Abstract

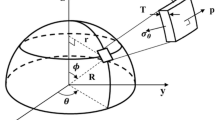

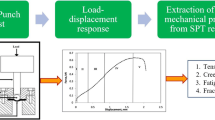

Small punch creep (SPC) test has an important role in the remaining life calculation of in-service components functioning at high temperature and harsh ambience. Since the extraction of conventional full scale specimens from the components in service impairs its integrity, SPC test can be used as an alternative technique. This test method requires very thin disc similar to those needed for transmission electron microscopy (~ 3 mm diameter and 0.5 mm thick). The pre-requisite to employ this test technique is to establish correlations between uniaxial creep and SPC tests in priori. The purpose and scope of this work is to present briefly the principle of SPC testing method in comparison with uniaxial creep test. The differences in terms of specimen geometry and deformation process have been clearly brought out. The correlations developed by several researchers for determining the creep properties from SPC test along with uniaxial creep results for comparison is presented. The contributions by several authors in the direction of numerical simulation and fractography of SPC test is also briefed.

Graphic abstract

Similar content being viewed by others

References

T.G. Le, K.B. Yoon, T.M. Jeong, Degradation and reduction of small punch creep life of service-exposed Super304H steel. J. Mech. Sci. Technol. 33, 5243–5250 (2019)

R.J. Lancaster, S.P. Jeffs, H.W. Illsley, C. Argyrakis, R.C. Hurst, G.J. Baxter, Development of a novel methodology to study fatigue properties using the small punch test. Mater. Sci. Eng. A 748, 21–29 (2019)

S. Arunkumar, Overview of small punch test. Met. Mater. Int. 26(6), 719–738 (2020)

S. Tettamanti, R. Crudeli, Small punch creep test: a promising methodology for high temperature plant components life evaluation. VTT (Valtion Teknillinen Tutkimuskeskus) Symp. 185, 501–509 (1998)

R.J. Lancaster, S.P. Jeffs, Small Punch Creep (INTECH Open Science, London, 2018), pp. 151–172

J.D. Parker, J.D. James, Disc-bend creep deformation behaviour of 1/2Cr1/2Mo1/4V low alloy steel, in 5th International Conference: Creep and Fracture of Engineering Materials and Structures, Swansea, (CRC Press, Wales, 1993), pp. 651–660

T.H. Hyde, C.J. Hyde, W. Sun, A basis for selecting the most appropriate small specimen creep test type. J. Press. Vessel Technol. 136, 1–6 (2014)

A. Kanaya, J. Kusumoto, M. Nagae, T. Kobayashi, Residual creep life evaluation by small punch creep test. Mech. Eng. Congr. JSME MECJ-05 5(1), 331–332 (2005)

T. Sugimoto, K. Doki, S. Komazaki, S. Misawa, Evaluation of toughness and creep properties of aged main valve CrMoV casting steel by using small punch specimens. Tetsu-to Hagane 91(4), 46–51 (2005)

T. Nakata, S. Komazaki, Y. Kohno, H. Tanigawa, Development of a small punch testing method to evaluate the creep property of high Cr ferritic steel: part II—stress analysis of small punch test specimen by finite element method. Mater. Sci. Eng. A666, 80–87 (2016)

M.L. Saucedo-Muñoz, V. Miranda-Lopez, S. Komazaki, V.M. Lopez-Hirata, Relation of small punch creep test properties with microstructure changes for an ASTM A387 Cr–Mo steel. Mater. Sci. Eng. A 761, 138033 (2019)

F. Dobes, K. Milicka, Comparison of conventional and small punch creep tests of mechanically alloyed Al–C–O alloys. Mater. Charact. 59, 961–964 (2008)

L.Y. Wang, Z.J. Zhou, C.P. Li, G.F. Chen, G.P. Zhang, Comparative investigation of small punch creep resistance of Inconel 718 fabricated by selective laser melting. Mater. Sci. Eng. A 745, 31–38 (2019)

S. Yang, L. Xue, X. Ling, Characterization of low-temperature creep deformation and primary creep stage of TA2 using small punch creep test. Eng. Fract. Mech. 205, 1–9 (2019)

R.V. Prakash, S. Arunkumar, in Evaluation of Damage in Materials due to Fatigue Cycling Through Static and Cyclic Small Punch Testing, Small Specimen Test Techniques, ed. by M.A. Sokolov, E. Lucon (ASTM International, West Conshohocken, 2015), pp. 168–186

S. Arunkumar, R.V. Prakash, Estimation of tensile properties of pressure vessel steel through automated ball indentation and small punch test. Trans. Indian Inst. Met. 69(6), 1245–1256 (2016)

R.V. Prakash, S. Arunkumar, Influence of friction on the response of small punch test. Trans. Indian Inst. Met. 69(2), 617–622 (2016)

R.V. Prakash, S. Arunkumar, Evaluation of Fatigue Data Through Miniature Specimen Test Techniques (American Society of Mechanical Engineers Pressure Vessels and Piping Division (Publication), New York, 2015)

H.K. Al-Abedy, I.A. Jones, W. Sun, Small punch creep property evaluation by finite element of Kocks–Mecking–Estrin model for P91 at elevated temperature. Theoret. Appl. Fract. Mech. 98, 244–254 (2018)

B. Ule, T. Sustar, F. Dobes, K. Milicka, V. Bicego, S. Tettamanti, K. Maile, C. Schwarzkopf, M.P. Whelan, R.H. Kozlowski, J. Klaput, Small punch test method assessment for the determination of the residual creep life of service exposed components: outcomes from an interlaboratory exercise. Nucl. Eng. Des. 192, 1–11 (1999)

F. Cortellino, J.P. Rouse, B. Cacciapuoti, W. Sun, T.H. Hyde, Experimental and numerical analysis of initial plasticity in P91 steel small punch creep samples. Exp. Mech. 57, 1193–1212 (2017)

K. Song, L. Zhao, L. Xu, Y. Han, H. Jing, Experimental and numerical analysis of creep and damage behaviour of P92 steel by small punch tests. Theoret. Appl. Fract. Mech. 100, 181–190 (2019)

D. Blagoeva, Y.Z. Li, R.C. Hurst, Qualification of P91 welds through small punch creep testing. J. Nucl. Mater. 409(2), 124–130 (2011)

H. Chen, T.H. Hyde, K.T. Voisey, D.G. McCartney, Application of small punch creep testing to a thermally sprayed CoNiCrAlY bond coat. Mater. Des. 47, 677–686 (2013)

V. Raman, S.V. Raj, An analysis of Harper–Dorn creep based on the specimen size effects. Scr. Metall. 19, 629–634 (1985)

S.V. Raj, On the grain size dependence of Harper–Dorn creep. Mater. Sci. Eng. 96, 57–64 (1987)

E. Nes, W. Blum, P. Eisenlohr, Harper–Dorn creep and specimen size. Metall. Mater. Trans. A 33, 305–310 (2002)

T.H. Hyde, W. Sun, J.A. Williams, Requirements for and use of miniature test specimens to provide mechanical and creep properties of materials: a review. Int. Mater. Rev. 52(4), 213–255 (2007)

P.J.M. Janssen, ThH de Keijser, M.G.D. Geers, An experimental assessment of grain size effects in the uniaxial straining of thin Al sheet with a few grains across the thickness. Mater. Sci. Eng. A 419, 238–248 (2006)

R.W. Hertzberg, R.P. Vinci, J.L. Hertzberg, Deformation and fracture mechanics of engineering materials, 5th edn. (Wiley, NewYork, 2013)

M.F. Ashby, D.R.H. Jones, Engineering Materials I—An Introduction to Properties, Applications and Design, 3rd edn. (Elsevier Butterworth-Heinemann, Boston, 2005)

G.E. Dieter, Mechanical Metallurgy (McGraw-Hill Book Company, New York, 1988)

F. Dobes, K. Milicka, P. Kratochvil, Small punch creep in Fe28AlCr0.02Ce alloy. Intermetallics 12, 1397–1401 (2004)

J.D. Parker, J.D. James, Creep behaviour of miniature disc specimens of low alloy steel, developments in a progressing technology. ASME PVP 279, 167–172 (1994)

S. Komazai, T. Hashida, T. Shoji, K. Suzuki, Development of small punch tests for creep property measurement of tungsten-alloyed 9%Cr ferritic steels. J. Test. Eval. JTEVA 28(4), 249–256 (2000)

F. Dobes, K. Milicka, Small punch testing in creep conditions. J. Test. Eval. JTEVA 29(1), 31–35 (2001)

M.L. Saucedo-Munoz, S. Komazaki, T. Takahashi, T. Hashida, T. Shoji, Creep property measurement of service-exposed SUS 316 austenitic stainless steel by the small-punch creep-testing technique. J. Mater. Res. 17(8), 1945–1953 (2002)

X. Ling, Y. Zheng, Y. You, Y. Chen, Creep damage in small punch specimens of type 304 stainless steel. Int. J. Press. Vessels Pip. 84, 304–309 (2007)

K.I. Kobayashi, I. Kajihara, H. Koyama, G.C. Stratford, Deformation and fracture mode during small punch creep tests. J. Solid Mech. Mater. Eng. 4(1), 75–86 (2010)

X. Mao, T. Shoji, H. Takahashi, Characterization of fracture behavior in small punch test by combined recrystallization-etch method and rigid plastic analysis. J. Test. Eval. 15(1), 30–37 (1987)

Nishioka, T., Ohsawa, T., Sawaragi, Y., Uemura, H., Effects of various factors on creep behaviour in low alloy steel by small punch testing methods, in Proceedings of 1st Annual International Conference on SSTT (Small Sample Test Techniques), Metallurgical Journal, vol 63 (2010), pp. 34–38.

Li, Y., Sturm, R., Determination of creep properties from small punch test, in Proceedings of PVP2008, ASME Pressure Vessels and Piping Division Conference, July 27–31, 2008, Chicago, Illinois, USA (2008)

T. Izaki, T. Kobayashi, J. Kusumoto, A. Kanaya, A creep life assessment method for boiler pipes using small punch creep test. Int. J. Press. Vessels Pip. 86, 637–642 (2009)

F. Dobeš, K. Milička, Application of creep small punch testing in assessment of creep lifetime. Mater. Sci. Eng. A 510–511, 440–443 (2009)

F. Hou, H. Xu, Y. Wang, L. Zhang, Determination of creep property of 1.25Cr0.5Mo pearlitic steels by small punch test. Eng. Fail. Anal. 28, 215–221 (2013)

L. Zhao, H. Jing, L. Xu, Y. Han, J. Xiu, Y. Qiao, Evaluating of creep property of distinct zones in P92 steel welded joint by small punch creep test. Mater. Des. 47, 677–686 (2013)

M.D. Mathew, J. Ganesh Kumar, V. Ganesan, Small punch creep studies for optimization of nitrogen content in 316LN SS for enhanced creep resistance. Metall. Mater. Trans. A 45A, 731–737 (2014)

R.J. Lancaster, W.J. Harrison, G. Norton, An analysis of small punch creep behaviour in the γ titanium aluminide Ti–45Al–2Mn–2Nb. Mater. Sci. Eng. A 626, 263–274 (2015)

S.P. Jeffs, R.J. Lancaster, T.G. Garcia, Creep lifing methodologies applied to a single crystal super alloy by use of small scale test techniques. Mater. Sci. Eng. A 636, 529–535 (2015)

S.P. Jeffs, R.J. Lancaster, Elevated temperature creep deformation of a single crystal super alloy through the small punch creep method. Mater. Sci. Eng. A 626, 330–337 (2015)

G.J. Kumar, K. Laha, Small punch creep deformation and rupture behaviour of 316L(N) stainless steel. Mater. Sci. Eng. A 641, 315–322 (2015)

T. Lee, F.A. Ibupoto, J.H. Lee, B.J. Kim, M.K. Kim, A direct methodology for small punch creep test. Exp. Mech. 56, 395–405 (2016)

C. Wen, T. Xu, K. Guan, Correlation factor study of small punch creep test and its life prediction. Materials 9(796), 1–15 (2016)

G.S. Deshmukh, M.L. Prasad, D.R. Peshve, G.J. Kumar, M.D. Mathew, G. Amarendra, Creep properties assessment of P92 steel by small punch creep tests. Trans. Indian Inst. Met. 69(4), 907–915 (2016)

D. Andres, R. Lacalle, J.A. Alvarez, Creep property evaluation of light alloys by means of small punch test: creep master curves. Mater. Des. 96, 122–130 (2016)

P. Dymacek, Recent developments in small punch testing: applications at elevated temperatures. Theor. Appl. Fract. Mech. 86 A, 25–33 (2016)

S. Yang, Y. Zheng, Y. Duan, X. Ling, Creep characteristics and deformation analysis of service-exposed material using small punch creep test. Eng. Fract. Mech. 195, 242–252 (2018)

J.H. Kim, U. Ro, H. Lee, S.J. Kang, B.H. Lee, M.K. Kim, A direct assessment of creep life based on small punch creep test. Theoret. Appl. Fract. Mech. 104, 102346 (2019)

P. Dymacek, F. Dobes, Y. Jiraskova, N. Pizurova, M. Friak, Tensile, creep and fracture testing of prospective Fe–Al-based alloys using miniature specimens. Theoret. Appl. Fract. Mech. 99, 18–26 (2019)

J.P. Rouse, F. Cortellino, W. Sun, T.H. Hyde, J. Shingledecker, Small punch creep testing: review on modelling and data interpretation. Mater. Sci. Technol. 29(11), 1328–1345 (2013)

M. Bruchhausen, E. Altstadt, T. Austin, P. Dymacek, S. Holmström, S. Jeffs, R. Lacalle, R. Lancaster, K. Matocha, J. Petzova, European standard on small punch testing of metallic materials. Ubiquity Proc. 1(S1), 11 (2018)

D.T. Blagoeva, R.C. Hurst, Application of the CEN (European Committee for Standardization) small punch creep testing code of practice to a representative repair welded P91 pipe. Mater. Sci. Eng. A 510–511, 219–223 (2009)

Y.Z. Li, R. Sturm, Small punch test for weld heat affected zones. Mater. High Temp. 23(3–4), 225–232 (2006)

Y.Z. Li, R. Sturm, Determination of creep properties from small punch test. Proc. ASME Press. Vessels Pip. Conf. 3, 741–752 (2009)

R. Sturm, Y.Z. Li, Small-punch test testing of a weld’s heat affected zones’. Mater. Technol. 40, 49–54 (2006)

European Committee for Standardization, Small punch test method for metallic materials, in CEN Workshop Agreement, CWA, 15627: 2007 (E) (2007)

F.C. Monkman, N.J. Grant, An empirical relationship between rupture life and minimum creep rate in creep-rupture tests. Proc. ASTM Int. 56, 593–620 (1956)

V.M. Radhakrishnan, The relationship between minimum creep rate and rupture time in Cr–Mo steels. J. Mater. Eng. Perform. 1, 123–128 (1992)

F. Dobes, K. Milicka, The relation between minimum creep rate and time to fracture. Met. Sci. 10, 382–384 (1976)

R.W. Evans, B. Wilshire, Creep of metals and alloys (The Institute of Metals, London, 1985), pp. 197–243

R.W. Evans, A constitutive model for the high-temperature creep of particle-hardened alloys based on the θ projection method. Proc. R. Soc. Lond. A 456, 835–868 (2000)

M. Law, W. Payten, K. Snowden, Modelling creep of pressure vessels with thermal gradients using theta projection data. Int. J. Press. Vessels Pip. 79(12), 847–851 (2002)

K. Maruyama, C. Harada, H. Oikawa, A strain-time equation applicable up to tertiary creep stage. J. Soc. Mater. Sci. Jpn. 34(38), 1289–1295 (1985)

B. Ule, T. Rodic, T. Sustar, Modification of θ projection creep law by introducing mean stress term. Mater. Sci. Technol. 13, 555–559 (1997)

Y. Zheng, S. Yang, X. Ling, Creep life prediction of small punch creep testing specimens for service-exposed Cr5Mo using theta-projection method. Eng. Fail. Anal. 72, 58–66 (2017)

B. Gulcimen, P. Hahner, Determination of creep properties of a P91 weldment by small punch testing and a new evaluation approach. Mater. Sci. Eng. A 588, 125–131 (2013)

S. Yang, X. Ling, Y. Zheng, Creep behaviours evaluation of Incoloy800H by small punch creep test. Mater. Sci. Eng. A 685, 1–6 (2017)

Y.W. Ma, S. Shim, K.B. Yoon, Assessment of power law creep constants of Gr91 steel using small punch creep tests. Fatigue Fract. Eng. Mater. Struct. 32, 951–960 (2009)

M.T. Whittaker, M. Evans, B. Wilshire, Long-term creep data prediction for type 316H stainless steel. Mater. Sci. Eng. A 552, 145–150 (2012)

B. Wilshire, A.J. Battenbough, Creep and creep fracture of polycrystalline copper. Mater. Sci. Eng. A 443(1–2), 156–166 (2007)

B. Wilshire, P.J. Scharning, Long-term creep life prediction for a high chromium steel. Scr. Mater. 56(8), 701–704 (2007)

Holmström, S., Hähner, P., Hurst, R.C., Bruchhausen, M., Fischer, B., Lapetite, J.-M., Small punch creep testing for material characterization and life time prediction, in Materials for Advanced Power Engineering. Juelich, Germany: FZ. Juelich, Germany; (2014) 627–635.

S. Holmström, P. Auerkari, R. Hurst, D. Blagoeva, Using small punch test data to determine creep strain and strength reduction properties for heat affected zones. Mater. Sci. Technol. [Internet] 30(1), 63–66 (2014)

P.C. Zhai, T. Hashida, S. Komazaki, Q.J. Zhang, Numerical analysis for small punch creep tests by finite element methods. J. Test. Eval. 32(4), 298–303 (2004)

R.W. Evans, M. Evans, Numerical modelling of small disc creep test. Mater. Sci. Technol. 22(10), 1155–1162 (2006)

P. Dymacek, K. Milicka, Creep small-punch testing and its numerical simulations. Mater. Sci. Eng. A 510–511, 444–449 (2009)

Z. Zhou, Y. Zheng, X. Ling, R. Hu, J. Zhou, A study of influence factors of small punch creep test by experimental investigation and finite element analysis. Mater. Sci. Eng.A 527, 2784–2789 (2010)

T.H. Hyde, M. Stoyanov, W. Sun, C.J. Hyde, On the interpretation of results from small punch creep tests. J. Strain Anal. Eng. Des. 45, 141–164 (2010)

F. Cortellino, W. Sun, T.H. Hyde, J. Shingledecker, The effects of geometrical inaccuracies of the experimental set-up on small punch creep test results. J. Strain Anal. 49(8), 571–582 (2014)

B. Cacciapuoti, W. Sun, D.G. McCartney, A study on the evaluation of contact angle of small punch creep test of ductile materials. Int. J. Press. Vessels Pip. 145, 60–74 (2016)

A. Oritz-Mariscal, M.L. Saucedo-Munoz, S. Komazaki, Application of small punch creep testing for evaluation of creep properties of as-received and artificially aged 5Cr–0.5Mo steel. Mater. Sci. Eng. A (2018). https://doi.org/10.1016/j.msea.2017.10.060

S. Yang, Y. Zheng, X. Ling, Evaluation of multiaxial creep and damage evolution for small punch creep test considering critical-strain criterion. Eng. Fail. Anal. 91, 99–107 (2018)

W. Wu, J. Xiaozhe, L. Hao, S. Wei, Determination of creep damage properties from small punch creep tests considering pre-straining effect using an inverse approach. Mech. Mater. 139, 103171 (2019)

L. Zhao, K. Song, L. Xu, Y. Han, H. Jing, Y. Zhang, H. Li, Determination of creep properties of an advanced Fe–Cr–Ni alloy using small punch creep test with a modified creep strain model. Theoret. Appl. Fract. Mech. 104, 102324 (2019)

L. Zhao, K. Song, L. Xu, Y. Han, H. Jing, H. Li, Y. Zhang, Investigating creep rupture and damage behaviour of 41Fe–255Cr–23Ni alloy small punch creep specimens using a novel microstructure meshing approach. Mater. Sci. Eng. A 766, 138370 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arunkumar, S. Small Punch Creep Test: An Overview. Met. Mater. Int. 27, 1897–1914 (2021). https://doi.org/10.1007/s12540-020-00783-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00783-w