Abstract

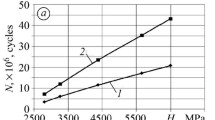

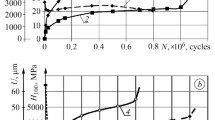

In this paper, we study the effect of various physical and mechanical properties, chemical and phase compositions of diffusion coatings of steels on the durability of tribosystems during rolling friction with point and linear contacts in an I-20 oil medium. Gradient coatings obtained by ion nitriding in anhydrous media and titanium and chromium nitride coatings, respectively, obtained by cathode-ion bombardment and galvanic deposition on steels with various levels of hardness after heat treatment were considered. The main factors affecting the contact endurance of coated steels and ways to increase the durability of tribosystems during rolling friction were identified in comparative tests using friction machines. A direct linear dependence of the durability of the coating-base composition on the hardness of the base for steels without metastable structures in the material and a deviation from this dependence toward increasing durability for steels with residual austenite in the structure of the material were established.

Similar content being viewed by others

REFERENCES

Johnson, K.L., Contact Mechanics, Cambridge: Cambridge Univ. Press, 1985.

Kaplun, P.V., Honchar, V.A., and Parshenko, A.V., UA Patent 106181, Byull. Izobret., 2016, no. 8.

Goryacheva, I.G. and Fel’dshtein, I.V., The influence of the internal system of defects on the stress state of elastic bodies, Izv. Ross. Akad. Nauk, Mekh. Tverd. Tela, 1996, no. 5, pp. 55–61.

Zinchenko, V.M., Inzheneriya poverkhnosti zubchatykh koles metodami khimiko-termicheskoi obrabotki (Engineering of Gear Surface by Chemical and Thermal Treatment), Moscow: Mosk. Gos. Tekh. Univ. im. N.E. Baumana, 2001.

Balits’kii, O.I., Kolesnikov, V.O., Eliash, Ya., and Gavrilyuk, M.R., Destruction of flooded high-nitrogen manganese steels in rolling friction conditions, Fiz.-Khim. Mekh. Mater., 2014, no. 4, pp. 110–117.

Kaplun, V.G. and Kaplun, P.V., Ionnoe azotirovanie v bezvodorodnykh sredakh: monografiya (Ion Nitriding in Anhydrous Media: Monograph), Khmelnytskyi: Kmel’nitsk. Nats. Univ., 2015.

Goryacheva, I.G. and Torskaya, E.V., Modeling the accumulation of contact fatigue damage in materials with residual stresses under rolling friction, J. Frict. Wear, 2019, vol. 40, no. 1, pp. 33–38.

Kaplun, P.V., Influence of hydrogen on the ion nitriding of steels, Mater. Sci., 2018, vol. 53, no. 6, pp. 818–822.

Kaplun, P.V. and Lyashenko, B.A., Effect of coatings on the fatigue characteristics of steels under contact load, Strength Mater., 2018, vol. 50, no. 2, pp. 288–294.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translation by A. Ivanov

About this article

Cite this article

Kaplun, V.G., Kaplun, P.V. & Gonchar, V.A. Durability of the “Coating–Base” Composition during Rolling Friction. J. Frict. Wear 41, 267–272 (2020). https://doi.org/10.3103/S1068366620030083

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366620030083