Abstract

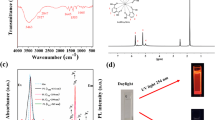

High transparency and toughness are prerequisites for sustainable polymers if they are to find wide application as alternatives to petroleum-based polymers. However, the utility of sustainable polymers such as commercially available polylactide (PLA) is limited by their inherent brittleness and high cost. Unfortunately, toughening PLA-based materials via cost-effective blending strategies without sacrificing transparency remains a challenge. Herein, we report a novel strategy involving active refractive index matching for creation of highly transparent and tough PLA blends. Specifically, we engineered the refractive index of a promising renewable poly(epichlorohydrin-co-ethylene oxide) elastomer by introducing polar ionic moieties via a simple chemical method, and we blended the resulting ionomers with PLA. The best blend showed an impact strength of > 80 kJ/m2, an elongation at break of 400%, and high transparency (90%). These characteristics are of great importance for potential applications such as packaging. Our strategy offers a versatile new way to prepare high-performance sustainable polymer materials with excellent transparency.

Similar content being viewed by others

References

Loste, J.; Lopez-Cuesta, J. M.; Billon, L.; Garay, H.; Save, M. Transparent polymer nanocomposites: an overview on their synthesis and advanced properties. Prog. Polym. Sci.2019, 89, 133–158.

Groh, K. J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P. A.; Lennquist, A.; Leslie, H. A.; Maffini, M.; Slunge, D.; Trasande, L.; Warhurst, A. M.; Muncke, J. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total. Environ.2019, 651, 3253–3268.

Wang, Q.; Geng, Y.; Lu, X.; Zhang, S. First-row transition metal-containing ionic liquids as highly active catalysts for the glycolysis of poly(ethylene terephthalate) (PET). ACS Sustain. Chem. Eng.2015, 3, 340–348.

Meng, B.; Deng, J.; Liu, Q.; Wu, Z.; Yang, W. Transparent and ductile poly(lactic acid)/poly(butyl acrylate) (PBA) blends: structure and properties. Eur. Polym. J.2012, 48, 127–135.

Gu, L.; Nessim, E. E.; Li, T.; Macosko, C. W. Toughening poly(lactic acid) with poly(ethylene oxide)-poly(propylene oxide)poly(ethylene oxide) triblock copolymers. Polymer2018, 166, 261–269.

Chen, Y.; Wang, W.; Yuan, D.; Xu, C.; Cao, L.; Liang, X. Bio-based PLA/NR-PMMA/NR ternary thermoplastic vulcanizates with balanced stiffness and toughness: “soft-hard” core-shell continuous rubber phase, in situ compatibilization, and properties. ACS Sustain. Chem. Eng.2018, 6, 6488–6496.

Chen, B. K.; Wu, T. Y.; Chang, Y. M.; Chen, A. F. Ductile polylactic acid prepared with ionic liquids. Chem. Eng. J.2013, 886–893.

Xu, H.; Xie, L.; Chen, J. B.; Jiang, X.; Hsiao, B. S.; Zhong, G. J.; Fu, Q.; Li, Z. M. Strong and tough micro/nanostructured poly(lactic acid) by mimicking the multifunctional hierarchy of shell. Mater. Horiz.2014, 1, 546–552.

Zhang, K.; Ran, X.; Wang, X.; Han, C.; Han, L.; Wen, X.; Zhuang, Y.; Dong, L. Improvement in toughness and crystallization of poly(L-lactic acid) by melt blending with poly(epichlorohydrin-co-ethylene oxide). Polym. Eng. Sci.2011, 51, 2370–2380.

Nagarajan, V.; Zhang, K.; Misra, M.; Mohanty, A. K. Overcoming the fundamental challenges in improving the impact strength and crystallinity of PLA biocomposites: influence of nucleating agent and mold temperature. ACS Appl. Mater. Interfaces2015, 7, 11203–14.

Colomines, G.; Lee, A. V. D.; Robin, J. J.; Boutevin, B. Study of the crystallinity of polyesters derived from the glycolysis of PET. Macromol. Chem. Phys.2006, 207, 1461–1473.

Zhang, W.; Gui, Z.; Lu, C.; Cheng, S.; Cai, D.; Gao, Y. Improving transparency of incompatible polymer blends by reactive compatibilization. Mater. Lett.2013, 92, 68–70.

Evora, V.; Shukla, A. Fabrication, characterization, and dynamic behavior of polyester/TiO2 nanocomposites. Mater. Sci. Eng. A2003, 361, 358–366.

Chen, Y.; Pan, M.; Li, Y.; Xu, J. Z.; Zhong, G. J.; Ji, X.; Yan, Z.; Li, Z. M. Core-shell nanoparticles toughened polylactide with excellent transparency and stiffness-toughness balance. Compos. Sci. Technol.2018, 164, 168–177.

Liu, T.; Xiang, F.; Qi, X.; Yang, W.; Huang, R.; Fu, Q. Optically transparent poly(methyl methacrylate) with largely enhanced mechanical and shape memory properties via in-sttu formation of polylactide stereocomplex in the matrix. Paymer2017, 126, 231–239.

Choochottiros, C.; Chin, I. J. Potential transparent PLA impact modifiers based on PMMA copolymers. Eur. Polym. J.2013, 49, 957–966.

Leibler, L. Nanostructured plastics: joys of self-assembling. Prog. Polym. Sci.2005, 30, 898–914.

Parlak, O.; Demir, M. M. Toward transparent nanocomposites based on polystyrene matrix and PMMA-grafted CeO2 nanoparticles. ACS Appl. Mater. Interfaces2011, 3, 4306–14.

Kim, P.; Li, C.; Riman, R. E.; Watkins, J. Refractive index tuning of hybrid materials for highly transmissive luminescent lanthanide particle-polymer composites. ACS Appl. Mater. Interfaces2018, 10, 9038–9047.

Novak, B. Hybrid nanocomposite materials between inorganic glasses and organic polymers. Adv. Mater.1993, 5, 422–433.

Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci.2004, 4, 835–64.

Ljungberg, N.; Wesslén, B. Preparation and properties of plasticized poly(lactic acid) films. Biomacromolecules2005, 6, 1789–1796.

Liu, B.; Jiang, L.; Liu, H.; Zhang, J. Synergetic effect of dual compatibilizers on in situ formed poly(lactic acid)/soy protein composites. Ind. Eng. Chem. Res.2010, 49, 6399–6406.

Lemmouchi, Y.; Murariu, M.; Santos, A. M. D.; Amass, A. J.; Schacht, E.; Dubois, P. Plasticization of poly(lactide) with blends of tributyl citrate and low molecular weight poly(D,L-lactide)-b-poly(ethylene glycol) copolymers. Eur. Polym. J.2009, 45, 2839–2848.

Ponkratov, D. O.; Lozinskaya, E. I.; Vlasov, P. S.; Aubert, P. H.; Plesse, C.; Vidal, F.; Vygodskii, Y. S.; Shaplov, A. S. Synthesis of novel families of conductive cationic poly(ionic liquid)s and their application in all-polymer flexible pseudo-supercapacitors. Electrochim. Acta2018, 281, 777–788.

Hayano, S.; Ota, K.; Ban, H. T. Syntheses, characterizations and functions of cationic polyethers with imidazolium-based ionic liquid moieties. Polym. Chem.2018, 9, 948–960.

Seki, S.; Tsuzuki, S.; Hayamizu, K.; Umebayashi, Y.; Serizawa, N.; Takei, K.; Miyashiro, H. Comprehensive refractive index property for room-temperature ionic liquids. J. Chem. Eng. Data.2012, 57, 2211–2216.

Shimizu, K.; Tariq, M.; Gomes, M. F. C.; Rebelo, L. P. N.; Lopes, J. N. C. Assessing the dispersive and electrostatic components of the cohesive energy of ionic liquids using molecular dynamics simulations and molar refraction data. J. Phys. Chem. B2010, 114, 5831–5834.

Hu, H.; Yuan, W.; Jia, Z.; Baker, G. L. Ionic liquid-based random copolymers: a new type of polymer electrolyte with low glass transition temperature. RSC Adv.2015, 5, 3135–3140.

Hu, H.; Yuan, W.; Lu, L.; Zhao, H.; Jia, Z.; Baker, G. L. Low glass transition temperature polymer electrolyte prepared from ionic liquid grafted polyethylene oxide. J. Polym. Sci., Part A: Polym. Chem.2014, 52, 2104–2110.

Cui, J.; Nie, F. M.; Yang, J. X.; Pan, L.; Ma, Z.; Li, Y. S. Novel imidazolium-based poly(ionic liquid)s with different counterions for self-healing. J. Mater. Chem.2017, 5, 25220–25229.

Cui, J.; Ma, Z.; Pan, L.; An, C. H.; Liu, J.; Zhou, Y. F.; Li, Y. S. Self-healable gradient copolymers. Mater. Chem. Front.2019, 3, 464–471.

Huang, D.; Ding, Y.; Jiang, H.; Sun, S.; Ma, Z.; Zhang, K.; Pan, L.; Li, Y. Functionalized elastomeric ionomers used as effective toughening agents for poly(lactic acid): enhancement in interfacial adhesion and mechanical performance. ACS Sustain. Chem. Eng.2019, 8, 573–585.

Chen, L.; Hu, K.; Sun, S. T.; Jiang, H.; Huang, D.; Zhang, K. Y.; Pan, L.; Li, Y. S. Toughening poly(lactic acid) with imidazolium-based elastomeric ionomers. Chinese J. Polym. Sci.2018, 36, 1342–1352.

Hayano, S.; Ohta, K.; Ban, H. T. Highly deliquescent cationic polyether with imidazolium halide group. Chem. Lett.2017, 46, 1033–1035.

Prattipati, V.; Hu, Y. S.; Bandi, S.; Mehta, S.; Schiraldi, D. A.; Hiltner, A.; Baer, E. Improving the transparency of stretched poly(ethylene terephthalate)/polyamide blends. J. Appl. Polym. Sci.2006, 99, 225–235.

Wang, R.; Wang, S.; Zhang, Y. Morphology, mechanical properties, and thermal stability of poly(L-lactic acid)/poly(butylene succinate-co-adipate)/silicon dioxide composites. J. Appl. Polym. Sci.2009, 113, 3630–3637.

Singh, A. K.; Prakash, R.; Pandey, D. Evidence for in situ graft copolymer formation and compatibilization of PC and PMMA during reactive extrusion processing in the presence of the novel organometallic transesterification catalyst tin(II) 2-ethylhexanoate. RSC Adv.2012, 2, 10316–10323.

Nie, F. M.; Cui, J.; Zhou, Y. F.; Pan, L.; Ma, Z.; Li, Y. S. Molecular-level tuning toward aggregation dynamics of self-healing materials. Macromolecules2019, 52, 5289–5297.

Zhang, K.; Nagarajan, V.; Misra, M.; Mohanty, A. K. Supertoughened renewable PLA reactive multiphase blends system: phase morphology and performance. ACS Appl. Mater. Interfaces2014, 6, 12436–12448.

Nagarajan, V.; Mohanty, A. K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: focus on toughness and heat resistance. ACS Sustain. Chem. Eng.2016, 4, 2899–2916.

Hu, K.; Huang, D.; Jiang, H.; Sun, S.; Ma, Z.; Zhang, K.; Pan, L.; Li, Y. Toughening biosourced poly(lactic acid) and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) blends by a renewable poly(epichlorohydrin-co-ethylene oxide) elastomer. ACS Omega2019, 4, 19777–19786.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51573130).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Sun, ST., Wang, H., Huang, D. et al. Refractive Index Engineering as a Novel Strategy toward Highly Transparent and Tough Sustainable Polymer Blends. Chin J Polym Sci 38, 1335–1344 (2020). https://doi.org/10.1007/s10118-020-2439-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2439-1