Abstract

In an elastohydrodynamic lubricated (EHL) contact under Zero Entrainment Velocity (ZEV) condition, surfaces cannot be separated by hydrodynamic lift. In this work, two other phenomena responsible for a film thickness build-up in ZEV contacts are studied using a numerical model. First, the thermal effect called “viscosity wedge” is investigated in steady-state conditions. Second, the “squeeze” effect is described in an environment where dynamic (time dependent) loads are considered. Then, both the viscosity wedge and squeeze effects are considered together. For each one of the two mechanisms, a characteristic time is considered. The ratio of these two times allows the identification of a dominant effect. Depending on this ratio, a prediction is attempted using semi-analytical models describing each effect. For an ideal set of parameters, it is shown that the combination of squeeze and viscosity wedge in EHL contact under ZEV allows for an enhanced performance.

Similar content being viewed by others

Abbreviations

- A :

-

Steady-state thermal conditions

- B :

-

Transient isothermal conditions

- C :

-

Transient thermal conditions

- *:

-

Semi-analytical formula

- 1,2:

-

Solids 1 and 2, respectively

- c :

-

Central—film thickness

- f :

-

Fluid

- m :

-

Minimum—film thickness

- min:

-

Minimum—overtime

- a (m):

-

Dry contact radius(Hertz)

- \({a}_{v}\) (K−1):

-

Parameter for the Murnaghan density formula

- \({a}_{\mathrm{C}\mathrm{Y}}\) (−):

-

Parameter for the Carreau–Yasuda non-Newtonian viscosity formula

- \({A}_{1}\) (K):

-

Coefficient for the WLF viscosity correlation

- \({A}_{2}\) (Pa−1):

-

Coefficient for the WLF viscosity correlation

- \({B}_{1}\) (Pa−1):

-

Coefficient for the WLF viscosity correlation

- \({B}_{2}\) (−):

-

Coefficient for the WLF viscosity correlation

- \({C}_{1}\) (−):

-

Coefficient for the WLF viscosity correlation

- \({C}_{2}\) (−):

-

Coefficient for the WLF viscosity correlation

- \({C}_{p}\) (J k g−1 K−1):

-

Heat capacity

- \(E\) (Pa):

-

Young modulus

- \({E}^{^{\prime}}\) (Pa):

-

Material parameter

- F (−):

-

Variable for the WLF viscosity correlation

- \({G}_{\mathrm{C}\mathrm{Y}}\) (Pa):

-

Parameter for the Carreau–Yasuda non-Newtonian viscosity formula

- h (m):

-

Film thickness

- h0 (m):

-

Rigid body separation

- \({h}_{c}^{{\mathrm{W}\mathrm{a}\mathrm{n}\mathrm{g}}^{*}}\) (m):

-

Transient semi-analytical formula for the prediction of \({h}_{c}\)

- \({h}_{m}^{A*}\) (m):

-

Steady-state semi-analytical formula for the prediction of \({h}_{m}\)

- k (W m−1 K−1):

-

Thermal conductivity

- \({K}_{00}\) (−):

-

Parameter for the Murnaghan density formula

- \({K}_{M}\) (−):

-

Parameter for the Murnaghan density formula

- \({K}_{M}^{^{\prime}}\) (−):

-

Parameter for the Murnaghan density formula

- L (−):

-

Dimensionless Moes parameter

- M (−):

-

Dimensionless Moes parameter

- \({n}_{\mathrm{C}\mathrm{Y}}\) (−):

-

Parameter for the Carreau–Yasuda non-Newtonian viscosity formula

- p (Pa):

-

Pressure

- ph (Pa):

-

Hertz contact pressure

- Q (W m−3):

-

Total heat source

- R (m):

-

Radius of curvature

- Req (m):

-

Equivalent radius of curvature

- t (s):

-

Time

- \({t}_{\mathrm{F}\mathrm{i}\mathrm{n}\mathrm{a}\mathrm{l}}\) (s):

-

Time at the end of calculation

- \({t}_{\mathrm{L}\mathrm{o}\mathrm{a}\mathrm{d}\mathrm{i}\mathrm{n}\mathrm{g}}\) (s):

-

Time at which the reference load is reached, the loading time

- \({t}_{T}\) (s):

-

Characteristic thermal time

- \(\overline{t}\) (−):

-

Dimensionless time

- \(\overline{{t_{{C|m,\,{\text{min}}}} }}\) (−):

-

Dimensionless instant at which the minimum value of the minimum film thickness is observed in transient thermal conditions

- \(\overline{t} _{T}\) (−):

-

Characteristic thermal–transient ratio

- T (K):

-

Temperature

- \({T}_{0}\) (K):

-

External temperature

- \({T}_{g}\) (K):

-

Glass transition temperature

- \({T}_{g0}\) (K):

-

Glass transition temperature at ambient pressure

- \({T}_{R}\) (K):

-

Reference temperature

- u (m s−1):

-

Surface velocity

- \({U}_{DH}\) (−):

-

Dimensionless velocity parameter

- w (N m−1):

-

Load per unit length

- \({w}_{i}\) (N m−1):

-

Initial load per unit length

- \({w}_{\mathrm{r}\mathrm{e}\mathrm{f}}\) (N m−1):

-

Reference load per unit length

- \(x, y, z\) (m):

-

Coordinates

- \({\alpha }^{*}\) (Pa−1):

-

Reciprocal asymptotic isoviscous pressure–viscosity coefficient

- \({\beta }_{k}\) (K−1):

-

Temperature–density parameter

- \(\delta\) (m):

-

Equivalent elastic surface displacement of both solids

- \(\eta\) (m):

-

Dynamic viscosity

- \({\eta }_{e}\) (k g s−1 m−2):

-

Generalised viscosity parameter

- \({\eta }_{e}^{^{\prime}}\) (k g s−1 m−3):

-

Generalised viscosity parameter

- \({\lambda }^{{Wang}^{*}}\) (−):

-

Parameter for the transient central film thickness prediction formula

- \({\mu }_{g}\) (Pa s):

-

Viscosity at glass transition

- v (−):

-

Poisson coefficient

- \(\rho\) (k g m−3):

-

Density

- \({\rho }_{e}\) (k g m−3):

-

Generalised density parameter

- \({\rho }_{e}^{^{\prime}}\) (k g s):

-

Generalised density parameter

- \(\rho _{{e^{\prime\prime}}}\) (k g m s):

-

Generalised density parameter

- \({\rho }_{R}\) (k g m−3):

-

Reference density

- \({\rho }^{*}\) (k g m−3):

-

Generalised density parameter

- \({\left(\frac{\rho }{\eta }\right)}_{e}\) (m s):

-

Generalised density/viscosity ratio

- \({\tau }_{\mathrm{z}x}\) (Pa):

-

Shear stress along the x-axis

- \({\tau }_{\mathrm{e}}\) (Pa):

-

Shear stress norm

References

Ertel, A.M.: In Russian (hydrodynamic lubrication based on new principles). Nauk SSSR Prikadnaya Math. I Mekhanika 3(2), 41–52 (1939)

Grubin, A.N., Vinogradova, I.E.: In Russian (Investigation of the contact of machine components). Cent. Sci. Res. Inst. Technol. Mech. Eng. 30, 1–2 (1949)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts-I-theorectical formulation. J. Lubr. Tech. 98(2), 223–228 (1976)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts-III-fully flooded results. J. Lubr. Tech. 99(2), 264–275 (1977)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts-IV-starvation results. J. Lubr. Tech. 99(1), 15–23 (1977)

Moes, H.: Optimum similarity analysis with applications to elastohydrodynamic lubrication. Wear 159(1), 57–66 (1992)

Chittenden, R.J., Dowson, D., Dunn, J.F., Taylor, C.M.: A theoretical analysis of the isothermal elastohydrodynamic lubrication of concentrated contacts I: direction of lubricant entrainment coincident with the major axis of the hertzian contact ellipse. Proc. R. Soc. A 397(1813), 245–269 (1985)

Evans, H.P.: The isothermal elastohydrodynamic lubrication of spheres. J. Tribol. 103(4), 547 (1980)

Venner, C.H.: Multilevel solution of the EHL line and point contact problems. [Ph.D. Thesis] Enschede. University of Twente, (1991)

Bruyere, V., Fillot, N., Morales-Espejel, G.E., Vergne, P.: Computational fluid dynamics and full elasticity model for sliding line thermal elastohydro dynamic contacts. Tribol. Int. 46(1), 3–13 (2012)

Raisin, J., Fillot, N., Dureisseix, D., Vergne, P., Lacour, V.: Characteristic times in transient thermal elastohydrodynamic line contacts”. Tribol. Int. 82, 472–483 (2015)

Cameron, A.: The viscosity wedge. ASLE Trans. 1(2), 248–253 (1958)

Jones, W.R.J., Shogrin, B.A., Kingsbury, E.P.: Long term performance of a retainerless bearing cartridge with an oozing flow lubricator for spacecraft applications. NASA TM-107492. (1997)

Shogrin, B.A., Jones, W.R., Kingsbury, E.P.P., Jansen, M.J., Prahl, J.M.: Experimental study of load carrying capacity of point contacts at zero entrainment velocity. NASA TM-208650. (1998)

Shogrin, B.A., Jones, W.R., Kingsbury, E.P., Prahl, J.M.: Experimental determination of load carrying capacity of point contacts at zero entrainment velocity. NASA TM-208848. (1999)

Thompson, P.: The effect of sliding speed on film thickness and pressure supporting ability of a point contact under zero entrainment velocity conditions. NASA TM-210566, (2000)

Guo, F., Wong, P.L., Yang, P., Yagi, K.: Film formation in EHL point contacts under zero entraining velocity conditions. Tribol. Trans. 45(4), 521–530 (2002)

Zhang, B., Wang, J.: Enhancement of thermal effect in zero entrainment velocity contact under low surface velocity. Proc. Inst. Mech. Eng. Part J 230(12), 1554–1561 (2016)

Zhang, B., Wang, J., Omasta, M., Kaneta, M.: Variation of surface dimple in point contact thermal EHL under ZEV condition. Tribol. Int. 94, 383–394 (2016)

Guo, F., Yang, P., Wong, P.L.: On the thermal elastohydrodynamic lubrication in opposite sliding circular contacts. Tribol. Int. 34(7), 443–452 (2001)

Yagi, K., Kyogoku, K., Nakahara, T.: Relationship between temperature distribution in EHL film and dimple formation. J. Tribol. 127(3), 658 (2005)

Zhang, B., Wang, J., Omasta, M., Kaneta, M.: Effect of fluid rheology on the thermal EHL under ZEV in line contact. Tribol. Int. 87, 40–49 (2015)

Meziane, B., Vergne, P., Devaux, N., Lafarge, L., Morales-Espejel, G.E., Fillot, N.: Film thickness build-up in zero entrainment velocity wide point contacts. Tribol. Int. 141, 105897 (2020)

Dowson, D., Jones, D.A.: Lubricant entrapment between approaching elastic solids. Nature 214(5091), 947–948 (1967)

Safa, M.M., Gohar, R.: Squeeze films in elastohydrodynamic lubrication. Leeds–Lyon Symposium on Tribology. 10, 227–233 (1985).

Larsson, R., Höglund, E.: Elastohydrodynamic lubrication at pure squeeze motion. Wear 179(1–2), 39–43 (1994)

Dowson, D., Wang, D.: Impact elastohydrodynamics. Tribol. Ser. 30, 565–582 (1995)

Wang, J., Venner, C.H., Lubrecht, A.A.: Central film thickness prediction for line contacts under pure impact. Tribol. Int. 66, 203–207 (2013)

Venner, C.H., Wang, J., Lubrecht, A.A.: Central film thickness in EHL point contacts under pure impact revisited. Tribol. Int. 100, 1–6 (2016)

Wong, P.L., Li, X.M., Guo, F.: Evidence of lubricant slip on steel surface in EHL contact. Tribol. Int. 61, 116–119 (2013)

Li, X.M., Guo, F., Wong, P.L.: Shear rate and pressure effects on boundary slippage in highly stressed contacts. Tribol. Int. 59, 147–153 (2013)

Wheeler, J.-D., Fillot, N., Vergne, P., Philippon, D., Morales Espejel, G.: On the crucial role of ellipticity on elastohydrodynamic film thickness and friction. Proc. Inst. Mech. Eng. Part J. 230(12), 1503–1515 (2016)

Habchi, W.: A full-System Finite Element Approach to Elastohydrodynamic Lubrication Problems: Application to Ultra-low-viscosity Fluids. Lyon, Institut National des Sciences Appliquées de Lyon (2008)

Hertz, H.: Ueber die Berührung fester elastischer Körper. J. für die reine und Angew. Math. (Crelle’s J.) 1882(92), 156–171 (1882)

Murnaghan, F.D.: The compressibility of media under extreme pressures. Proc. Natl. Acad. Sci. 30(9), 244–247 (1944)

Bair, S., Mary, C., Bouscharain, N., Vergne, P.: An improved Yasutomi correlation for viscosity at high pressure. Proc. Inst. Mech. Eng. Part J. 227(9), 1056–1060 (2013)

Bair, S.: A rough shear-thinning correction for EHD film thickness. Tribol. Trans. 47(3), 361–365 (2004)

Dowson, D.: A generalized Reynolds equation for fluid-film lubrication. Int. J. Mech. Sci. 4(2), 159–170 (1962)

Wheeler, J.-D., Molimard, J., Devaux, N., Philippon, D., Fillot, N., Vergne, P., Morales-Espejel, G.E.: A generalized differential colorimetric interferometry method: extension to the film thickness measurement of any point contact geometry. Tribol. Trans. 61(4), 648–660 (2018)

Doki-Thonon, T., Fillot, N., Vergne, P., Morales Espejel, G.E.: Numerical insight into heat transfer and power losses in spinning EHD non-Newtonian point contacts. Proc. Inst. Mech. Eng. Part J 226(1), 23–35 (2012)

Ndiaye, S.-N., Martinie, L., Philippon, D., Devaux, N., Vergne, P.: A quantitative friction-based approach of the limiting shear stress pressure and temperature dependence. Tribol. Lett. 65(4), 149 (2017)

Kaneta, M., Nishikawa, H., Mizui, M., Guo, F.: Impact Elastohydrodynamics in Point Contacts. Proc. Inst. Mech. Eng. Part J. 225(1), 1–12 (2011)

Kaneta, M., Wang, J., Guo, F., Krupka, I., Hartl, M.: Effects of loading process and contact shape on point impact elastohydrodynamics. Tribol. Trans. 55(6), 772–781 (2012)

Reynolds, O.: IV. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil. Philos. Trans. R. Soc. Lond. 177, 157–234 (1886)

Bair, S.: Correlations for the Temperature and Pressure and Composition Dependence of Low-Shear Viscosity. In High Pressure Rheology for Quantitative Elastohydrodynamics, Elsevier, 135–182 (2019)

Vichard, J.P.: Transient effects in the lubrication of hertzian contacts. J. Mech. Eng. Sci. 13(3), 173–189 (1971)

Acknowledgements

This work was funded by the “Lubricated Interfaces for the Future” research chair established by INSA Lyon and the SKF company. The authors want to thank the rich discussions with Dr. Jonas Stahl from SKF PS&E during the preparation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Semi-analytical Formula for the Prediction of the Minimum Film Thickness in Steady-State ZEV Contacts

Appendix: Semi-analytical Formula for the Prediction of the Minimum Film Thickness in Steady-State ZEV Contacts

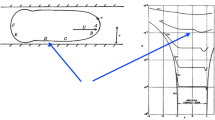

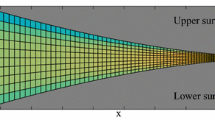

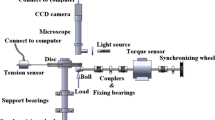

As described in Eqs. 19 and 20, a semi-analytical model was employed to attempt a prediction of the minimum film thickness under steady-state ZEV condition. The given formula was established using the experimental and numerical data measured in [23]. The corresponding study focused on the minimum film thickness in contacts between a sapphire disk and a steel barrel under ZEV condition. With \(293.15 \mathrm{K}\) boundary temperature, the relative difference between the model and the experimental results stays below \(16\%\). This study showed that in the present range of conditions, steel on steel contacts are similar to sapphire on steel ones and their respective minimum film thicknesses are close enough. Complementary calculations were conducted at lower loads in order to expand the range of the study. For material data on the lubricant and steel, refer to Tables 1 and 2, respectively. The material data for sapphire are listed in Table 10. The remaining input conditions are listed in Table 11.

Using these values, a curve-fit was established using the method of least squares, as given in Eqs. 28 and 29. This model is confronted to the numerical and experimental results in Fig.

12. The coefficient of determination for the experimental dataset is \(0.96\); for the numerical dataset, it is \(0.98\).

where \(w\) is expressed in \(\mathrm{N}\,{\mathrm{m}}^{-1},\)\({h}^{*}=69.8\, \mathrm{n}\mathrm{m},\)\({u}_{0}=2.74\, \mathrm{m} {\mathrm{s}}^{-1},\)\({w}_{0}=14695\, \mathrm{N} {\mathrm{m}}^{-1}\).

The factor \({\left(\frac{{R}_{\mathrm{e}\mathrm{q}}}{{R}^{*}}\right)}^{-0.42}\) found in Eq. 19 was determined by the method of least squares, using the simulation results of Case A and the partial model given in Eqs. 28 and 29. Because the exponent \(-0.42\) was determined with only two radii, and because these radius values are so close (\(0.01\,\mathrm{m}\) and \(0.0128\,\mathrm{m}\)), extreme precaution should be taken when using the formula in Eq. 19 if one would apply it to very different radius values.

Rights and permissions

About this article

Cite this article

Meziane, B., Fillot, N. & Morales-Espejel, G.E. Synergy of Viscosity Wedge and Squeeze Under Zero Entrainment Velocity in EHL Contacts. Tribol Lett 68, 74 (2020). https://doi.org/10.1007/s11249-020-01311-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-01311-y