Abstract

The hydraulic support column of comprehensive mining equipment is the most important part, subjecting to corrosion, wear and collision. The scrapped columns are restored by laser cladding to replace plating process for enhancing service life. All that is required after laser cladding is subtractive machining to improve the surface quality of the laser cladded coatings. This work focused on the remanufacturing machining strategy for re-contouring the laser cladding restored columns. First, surface roughness model of the laser cladded coatings by turn-burnishing was presented based on the surface generation mechanism. Then the effect of turning-induced roughness level on the surface roughness improvements by subsequent burnishing is addressed. Results indicated that the reduction of surface roughness by burnishing showed positive correlation with the feed in initial turning with conventional inserts, while was negatively correlated with the feed in initial turning with wiper inserts. In addition, the initial turning-induced surface roughness level generated great influence on the residual stress improvement in subsequent burnishing. Based on the findings, proper remanufacturing machining strategies for re-contouring the laser cladding-restored hydraulic support columns were presented.

Similar content being viewed by others

References

Chen C, Wang Y, Ou H, He Y, Tang X. A review on remanufacture of dies and moulds. J Clean Prod. 2014;64:13–23.

Morrow W, Qi H, Kim I, Mazumder J, Skerlos S. Environmental aspects of laser-based and conventional tool and die manufacturing. J Clean Prod. 2007;15:932–43.

Liu H, Wang C, Zhang X, Jiang Y, Cai C, Tang S. Improving the corrosion resistance and mechanical property of 45 steel surface by laser cladding with Ni60CuMoW alloy powder. Surf Coat Technol. 2013;228:S296–S300.

Xu P, Lin C, Zhou C, Yi X. Wear and corrosion resistance of laser cladding AISI 304 stainless steel/Al2O3 composite coatings. Surf Coat Technol. 2014;238:9–14.

Hemmati I, Ocelík V, De Hosson JTM. Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater Lett. 2012;84:69–72.

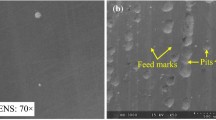

Zhang P, Liu Z, Guo Y. Machinability for dry turning of laser cladded parts with conventional vs. wiper insert. J Manuf Process. 2017;28:494–9.

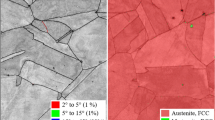

Zhang P, Liu Z, Su G, Du J, Zhang J. A study on corrosion behaviors of laser cladded Fe−Cr−Ni coating in as-cladded and machined conditions. Mater Corros. 2019;70:711–9.

Tekkaya AE, Kleiner M, Biermann D, Hiegemann L, Rausch S, Franzen V, Kwiatkowski L, Kersting P. Friction analysis of thermally sprayed coatings finished by ball burnishing and grinding. Prod Eng Res Devel. 2013;7:601–10.

Hiegemann L, Weddeling C, Khalifa NB, Tekkaya A. Prediction of roughness after ball burnishing of thermally coated surfaces. J Mater Process Technol. 2015;217:193–201.

Luca L, Neagu-Ventzel S, Marinescu I. Effects of working parameters on surface finish in ball-burnishing of hardened steels. Precision Eng. 2005;29:253–6.

Sova A, Courbon C, Valiorgue F, Rech J, Bertrand P. Effect of turning and ball burnishing on the microstructure and residual stress distribution in stainless steel cold spray deposits. J Therm Spray Technol. 2017;26:1–13.

Maiß O, Denkena B, Grove T. Hybrid machining of roller bearing inner rings by hard turning and deep rolling. J Mater Process Technol. 2016;230:211–6.

Zhang P, Liu Z. Enhancing surface integrity and corrosion resistance of laser cladded Cr–Ni alloys by hard turning and low plasticity burnishing. Appl Surf Sci. 2017;409:169–78.

Courbon C, Sova A, Valiorgue F, Pascal H, Sijobert J, Kermouche G, Bertrand P, Rech J. Near surface transformations of stainless steel cold spray and laser cladding deposits after turning and ball-burnishing. Surf Coat Technol. 2019;371:235–44.

Zhang P, Liu Z. Machinability investigations on turning of Cr–Ni-based stainless steel cladding formed by laser cladding process. Int J Adv Manuf Technol. 2016;82:1707–14.

Guddat J, M'saoubi R, Alm P, Meyer D, Hard turning of AISI 52100 using PCBN wiper geometry inserts and the resulting surface integrity. Proc Eng. 2011;19:118–24.

Grzesik W, Wanat T. Surface finish generated in hard turning of quenched alloy steel parts using conventional and wiper ceramic inserts. Int J Mach Tools Manuf. 2006;46:1988–95.

Davim JP, Figueira L. Comparative evaluation of conventional and wiper ceramic tools on cutting forces, surface roughness, and tool wear in hard turning AISI D2 steel. Proc Inst Mech Eng Part B. 2007;221:625–33.

Johnson KL, Johnson KL. Contact mechanics. Cambridge: Cambridge University Press; 1987.

Hiegemann L, Weddeling C, Tekkaya AE. Analytical contact pressure model for predicting roughness of ball burnished surfaces. J Mater Process Technol. 2016;232:63–77.

Berg G, Grau P. Meyer's hardness law and its relation to other measures of ball hardness tests. Cryst Res Technol. 1997;32:149–54.

Borkar A, Kamble P, Seemikeri C. Surface integrity enhancement of Inconel 718 by using roller burnishing process. Int J Curr Eng Technol. 2014;4:2595–8.

Gaitonde V, Karnik S, Figueira L, Davim JP. Machinability investigations in hard turning of AISI D2 cold work tool steel with conventional and wiper ceramic inserts. Int J Refract Metal Hard Mater. 2009;27:754–63.

Guo Y, Sahni J. A comparative study of hard turned and cylindrically ground white layers. Int J Mach Tools Manuf. 2004;44:135–45.

Funding

This work was supported by the National Natural Science Foundation of China [grant numbers 51425503, 51675289], Key Technology Research and Development Program of Shandong [grant number 2018GGX103023] and Open Research Fund of Shandong Provincial Key Laboratory of Mine Mechanical Engineering, Shandong University of Science and Technology [grant number 2019KLMM209].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest in this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, P., Du, J., Zhang, H. et al. Effect of turning-induced initial roughness level on surface roughness and residual stress improvements in subsequent burnishing. Archiv.Civ.Mech.Eng 20, 80 (2020). https://doi.org/10.1007/s43452-020-00083-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00083-5