlled tensile testing can be achieved. The capability of the device is demonstrated in three representative tests of metallic nanowires – stress relaxation test, tensile test capturing rapid stress drop, and creep test. Conclusions: The reported MEMS device can be used for a range of tests where imaging for displacement measurement is not feasible, such as ex-situ tests, high-rate tests, and fatigue tests in different environments.

Similar content being viewed by others

References

Zhu T, Li J (2010) Ultra-strength materials. Prog Mater Sci 55:710–757

Richter G, Hillerich K, Gianola DS et al (2009) Ultrahigh strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett 9:3048–3052. https://doi.org/10.1021/nl9015107

Seo JH, Yoo Y, Park NY et al (2011) Superplastic deformation of defect-free Au nanowires via coherent twin propagation. Nano Lett 11:3499–3502. https://doi.org/10.1021/nl2022306

Yin S, Cheng G, Richter G et al (2019) Transition of Deformation Mechanisms in Single-Crystalline Metallic Nanowires. ACS Nano 13:9082–9090. https://doi.org/10.1021/acsnano.9b03311

Qin Q, Yin S, Cheng G et al (2015) Recoverable plasticity in penta-twinned metallic nanowires governed by dislocation nucleation and retraction. Nat Commun 6:5983. https://doi.org/10.1038/ncomms6983

Bernal RA, Aghaei A, Lee S et al (2015) Intrinsic bauschinger effect and recoverable plasticity in pentatwinned silver nanowires tested in tension. Nano Lett 15:139–146. https://doi.org/10.1021/nl503237t

Cheng G, Miao C, Qin Q et al (2015) Large anelasticity and associated energy dissipation in single-crystalline nanowires. Nat Nanotechnol 10:687–691. https://doi.org/10.1038/nnano.2015.135

Yao S, Zhu Y (2015) Nanomaterial-Enabled Stretchable Conductors: Strategies, Materials and Devices. Adv Mater 27:1480–1511. https://doi.org/10.1002/adma.201404446

Zhang Q, Uchaker E, Candelaria SL, Cao G (2013) Nanomaterials for energy conversion and storage. Chem Soc Rev 42:3127–3171. https://doi.org/10.1039/c3cs00009e

Loh OY, Espinosa HD (2012) Nanoelectromechanical contact switches. Nat Nanotechnol 7:283–295. https://doi.org/10.1038/nnano.2012.40

Yin S, Cheng G, Chang TH et al (2019) Hydrogen embrittlement in metallic nanowires. Nat Commun 10:2004. https://doi.org/10.1038/s41467-019-10035-0

Wang J, Sansoz F, Huang J et al (2013) Near-ideal theoretical strength in gold nanowires containing angstrom scale twins. Nat Commun 4:1742. https://doi.org/10.1038/ncomms2768

Cheng G, Yin S, Chang TH et al (2017) Anomalous Tensile Detwinning in Twinned Nanowires. Phys Rev Lett 119:256101. https://doi.org/10.1103/PhysRevLett.119.256101

Cheng G, Zhang Y, Chang TH, Liu Q, Chen L, Lu WD, Zhu T, Zhu Y, (2019) In Situ Nano-thermomechanical Experiment Reveals Brittle to Ductile Transition in Silicon Nanowires. Nano Letters 19 (8):5327–5334

Zhu Y, Ke C, Espinosa HD (2007) Experimental techniques for the mechanical characterization of one-dimensional nanostructures. Exp Mech 47:7–24

Zhu Y (2017) Mechanics of Crystalline Nanowires: An Experimental Perspective. Appl Mech Rev 69:010802

Zhu Y, Chang TH (2015) A review of microelectromechanical systems for nanoscale mechanical characterization. J Micromechanics Microengineering 25:093001

Kang W, Rajagopalan J, Saif MTA (2010) In situ uniaxial mechanical testing of small scale materials - A review. Nanosci Nanotechnol Lett 2:282–287

Naraghi M, Chasiotis I, Kahn H et al (2007) Novel method for mechanical characterization of polymeric nanofibers. Rev Sci Instrum 78:085018. https://doi.org/10.1063/1.2771092

Zhang D, Breguet JM, Clavel R et al (2010) In situ electron microscopy mechanical testing of silicon nanowires using electrostatically actuated tensile stages. J Microelectromechanical Syst 19:663–674. https://doi.org/10.1109/JMEMS.2010.2044746

Naraghi M, Ozkan T, Chasiotis I et al (2010) MEMS platform for on-chip nanomechanical experiments with strong and highly ductile nanofibers. J Micromechanics Microengineering 20:125022. https://doi.org/10.1088/0960-1317/20/12/125022

Kiuchi M, Matsui S, Isono Y (2007) Mechanical characteristics of FIB deposited carbon nanowires using an electrostatic actuated Nano Tensile testing device. J Microelectromechanical Syst 16:191–201. https://doi.org/10.1109/JMEMS.2006.889663

Lu Y, Ganesan Y, Lou J (2010) A Multi-step method for In situ mechanical characterization of 1-D nanostructures using a novel micromechanical device. Exp Mech 50:47–54. https://doi.org/10.1007/s11340-009-9222-0

Haque MA, Espinosa HD, Lee HJ (2010) MEMS for in situ testing - Handling, actuation, loading, and displacement measurements. MRS Bull 35:375–381. https://doi.org/10.1557/mrs2010.570

Ramachandramoorthy R, Gao W, Bernal R, Espinosa H (2016) High Strain Rate Tensile Testing of Silver Nanowires: Rate-Dependent Brittle-to-Ductile Transition. Nano Lett 16:255–263. https://doi.org/10.1021/acs.nanolett.5b03630

Li C, Zhang D, Cheng G, Zhu Y (2020) Microelectromechanical Systems for Nanomechanical Testing: Electrostatic Actuation and Capacitive Sensing for High-Strain-Rate Testing. Exp Mech 60:329–343. https://doi.org/10.1007/s11340-019-00565-5

Zhang H, Jiang C, Lu Y (2017) Low-Cycle Fatigue Testing of Ni Nanowires Based on a Micro-Mechanical Device. Exp Mech 57:495–500. https://doi.org/10.1007/s11340-016-0199-1

Baumert EK, Pierron ON (2013) Fatigue degradation properties of LIGA Ni films using kilohertz microresonators. J Microelectromechanical Syst 22:16–25. https://doi.org/10.1109/JMEMS.2012.2212422

Bernal RA, Filleter T, Connell JG et al (2014) In Situ Electron Microscopy Four-Point Electromechanical Characterization of Freestanding Metallic and Semiconducting Nanowires. Small 10:725–733. https://doi.org/10.1002/smll.201300736

Zhang Y, Liu X, Ru C et al (2011) Piezoresistivity characterization of synthetic silicon nanowires using a MEMS Device. J Microelectromechanical Syst 20:959–967. https://doi.org/10.1109/JMEMS.2011.2153825

Caillard D, Martin JL (2003) Thermally activated mechanisms in crystal plasticity. Elsevier, Amsterdam

Zhu Y, Espinosa HD (2005) An electromechanical material testing system for in situ electron microscopy and applications. Proc Natl Acad Sci U S A 102:14503–14508. https://doi.org/10.1073/pnas.0506544102

Espinosa HD, Zhu Y, Moldovan N (2007) Design and operation of a MEMS-based material testing system for nanomechanical characterization. J Microelectromechanical Syst 16:1219–1231. https://doi.org/10.1109/JMEMS.2007.905739

Shin J, Richter G, Gianola DS (2020) Suppressing instabilities in defect-scarce nanowires by controlling the energy release rate during incipient plasticity. Mater Des 189:108460. https://doi.org/10.1016/j.matdes.2019.108460

Naraghi M, Kolluru PV, Chasiotis I (2014) Time and strain rate dependent mechanical behavior of individual polymeric nanofibers. J Mech Phys Solids 62:257–275. https://doi.org/10.1016/j.jmps.2013.10.006

Pantano MF, Bernal RA, Pagnotta L, Espinosa HD (2015) Multiphysics design and implementation of a microsystem for displacement-controlled tensile testing of nanomaterials. Meccanica 50:549–560. https://doi.org/10.1007/s11012-014-9950-9

Ouyang J, Zhu Y (2012) Z-shaped MEMS thermal actuators: Piezoresistive self-sensing and preliminary results for feedback control. J Microelectromech Syst 21:596–604. https://doi.org/10.1109/JMEMS.2012.2189361

Tsuchiya T, Ura Y, Sugano K, Tabata O (2012) Electrostatic tensile testing device with nanonewton and nanometer resolution and its application to C 60 nanowire testing. J Microelectromech Syst 21:523–529. https://doi.org/10.1109/JMEMS.2011.2182503

Pant B, Choi S, Baumert EK et al (2012) MEMS-Based Nanomechanics: Influence of MEMS Design on Test Temperature. Exp Mech 52:607–617. https://doi.org/10.1007/s11340-011-9526-8

Zhu Y, Moldovan N, Espinosa HD (2005) A microelectromechanical load sensor for in situ electron and x-ray microscopy tensile testing of nanostructures. Appl Phys Lett 86:013506. https://doi.org/10.1063/1.1844594

Åström KJ, Hägglund T (2004) Revisiting the Ziegler-Nichols step response method for PID control. J Process Control 14:635–650. https://doi.org/10.1016/j.jprocont.2004.01.002

Zhu Y, Qin Q, Xu F et al (2012) Size effects on elasticity, yielding, and fracture of silver nanowires: In situ experiments. Phys Rev B - Condens Matter Mater Phys 85:045443. https://doi.org/10.1103/PhysRevB.85.045443

Wiley B, Sun Y, Xia Y (2007) Synthesis of Silver Nanostructures with Controlled Shapes and Properties. Acc Chem Res 40:1067–1076. https://doi.org/10.1021/ar7000974

Sedlmayr A, Bitzek E, Gianola DS et al (2012) Existence of two twinning-mediated plastic deformation modes in Au nanowhiskers. Acta Mater 60:3985–3993. https://doi.org/10.1016/j.actamat.2012.03.018

Jing GY, Duan HL, Sun XM et al (2006) Surface effects on elastic properties of silver nanowires: Contact atomic-force microscopy. Phys Rev B - Condens Matter Mater Phys 73:235409. https://doi.org/10.1103/PhysRevB.73.235409

Chang TH, Cheng G, Li C, Zhu Y (2016) On the size-dependent elasticity of penta-twinned silver nanowires. Extrem Mech Lett 8:177–183. https://doi.org/10.1016/j.eml.2016.03.007

Park HS, Zimmerman JA (2005) Modeling inelasticity and failure in gold nanowires. Phys Rev B - Condens Matter Mater Phys 72:054106. https://doi.org/10.1103/PhysRevB.72.054106

Zhu T, Li J, Samanta A et al (2008) Temperature and strain-rate dependence of surface dislocation nucleation. Phys Rev Lett 100:025502. https://doi.org/10.1103/PhysRevLett.100.025502

Zheng H, Cao A, Weinberger CR et al (2010) Discrete plasticity in sub-10-nm-sized gold crystals. Nat Commun 1:144. https://doi.org/10.1038/ncomms1149

Lu L, Zhu T, Shen Y et al (2009) Stress relaxation and the structure size-dependence of plastic deformation in nanotwinned copper. Acta Mater 57:5165–5173. https://doi.org/10.1016/j.actamat.2009.07.018

Narayanan S, Cheng G, Zeng Z et al (2015) Strain Hardening and Size Effect in Five-fold Twinned Ag Nanowires. Nano Lett 15:4037–4044. https://doi.org/10.1021/acs.nanolett.5b01015

Acknowledgement

The authors gratefully acknowledge financial support from the National Science Foundation (NSF) through Award Nos. CMMI-1762511 and 1929646. The authors would like to thank Dr. G. Richter for providing the Au nanowires.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Li, C., Cheng, G., Wang, H. et al. Microelectromechanical Systems for Nanomechanical Testing: Displacement- and Force-Controlled Tensile Testing with Feedback Control. Exp Mech 60, 1005–1015 (2020). https://doi.org/10.1007/s11340-020-00619-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00619-z