Abstract

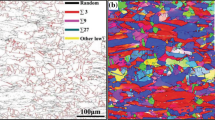

Thin-walled copper tubes are usually produced by multi-pass float-plug drawing deformation. In general, the annealing treatment subsequently is necessary to release the stored energy and adjusts the microstructure. In this study, an investigation on the evolution of annealing twins as well as textures in the thin-walled (Ф6 mm × 0.3 mm) copper tube underwent holding time-free heat treatment was reported. Electron backscattered diffraction analysis reveals that a large number of Σ3 boundaries (60° 〈111〉 twin relationship) are produced at the early stage of heat treatment, which is due to the lower boundary energy. With the recrystallization proceeding, the migration rate of grain boundaries decreases on account of the grain growth; meanwhile, the unique Σ9 boundaries (38.9° 〈110〉 relationship) are formed due to the interaction of the Σ3 boundaries. As a result, the number fractions of Σ3 boundaries and high-angle grain boundaries decrease rapidly. During the grain growth stage, a strong recrystallization texture was formed due to the fact that the grains of Goss orientation have a growth advantage over the others. As a result, the initial copper texture was transferred into the Goss texture in domination.

Similar content being viewed by others

References

H.C.H. Carpenter, S. Tamura, Proc. R. Soc. Lond. A 113, 28 (1926)

D. Field, L. Bradford, M. Nowell, T. Lillo, Acta Mater. 55, 4233 (2007)

T.H. Chuang, H.C. Wang, C.H. Tsai, C.C. Chang, C.H. Chuang, J.D. Lee, H.H. Tsai, Scr. Mater. 67, 605 (2012)

B. Lin, Y. Jin, C.M. Hefferan, S.F. Li, J. Lind, R.M. Suter, M. Bernacki, N. Bozzolo, A.D. Rollett, G.S. Rohrer, Acta Mater. 99, 63 (2015)

D.G. Brandon, Acta Mater. 14, 1479 (1966)

V. Randle, Acta Mater. 52, 4067 (2004)

V. Randle, Mater. Sci. Technol. 26, 774 (2010)

T. Watanabe, J. Mater. Sci. 46, 4095 (2011)

K. Lu, L. Lu, S. Suresh, Science 324, 349 (2009)

C.A. Stein, A. Cerrone, T. Ozturk, S. Lee, P. Kenesei, H. Tucker, R. Pokharel, J. Lind, C. Hefferan, R.M. Suter, A.R. Ingraffea, A.D. Rollett, Curr. Opin. Solid St. M. 18, 244 (2014)

E.A. Holm, S.M. Foiles, Science 328, 1138 (2010)

W.G. Burgers, C.G. Dunn, F. Lionetti, A.J. Shaler, L.D. Jaffe, Trans. AIMME 185, 860 (1949)

W.G. Burgers, J.C. Meijs, T.J. Tiedema, Acta Mater. 1, 75 (1953)

S. Dash, N. Brown, Acta Mater. 11, 1067 (1963)

H. Gleiter, Acta Mater. 17, 1421 (1969)

S. Mahajan, C.S. Pande, M.A. Imam, B.B. Rath, Acta Mater. 45, 2633 (1997)

C.S. Pande, M.A. Imam, B.B. Rath, Met. Trans. A 21, 2891 (1990)

R.L. Fullman, J.C. Fisher, J. Appl. Phys. 22, 1350 (1951)

P.J. Goodhew, Metal Sci. 13, 108 (1979)

M.A. Meyers, L.E. Murr, Acta Mater. 26, 951 (1978)

L.E. Murr, J. Appl. Phys. 39, 5557 (1968)

X.P. Chen, L.F. Li, H.F. Sun, L.X. Wang, Q. Liu, Mater. Sci. Eng., A 622, 108 (2015)

X.M. Chen, Y.C. Lin, F. Wu, J. Alloys Compd. 724, 198 (2017)

W. Wang, S. Lartigue-Korinek, F. Brisset, A.L. Helbert, J. Bourgon, T. Baudin, J. Mater. Sci. 50, 2167 (2014)

E. Niloofar, Z.H. Abbas, S. Amirali, A.L. Helbert, B. Thierry, Adv. Eng. Mater. 20, 1700928 (2018)

S. Suwas, R.K. Ray, Crystallographic Texture of Materials, 1st edn. (Brian Derby, Manchester, 2014)

C.F. Gu, L.S. Toth, Y.D. Zhang, M. Hoffman, Scr. Mater. 51, 92 (2014)

J.J. Sidor, L.A.I. Kestens, Scr. Mater. 273, 68 (2013)

Z.N. Mao, R.C. Gu, F. Liu, Y. Liu, X.Z. Liao, J.T. Wang, Mater. Sci. Eng., A 186, 674 (2016)

G. Anand, K. Barai, R. Madhavan, P.P. Chattopadhyay, Mater. Sci. Eng., A 114, 638 (2015)

L.F. Shuai, T.L. Huang, G.L. Wu, X. Huang, O.V. Mishin, J. Alloys Compd. 399, 749 (2018)

J.H. Choi, S.Y. Kang, D.N. Lee, J. Mater. Sci. 4055, 35 (2000)

T. Baudin, A.L. Etter, R. Penelle, Mater. Charact. 947, 58 (2007)

N.A. Hamdany, H.G. Brokmeier, M. Salih, Z.Y. Zhong, B. Schwebke, N. Schell, W. Gan, Mater. Charact. 125, 139 (2018)

S.W. Wang, S.H. Zhang, H.W. Song, Y. Chen, Chin. J. Nonferrous Met. 4, 782 (2019)

S.W. Wang, Y. Chen, H.W. Song, A.A. El-Aty, J.S. Liu, S.H. Zhang, Int. J. Mater. Form. (2020). https://doi.org/10.1007/s12289-020-01538-z

K.H. Song, Y.B. Chun, S.K. Hwang, Mater. Sci. Eng., A 454, 629 (2007)

K.K. Alaneme, E.A. Okotete, J. Sci.: Adv. Mater. Devices 4, 19 (2019)

Q.Y. He, T.L. Huang, L.F. Shuai, Y.B. Zhang, G.L. Zhang, X.X. Huang, D.J. Jensen, Scr. Mater. 153, 68 (2018)

G.L. Wu, D.J. Jensen, Acta Mater. 55, 4955 (2007)

T.J. Sabin, G. Winther, D.J. Jensen, Acta Mater. 51, 3999 (2003)

S. Mahajan, Scr. Mater. 68, 95 (2013)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena, 2nd edn. (Pergamon, New York, 2004)

W.X. Chen, C. Jia, B.J. Hu, C.W. Zheng, D.Z. Li, Mater. Sci. Eng., A 733, 419 (2018)

W.L. Grube, S.R. Rouze, Can. Metall. Quart. 2, 31 (1963)

L.C. Lim, R. Raj, Acta Mater. 32, 1177 (1984)

H. Beladi, P. Cizek, P.D. Hodgson, Metall. Mater. Trans. A 40, 1175 (2009)

H. Kim, C. Kang, M. Huh, O. Engler, Scr. Mater. 57, 325 (2007)

P.R. Rios, G. Gottstein, L.S. Shvindlerman, Mater. Sci. Eng., A 332, 231 (2002)

H. Tian, H.L. Suo, O.V. Mishin, Y.B. Zhang, D.J. Jensen, J.C. Grivel, J. Mater. Sci. 48, 4183 (2013)

Acknowledgements

This work was financially supported by the Natural Science Foundation of Shandong Province under Grant No. ZR2018MEE005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wang, SW., Song, HW., Chen, Y. et al. Evolution of Annealing Twins and Recrystallization Texture in Thin-Walled Copper Tube During Heat Treatment. Acta Metall. Sin. (Engl. Lett.) 33, 1618–1626 (2020). https://doi.org/10.1007/s40195-020-01090-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01090-4