Abstract

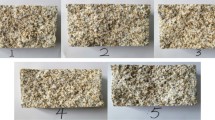

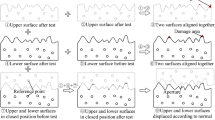

Rock-like materials and Barton’s standard joint curve were used to make filled joint specimens, and the shear characteristics of the filled joints were studied. Discrete element software was used to analyze the failure mechanism during filled joint shearing. Based on the experimental findings, a new theoretical model of joint shear strength was proposed. It was found that joint roughness has a great effect on filled joint shear failure, which is manifested via three different morphologies. The effects of the filler on the shear stress–strain curve are mainly a higher slope in the elastic phase and a lower slope in the plastic phase. The shear failure of the filled joint starts from local small damage of the filling and then progresses to failure of the bonding surface or the filling itself. Based on the proportion of the joint failure surface area to the joint surface area, a new formula for calculating shear strength is proposed.

Similar content being viewed by others

References

Fan, X.; Kulatilake, P.; Chen, X.: Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: a particle mechanics approach. Eng. Geol. 190, 17–32 (2015)

Halakatevakis, N.; Sofianos, A.I.: Correlation of the Hoek-Brown failure criterion for a sparsely jointed rock mass with an extended plane of weakness theory. Int. J. Rock Mech. Min. Sci. 47(7), 1166–1179 (2010)

Butron, C.; Axelsson, M.; Gustafson, G.: Silica sol for rock grouting: laboratory testing of strength, fracture behaviour and hydraulic conductivity. Tunn. Undergr. Space Technol. 24(6), 603–607 (2019)

Li, W.T.; Yang, N.; Mei, Y.C.; Zhang, Y.H.; Wang, L.; Ma, H.Y.: Experimental investigation of the compression-bending property of the casing joints in a concrete filled steel tubular supporting arch for tunnel engineering. Tunn. Undergr. Space Technol. 96, 1–17 (2020)

De Toledo, P.E.C.; Freitas, M.H.: Laboratory testing and parameters controlling the shear strength of filled rock joints. Geotechnique 43(1), 1–19 (1993)

Pereira, J.P.: Rolling friction and shear behavior of rock discontinuities filled with sand. Int. J. Rock Mech. Min. Sci. 34, 8–22 (1997)

Indraratna, B.; Welideniya, H.S.; Brown, E.T.: A shear strength model for idealized filled joints under constant normal stiffness. Geotechnique 55(3), 215–226 (2005)

Indraratna, B.; Premadasa, W.; Brown, E.T.: Shear behaviour of rock joints with unsaturated infill. Geotechnique 63(15), 1356–1360 (2013)

Barton, N.: Review of a new shear-strength criterion for rock joints. Eng. Geol. 7, 287–332 (1973)

Barton, N.; Choubey, V.: The shear strength of rock joints in theory and practice. Rock Mech. 10, 1–54 (1977)

Kulatilake, P.H.S.W.; Shou, G.; Huang, T.H.; Morgan, R.M.: New peak shear strength criterion for anisotropic rock joints. In: International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, vol. 32, no. 7, pp. 673–697 (1996)

Grasselli, G.: Shear strength of rock joints based on quantified surface description. Rock Mech. Rock Eng. 39(4), 295–314 (2006)

Xia, C.C.; Tang, Z.C.; Song, Y.L.; Liu, Y.M.: Analysis of relationship between joint peak shear displacement and its influence factor. Rock Soil Mech. 32, 1654–1658 (2011)

Tang, Z.C.; Liu, Q.S.; Liu, X.Y.: Shear behavior of rock joints and comparative study on shear strength criteria with three-dimensional morphology parameters. Chin. J. Geotech. Eng. 36(6), 873–879 (2014)

Tang, Z.C.; Xia, C.C.; Ding, Z.Z.: Analysis of shear deformation law for intermittent jointed rock mass. Rock Soil Mech. 32(8), 2353–2358 (2011)

Xu, D.P.; Feng, X.T.; Cui, Y.J.: A simple shear strength model for interlayer shear weakness zone. Eng. Geol. 147, 114–123 (2012)

Indraratna, B.; Premadasa, W.N.; Brown, E.T.; Gens, A.; Heitor, A.: Shear strength of rock joints influenced by compacted infill. Int. J. Rock Mech. Min. Sci. 70, 296–307 (2014)

Cao, P.; Deng, H.; Chen, Y.; Fu, N.: The shear characteristic and failure mechanism study of infilled rock joints with constant normal load. J. VibroEng. 21(4), 940–951 (2019)

Mirzaghorbanali, A.; Nemcik, J.; Aziz, N.: Effects of cyclic loading on the shear behavior of filled rock joints under constant normal stiffness conditions. Rock Mech. Rock Eng. 47(4), 1373–1391 (2014)

Jahanian, H.; Sadaghiani, M.H.: Experimental study on the shear strength of sandy clay filled regular rough rock joints. Rock Mech. Rock Eng. 48(3), 907–922 (2015)

Meng, F.; Zhou, H.; Wang, Z.; Zhang, L.; Kong, L.; Li, S.; Zhang, C.: Influences of shear history and infilling on the mechanical characteristics and acoustic emissions of joints. Rock Mech. Rock Eng. 50(8), 2039–2057 (2017)

Shrivastava, A.K.; Rao, K.S.: Physical modeling of shear behavior of infilled rock joints under CNL and CNS boundary conditions. Rock Mech. Rock Eng. 51(1), 101–118 (2018)

Cundall, P.A.: A Computer model for simulating progressive, large-scale movements in blocky rock systems. In: Proceedings of the International Symposium on Rock Mechanics, vol. 2, pp. 2–8 (1971)

Potyondy, D.O.; Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41, 1329–1364 (2004)

Ghazvinian, A.; Sarfarazi, V.; Schubert, W.; Blumel, M.: A study of the failure mechanism of planar non-persistent open joints using PFC2D. Rock Mech. Rock Eng. 45(5), 677–693 (2012)

Cheng, Y.; Yang, W.; He, D.: Influence of structural plane microscopic parameters on direct shear strength. Adv. Civ. Eng. (2018). https://doi.org/10.1155/2018/9178140

Bahaaddini, M.; Sharrock, G.; Hebblewhite, B.K.: Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 49, 206–225 (2013)

Xu, L.; Ren, Q.W.: Shear failure mechanism of infilling rock joints and its PFC simulation. Appl. Mech. Mater. 723, 317–321 (2015)

Zhou, Y.; Misra, A.; Wu, S.C.; Zhang, X.P.: Macro-and mechanics of rock joint direct shear test using particle flow theory. Chin. J. Geotech. Eng. 31, 1245–1256 (2012)

Xia, C.C.; Song, Y.L.; Tang, Z.C.; Song, Y.J.; Shou, C.: Particle flow numerical simulation for shear behavior of rough joints. Chin. J. Rock Mech. Eng. 31(6), 1545–1552 (2012)

Karakus, M.; Liu, Y.; Zhang, G.; Tang, H.: A new shear strength model incorporating influence of infill materials for rock joints. Geomech. Geophys. Geo-Energy Geo-Resour. 2(3), 183–193 (2016)

Xu, W.Z.; Lin, K.; Cao, R.H.: Simulation and macro-mesoscopic parameter analysis for direct shear of filled rough joints. J. Southwest Jiaotong Univ. 53(3), 548–557 (2018)

Xiao, W.G.; Dui, G.S.; Zhu, Y.P.; Chen, T.: Ren, Q: Study of constitutive model for single infilled jointed rock mass. Chin. J. Rock Mech. Eng. 29(2), 3463–3468 (2010)

Duriez, J.; Darve, F.; Donze, F.V.: A discrete modeling-based constitutive relation for filled rock joints. Int. J. Rock Mech. Min. Sci. 48(3), 458–468 (2011)

Chen, J.G.; Xu, P.; Zhang, Y.; Li, Y.B.: Experimental research on pre-peak constitutive relation of filled fracture with expansive medium. Rock Soil Mech. 32(10), 2998–3002 (2011)

Shi, L.; Cai, M.F.; Zhao, J.: Fracture mechanism and experiment of infilled rock joints. J. Univ. Sci. Technol. B 34(3), 253–259 (2012)

Sun, F.T.; She, C.X.; Wan, L.T.: A peak shear strength model for cement filled rock joint. Chin. J. Rock Mech. Eng. 12, 2481–2489 (2014)

Fan, W.C.; Cao, P.; Zhang, K.: Experimental study on failure modes of jointed rock materials under different compressive shear stress ratios. J. Cent. South Univ. 3, 926–932 (2015)

Zheng, W.X.; Zhao, Y.L.; Wang, M.: Experimental study on rock like material with crack under uniaxial compression. J. Hunan Univ. Sci. Technol. 28(4), 1–6 (2013)

Asheghi, R.; Hosseini, S.A.; Sanei, M.; Abbaszadeh Shahri, A.: Updating the neural network sediment load models using different sensitivity analysis methods: a regional application. J. Hydroinform. (2020). https://doi.org/10.2166/hydro.2020.098

Han, W.; Li, G.; Sun, Z.; Luan, H.; Liu, C.; Wu, X.: Numerical investigation of a foundation pit supported by a composite soil nailing structure. Symmetry 12(2), 252 (2020)

Shi, C.; Xu, W.Y.: Techniques and Practice of Numerical Simulation of Particle Flow. China Building Industry Press, Beijing (2015)

Cao, R.H.; Cao, P.; Lin, H.; Zhang, K.; Tan, X.W.: Particle flow analysis of direct shear tests on joints with different roughnesses. Rock Soil Mech. 34(2), 456–463 (2013)

Abbaszadeh Shahri, A.; Larsson, S.; Johansson, F.: Updated relations for the uniaxial compressive strength of marlstones based on P-wave velocity and point load index test. Innov. Infrastruct. Solut. 1, 17 (2016). https://doi.org/10.1007/s41062-016-0016-9

Yang, B.; Jiao, Y.; Lei, S.: A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng. Comput. 23(6), 607–631 (2006)

Ding, X.; Zhang, L.; Zhu, H.; Zhang, Q.: Effect of model scale and particle size distribution on PFC3D simulation results. Rock Mech. Rock Eng. 47(6), 2139–2156 (2014)

Zhang, G.; Karakus, M.; Tang, H.; Ge, Y.; Zhang, L.: A new method estimating the 2D joint roughness coefficient for discontinuity surfaces in rock masses. Int. J. Rock Mech. Min. Sci. 72, 191–198 (2014)

Wang, G.; Han, W.; Jiang, Y.; Luan, H.; Wang, K.: Coupling analysis for rock mass supported with CMC or CFC rockbolts based on viscoelastic method. Rock Mech. Rock Eng. 52(11), 4565–4588 (2019)

Wang, K.; Wang, G.; Jiang, Y.; Wang, S.; Han, W.; Chen, X.: How transport properties of a shale gas reservoir change during extraction: a strain-dependent triple-porosity model. J. Pet. Sci. Eng. 180, 1088–1100 (2019)

Wang, G.; Zhang, X.; Jiang, Y.; Wu, X.; Wang, S.: Rate-dependent mechanical behavior of rough rock joints. Int. J. Rock Mech. Min. Sci. 83, 231–240 (2016)

Han, W.; Jiang, Y.; Luan, H.; Du, Y.; Zhu, Y.; Liu, J.: Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput. Geotech. 125, 103670 (2020)

Wang, X.; Yuan, W.; Yan, Y.; Zhang, X.: Scale effect of mechanical properties of jointed rock mass: a numerical study based on particle flow code. Geomech. Eng. 21(3), 259–268 (2020)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Nos. 51479108 and 41672281) and the Taishan Scholar Talent Team Support Plan for Advantaged & Unique Discipline Areas, Shanghai Municipal Science and Technology Major Project (Grant No. 2017SHZDZX02).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, G., Wu, X., Zhang, X. et al. Macro–Microscopic Study on the Shear Characteristics of Filled Joints with Different Roughnesses. Arab J Sci Eng 45, 8331–8348 (2020). https://doi.org/10.1007/s13369-020-04705-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04705-1