Abstract

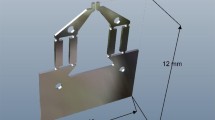

This paper presents the design, modeling, fabrication, and test of a monolithic compliant gripper for micro-manipulation applications. A compact compliant mechanism that enables in-principle straight-line parallel jaw motion is obtained, by combining the Scott–Russell mechanism and the parallelogram mechanism. The right-circular corner-filleted (RCCF) flexure hinge is adopted to achieve a large displacement of lumped-compliance joints. A pseudo-rigid-body model (PRBM) method with the help of the virtual work principle is performed to obtain parametric analytical models including the amplification coefficient and kinetostatics. Finite element analysis (FEA) is conducted to validate the analytical model and capture adverse parasitic motions of jaws. A monolithic prototype was fabricated, the test results of which show satisfactory performances.

Similar content being viewed by others

References

Howell LL. Compliant mechanisms. New York: Wiley; 2001.

Jain RK, Majumder S, Ghosh B, Saha S. Micro manipulation by a compliant piezoelectric micro gripper towards robotic micro assembly. Int J Mechatron Manuf Syst. 2016;9(1):3–23.

George BL, Bharanidaran R. Design of compliant gripper for surgical applications. Aust J Mech Eng. 2019;1–7.

Zubir MN, Mohd BS, Tian Y. Development of a novel flexure-based microgripper for high precision micro-object manipulation. Sens Actuators A. 2009;150(2):257–66.

Deaconescu T, Deaconescu A. Pneumatic muscle-actuated adjustable compliant gripper system for assembly operations. Strojniski Vestnik/J Mech Eng. 2017;63(4):225–34.

Jain RK, Majumder S, Ghosh B. Design and analysis of piezoelectric actuator for micro gripper. Int J Mech Mater Des. 2015;11(3):253–76.

Bhattacharya S, Chattaraj R, Das M, Patra A, Bepari B, Bhaumik S. Simultaneous parametric optimization of IPMC actuator for compliant gripper. Int J Precis Eng Manuf. 2015;16(11):2289–97.

Lofroth M, Avci E. Development of a novel modular compliant gripper for manipulation of micro objects. Micromachines. 2019;10(5):313.

Lamers AJ, Sánchez JAG, Herder JL. Design of a statically balanced fully compliant grasper. Mech Mach Theory. 2015;92:230–9.

Hao G, Hand RB. Design and static testing of a compact distributed-compliance gripper based on flexure motion. Arch Civ Mech Eng. 2016;16(4):708–16.

Carrozza MC, Menciassi A, Tiezzi G, Dario P. The development of a LIGA-microfabricated gripper for micromanipulation tasks. J Micromech Microeng. 1998;8(2):141.

Jain RK, Majumder S, Ghosh B, Saha S. Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper. J Manuf Syst. 2015;35:76–91.

Mehrabi H, Hamedi M, Aminzahed I. A novel design and fabrication of a micro-gripper for manipulation of micro-scale parts actuated by a bending piezoelectric. Microsyst Technol 2019;1–9.

Sun X, et al. A novel piezo-driven microgripper with a large jaw displacement. Microsyst Technol. 2015;21(4):931–42.

Wang DH, Yang Q, Dong HM. A monolithic compliant piezoelectric-driven microgripper: design, modeling, and testing. IEEE/ASME Trans Mechatron. 2011;18(1):138–47.

Zhang D, et al. Development of a monolithic compliant SPCA-driven micro-gripper. Mechatronics. 2015;25:37–433.

Hao G, Li H. Nonlinear analytical modeling and characteristic analysis of a class of compound multibeam parallelogram mechanisms. J Mech Robot. 2015;7(4):041016.

Beroz J, et al. Compliant microgripper with parallel straight-line jaw trajectory for nanostructure manipulation. In: Proceedings of 26th American Society of precision engineering annual meeting, Denver, USA. 2011.

Beroz J, Awtar S, John Hart A. Extensible-link kinematic model for characterizing and optimizing compliant mechanism motion. J Mech Des. 2014;136(3):031008.

Gopal V, Alphin MS, Bharanidaran R. Design of compliant mechanism microgripper utilizing the Hoekens straight line mechanism. J Test Eval. 2019;49(3):1.

Ai W, Xu Q. New structural design of a compliant gripper based on the Scott–Russell mechanism. Int J Adv Rob Syst. 2014;11(12):192.

Liao YG. Design and analysis of a modified Scott Russell straight-line mechanism for a robot end-effector. J Appl Sci Eng Technol. 2011;4:42–9.

Xu Q. Design and development of a novel compliant gripper with integrated position and grasping/interaction force sensing. IEEE Trans Autom Sci Eng. 2015;14(3):1415–28.

Nah SK, Zhong ZW. A microgripper using piezoelectric actuation for micro-object manipulation. Sens Actuators A. 2007;133(1):218–24.

Chen, G-M, Jia J-Y, Li Z-W. Right-circular corner-filleted flexure hinges. In: IEEE international conference on automation science and engineering, 2005. IEEE; 2005.

Edwards BT, Jensen BD, Howell LL. A pseudo-rigid-body model for initially-curved pinned-pinned segments used in compliant mechanisms. J Mech Des. 1999;123(3):464–8.

Joshi RS, Mitra AC, Kandharkar SR. Design and analysis of compliant micro-gripper using pseudo rigid body model (PRBM). Mater Today Proc. 2017;4(2):1701–7.

Sigmund O. On the design of compliant mechanisms using topology optimization. J Struct Mech. 1997;25(4):493–524.

Bruns TE, Tortorelli DA. Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng. 2001;190(26–27):3443–599.

Sun X, Chen W, Chen W, Qi S, Li W, Hu C, Tao J. Design and analysis of a large-range precision micromanipulator. Smart Mater Struct. 2019;28(11):115031.

Tian Y, Shirinzadeh B, Zhang D, Alici G. Development and dynamic modelling of a flexure-based Scott–Russell mechanism for nano-manipulation. Mech Syst Signal Process. 2009;23(3):957–78.

Sollpaur SB, Patil MS, Deshmukh SP. Evaluation of stiffness and parametric modelling of XY flexure mechanism for precision applications. J Model Simul Mater. 2018;1(1):8–15.

Hao G, Meng Q, Li Y. Design of large-range XY compliant parallel manipulators based on parasitic motion compensation. In: ASME 2013 international design engineering technical conferences and computers and information in engineering conference. American Society of Mechanical Engineers; 2013.

Hao G, Zhu J. Design of a monolithic double-slider based compliant gripper with large displacement and anti-buckling ability. Micromachines. 2019;10(10):665.

Acknowledgement

The authors would like to thank Mr. Tim Power and Mr. Michael O’Shea in the School of Engineering at University College Cork for their great help in the fabrication work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, J., Hao, G. Design and test of a compact compliant gripper using the Scott–Russell mechanism. Archiv.Civ.Mech.Eng 20, 81 (2020). https://doi.org/10.1007/s43452-020-00085-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00085-3