Abstract

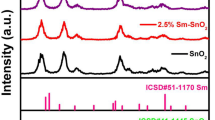

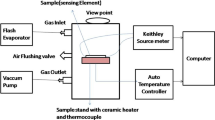

This work presents an approach for formaldehyde detection using Sn doped ZnO thin film. The concentration of Sn dopant varies at 0.5at%, 1.0at% and 1.5at%. XRD results show that the thin film possessed a crystallite structure with the highest peak at 002. The crystallite size of undoped, 0.5at%, 1.0at% and 1.5at% Sn doped ZnO thin film are 10.09 nm, 33.36 nm, 8.736 nm and 9.31 nm, respectively. Surface roughness obtained from AFM was 16.9 nm, 10.19 nm, 5.48 nm and 8.57 nm for undoped 0.5at%, 1.0at% and 1.5at% Sn doped ZnO thin film, respectively. The optimal sensitivity is acquired when 1.0at% Sn doped ZnO thin film is used for the detection of 3.4 ppb formaldehyde, where the sensing performance is 92%; while the sensing performance of undoped thin film is only 50%. The response time for undoped and 1.0at% Sn doped ZnO thin film is 10-8 s and 4-10 s, while the recovery time is 38-207 s and 15-34 s, respectively. The 1.0at% Sn doped ZnO thin film also demonstrates a good response in formaldehyde sensing, which was measured for nine consecutive days, where the sensing performance was over 90%.

Highlights

-

Sn doped ZnO thin film with various concentrations (0.5 at.%, 1.0 at.% and 1.5 at.%) on an interdigitated electrode (IDE) was prepared by using the sol gel method.

-

Sn doping increased the gas sensitivity due an excess of free electrons, whereby 1.0 at.% Sn doped was the best sensor for detecting formaldehyde, with a response of up to 92%.

-

A 1.0 at.% Sn doped ZnO thin film can maintain the sensitivity for over 65% for 9 consecutive days, compared with an undoped ZnO thin film.

Similar content being viewed by others

References

Golden R (2011) Identifying an indoor air exposure limit for formaldehyde considering both irritation and cancer hazards. Crit Rev Toxicol 41:672–721

Bagheri H, Ghambarian M, Salemi A, Es-Haghi A (2009) Trace determination of free formaldehyde in DTP and DT vaccines and diphtheria–tetanus antigen by single drop microextraction and gas chromatography–mass spectrometry. J Pharm Biomed Anal 50:287–292

Hopkins JR, Still T, Al-Haider S, Fisher IR, Lewis AC, Seakins PW (2003) A simplified apparatus for ambient formaldehyde detection via GC-pHID. Atmos Environ 37:2557–65

Wang YH, Chia YL, Che HL, Lung MF (2008) Enhanced sensing characteristics in MEMS-based formaldehyde gas sensors. Microsyst Technol 14:995–1000

Levin JO, Andersson K, Lindahl R, Nilsson CA (1985) Determination of sub-part-per-million levels of formaldehyde in air using active or passive sampling on 2,4-dinitrophenylhydrazine-coated glass fiber filters and high-performance liquid chromatography. Anal Chem 57:1032–35

Friedfeld S, Fraser M, Lancaster D, Leleux D, Rehle D, Tittel F (2000) Field intercomparison of a novel optical sensor for formaldehyde quantification. Geophys Res Lett 7:2093–96

Kim EK, Lee HY, Park J, Park SJ, Kwak JH, Moon SE, Maeng S, Park KH (2004) Fabrication and atmospheric-pressure-dependent electrical properties of a ZnO nanowire device. J Korean Phys Soc 51:170–173

Dilonardo E, Penza M, Alvisi M, Di Franco C, Palmisano F, Torsi L, Cioffi N (2016) Evaluation of gas-sensing properties of ZnO nanostructures electrochemically doped with Au nanophases. NBeilstein Journala Nnotechnology 7:22–31

Pisarkiewicz T, Sutor A, Potempa P, Maziarz W, Thust H, Thelemann T (2003) Microsensor based on low temperature cofired ceramics and gas sensitive thin film. Thin Solid Films 436:84–89

Rothschild A, Komem Y (2004) The effect of grain size on the sensitivity of nanocrystalline metal-oxide gas sensors. J Appl Phys 95:6374–6380

Németh Á, Horváth E, Lábadi Z, Fedák L, Bársony I (2007) Single step deposition of different morphology ZnO gas sensing films. Sens Actuators B Chem 127:157–160

Kim SD, Kim BJ, Yoon JH, Kim JS (2007) Design, fabrication and characterization of a low-power gas sensor with high sensitivity to CO gas. J Korean Phys Soc 51:2069–2076

Katoch A, Abideen ZU, Kim JH, Kim SS, Met (2016) Crystallinity dependent gas-sensing abilities of ZnO hollow fibers. Met Mater Int 22:942–946

Fine GF, Cavanagh LM, Afonja A, Binions R (2010) Metal oxide semi-conductor gas sensors in environmental monitoring. Sensors 10:5469–5502

Paudel TR, Lambrecht WRL (2006) Phys Rev B 203:1383–1389

Agarwal DC, Chauhan RS, Kumar A, Kabiraj D, Singh F, Khan SA, Avasthi DK, Ghatak P, Satyam PV (2006) Synthesis and characterization of ZnO thin film grown by electron beam evaporation. J Appl Phys 99:123105

Dave PY, Patel KH, Chauhan KV, Chawla AK, Rawal SK (2016) Examination of Zinc Oxide films prepared by magnetron sputtering. Procedia. Technology 23:328–335

Dedova T (2007) Chemical spray pyrolysis deposition of zinc sulfide thin films and zinc oxide nanostructured layers. PhD Thesis, Tallinn University of Technology Estonia

Lippert T, Schneider CW (2016) Thin film deposition of functional materials by pulsed laser deposition. https://www.azom.com/article.aspx?ArticleID=5986. Accessed 12 Oct 2018

Zahari FF (2012) Electron beam evaporation. https://missinglilo.files.wordpress.com/2012/04/een3106.pdf. Accessed Sept 2017

Nair S (2016) Magnetron sputtering. https://www.slideshare.net/SandeepNair41/sputtering-60950269. Accessed Sept 2017

Yung KC, Liem H, Choy HS (2009) Enhanced redshift of the optical band gap in Sn doped ZnO free stnding films using the sol-gel method. J Phys D Appl Phys 42:185002

Ajili M, Castagné M, Turki NK (2013) Study on the doping effect of Sn-doped ZnO thin films. Superlattices Microstruct 53:213–222

Jun LQ, Djaswadi GW, Hawari HF, Zakariya MA (2018) Simulation of interdigitated electrodes (IDEs) geometry using COMSOL multiphysics. International conference on intelligent and advanced system (ICIAS), Kuala Lumpur, pp. 1–6

Cauda V, Gazia R, Porro S, Stassi S, Canavese G, Roppolo I, Chiolerio A (2014) Nanostructured ZnO materials:synthesis properties and applications. Handb Nanomater Prop 5:137–177

Maia A, Ochoa M, Portugal A, Duraes L (2015) Nanocrystalline ZnO thin films-influence of sol-gel conditions on the underlying chemistry and film microstructure and transparency. Mater Today: Proc 2:49–56

Singh V, Hojamberdiev M, Kumar M (2020) Enhanced sensing performance of ZnO nanostructures-based gas sensors. A review. Energy Rep 6:46–62

Li Y, Gong J, He G, Deng Y (2012) Enhancement of photoresponse and UV-assisted gas sensing with Au decorated ZnO nanofibers. Mater Chem Phys 134:1172–1178

Prajapati CS, Kushwaha A, Sahay PP (2013) Optoelectronics and formaldehyde sensing properties of tin-doped ZnO thin films. Appl Phys A Mater Sci Process 113:651–662

Zhang P, Pan G, Zhang B, Zhen J, Sun Y (2014) High sensitivity ethanol gas sensor based on Sn-doped ZnO under visible light irradiation at low temperature. Mater Res 17:4

Shaban M, Zayed M, Ahmed MA, Hamdy H (2015) Influence of growth time on the morphology of ZnO nanostructures prepared by low-temperature chemical bath deposition. J Appl Phys 4:35–40

Arora N, Jagirdar BR (2014) Au5Sn + AuSn physical mixture to phase pure AuSn and Au5Sn intermetallic nanocrystals with tailored morphology: digestive ripening assisted approach. Phys Chem 16:11381

Prajapati CS, Kushwaha A, Sahay PP (2013) Influence of Fe doping on the structural, optical and acetone sensing properties of sprayed ZnO thin films. Mater Res Bull 48:2687–2695

Pramod NG, Pandey SN, Sahay PP (2013) Sn-doped In2O3 nanocrystalline thin films deposited by spray pyrolysis: microstructural, optical, electrical, and formaldehyde-sensing characteristics. J Therm Spray Technol 22:1035–1043

Bougrine A, Addou M, Kachouane A, Bérnède JC, Morsli M (2005) Effect of tin incorporation on physicochemical properties of ZnO films prepared by spray pyrolysis. Mater Chem Phys 91:247–252

Sahay PP, Nath RK (2008) Al-doped ZnO thin films as methanol sensors. Sens Actuators B Chem 134:654–659

Raoufi D, Raoufi T (2009) The effect of heat treatment on the physical properties of sol-gel derived ZnO thin films. Appl Surf Sci 255:5812–5817

Chou TP, Zhang Q, Fryxell GE, Cao GZ (2007) Hierarchically structured ZnO film for dye sensitized solar cells with enhanced energy conversion efficiency. Adv Mater 19:2588–2592

Bhati VS, Ranwa S, Fanetti M, Valant M, Kumar M (2018) Efficient hydrogen sensor based on Ni-doped ZnO nanostructures by RF sputtering. Sens Actuators B 255:588–597

Iqbal J, Jan T, Ronghai Y (2013) Effect of Co doping on morphology, optical and magnetic properties of ZnO 1-D nanostructures. J Mater Science:Material Electonnics 24:4393–4398

Dey A (2018) Semiconductor metal oxide gas sensors: A review. Mater Sci Eng b 229:206–217

Zhang L, Zhao J, Zheng J, Li L, Zhu Z (2011) Shuttle-like ZnO nano/microrods: Facile synthesis, optical characterization and high formaldehyde sensing properties. Appl Surf Sci 258:711–718

Chu X, Chen T, Zhang W, Zheng B, Shui H (2009) Investigation on formaldehyde gas sensor with ZnO thick film prepared through microwave heating method. Sens Actuators B Chem 142:49–54

Lv P, Tang ZA, Yu J, Zhang FT, Wei GF, Huang ZX, Hu Y (2008) Study on a micro-gas sensor with SnO2–NiO sensitive film for indoor formaldehyde detection. Sens Actuators B Chem 132:74–80

Wang J, Zhang P, Qi JQ, Yao P (2009) Silicon-based (2009) micro-gas sensors for detecting formaldehyde. J Sens Actuators B Chem 136:399–404

Zheng Y, Wang J, Yao P (2011) Formaldehyde sensing properties of electrospun NiO-doped SnO2 nanofibers. Sens Actuators B Chem 156:723–730

Tian S, Ding X, Zeng D, Wu J, Zhang XieC (2013) A low temperature gas sensor based on Pd-functionalized mesoporous SnO2 fibers for detecting trace formaldehyde. RSC Adv 3:11823

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ishak, S., Johari, S. & Ramli, M.M. Formaldehyde detection using Sn doped ZnO thin film. J Sol-Gel Sci Technol 95, 265–275 (2020). https://doi.org/10.1007/s10971-020-05318-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05318-8