Abstract

In this study, we attempt to build a statistical (machine) learning model to predict the parabolic rate constant \((k_{\text{P}} )\) for the high-temperature oxidation of Ti alloys. Exploring the experimental studies on high-temperature oxidation of Ti alloys, we built our dataset for machine learning. Apart from the alloy composition, we included the constituent phase of the alloy, temperature of oxidation, time for oxidation, oxygen and moisture content, remaining atmosphere (gas except O2 gas in dry atmosphere), and mode of oxidation testing as the independent features while the parabolic rate constant \((k_{\text{P}} )\) is set as the target feature. We employed three different ML models to predict the ‘\(k_{\text{P}}\)’ for Ti alloys. Among the regression models, the gradient boosting regressor yields the coefficient of determination (R2) of 0.92 for \(k_{\text{P}}\). The knowledge gained from this study can be used to design novel Ti alloys with excellent resistance towards high-temperature oxidation.

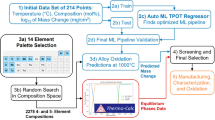

Graphic Abstract

Similar content being viewed by others

References

R. R. Boyer, Materials Science and Engineering A. 213, 1996 (103).

Y. Kosaka, K. Faller and S. P. Fox, JOM 56, 2004 (32).

F. H. Froes, C. Suryanarayana and D. Eliezer, Journal of Materials Science 27, 1992 (5113).

J. Stringer, Acta Metallurgica 8, 1960 (758).

P. Kofstad, Journal of the Less Common Metals 12, 1967 (449).

A. M. Chaze and C. Coddet, Journal of Materials Science 22, 1987 (1206).

T. Kitashima, L. J. Liu and H. Murakami, Journal of the Electrochemical Society 160, 2013 (C441).

R. W. Evans, R. J. Hull and B. Wilshire, Journal of Materials Processing and Technology 1996, (56), 1996 (492).

A. E. Jenkins, Journal of the Institute of Metals 82, 1954 (213).

A. E. Jenkins, Journal of the Institute of Metals 84, 1955 (1).

T. Kitashima, Y. Y. Mitarai, S. Iwasaki and S. Kuroda, Effects of Alloying Elements on the Tensile and Oxidation Properties of Alpha and Near-Alpha Ti Alloys. in Proceedings of the 13th World Conference Titanium, The Minerals, Metals and Materials Society, (2016), pp. 479–483.

T. Kitashima and T. Kawamura, Scripta Materialia 2016, (124), 2016 (56).

A. M. Chaze and C. Coddet, Oxidation of Metals 27, 1987 (1).

D. Vojtech, B. Bàrtová and T. Kubatík, Materials Science and Engineering A. 361, 2003 (50).

S. Matsunaga, S. Serizawa and Y. Y. Mitarai, Materials Transactions 57, 2016 (1902).

C. Leyens, in Titanium and Titanium Alloys, ed. C. Leyens and M. Peters, (Wiley-VCH GmbH & Co., Weinheim, 2003), p 187.

J. Dai, J. Zhu, C. Chen and F. Weng, Journal of Alloys and Compounds 685, 2016 (784).

J. Schneider and L. C. Ciacchi, Surface Science 604, 2010 (1105).

B. Ohler, S. Prada, G. Pacchioni and W. Langel, The Journal of Physical Chemistry C 117, 2013 (358).

H. H. Wu and D. R. Trinkle, Physical Review Letters 107, 2011 (045504).

H. H. Wu and D. R. Trinkle, Journal of Applied Physics 113, 2013 (223504).

J. Liu, X. Fan, C. Sun and W. Zhu, RSC Advances 6, 2016 (71311).

K. Maeda, S. Suzuki, K. Ueda, T. Kitashima, S. K. Bhattacharya, R. Sahara and T. Narushima, Journal of Alloys and Compounds 776, 2019 (519).

S. K. Bhattacharya, R. Sahara, T. Kitashima, K. Ueda and T. Narushima, Japanese Journal of Applied Physics 56, 2017 (125701).

S. K. Bhattacharya, R. Sahara, T. Kitashima, K. Ueda and T. Narushima, Science and Technology of Advanced Materials 18, 2017 (998).

S. K. Bhattacharya, R. Sahara, T. Kitashima, K. Ueda and T. Narushima, Applied Surface Science 463, 2019 (686).

D. Shin, S. Lee, A. Shyam and J. A. Hallens, Science and Technology of Advanced Materials 18, 2017 (828).

D. Xue, D. Xue, R. Yuan, Y. Zhou, P. V. Balachandran, X. Ding, J. Sun and T. Lookman, Acta Materialia 125, 2017 (532).

J. Schmidt, M. R. G. Marques, S. Botti and M. A. L. Marques, npj Computational Materials. 5, 2019 (83).

J. S. Chou, N. T. Ngo and W. K. Chong, Engineering Applications of Artificial Intelligence 65, 2017 (471).

D. Harris and S. Harris, Digital design and computer architecture (2nd ed.). San Francisco, Calif.: Morgan Kaufmann. p. 129. ISBN 978-0-12-394424-5. (2012-08-07).

J. H. Friedman, Annals of Statistics 29, 2001 (1189). https://doi.org/10.1214/aos/1013203451.

L. Mason, J. Baxter, P. Bartlett and M. Frean, Boosting algorithms as gradient descent. in Advances in Neural Information Processing Systems, eds. S. A. Solla, T. K. Leen and K. Müller (MIT Press, Cambridge, 1999), p. 512.

V. Cherkassky and Y. Ma, Neural Computing 15, 2003 (1691).

F. Pedregosa, G. Varoquaux, A. Gramfort, V. Michel, et al., Journal of Machine Learning Research 12, 2012 (2825).

Leave-one-out cross-validation. in eds. C. Sammut, G. I. Webb, Encyclopedia of Machine Learning. (Springer, Boston, 2011).

M. Stone, Journal of Royal Statistical Society: Series B (Methodological) 36, 1974 (111).

T. Kitashima and Y. Y. Mitarai, Metallurgical and Materials Transactions A. 46A, 2015 (2758).

R. Haul and G. Dümbgen, Journal of Physics and Chemistry of Solids 26, 1965 (1).

E. Iguchi and K. Yajima, Journal of the Physical Society of Japan 32, 1972 (1415).

K. Kusabiraki, T. Sugihara and T. Ooka, Tetsu-to-Hagane. 78, 1992 (327).

M. Dechamps and P. Lehr, Journal of the Less-Common Metals 56, 1977 (193).

L. Bataillou, C. Desgranges, L. Martinelli and D. Monceau, Corrosion Science. 136, 2018 (148).

K. Aniolek, M. Kupta and D. Grzegorz, Vaccum. 168, 2019 (108859).

Y. Song, B. Fu, T. Dong, T. Li, F. Wang, X. Zhao and J. Liu, Materials. 13, 2020 (1082).

Acknowledgements

SKB is thankful to Dr. Sayan Sarcar, Assistant Professor, Faculty of Library Information and Media Science, University of Tsukuba, Tsukuba, Japan for fruitful discussions. This work was supported by the Council for Science, Technology and Innovation under the Cross-ministerial Strategic Innovation Promotion Program. This study was also partially supported by the Japan Society for the Promotion of Science KAKENHI Grant (Number 18H01718), ISIJ Research Promotion Grant and NIMS-Tohoku cross appointment system.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhattacharya, S.K., Sahara, R. & Narushima, T. Predicting the Parabolic Rate Constants of High-Temperature Oxidation of Ti Alloys Using Machine Learning. Oxid Met 94, 205–218 (2020). https://doi.org/10.1007/s11085-020-09986-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09986-3