Abstract

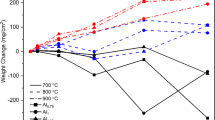

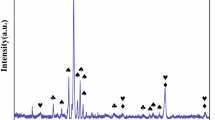

In this work, the influence of 0.5 at.% and 1 at.% Y additions on the high-temperature oxidation resistance of the equiatomic alloy NbMoCrTiAl at 1000 °C in air was investigated. Continuous isothermal and cyclic thermogravimetric experiments were conducted to characterize the oxidation kinetics of the alloys. Various analytical methods such as X-ray diffraction and electron microscopy with energy-dispersive X-ray spectroscopy were used to study the growth, morphology and composition of the oxide scales. It was found that the Y additions led to the formation of Al2Y phase along grain boundaries. The isothermal oxidation experiments of both Y-containing alloys showed lower oxidation rates after a short period of transient oxidation probably due to a reduction of fast-growing and voluminous Nb2O5 oxides within the oxide layer. During the steady-state period, however, oxidation of Al2Y caused local stresses resulting in crack formation and subsequent breakaway oxidation, i.e. pronounce increase in the oxidation rates. The cyclic oxidation experiments revealed lower oxidation rates and thinner, more adherent oxide scales formed on the alloy NbMoCrTiAl1Y compared to NbMoCrTiAl. The increased scale adherence was attributed to the formation of pegs due to the oxidation of Al2Y phase at the oxide/metal interface.

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, et al., Advanced Engineering Materials6, 2004 (299).

J. W. Yeh, Y. L. Chen, S. J. Lin and S. K. Chen, MSF560, 2007 (1).

O. N. Senkov, C. Woodward and D. B. Miracle, JOM Journal of the Minerals Metals and Materials Society66, 2014 (2030).

O. N. Senkov, S. V. Senkova, D. M. Dimiduk, C. Woodward and D. B. Miracle, Journal Materials Science47, 2012 (6522).

O. N. Senkov, D. B. Miracle, K. J. Chaput and J.-P. Couzinie, Journal of Materials Research33, 2018 (3092).

O. N. Senkov, G. B. Wilks, D. B. Miracle, C. P. Chuang and P. K. Liaw, Intermetallics18, 2010 (1758).

O. N. Senkov, G. B. Wilks, J. M. Scott and D. B. Miracle, Intermetallics19, 2011 (698).

O. Senkov, D. Isheim, D. Seidman and A. Pilchak, Entropy18, 2016 (102).

J. K. Jensen, B. A. Welk, R. E. A. Williams, et al., Scripta Materialia121, 2016 (1).

C. M. Liu, H. M. Wang, S. Q. Zhang, H. B. Tang and A. L. Zhang, Journal of Alloys and Compounds583, 2014 (162).

J. Zheng, X. Hou, X. Wang, Y. Meng, X. Zheng and L. Zheng, International Journal of Refractory Metals & Hard Materials54, 2016 (322).

D. J. Young, High Temperature Oxidation and Corrosion of Metals, (Elsevier, Burlington, 2008).

P. Kofstad, High Temperature Corrosion, (Elsevier Applied Science, London, 1988).

R. Bürgel, H. Jürgen Maier and T. Niendorf, Handbuch Hochtemperatur-Werkstofftechnik, (Vieweg + Teubner, Wiesbaden, 2011).

D. P. Whittle and J. Stringer, Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences295, 1980 (309).

P. Y. Hou, MSF696, 2011 (39).

D. Naumenko, B. A. Pint and W. J. Quadakkers, Oxidation of Metals86, 2016 (1–43).

Y. Wu, K. Hagihara and Y. Umakoshi, Intermetallics12, 2004 (519).

X. Gong, R. R. Chen, H. Z. Fang, et al., Corrosion Science131, 2018 (376).

L. L. Zhao, G. Y. Li, L. Q. Zhang, et al., Intermetallics18, 2010 (1586).

L. L. Xiang, L. L. Zhao, Y. L. Wang, L. Q. Zhang and J. P. Lin, Intermetallics27, 2012 (6).

B. Gorr, F. Mueller, H.-J. Christ, et al., Journal of Alloys and Compounds688, 2016 (468).

H. Chen, A. Kauffmann, B. Gorr, et al., Microstructure and mechanical properties at elevated temperatures of a new Al-containing refractory high-entropy alloy Nb-Mo-Cr-Ti-Al. Journal of Alloys and Compounds661, 2016 (206).

H. Chen, A. Kauffmann, S. Seils, et al., Acta Materialia176, 2019 (123).

F. Müller, B. Gorr, H.-J. Christ, et al., Corrosion Science159, 2019 (108161).

B. Gorr, F. Mueller, H.-J. Christ, et al., in TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings, Materials Society TM, ed. (Springer, Cham, 2018) p. 647.

B. Gorr, F. Müller, M. Azim, et al., Oxidation of Metals88, 2017 (339).

C. E. Lundin and D. T. Klodt, Journal of the Institute of Metals90, 1962 (341).

J. J. English, Defense Metals Information Center. Binary and Ternary Phase Diagrams of Columbium, Molybdenum, Tantalum, and Tungsten, (Battelle Memorial Institute, Columbus, Ohio, 1961).

K. Nishiyama, T. Abe, T. Sakaguchi and N. Momozawa, Journal of Alloys and Compounds355, 2003 (103).

K. S. Thomas and S. K. Varma, Corrosion Science99, 2015 (145).

S. K. Varma, C. Parga, K. Amato and J. Hernandez, Journal Materials Science45, 2010 (3931).

T. S. Ercit, Mineralogy and Petrology43, 1991 (217).

M. P. Arbuzov and V. G. Chupria, Soviet Physics Journal8, 1965 (87).

R. F. Cabral, M. H. Prado da Silva, J. B. de Campos and E. S. Lima, MSF727–728, 2012 (799).

K.-C. Lo, H. Murakami, J.-W. Yeh and A.-C. Yeh, Intermetallics119, 2020 (106711).

E. A. Gulbransen, K. F. Andrew and F. A. Brassart, Journal of the Electrochemical Society110, 1963 (952).

M. A. Azim, B. Gorr, H.-J. Christ, M. Heilmaier, U. Koch and M. Engelhard, Oxidation of Metals87, 2017 (89).

P. Kofstad, P. B. Anderson and O. J. Krudtaa, Journal of the Less Common Metals.3, 1961 (89).

P. Kofstad and H. Kjollesdal, Transaction Metallurgical Soc. AIME.221, 1961 (285).

G. A. Greene and C. C. Finfrock, Oxidation of Metals55, 2001 (505).

C. T. Liu, J. Ma and X. F. Sun, Journal of Alloys and Compounds491, 2010 (522).

Acknowledgements

The financial support by the Deutsche Forschungsgemeinschaft (DFG), Grant Nos. GO 2283/2-1, GO 2283/4-1, HE 1872/31-1 and HE 1872/34-1, is gratefully acknowledged. The part of this work was performed at the Micro- and Nanoanalytics Facility (MNaF) of the University of Siegen.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Müller, F., Gorr, B., Christ, HJ. et al. Effect of Y Additions on the Oxidation Behaviour of Novel Refractory High-Entropy Alloy NbMoCrTiAl at 1000 °C in Air. Oxid Met 94, 147–163 (2020). https://doi.org/10.1007/s11085-020-09983-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09983-6