Abstract

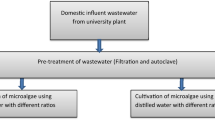

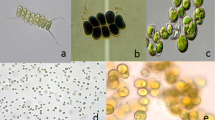

The development of biofuels as an alternative to the use of fossil fuels is growing worldwide due to environmental concerns and energy independence; thus, considerable technical progress has been achieved in biofuel production. Microalgae have been widely used for nutrient removal during wastewater treatment and produce compounds that can be used as feedstock for biofuel synthesis. In this work, the green microalga Coelastrum sp. was cultivated using industrial wastes: molasses as the carbon source and synthetic wastewater as the culture medium to determine the potential of its use for biofuel production. The use of synthetic wastewater (SWW) and molasses improved biomass production when compared with cultures carried out in a standard laboratory culture medium, such as tris-acetate-phosphate (TAP). Growth rates of 0.31 and 1.4 day−1 were attained during exponential growth rate with SWW and molasses and TAP media, respectively. The best results in biomass and lipid content, 2.29 ± 0.05 and 0.71 ± 0.03 g L−1, were obtained after 15 days of culture in SWW with molasses. The analysis of the lipid profile, produced by Coelastrum sp. cultured under these conditions, determined that the microalga can be considered as a high-quality feedstock for producing green diesel, bio-jet fuel, or biodiesel.

Similar content being viewed by others

References

Brännström H, Hemanathan K, Raimo A (2018) Current and potential biofuel production from plant oils. Bioenergy Res 11:592–613. https://doi.org/10.1007/s12155-018-9923-2

Perez-García O, de-Bashan LE, Hernández JP, Bashan Y (2010) Efficiency of growth and nutrient uptake from wastewater by heterotrophic, autotrophic, and mixotrophic cultivation of Chlorella vulgaris immobilized with Azospirillum brasilense. J Phycol 46:800–812. https://doi.org/10.1111/j.1529-8817.2010.00862.x

Abreu AP, Fernandes B, Vicente AA, Teixeira J, Dragone G (2012) Mixotrophic cultivation of Chlorella vulgaris using industrial dairy waste as organic carbon source. Bioresour Technol 118:61–66. https://doi.org/10.1016/j.biortech.2012.05.055

Gaurav K, Srivastava R, Sharma JG, Singh R, Singh V (2016) Molasses-based growth and lipid production by Chlorella pyrenoidosa: a potential feedstock for biodiesel. Int J Green Energy 13(3):320–327. https://doi.org/10.1080/15435075.2014.966268

Yan D, Lu Y, Chen YF, Wu Q (2011) Waste molasses alone displaces glucose-based medium for microalgal fermentation towards cost-saving biodiesel production. Bioresour Technol 102:6487–6493. https://doi.org/10.1016/j.biortech.2011.03.036

Cheng Y, Lu Y, Gao C, Wu Q (2009) Algae-based biodiesel production and optimization using sugar cane as the feedstock. Energy Fuel 23:4166–4173. https://doi.org/10.1021/ef9003818

Kang S, Fu J, Zhou N, Liu R, Peng Z, Xu Y (2018) Concentrated levulinic acid production from sugar cane molasses. Energy Fuel 32:3526–3531. https://doi.org/10.1021/acs.energyfuels.7b03987

Teclu D, Tivchev G, Laing M, Wallis M (2009) Determination of the elemental composition of molasses and its suitability as carbon source for growth of sulphate-reducing bacteria. J Hazard Mater 161:1157–1165. https://doi.org/10.1016/j.jhazmat.2008.04.120

Kim KH, Lee HY, Lee CY (2015) Pretreatment of sugarcane molasses and citric acid production by Candida zeylanoides. Microbiol Biotechnol Lett 43:164–168. https://doi.org/10.4014/mbl.1503.03006

CONADESUCA (2016) Melazas de caña de azúcar y su uso en la fabricación de dietas para ganado. https://www.gob.mx/cms/uploads/attachment/file/171888/Nota_Informativa_Noviembre_Melazas.pdf. Accessed 28 May 2019

Isleten-Hosoglu M, Gultepe I, Elibol M (2012) Optimization of carbon and nitrogen sources for biomass and lipid production by Chlorella saccharophila under heterotrophic conditions and development of Nile red fluorescence based method for quantification of its neutral lipid content. Biochem Eng J 61:11–19. https://doi.org/10.1016/j.bej.2011.12.001

Liu J, Huang J, Jiang Y, Chen F (2012) Molasses-based growth and production of oil and astaxanthin by Chlorella zofingiensis. Bioresour Technol 107:393–398. https://doi.org/10.1016/j.biortech.2011.12.047

Cai T, Park SY, Li Y (2013) Nutrient recovery from wastewater streams by microalgae: status and prospects. Renew Sust Energ Rev 19:360–369. https://doi.org/10.1016/j.rser.2012.11.030

Mousavi S, Najafpour GD, Mohammadi M, Seifi MH (2018) Cultivation of newly isolated microalgae Coelastrum sp. in wastewater for simultaneous CO2 fixation, lipid production and wastewater treatment. Bioprocess Biosyst Eng 41:519–530. https://doi.org/10.1007/s00449-017-1887-7

Úbeda B, Gálvez JA, Michel M, Bartual A (2017) Microalgae cultivation in urban wastewater: Coelastrum cf. pseudomicroporum as a novel carotenoid source and a potential microalgae harvesting tool. Bioresour Technol 228:210–217. https://doi.org/10.1016/j.biortech.2016.12.095

Liu Z, Liu C, Hou Y, Chen S, Xiao D, Zhang J, Chen F (2013) Isolation and characterization of a marine microalga for biofuel production with Astaxanthin as a co-product. Energies 6:2759–2772. https://doi.org/10.3390/en6062759

Minillo A, Godoy HC, Fonseca GG (2013) Growth performance of microalgae exposed to CO2. J Clean Energy Technol 1:110–114. https://doi.org/10.7763/JOCET.2013.V1.26

Hirose M, Mukaida F, Okada S, Noguchi T (2013) Active hydrocarbon biosynthesis and accumulation in a green alga Botryococcus braunii (race A). Eukaryot Cell 12:1132–1141. https://doi.org/10.1128/EC.00088-13

Herrera-Valencia VA, Us-Vázquez RA, Larqué-Saavedra FA, Barahona-Pérez LF (2012) Naturally occurring fatty acid methyl esters and ethyl esters in the green microalga Chlamydomonas reinhardtii. Ann Microbiol 62:865–870. https://doi.org/10.1007/s13213-011-0361-z

Santhakumaran P, Kookal S, Mathew L, Ray JG (2019) Bioprospecting of three rapid-growing freshwater green algae. Bioresour Technol 12:680–693. https://doi.org/10.1007/s12155-019-09990-9

Valdez-Ojeda R, González-Muñoz M, Us-Vázquez R, Narváez-Zapata J, Chavarria-Hernandez JC, López-Adrián S, Barahona-Pérez F, Toledano-Thompson T, Garduño-Solórzano G, Escobedo-Gracia Medrano RM (2015) Characterization of five fresh water microalgae with potential for biodiesel production. Algal Res 7:33–44. https://doi.org/10.1016/j.algal.2014.11.009

Nanduca HE (2015) Utilización de aguamiel de café y melaza en agua residual sintética en el cultivo de la microalga Scenedesmus sp para la producción de lípidos. M. Sc. Dissertation, Centro de Investigación Científica de Yucatán, Mexico

Harris EH (1989) The Chlamydomonas sourcebook, a comprehensive guide to biology and laboratory use. Academic, San Diego

Gorman DS, Levine RP (1965) Cytochrome f and plastocyanin: their sequence in the photosynthetic electron transport chain of Chlamydomonas reinhardii. Proc Natl Acad Sci U S A 54:1665–1669. https://doi.org/10.1073/pnas.54.6.1665

Azianabiha AHK, Zahira Y, Siti RSA, Mohd ST (2016) Enhanced growth and nutrients removal efficiency of Characium sp. cultured in agricultural wastewater via acclimatized inoculum and effluent recycling. J Environ Chem Eng 4:3426–3432. https://doi.org/10.1016/j.jece.2016.07.020

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917. https://doi.org/10.1139/o59-099

Widjaja A, Chien CC, Hu YH (2009) Study of increasing lipid production from fresh water microalgae Chlorella vulgaris. J Taiwan Inst Chem Eng 40:13–20. https://doi.org/10.1016/j.jtice.2008.07.007

Pratas MJ, Freitas S, Oliveira MB, Monteiro SC, Lima AS, Coutinho JA (2010) Densities and viscosities of fatty acid methyl and ethyl esters. J Chem Eng Data 55:3983–3990. https://doi.org/10.1021/je1012235

Ramírez-Verduzco LF (2013) Density and viscosity of biodiesel as a function of temperature: empirical models. Renew Sust Energ Rev 19:652–665. https://doi.org/10.1016/j.rser.2012.11.022

Ramírez-Verduzco LF, Rodríguez-Rodríguez JE, del Rayo J-JA (2012) Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 91:102–111. https://doi.org/10.1016/j.fuel.2011.06.070

Knothe G (2002) Structure indices in FA chemistry. How relevant is the iodine value? J Am Oil Chem Soc 79:847–854. https://doi.org/10.1007/s11746-002-0569-4

Knothe G, Steidley KR (2005) Kinematic viscosity of biodiesel fuel components and related compounds. Influence of compound structure and comparison to petrodiesel fuel components. Fuel 84:1059–1065. https://doi.org/10.1016/j.fuel.2005.01.016

Pratas MJ, Freitas S, Oliveira MB, Monteiro SC, Lima ÁS, Coutinho JA (2011) Densities and viscosities of minority fatty acid methyl and ethyl esters present in biodiesel. J Chem Eng Data 56:2175–2180. https://doi.org/10.1021/je1012235

Freedman B, Bagby MO (1989) Heats of combustion of fatty esters and triglycerides. J Am Oil Chem Soc 66:1601–1605. https://doi.org/10.1007/BF02636185

Mishra S, Anand K, Mehta PS (2016) Predicting the cetane number of biodiesel fuels from their fatty acid methyl ester composition. Energy Fuel 30:10425–10434. https://doi.org/10.1021/acs.energyfuels.6b01343

Serrano M, Oliveros R, Sánchez M, Moraschini A, Martínez M, Aracil J (2014) Influence of blending vegetable oil methyl esters on biodiesel fuel properties: oxidative stability and cold flow properties. Energy 65:109–115. https://doi.org/10.1016/j.energy.2013.11.072

Park JY, Kim DK, Lee JP, Park SC, Kim YJ, Lee JS (2008) Blending effects of biodiesels on oxidation stability and low temperature flow properties. Bioresour Technol 99:1196–1203. https://doi.org/10.1016/j.biortech.2007.02.017

Zhan J, HongY HH (2016) Effects of nitrogen sources and C/N ratios on the lipid-producing potential of Chlorella sp. HQ. J Microbiol Biotechnol 26:1290–1302. https://doi.org/10.4014/jmb.1512.12074

Gao F, Yang H-L, Li C, Peng Y-Y, Lu M-M, Jin W-H, Bao J-J, Guo Y-M (2019) Effect of organic carbon to nitrogen ratio in wastewater on growth, nutrient uptake and lipid accumulation of a mixotrophic microalgae Chlorella sp. Bioresour Technol 282:118–124. https://doi.org/10.1016/j.biortech.2019.03.011

Chen F, Johns MR (1991) Effect of C/N ratio and aeration on the fatty acid composition of heterotrophic Chlorella sorokiniana. J Appl Phycol 3:203–209. https://doi.org/10.1007/BF00003578

Perez-García O, Bashan Y, Puente ME (2011) Organic carbon supplementation of sterilized municipal wastewater is essential for heterotrophic growth and removing ammonium by the microalga Chlorella vulgaris. J Phycol 47:190–199. https://doi.org/10.1111/j.1529-8817.2010.00934.x

Rai MP, Gupta S (2017) Effect of media composition and light supply on biomass, lipid content and FAME profile for quality biofuel production from Scenedesmus abundans. Energy Convers Manag 141:85–92. https://doi.org/10.1016/j.enconman.2016.05.018

Griffiths MJ, van Hille RP, Harrison STL (2014) The effect of degree and timing of nitrogen limitation on lipid productivity in Chlorella vulgaris. Appl Microbiol Biotechnol 98:6147–6159. https://doi.org/10.1007/s00253-014-5757-9

El-Sheekh MM, Bedaiwy MY, Osman ME, Ismail MM (2014) Influence of molasses on growth, biochemical composition and ethanol production of the green algae Chlorella vulgaris and Scenedesmus obliquus. Journal of Agricultural Engineering and Biotechnology 2:20–28. https://doi.org/10.18005/JAEB0202002

Figueroa GM, Pittman JK, Theodoropoulos C (2017) Kinetic modelling of starch and lipid formation during mixotrophic, nutrient-limited microalgal growth. Bioresour Technol 241:868–878. https://doi.org/10.1016/j.biortech.2017.05.177

Gifuni I, Olivieri G, Pollio A, Marzocchella A (2018) Identification of an industrial microalgal strain for starch production in biorefinery context: the effect of nitrogen and carbon concentration on starch accumulation. New Biotechnol 41:46–54. https://doi.org/10.1016/j.nbt.2017.12.003

Yao LX, Gerde JA, Lee SL, Wang T, Harrata KA (2015) Microalgae lipid characterization. J Agric Food Chem 63:1773–1787. https://doi.org/10.1021/jf5050603

Frassanito R, Cantonati M, Tardio M, Mancini I, Guella G (2005) On-line identification of secondary metabolites in freshwater microalgae and cyanobacteria by combined liquid chromatography-photodiode array detection-mass spectrometric techniques. J Chromatogr A 1082:33–42. https://doi.org/10.1016/j.chroma.2005.02.066

Meng X, Pan Q, Ding Y, Jiang L (2014) Rapid determination of phospholipid content of vegetable oils by FTIR spectroscopy combined with partial least-square regression. Food Chem 147:272–278. https://doi.org/10.1016/j.foodchem.2013.09.143

Linstrom PJ, Mallard WG (2018) NIST chemistry webbook, NIST Standard Reference Database Number 69. https://webbook.nist.gov/chemistry/. Accessed 28 May 2019

Taylor RJ, Petty RH (1994) Selective hydroisomerization of long chain normal paraffins. Appl Catal A Gen 119:121–138. https://doi.org/10.1016/0926-860X(94)85029-1

Calemma V, Peratello S, Perego C (2000) Hydroisomerization and hydrocracking of long chain n-alkanes on Pt/amorphous SiO2-Al2O3 catalyst. Appl Catal A Gen 190:207–218. https://doi.org/10.1016/S0926-860X(99)00292-6

López-Rosales AR, Ancona-Canché K, Chavarria-Hernandez JC, Barahona-Pérez F, Toledano-Thompson T, Garduño-Solórzano G, López-Adrian S, Canto-Canché B, Polanco-Lugo E, Valdez-Ojeda R (2019) Fatty acids, hydrocarbons and terpenes of Nannochloropsis and Nannochloris isolates with potential for biofuel production. Energies 12:130. https://doi.org/10.3390/en12010130

Wang WC, Tao L (2016) Bio-jet fuel conversion technologies. Renew Sust Energ Rev 53:801–822. https://doi.org/10.1016/j.rser.2017.04.058

Funding

The authors gratefully acknowledge the ASA-CONACYT financial support Grant No. 243145 for this project and CONACYT for María Guadalupe del Rayo Serrano-Vázquez scholarship No. 338220.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Glossary

- ASTM

-

American Society of Testing Materials

- BD

-

Biodiesel

- BJ

-

Bio-jet fuel

- EN

-

European Standards

- E-T

-

Esterification + transesterification

- FAME

-

Fatty acid methyl ester

- FFA

-

Free fatty acids

- FT-IR

-

Fourier transform infrared spectroscopy

- GD

-

Green diesel

- H

-

High quality

- H/C

-

Hydrogen to oxygen atomic ratio

- HC

-

Hydrocarbons

- HC

-

Hydrocracking

- HEFA

-

Hydrotreatment process for obtaining bio-jet fuel and green diesel

- HI

-

Hydroisomerization

- M

-

Medium quality

- NIST

-

National Institute of Standards and Technology

- NMX

-

Official Mexican Norm

- PQ

-

Potential quality as product or feedstock

- TLC

-

Thin layer chromatography

- TG

-

Triglycerides

- SWW

-

Synthetic wastewater

Rights and permissions

About this article

Cite this article

Valdez-Ojeda, R.A., del Rayo Serrano-Vázquez, M.G., Toledano-Thompson, T. et al. Effect of Media Composition and Culture Time on the Lipid Profile of the Green Microalga Coelastrum sp. and Its Suitability for Biofuel Production. Bioenerg. Res. 14, 241–253 (2021). https://doi.org/10.1007/s12155-020-10160-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10160-5